Inconel alloy MA754.pdf - Special Metals Corporation

Inconel alloy MA754.pdf - Special Metals Corporation

Inconel alloy MA754.pdf - Special Metals Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

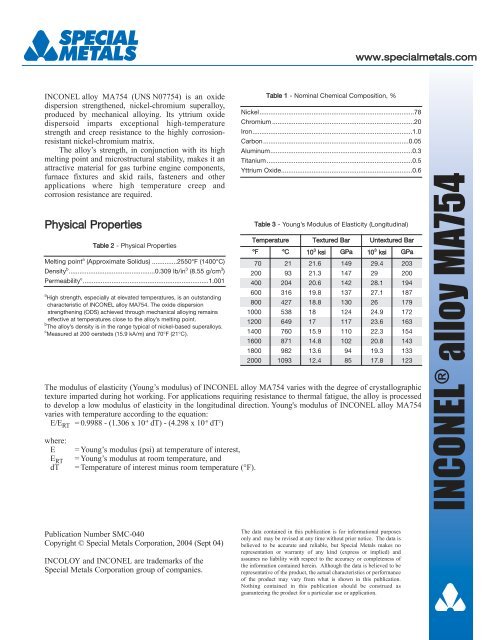

www.specialmetals.comINCONEL <strong>alloy</strong> MA754 (UNS N07754) is an oxidedispersion strengthened, nickel-chromium super<strong>alloy</strong>,produced by mechanical <strong>alloy</strong>ing. Its yttrium oxidedispersoid imparts exceptional high-temperaturestrength and creep resistance to the highly corrosionresistantnickel-chromium matrix.The <strong>alloy</strong>’s strength, in conjunction with its highmelting point and microstructural stability, makes it anattractive material for gas turbine engine components,furnace fixtures and skid rails, fasteners and otherapplications where high temperature creep andcorrosion resistance are required.Physical PropertiesTable 2 - Physical PropertiesMelting point a (Approximate Solidus) ..............2550°F (1400°C)Density b ................................................0.309 lb/in 3 (8.55 g/cm 3 )Permeability c ......................................................................1.001a High strength, especially at elevated temperatures, is an outstandingcharacteristic of INCONEL <strong>alloy</strong> MA754. The oxide dispersionstrengthening (ODS) achieved through mechanical <strong>alloy</strong>ing remainseffective at temperatures close to the <strong>alloy</strong>’s melting point.b The <strong>alloy</strong>’s density is in the range typical of nickel-based super<strong>alloy</strong>s.c Measured at 200 oersteds (15.9 kA/m) and 70°F (21°C).Table 1 - Nominal Chemical Composition, %Nickel......................................................................................78Chromium ...............................................................................20Iron.........................................................................................1.0Carbon.................................................................................0.05Aluminum...............................................................................0.3Titanium .................................................................................0.5Yttrium Oxide.........................................................................0.6Table 3 - Young’s Modulus of Elasticity (Longitudinal)TemperatureTextured BarUntextured Bar°F °C 10 3 ksi GPa 10 3 ksi GPa70 21 21.6 149 29.4 203200 93 21.3 147 29 200400 204 20.6 142 28.1 194600 316 19.8 137 27.1 187800 427 18.8 130 26 1791000 538 18 124 24.9 1721200 649 17 117 23.6 1631400 760 15.9 110 22.3 1541600 871 14.8 102 20.8 1431800 982 13.6 94 19.3 1332000 1093 12.4 85 17.8 123The modulus of elasticity (Young’s modulus) of INCONEL <strong>alloy</strong> MA754 varies with the degree of crystallographictexture imparted during hot working. For applications requiring resistance to thermal fatigue, the <strong>alloy</strong> is processedto develop a low modulus of elasticity in the longitudinal direction. Young's modulus of INCONEL <strong>alloy</strong> MA754varies with temperature according to the equation:E/E RT = 0.9988 - (1.306 x 10 -4 dT) - (4.298 x 10 -8 dT 2 )where:EE RTdT= Young’s modulus (psi) at temperature of interest,= Young’s modulus at room temperature, and= Temperature of interest minus room temperature (°F).INCONEL ® <strong>alloy</strong> MA754Publication Number SMC-040Copyright © <strong>Special</strong> <strong>Metals</strong> <strong>Corporation</strong>, 2004 (Sept 04)INCOLOY and INCONEL are trademarks of the<strong>Special</strong> <strong>Metals</strong> <strong>Corporation</strong> group of companies.The data contained in this publication is for informational purposesonly and may be revised at any time without prior notice. The data isbelieved to be accurate and reliable, but <strong>Special</strong> <strong>Metals</strong> makes norepresentation or warranty of any kind (express or implied) andassumes no liability with respect to the accuracy or completeness ofthe information contained herein. Although the data is believed to berepresentative of the product, the actual characteristics or performanceof the product may vary from what is shown in this publication.Nothing contained in this publication should be construed asguaranteeing the product for a particular use or application.

INCONEL ® <strong>alloy</strong> MA754Thermal & Electrical PropertiesThermal Expansion (CTE)The thermal expansion characteristics of INCONEL <strong>alloy</strong>MA754 closely match those of other chromium-containingnickel <strong>alloy</strong>s.Thermal ConductivityElectrical ResistivityINCONEL <strong>alloy</strong> MA754 has resistivity characteristicssimilar to those of 80-20 Ni-Cr resistance heating <strong>alloy</strong>s. Itsoxide dispersion strengthening helps resist creep andsagging at high temperatures.This property increases with temperature and is higher thanfor ceramics.Table 4 - Thermal and Electrical Properties of INCONEL <strong>alloy</strong> MA754Temperature,°CExpansion coefficient(longitudinal),10 -6 •°CExpansion coefficient(transverse),10 -6 •°CThermal conductivity,W/m•°CElectrical resistivity,µΩ•mSpecific heat,J/kg•°C26 - - 14.3 1.08 440100 12.2 12.5 15.8 1.09 461200 13.1 13.4 17.7 1.10 488300 13.7 14.0 19.5 1.11 515400 14.2 14.3 21.4 1.12 540500 14.6 14.8 23.2 1.14 567600 15.1 15.2 25.0 1.15 595700 15.7 15.8 27.0 1.14 620800 16.1 16.2 28.9 1.14 647900 16.6 16.6 30.8 1.15 6721000 17.0 17.1 32.6 1.16 6951100 - - 34.2 1.18 7201200 - - 35.8 1.19 -2

INCONEL ®<strong>alloy</strong> MA754Mechanical PropertiesPlate & SheetINCONEL <strong>alloy</strong> MA754 develops optimum high-temperature strength through controlled thermo-mechanical processingdesigned to create a stable, recrystallized, coarse grain structure. Plate products are processed to achieve isotropic properties.Textured BarINCONEL <strong>alloy</strong> MA754 can be processed to have a highly textured crystallographic structure, producing excellent resistanceto thermal fatigue. In such a condition, the properties are anisotropic. Elastic properties are also affected by thecrystallographic texture.In this condition, the ODS mechanism is augmented, for superior mechanical properties in the longitudinal direction, bythe high aspect ratio grain structure. The highly directional structure is responsible for anisotropic mechanical properties. Forapplications that require exceptional resistance to thermal fatigue, like gas turbine vanes, INCONEL <strong>alloy</strong> MA754 is given astrong texture with a crystallographic direction parallel to the working direction. Such texture results in a low modulusof elasticity in the longitudinal direction, improving resistance to thermal fatigue by lowering stresses for given thermalstrains.2004020Stress, ksi175150125100755025UTS0.2% YS% Elong3530252015Elongation, %Stress, ksi151052000F-Long2000F-L-T2100F-Long2100F-L-T00200400600800 1000 1200 1400 1600Temperature, °F1800 20001022000100 1000Hours to rupture10000Figure 1. Tensile properties of textured bar - longitudinal.Figure 3. Stress rupture strength of INCONEL <strong>alloy</strong> MA754textured bar.200175150UTS0.2% YS% Elong4030Stress, ksi1251007520Elongation, %50102500200400600800 1000 1200 1400 1600Temperature, °F1800 200002200Figure 2. Tensile properties of textured bar - long transverse (L-T).3

INCONEL ® <strong>alloy</strong> MA754Corrosion ResistanceOxidation ResistanceINCONEL <strong>alloy</strong> MA754 has excellent oxidation resistance.It may be used in high-temperature oxidizing environmentswithout the need for expensive special coatings usuallyrequired for conventional high-temperature <strong>alloy</strong>s.Nitridation ResistanceThe nature of the <strong>alloy</strong>’s protective scale, and its high nickelcontent, provide excellent resistance to nitridation.Mass Change, mg/cm 2500-50-100-150-200MA754601617-250-300-3500 200 400 600 800600800H1000 1200Exposure Time - hoursFigure 4. Mass change of several wrought high temperature <strong>alloy</strong>sin air + 5% water vapor at 2150°F (1177°C).330Mass Change, mg/cm 2121086420617800H601600330MA7540 200 400 600 800 1000 1200 1400Time, hoursFigure 5. Mass change of several high temperature <strong>alloy</strong>s in N 2 -5%H 2 at 2150°F (1177°C).Table 5 - Penetration results for eight <strong>alloy</strong>s exposed in air + 5% water vapor for 1008 hours at 2150°C (1177°F)AlloyMetal Loss,milsMaximum Attack, mils330 Stainless Steel 10.0 14.6600 12.4 13.6617 0.8 5.6800H 18.0 20.4INCONEL <strong>alloy</strong> MA754 0.1 3.8601 1.7 >23.84

INCONEL ®<strong>alloy</strong> MA754Burner-Rig PropertiesUncoated INCONEL <strong>alloy</strong> MA754 has been used extensively in jet fuel combustion environments. Tests at 1700°F (927°C)for 168 h in JP-5 fuel with 0.3% sulfur and 5 ppm sea water. Air-to-fuel ratio: 30 to 1. Thermal cycle: 58 min at 1700°F(927°C), rapid cool to room temperature in 2 min.Table 6 - Burner-Rig PropertiesMaterialWeight Change, Mg/cm 2 Metal Loss Max. AttackUndescaled DescaledmilµmmilµmINCONEL <strong>alloy</strong> MA754 -0.1 -7.4 0.79 20 3.11 79Alloy IN-738 +1.4 -6.1 1.06 27 5.83 148MAR-M a 509 +0.9 -12.4 1.10 28 5.98 152Alloy X-40 -0.8 -9.6 1.18 30 5.71 145Alloy 713C b -386.0 -431.0 130 3304 130 3304a Trademark of Martin Marietta Corp.b Completely destroyed.Creep & Fatigue PropertiesINCONEL <strong>alloy</strong> MA754 is one of the most creep-resistantcommercially available <strong>alloy</strong>s for service at over 2000°F(1095°C). This characteristic offers superior resistance tobowing and sagging under load at high temperatures. The<strong>alloy</strong> has good thermal fatigue resistance compared to manyhigh strength super<strong>alloy</strong>s. Thermal strains are reduced in thelow modulus direction of textured bar.Stress, ksi53210.5INCONEL <strong>alloy</strong> MA754INCOLOY <strong>alloy</strong> 330INCONEL <strong>alloy</strong> 601INCONEL <strong>alloy</strong> 617INCOLOY <strong>alloy</strong> 800HINCONEL <strong>alloy</strong> 6000.10.00001 0.00010 0.00100 0.01000 0.10000 1.00000Creep Rate, %/hFigure 6. Minimum creep rate results for several wrought hightemperature <strong>alloy</strong>s at 2150°F (1177°C).5

INCONEL ® <strong>alloy</strong> MA754WorkingMachiningThe <strong>alloy</strong> is readily machined by all conventional techniques. Its annealed hardness is Rc 29. If electric discharge machining(EDM) or laser cutting is to be used, it is recommended that the recast layer be removed by grinding.Information on machining is available in the <strong>Special</strong> <strong>Metals</strong> publication “Machining” on the website,www.specialmetals.com.JoiningThe strongest joints are produced by processes such as laser and electron beam welding and diffusion bonding. Brazing hasbeen used for years with great success in applications such as gas turbine engines. Mechanical joints such as rivets, pins,threaded connections and fir tree joints are also often used. Conventional TIG welding can be used but leads to reduced hightemperaturestress rupture strength at the joint.Information on joining is available in the <strong>Special</strong> <strong>Metals</strong> publication “Joining” on the website, www.specialmetals.com.FormingIn the final annealed condition, INCONEL <strong>alloy</strong> MA754 has a coarse, creep resistant grain structure, and thus exhibits limitedhot formability. The <strong>alloy</strong> can be hot worked into the desired shape prior to the grain coarsening final anneal. INCONEL <strong>alloy</strong>MA754 is easily cold worked, but such deformation may cause the <strong>alloy</strong> to recrystallize to a fine grain condition uponexposure to high temperature. A fine grain structure will have reduced high temperature strength properties. <strong>Special</strong> <strong>Metals</strong><strong>Corporation</strong> should be contacted to work with the fabricator to develop such processes.Product FormsINCONEL <strong>alloy</strong> MA754 is designated as UNS N07754.Alloy MA754 is available as tube, sheet, plate, round barand flat bar.Table 7 - Available Forms and Size Ranges of INCONEL <strong>alloy</strong> MA 754inchesmmHot-rolled sheet 0.05-0.1 1-3Hot-rolled plate 0.2-1.5 5-38Hot-finished round bar 0.75-2 19-51Flat bar from: 3/4 x 4 19 x 102to: 3 1/2 x 5 1/2 89 x 140Tubeextruded tubing can be produced over arange of diameters and wall thicknesses.6

The <strong>Special</strong> <strong>Metals</strong> <strong>Corporation</strong>trademarks include:BRIGHTRAY ®NILO ®CORRONEL ®NILOMAG ®DEPOLARIZED ®NIMONIC ®DURANICKEL ®NIOTHERM ®FERRY ®NI-ROD ®INCOBAR ®NI-SPAN-C ®INCOCLAD ®RESISTOHM ®INCO-CORED ®UDIMAR ®INCOFLUX ®UDIMET ®INCOLOY ®601GC ®INCONEL ®625LCF ®INCOTEST ®718SPF INCOTHERM ®725NDUR ®INCO-WELD ®800HT ®KOTHERM ®956HT MONEL ®7

www.specialmetals.comU.S.A.<strong>Special</strong> <strong>Metals</strong> <strong>Corporation</strong>Billet, rod & bar, flat& tubular products3200 Riverside DriveHuntington, WV 25705-1771Phone +1 (304) 526-5100+1 (800) 334-4626Fax +1 (304) 526-5643Billet & bar products4317 Middle Settlement RoadNew Hartford, NY 13413-5392Phone +1 (315) 798-2900+1 (800) 334-8351Fax +1 (315)798-2016Atomized powder products100 Industry LanePrinceton, KY 42445Phone +1 (270) 365-9551Fax +1 (270) 365-5910Shape Memory Alloys4317 Middle Settlement RoadNew Hartford, NY 13413-5392Phone +1 (315) 798-2939Fax +1 (315) 798-6860United Kingdom<strong>Special</strong> <strong>Metals</strong> Wiggin Ltd.Holmer RoadHereford HR4 9SLPhone +44 (0) 1432 382200Fax +44 (0) 1432 264030<strong>Special</strong> <strong>Metals</strong> Wire ProductsHolmer RoadHereford HR4 9SLPhone +44 (0) 1432 382556Fax +44 (0) 1432 352984China<strong>Special</strong> <strong>Metals</strong> Pacific Pte. Ltd.Room 1802, Plaza 661266 West Nanjing RoadShanghai 200040Phone +86 21 3229 0011Fax +86 21 6288 1811<strong>Special</strong> <strong>Metals</strong> Pacific Pte. Ltd.Room 910, Ke Lun Mansion12A Guanghua RoadChaoyang DistrictBeijing 100020Phone +86 10 6581 8396Fax +86 10 6581 8381France<strong>Special</strong> <strong>Metals</strong> Services SA17 Rue des Frères Lumière69680 Chassieu (Lyon)Phone +33 (0) 4 72 47 46 46Fax +33 (0) 4 72 47 46 59Germany<strong>Special</strong> <strong>Metals</strong> Deutschland Ltd.Postfach 20 04 0940102 DüsseldorfPhone +49 (0) 211 38 63 40Fax +49 (0) 211 37 98 64Hong Kong<strong>Special</strong> <strong>Metals</strong> Pacific Pte. Ltd.Unit A, 17th Floor, On Hing Bldg1 On Hing TerraceCentral, Hong KongPhone +852 2439 9336Fax +852 2530 4511India<strong>Special</strong> <strong>Metals</strong> Services Ltd.No. 60, First Main Road, FirstBlockVasantha Vallabha NagarSubramanyapura PostBangalore 560 061Phone +91 (0) 80 2666 9159Fax +91 (0) 80 2666 8918Italy<strong>Special</strong> <strong>Metals</strong> Services SpAVia Assunta 5920054 Nova Milanese (MI)Phone +390 362 4941Fax +390 362 494224The Netherlands<strong>Special</strong> <strong>Metals</strong> Service BVPostbus 86813009 AR RotterdamPhone +31 (0) 10 451 44 55Fax +31 (0) 10 450 05 39Singapore<strong>Special</strong> <strong>Metals</strong> Pacific Pte. Ltd.24 Raffles Place#27-04 Clifford CentreSingapore 048621Phone +65 6532 3823Fax +65 6532 3621Affiliated Companies<strong>Special</strong> <strong>Metals</strong> WeldingProducts1401 Burris RoadNewton, NC 28658, U.S.A.Phone +1 (828) 465-0352+1 (800) 624-3411Fax +1 (828) 464-8993Canada HouseBidavon Industrial EstateWaterloo RoadBidford-On-AvonWarwickshire B50 4JN, U.K.Phone +44 (0) 1789 491780Fax +44 (0) 1789 491781Controlled Products Group590 Seaman Street, Stoney CreekOntario L8E 4H1, CanadaPhone +1 (905) 643-6555Fax +1 (905) 643-6614A-1 Wire Tech, Inc.A <strong>Special</strong> <strong>Metals</strong> Company4550 Kishwaukee StreetRockford, IL 61109, U.S.A.Phone +1 (815) 226-0477+1 (800) 426-6380Fax +1 (815) 226-0537Rescal SAA <strong>Special</strong> <strong>Metals</strong> Company200 Rue de la Couronne des Prés78681 Epône Cédex, FrancePhone +33 (0) 1 30 90 04 00Fax +33 (0) 1 30 90 02 11DAIDO-SPECIAL METALSLtd.A Joint Venture CompanyDaido Shinagawa Building6-35, Kohnan 1-chomeMinato-ku, Tokyo 108-0057, JapanPhone +81 (0) 3 5495 7237Fax +81 (0) 3 5495 1853