Poly Shield Heat Laminated Sheathing/Underlayment - BlueLinx

Poly Shield Heat Laminated Sheathing/Underlayment - BlueLinx

Poly Shield Heat Laminated Sheathing/Underlayment - BlueLinx

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

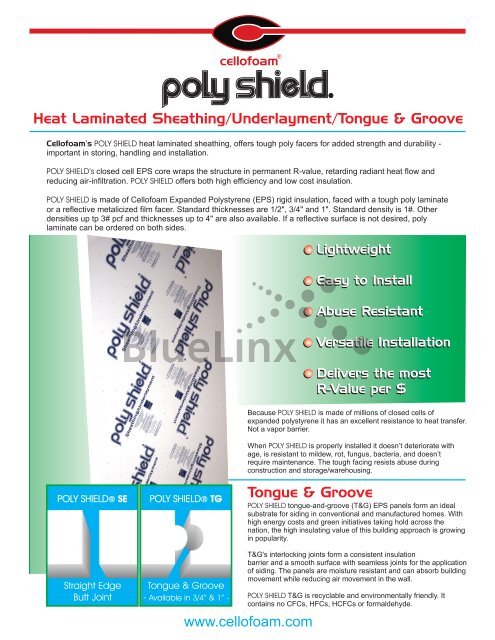

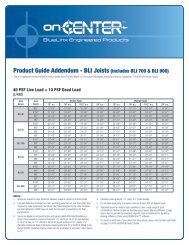

<strong>Heat</strong> <strong>Laminated</strong> <strong>Sheathing</strong>/<strong>Underlayment</strong>/Tongue & GrooveCellofoam’s POLY SHIELD heat laminated sheathing, offers tough poly facers for added strength and durability -important in storing, handling and installation.POLY SHIELD’s closed cell EPS core wraps the structure in permanent R-value, retarding radiant heat flow andreducing air-infiltration. POLY SHIELD offers both high efficiency and low cost insulation.POLY SHIELD is made of Cellofoam Expanded <strong>Poly</strong>styrene (EPS) rigid insulation, faced with a tough poly laminateor a reflective metalicized film facer. Standard thicknesses are 1/2" , 3/4" and 1". Standard densityis 1#. Otherdensities up tp 3# pcf and thicknesses up to 4"are also available. If a reflective surface is not desired, polylaminate can be ordered on both sides.LightweightEasy to InstallAbuse ResistantVersatile InstallationDelivers the mostR-Value per $Because POLY SHIELD is made of millions of closed cells ofexpanded polystyrene it has an excellent resistance to heat transfer.Not a vapor barrier.When POLY SHIELD is properly installed it doesn’t deteriorate withage, is resistant to mildew, rot, fungus, bacteria, and doesn’trequire maintenance. The tough facing resists abuse duringconstruction and storage/warehousing.POLY SHIELD® SEPOLY SHIELD® TGTongue & GroovePOLY SHIELD tongue-and-groove (T&G) EPS panels form an idealsubstrate for siding in conventional and manufactured homes. Withhigh energy costs and green initiatives taking hold across thenation, the high insulating value of this building approach is growingin popularity.Straight EdgeButt JointTongue & Groove- Available in 3/4” & 1” -T&G's interlocking joints form a consistent insulationbarrier and a smooth surface with seamless joints for the applicationof siding. The panels are moisture resistant and can absorb buildingmovement while reducing air movement in the wall.POLY SHIELD T&G is recyclable and environmentally friendly. Itcontains no CFCs, HFCs, HCFCs or formaldehyde.www.cellofoam.com

PHYSICAL PROPERTIES OF CELLOFOAM® EXPANDED POLYSTYRENEPropertyUnitsASTMSPECIAL ORDER ONLYTest Type I Type VIII Type II Type IXNominal Densitypcf C 303 1.0 1.25 1.5 2.0Thermal Resistanceper inch C 518 orR Factor at 25ºF thickness C 177 4.35 4.54 4.76 5.00at 40ºF 4.17 4.25 4.55 4.76at 75ºF 3.85 3.92 4.17 4.35Coefficient of Thermal expansion in/(in) (F) D 696 0.000035 0.000035 0.000035 0.000035Maximum Service temperatureLong Term º F ---- 167 167 167 167Intermitten ºF ---- 180 180 180 180Compressive Strength at10% deformation psi D 1621 10-14 13-18 15-21 25-33Flexural Strengthpsi C 203 25-30 32-38 40-50 55-75Capilllarity ---- ---- none none none noneWater vapor transmission perm in E96 2.0-5.0 1.5-3.5 1.0-3.5 0.6-2.0Water absorption (by volume) % C 272 < 4.0 < 3.0 < 3.0 < 2.0Flame SpreadUL 723