supercapacitors as energy storage devices - Acta Energetica

supercapacitors as energy storage devices - Acta Energetica

supercapacitors as energy storage devices - Acta Energetica

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

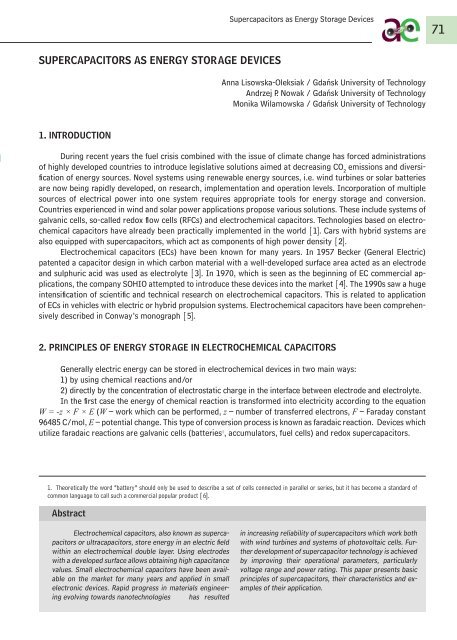

Supercapacitors <strong>as</strong> Energy Storage Devices71SUPERCAPACITORS AS ENERGY STORAGE DEVICESAnna Lisowska-Oleksiak / Gdańsk University of TechnologyAndrzej P. Nowak / Gdańsk University of TechnologyMonika Wilamowska / Gdańsk University of Technology1. INTRODUCTIONDuring recent years the fuel crisis combined with the issue of climate change h<strong>as</strong> forced administrationsof highly developed countries to introduce legislative solutions aimed at decre<strong>as</strong>ing CO 2emissions and diversificationof <strong>energy</strong> sources. Novel systems using renewable <strong>energy</strong> sources, i.e. wind turbines or solar batteriesare now being rapidly developed, on research, implementation and operation levels. Incorporation of multiplesources of electrical power into one system requires appropriate tools for <strong>energy</strong> <strong>storage</strong> and conversion.Countries experienced in wind and solar power applications propose various solutions. These include systems ofgalvanic cells, so-called redox flow cells (RFCs) and electrochemical capacitors. Technologies b<strong>as</strong>ed on electrochemicalcapacitors have already been practically implemented in the world [1]. Cars with hybrid systems arealso equipped with <strong>supercapacitors</strong>, which act <strong>as</strong> components of high power density [2].Electrochemical capacitors (ECs) have been known for many years. In 1957 Becker (General Electric)patented a capacitor design in which carbon material with a well-developed surface area acted <strong>as</strong> an electrodeand sulphuric acid w<strong>as</strong> used <strong>as</strong> electrolyte [3]. In 1970, which is seen <strong>as</strong> the beginning of EC commercial applications,the company SOHIO attempted to introduce these <strong>devices</strong> into the market [4]. The 1990s saw a hugeintensification of scientific and technical research on electrochemical capacitors. This is related to applicationof ECs in vehicles with electric or hybrid propulsion systems. Electrochemical capacitors have been comprehensivelydescribed in Conway’s monograph [5].2. PRINCIPLES OF ENERGY STORAGE IN ELECTROCHEMICAL CAPACITORSGenerally electric <strong>energy</strong> can be stored in electrochemical <strong>devices</strong> in two main ways:1) by using chemical reactions and/or2) directly by the concentration of electrostatic charge in the interface between electrode and electrolyte.In the first c<strong>as</strong>e the <strong>energy</strong> of chemical reaction is transformed into electricity according to the equationW = -z × F × E (W – work which can be performed, z – number of transferred electrons, F – Faraday constant96485 C/mol, E – potential change. This type of conversion process is known <strong>as</strong> faradaic reaction. Devices whichutilize faradaic reactions are galvanic cells (batteries 1 , accumulators, fuel cells) and redox <strong>supercapacitors</strong>.1. Theoretically the word “battery” should only be used to describe a set of cells connected in parallel or series, but it h<strong>as</strong> become a standard ofcommon language to call such a commercial popular product [6].AbstractElectrochemical capacitors, also known <strong>as</strong> <strong>supercapacitors</strong>or ultracapacitors, store <strong>energy</strong> in an electric fieldwithin an electrochemical double layer. Using electrodeswith a developed surface allows obtaining high capacitancevalues. Small electrochemical capacitors have been availableon the market for many years and applied in smallelectronic <strong>devices</strong>. Rapid progress in materials engineeringevolving towards nanotechnologies h<strong>as</strong> resultedin incre<strong>as</strong>ing reliability of <strong>supercapacitors</strong> which work bothwith wind turbines and systems of photovoltaic cells. Furtherdevelopment of supercapacitor technology is achievedby improving their operational parameters, particularlyvoltage range and power rating. This paper presents b<strong>as</strong>icprinciples of <strong>supercapacitors</strong>, their characteristics and examplesof their application.

72Anna Lisowska-Oleksiak; Andrzej P. Nowak; Monika Wilamowska / Gdańsk University of TechnologyThe other mechanism for charge <strong>storage</strong>, the so-called nonfaradaic mechanism, is a principle for electrochemicalcapacitor operation. At the electrode/electrolyte interface a capacitor with an electrical double layerdl is formed. It is composed of charges on a metal surface and ions of opposite charge in the solution directlyadjacent to the electrode surface.ELECTRICAL DOUBLE LAYER MODELSThe concept of the electrical double layer h<strong>as</strong> a long history. In modern times it can be traced back tostudies on dispersed ph<strong>as</strong>es carried out by Helmholtz (1857). Scientific development in this field is presentedin fig. 1. First models take into account the charge ordering (Helmholtz 1857) (fig. 1a) and diffuse layer effectcaused by thermal movements (Gouy-Chapman model) (fig. 1b). The Stern model (1927) (fig. 1c) combinesthese two approaches. The resulting theory says that there are actually two capacitors connected in series.One of them is a Helmholtz capacitor with a capacitance C Hand the other – a capacitor with diffused layer witha capacitance C dif. Total capacitance of an electrical double layer is C dl-1= C H-1+ C dyf-1. . Therefore charge orderingat the interface of two conductive ph<strong>as</strong>es results in the formation of a capacitor. Capacitance C of a doublelayer capacitor results from a charge accumulated at a proper range of potentials C = dq/dV and depends onthe geometry (area A and plate separation d). An interfacial capacitor h<strong>as</strong> a thickness of d depending on the sizeof solvent molecules, and in this c<strong>as</strong>e d denotes the diameter of those molecules of their clusters. Studies byGraham (1947) and the model created by Parsons (1978) take into account the presence of solvent dipoles in aninner layer capacitor, see fig. 1d.a) b) c)OHPdiffuse layerIPHd)OHPsolvent particleanioncationGouy-Chapman diffuse layerFig. 1. Electrode/electrolyte interface according to Helmholtz model (a), Gouy-Chapman diffuse layer (b), Stern diffuse layer (c) and Graham diffuselayer (d), where φM denotes Galvani potential and ψ is Volta potential, IHP and OHP are inner and outer Helmholtz planes respectively [5]

Supercapacitors <strong>as</strong> Energy Storage Devices732.1. ELECTROCHEMICAL DOUBLE-LAYER CAPACITORSThe literature refers to the group of electrochemical capacitors using electrical double layer charge <strong>as</strong>Electrochemical Double-Layer Capacitors or ECDLs.Capacitance of a capacitor is proportional to the surface of its plates and dielectric constant of the substancecontained between those plates, and inversely proportional to the plate separation. A× ε ×C 0εdr(1)where C is capacitance [Farad], A – electrode surface, d – plate separation, ε 0– permittivity of free space,and ε r– relative permittivity of the medium.Capacitance of a capacitor with an electrical double layer metal (e.g. Pt, Au)/electrolyte C dlvaries between16 and 50 μF/cm². This value is not attractive for practical applications.According to the equation (1) significant incre<strong>as</strong>e of capacitance C dlcan be achieved by using electrodematerials with a so-called developed surface area. Those may be conductive carbons with porous structure,oxides of transition metals and electroactive polymers. Activated carbon with a surface of 1000 m²/g and doublelayer capacitance C dl15 μF/cm² allows achieving a specific capacitance of 150 F/g (1000 m²/g × 10,000 cm²/m² ×15 μF/cm² = 150 F/g). Hence the name “supercapacitor” or “ultracapacitor” used for <strong>devices</strong> which use capacitancewith a dual layer of electrodes made of materials with highly developed surfaces. In practical applicationselectrode layers with a thickness of several micrometers are used.2.2. ELECTROCHEMICAL CAPACITORS USING SO-CALLED REDOX PSEUDOCAPACITANCEElectrochemical capacitors using so-called redox pseudocapacitance are another type of chemical capacitorwidely used in practical applications. They are known <strong>as</strong> redox electrochemical capacitors or redox <strong>supercapacitors</strong>.These <strong>devices</strong>, apart from utilizing charge of electrical double layer, are a source of current resultingfrom a charge transfer process occurring at substances adsorbed on the surface and undergoing faradaicreaction. The difference between a normal redox reaction and the described process is substrate availability. Incapacitors charge transfer is limited to the electrode surface only. The process occurs in multi-electron modeand in a wide range of potentials. This type of device use materials able to undergo surface redox reactions(e.g. ruthenium oxides, electroactive polymers). An example reaction where redox pseudocapacitance is usedmay be a reaction which occurs on the surface of ruthenium oxides, where surface hydroxyl groups in an acidicenvironment undergo reaction according to the following equation [7]: RuOz(OH)y δ H δe RuOzδ(OH)yδ(2)It is worth noting that the stoichiometry of this reaction is very complex and the surface layer of – OHgroups is treated <strong>as</strong> a whole. Stoichiometric coefficients of the reaction refer to the monolayer of active surfacegroups.3. DIFFERENCES BETWEEN ELECTROCHEMICAL CAPACITORS AND GALVANIC CELLSBoth capacitors and galvanic cells consist of two electrodes separated with electrolyte (fig. 2). The differencelies in the character of used electrode material and charge accumulation mechanisms. In electrochemicalcapacitors both electrodes are in most c<strong>as</strong>es made of the same material. In galvanic cells the electrodes havedifferent chemical properties (the anode material is different from that of the cathode).

74Anna Lisowska-Oleksiak; Andrzej P. Nowak; Monika Wilamowska / Gdańsk University of TechnologySeparatorwith electrolyteConductivec<strong>as</strong>ing wallElectrode material in contactwith electrolyteFig. 2. Schematic diagram of an electrochemical capacitorIn the process of capacitor charging or discharging an internal change of electrode potential V is continuouslyobserved. It follows the equation:C = q/V or = C × V (3)Curves for discharge of an electrochemical capacitor and a battery are presented in fig. 3.Battery discharge curveU [V]Electrochemical capacitor discharge curveFig. 3. Discharge curves of an electrochemical capacitor and a batteryIn contr<strong>as</strong>t to that characteristic, charging/discharging of galvanic cells is carried out at constant potential,except for values near 0 and 100% (fig. 2).This difference results in the fact that <strong>energy</strong> E accumulated by a capacitor is:E = 1/2 C × U 2 or E = 1/2 q × U (4)Timewhile for a battery the <strong>energy</strong> level is q × U, i.e. it is twice higher than the <strong>energy</strong> level in a capacitor ofthe same voltage U = ΔV. Power of a supercapacitor is expressed by the equation:

Supercapacitors <strong>as</strong> Energy Storage Devices75where R stands for the device’s resistance. 2UP 4 REquation (4) indicates that incre<strong>as</strong>e of <strong>energy</strong> accumulated in a capacitor can be achieved by:1) capacitance incre<strong>as</strong>e, which may be realized by:a. incre<strong>as</strong>ing electrode active surface,b. decre<strong>as</strong>ing plate separation,c. incre<strong>as</strong>ing relative dielectric permittivity of the medium2) voltage incre<strong>as</strong>e.According to the equation (5) power can be incre<strong>as</strong>ed by:1) voltage incre<strong>as</strong>e2) resistance decre<strong>as</strong>e.When designing a device we can influence the useful power level by appropriate selection of materials,electrode geometry and electrochemical stability of the electrolyte.Electrochemical capacitors <strong>as</strong> <strong>energy</strong> <strong>storage</strong> and conversion <strong>devices</strong> can be placed between electrolyticcapacitors 2 and batteries. This is illustrated by the Ragone diagram (fig. 4).(5)Specific power [W/kg]ElectrolytecapacitorElectrochemicaldouble-layercapacitorAcid-head cellsCadmium nickel and nickel-metalhydride cellsUltracapacitorLithium-ion batteriesFuelcellsSpecific <strong>energy</strong> [Wh/kg]Fig. 4. Ragone diagram for various electrochemical <strong>devices</strong> [8, 9]Time constants (RC) (d<strong>as</strong>hed lines in the diagram) indicate that the charging/discharging time for reversiblegalvanic cells is considerably longer than corresponding times for electrochemical capacitors.Batteries, just like low-temperature fuel cells, display low power density when compared to electrolyticcapacitors. At the same time batteries have higher <strong>energy</strong> density than capacitors. Using both batteries andelectrochemical capacitors in the same device can improve its operational parameters. The number of charging/dischargingcycles for electrochemical capacitors is much higher than for batteries. This results from thefact that in the cells new ph<strong>as</strong>es are created during the charge transfer process and difficulties resulting fromside effects occur. An electrochemical capacitor uses mainly electrostatic charge, so from a theoretical point ofview there is no limit for the number of charging/discharging cycles.2 In contr<strong>as</strong>t to electrochemical capacitors, electrolytic capacitors (with dimensions of several centimetres) have very small capacitances, me<strong>as</strong>uredin micro- or nanofarads. Electrolytic capacitors owe their name to the method of separator creation between the plates. Plates of electrolyticcapacitors are made of metals like aluminium, tantalum, titanium, niobium, etc. Plates are separated with a thin (10…100 nm) film of an oxide of therespective metal. This film occurs <strong>as</strong> a result of anodic polarization of both plates. Electrolytic capacitors should not be confused with electrochemicalcapacitors.

76Anna Lisowska-Oleksiak; Andrzej P. Nowak; Monika Wilamowska / Gdańsk University of Technology4. ELECTRODE MATERIALS4.1. CONDUCTIVE CARBONSCarbon materials are often used for electrodes of electrochemical capacitors [5, 7, 10]. As one knows,they owe their ability to conduct electric current to the presence of graphene layers where carbon atoms C havea hybridization sp 2 (<strong>as</strong> opposed to non-conductive carbon types sp 3 ). Resistance of graphite or so-called highlyoriented pyrolitic graphites (HOPG) is high and depends on their structure and porosity.Activated carbons are materials of very well developed surface. In a technical scale they are obtainedfrom natural materials i.e. fossil fuels and organic substances (e.g. wood, fruit stones, nutshells). In laboratoryconditions also sucrose and synthetic resins are used.Available carbon electrodes can have specific surfaces area reaching even 2500 m²/g. Carbon materialis used in the form of powder, fabric, felt or fibres. Electricity <strong>storage</strong> on carbon electrodes is capacitive in anelectrochemical double layer. These are so-called electrochemical double-layer capacitors (ECDLs).Progress in the field of nanotechnology allows one to expect that in the near future application of carbonnanomaterials in the form of single-walled and multi-walled nanotubes or nanoparticles will enable obtaining ahigher specific capacitance of electrode materials.4.2. METAL OXIDESOxides of transition metals are commonly used in redox electrochemical capacitors. The most populartypes are ruthenium oxides (RuO x) [5,7] for which x value varies from 1.9 to 2.0. Specific capacitance for rutheniumoxide capacitors can even reach 720 F/g. This is the highest value of specific capacitance achieved for anyknown electrode material; however, RuO xapplications are limited due to the high cost of this material. Promisingalternatives include oxides of manganese, iron, indium, tin, vanadium and their combinations. For these,specific capacitance is around 150 F/g. A supercapacitor composed of Fe 3O 4<strong>as</strong> a negative electrode and MnO 2<strong>as</strong> a positive electrode is characterized by an operating voltage up to 1.8 V in aqueous electrolyte. Specific capacitanceof such a device is 21.5 F/g, actual specific power – 405 W/kg and specific <strong>energy</strong> – 8.1 Wh/kg [11].Oxide materials, just like carbons, are stable during thousands of charging/discharging cycles.4.3. CONDUCTIVE POLYMERSConductive polymers, also known <strong>as</strong> synthetic metals, represent a very attractive group of electrode materials,which have found application in <strong>supercapacitors</strong> [5, 12]. These are mixed electron-ion conductors. Themost popularly used polymers include polypyrrole and derivatives of tiophene. Advantages of those materialsinclude f<strong>as</strong>t oxidation and reduction processes during charging and discharging, high charge density (~500 C/g)and e<strong>as</strong>y synthesis of electrode material.Thanks to their <strong>energy</strong> accumulation properties, conductive polymers have found application <strong>as</strong> electrodematerials in <strong>supercapacitors</strong>. These can be both p and n type polymers. Rudge et al have divided polymer <strong>supercapacitors</strong>into three categories.Type I, where both electrodes are made of identical p-conducting polymer. When the capacitor is fullycharged one electrode is oxidized (positively charged) and the other remains neutral (without charge). Potentialdifference between electrodes is ca 0.8-1.0 V.Type II, where electrodes are made of different p-conducting polymers which have different oxidationreductionpotentials. Using different polymers allows enhancing the potential range.Type III – contains both p-conducting polymer (e.g. polythiophene, poly(3-methylthiophene)) and an n-conducting polymer (derivative of bithienyl). Type III <strong>supercapacitors</strong> offer a wide range of operational potentials(up to 3 V for non-aqueous electrolytes) and appropriately higher <strong>energy</strong> density.Conductive polymers used <strong>as</strong> electrodes in electrochemical capacitors may be modified in order to improvetheir operational parameters. Most often modification is made with oxides of transition metals – manganeseand vanadium. Another option is modification of conductive polymers by attaching a redox group to apolymer chain. Yet another method is the introduction of inorganic substance into a polymer matrix. This additivefulfils the role of a multicentric redox system [13-15]. There are also methods for modifying electroactivepolymers with nanomaterials [16]. In all c<strong>as</strong>es activity of the composite material is created by both electroactivematerial and the modifying agent.

Supercapacitors <strong>as</strong> Energy Storage Devices775. ELECTROLYTESElectrolyte type is another cl<strong>as</strong>sification criterion for electrochemical capacitors. Both aqueous and nonaqueouselectrolytes are used (with aprotic solvents and ionic liquids).5.1. AQUEOUS ELECTROLYTESAqueous electrolytes restrict operational voltage to 1 V, <strong>as</strong> above this value during the charging processmolecules decompose on the positively polarized electrode and oxygen is generated, while on the negativeelectrode water is decomposed and hydrogen is generated. An advantage of aqueous electrolytes is the highconductivity value (e.g. 0.8 S/cm for sulphuric acid), and simple cleaning and drying of electrode material duringthe manufacturing process. Moreover, the price of aqueous electrolytes is considerably lower than that ofnon-aqueous ones.In order to avoid problems related to decre<strong>as</strong>ing effectiveness of supercapacitor charging, high-concentrationelectrolytes are used. They guarantee sufficiently low resistance values.5.2. NON-AQUEOUS ELECTROLYTES WITH APROTIC SOLVENTSUsing organic liquids which do not contain chemically active hydrogen atoms in their molecules in the roleof solvent enhances the stability window of the system (decomposition of the solvent’s molecules does not occur).This allows achieving higher operating voltage values. The higher the voltage level, the higher the amountof <strong>energy</strong> that can be accumulated (see equation (4)). Non-aqueous electrolytes allow achieving voltages up to3 V. Higher values are prevented by traces of water present in solvents.An adverse effect of using non-aqueous electrolytes is their high specific resistance value, which affectsthe capacitor’s power. Nonetheless, the loss of power is usually compensated by a possibility to achieve highervoltage.5.3. IONIC LIQUIDSIonic liquids are salts which are liquid in ambient temperatures. A low melting point results from thestructure of those salts, which consist of a large and <strong>as</strong>ymmetric cation (e.g. 1-alkyl-3-methylimidazolium, 1-alkyl-pyridinium) and a small anion. The range of their electrolytic stability depends only on the type of ionswhich the ionic liquid is composed of. Appropriate ion selection allows constructing <strong>supercapacitors</strong> operatingin a wide potential spectrum. There are known designs where the operational voltage is 3 V. Usage of ionic liquidsis limited by low conductivity value, in the range of mS/cm. Because of this feature ionic liquids are used in<strong>supercapacitors</strong> which are operated at higher temperatures.6. SUPERCAPACITOR APPLICATION EXAMPLESElectrochemical capacitors are incre<strong>as</strong>ingly reliable <strong>devices</strong> which can work with wind turbines or photovoltaiccell systems [17]. Very f<strong>as</strong>t charging/discharging rates offered by <strong>supercapacitors</strong> allow them topromptly adapt to load changes. Supercapacitors have found applications in household appliances, electronictools, mobile telephones, camer<strong>as</strong> etc. They are also used in the power supply systems of electrically drivencars. In the automotive industry the main purpose of <strong>supercapacitors</strong> is to provide support for cl<strong>as</strong>sic batteries– they act <strong>as</strong> an additional buffer during acceleration and braking. Such an arrangement lowers operationalcosts of the vehicle, <strong>as</strong> it extends battery lifetime. Supercapacitors protect the battery from harmful effects ofpeak loads. Recovery of braking <strong>energy</strong> by <strong>supercapacitors</strong> also allows reducing operational costs by decre<strong>as</strong>ing<strong>energy</strong> consumption.

78Anna Lisowska-Oleksiak; Andrzej P. Nowak; Monika Wilamowska / Gdańsk University of Technology7. CONCLUSIONSupercapacitors are dynamically entering the power engineering market. Legal regulations concerningenvironmental protection and sustainable development foster installation of renewable <strong>energy</strong> sources, and thisin turn generates the demand for reliable <strong>energy</strong> <strong>storage</strong> and conversion systems.Electrochemical capacitors are able to quickly charge and discharge. They also have long lifetimes, thoughthey are not able to store volumes of electricity <strong>as</strong> high <strong>as</strong> cl<strong>as</strong>sic batteries or fuel cells. Comparison of electrochemicalcapacitors and batteries reveals that they are in fact complementary systems. For that re<strong>as</strong>on it isa very good solution to combine <strong>supercapacitors</strong> with chemical sources of electricity.REFERENCES1. http://www.dailyreckoning.com.au/<strong>supercapacitors</strong>/2008/02/28/2. Shukla A.K., Arico A.S., Antonucci V., Renewable Sustainable Energy Rev., vol. 5, 2001, p. 1373. Becker H.E., U.S. Patent 2 800 616 (1957).4. Boos D.I, U.S. Patent 3 536 963 (to Standard Oil, SOHIO) (1970).5. Conway B.E., Electrochemical Supercapacitors, Plenum Publishing, New York 1999.6. Czerwiński A., Akumulatory, baterie, ogniwa, WKt, Warsaw 2005. 77. Frąckowiak E. and Bequin F, Carbon, vol. 39, 2001, p. 9378. Kótz R. and Carlen M., Electrochim. <strong>Acta</strong>, vol. 45, 2000, p. 2483.9. Plitz I., Dup<strong>as</strong>quier A., Badway F, Gural J., Pereira N., Gmitter A., Amatucci G.G., Appl. Phys. A, vol. 82, 2006, p. 615.10. Lota G., Lota K., Frąckowiak E., Electrochem. Commun., vol. 53, 2008, p. 2210.11. Cottineau T., Toupin M., Delahaye T., Brousse T., Belanger D., Appl. Phys. A, vol. 82, 2006, p. 599.12. M<strong>as</strong>tragostino M., Arbizzani C., Soavi F, Solid State Ion., vol. 148, 2002, p. 493.13. Gómez-Romero P, Chojak M., Kulesza PJ., Asensio J.A., Electrochem. Commun., vol. 5, 2003, p. 149.14. Gómez-Romero P, Cuent<strong>as</strong>-Gallegos K., Lira-Cantu M., Mater J. Sci., vol. 40, 2005, p. 1423.15. Lisowska-OleksiakA., Nowak A.P, J. Power Sources, vol. 173, 2007, p. 829.16. Arico A.S., Bruce P, Scrosati B., Tar<strong>as</strong>con JrM., Schalkwijk van W., Nat. Mater, vol. 4, 2005, p. 366.17. Lisowska-OleksiakA., Wilamowska M., Szybowska K., Przegląd Komunalny, August 2008.