Control of low-pressure carburizing processes - Stange Elektronik ...

Control of low-pressure carburizing processes - Stange Elektronik ...

Control of low-pressure carburizing processes - Stange Elektronik ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

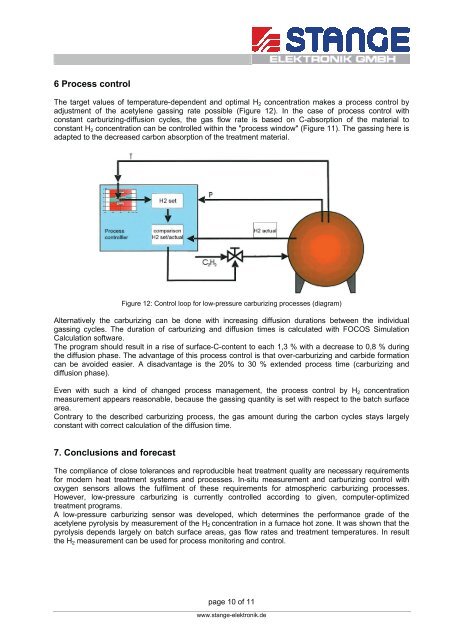

6 Process controlThe target values <strong>of</strong> temperature-dependent and optimal H 2 concentration makes a process control byadjustment <strong>of</strong> the acetylene gassing rate possible (Figure 12). In the case <strong>of</strong> process control withconstant <strong>carburizing</strong>-diffusion cycles, the gas f<strong>low</strong> rate is based on C-absorption <strong>of</strong> the material toconstant H 2 concentration can be controlled within the "process window" (Figure 11). The gassing here isadapted to the decreased carbon absorption <strong>of</strong> the treatment material.Figure 12: <strong>Control</strong> loop for <strong>low</strong>-<strong>pressure</strong> <strong>carburizing</strong> <strong>processes</strong> (diagram)Alternatively the <strong>carburizing</strong> can be done with increasing diffusion durations between the individualgassing cycles. The duration <strong>of</strong> <strong>carburizing</strong> and diffusion times is calculated with FOCOS SimulationCalculation s<strong>of</strong>tware.The program should result in a rise <strong>of</strong> surface-C-content to each 1,3 % with a decrease to 0,8 % duringthe diffusion phase. The advantage <strong>of</strong> this process control is that over-<strong>carburizing</strong> and carbide formationcan be avoided easier. A disadvantage is the 20% to 30 % extended process time (<strong>carburizing</strong> anddiffusion phase).Even with such a kind <strong>of</strong> changed process management, the process control by H 2 concentrationmeasurement appears reasonable, because the gassing quantity is set with respect to the batch surfacearea.Contrary to the described <strong>carburizing</strong> process, the gas amount during the carbon cycles stays largelyconstant with correct calculation <strong>of</strong> the diffusion time.7. Conclusions and forecastThe compliance <strong>of</strong> close tolerances and reproducible heat treatment quality are necessary requirementsfor modern heat treatment systems and <strong>processes</strong>. In-situ measurement and <strong>carburizing</strong> control withoxygen sensors al<strong>low</strong>s the fulfilment <strong>of</strong> these requirements for atmospheric <strong>carburizing</strong> <strong>processes</strong>.However, <strong>low</strong>-<strong>pressure</strong> <strong>carburizing</strong> is currently controlled according to given, computer-optimizedtreatment programs.A <strong>low</strong>-<strong>pressure</strong> <strong>carburizing</strong> sensor was developed, which determines the performance grade <strong>of</strong> theacetylene pyrolysis by measurement <strong>of</strong> the H 2 concentration in a furnace hot zone. It was shown that thepyrolysis depends largely on batch surface areas, gas f<strong>low</strong> rates and treatment temperatures. In resultthe H 2 measurement can be used for process monitoring and control.page 10 <strong>of</strong> 11www.stange-elektronik.de