Download - Victaulic

Download - Victaulic

Download - Victaulic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

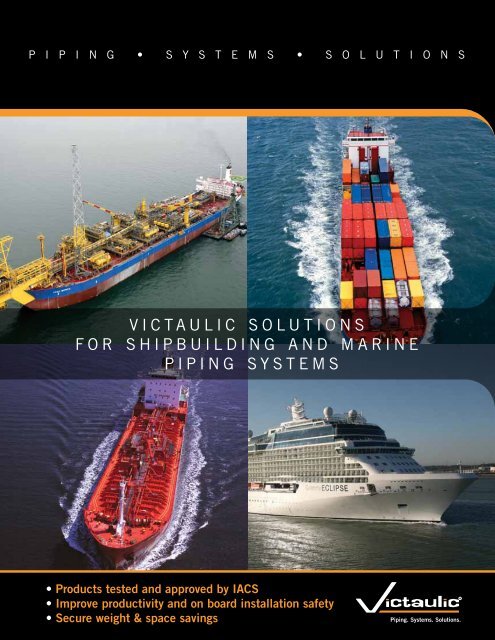

<strong>Victaulic</strong>: Grooved Pipe Joining Technology<strong>Victaulic</strong>, the world leader in grooved end mechanical pipe joiningsystems, was founded in New York City in 1925 to market a radicalnew concept in the piping industry — a mechanical bolted couplingthat would engage into grooves with a gasket seal.Today our grooved mechanical piping technology - a flame-freejoining method - is the most versatile, economical and reliablemechanical pipe joining system available for the shipbuildingand ship repair industry.By specifying and installing <strong>Victaulic</strong>, ship designers,owners and shipyards conserve time and financialresources through:Compressed project schedules<strong>Victaulic</strong> systems increase projectefficiency from the start.Lowered total installed costover the lifetime of the system.Safer work environmentReduced calendar days reduces exposureto on board installation accidents.Reduced downtimeduring scheduled maintenance, service checks,dry docking, conversions and upgrades.How our system works.The mechanical joint, or coupling, comprises four elements: thepipe groove, a gasket, the housings and nuts and bolts. The pipegroove is cold formed or machine grooved into a pipe end. Thehousing, which encases the gasket and engages into the grooves,creates a unified joint. The housing fully encloses the gasket,reinforcing and securing it in position. Holding the housing sectiontogether are bolts and nuts that are tightened with hand tools.The mechanical joint creates a triple seal because of the designrelationship between the pipe groove, gasket and housings. Thisseal is enhanced when the piping system is pressurized.Once installed, our mechanical system is easily inspected throughvisual confirmation of a proper installation.Metal-to-metal bolt-pad contact confirms that the joint is properlyinstalled and no re-work is necessary.Coupling Assembly2 Shipbuilding and Marine Piping Systems

HOUSINGGASKETGROOVEGROOVEBOLT/NUTNot all gasketsare the sameThe heart of a mechanical couplingsystem is the gasket. That is whystringent quality control measures,precision engineering and exhaustivetesting go into the manufacturing of a<strong>Victaulic</strong> gasket.<strong>Victaulic</strong> boasts the largest and mostexperienced team of engineersin the industry. Utilizing themost advanced nonlinear finiteelement analysis the researchand development team predictsthe performance of materialsin different configurations tounderstand the performance in field conditions.A proprietary compound accommodates theeffects of thermal expansion, pipe end flare andpressurization. The engineered, pressure-responsivedesign provides increased sealing performance asinternal system pressure is increased.As the industry’s only single-source manufacturer,<strong>Victaulic</strong> uses the latest molding technology toensure a quality product. <strong>Victaulic</strong> gaskets aresubject to stringent quality control standards and<strong>Victaulic</strong> uses extensive tests, such as air and wateraging, thermal cycling, compression set and tensilestrength, to prove the highest product performance.Cut Grooving PipeRoll Grooving PipeShipbuilding and Marine Piping Systems 3

Tankers/LPG/LNGSystemsSEA WATER• Ballast• Bilge• Cooling• Fire Main••••Non-essential LinesScuppers and DischargeTank cleaningWater Spray/Foam/SprinklerSystemsFLAMMABLE FLUIDS• Cargo Oil• Crude Oil• Crude Oil Washing• Fuel Oil Transfer• Hydraulic Oil• Lubricating Oil• Thermal Oil Lines• Vent LinesFRESH WATER• Condensate Returns• Cooling Water• Deck Drains• Fire Systems• Non-essential lines• Potable Water• Sanitary Drains• Sanitary• Scuppers and Discharge• Sounding and Venting• Vents and Overflows• Water Tanks/Dry SpacesINERT GASMISCELLANEOUS• C0 2• Main and Distribution Lines• Scrubber Effluent• Water Seal• Air Conditioning• Air Piping• Brine• Deck Scupper• Domestic Fresh Water• Domestic Sanitary Drains• Fire and Deck Wash Lines•• Non-Essential• Service Air (non-essential)Heating and Air Conditioning8 Shipbuilding and Marine Piping Systems

Passenger ShipsSystemsSEA WATER• Ballast• Bilge• Cooling• Fire Main•••Non-essential LinesScuppers and DischargeWater Spray/Foam/SprinklerSystemsFLAMMABLE FLUIDS• Fuel Oil Transfer• Hydraulic Oil• Lubricating Oil• Vent LinesFRESH WATER• Condensate Returns• Cooling Water• Deck Drains• Fire Systems• Non-essential lines• Potable Water• Sanitary Drains• Sanitary• Scuppers and Discharge• Sounding and Venting• Vents and Overflows• Water Tanks/Dry SpacesINERT GASMISCELLANEOUS• C0 2• Main and Distribution Lines• Scrubber Effluent• Water Seal• Air Conditioning• Air Piping• Brine• Deck Scupper• Domestic Fresh Water• Domestic Sanitary Drains• Fire and Deck Wash Lines•• Non-Essential• Service Air (non-essential)Heating and Air ConditioningShipbuilding and Marine Piping Systems 9

WorkboatsSystemsSEA WATER• Ballast• Bilge• Cooling• Fire Main•••Non-essential LinesScuppers and DischargeWater Spray/Foam/SprinklerSystemsFRESHFLAMMABLE FLUIDS• Fuel Oil Transfer• Hydraulic Oil• Lubricating Oil• Vent LinesWATER• Condensate Returns• Cooling Water• Deck Drains• Fire Systems• Non-essential lines• Potable Water• Sanitary Drains• Sanitary• Scuppers and Discharge• Sounding and Venting• Vents and Overflows• Water Tanks/Dry SpacesINERT GASMISCELLANEOUS• C0 2• Main and Distribution Lines• Scrubber Effluent• Water Seal• Air Conditioning• Air Piping• Brine• Deck Scupper• Domestic Fresh Water• Domestic Sanitary Drains• Fire and Deck Wash Lines•• Non-Essential• Service Air (non-essential)Heating and Air Conditioning10 Shipbuilding and Marine Piping Systems

Value-added EngineeringAt the root of all the benefits that <strong>Victaulic</strong> solutions bringto a project – such as on board installation productivity, safety,design flexibility, high performance, and quality – are the uniquefeatures of <strong>Victaulic</strong> products.Since 1925, Innovative Design From theOriginator of the Grooved Mechanical CouplingRIGIDITYRigidity is achieved with standardcouplings. The unique angled paddesign of Zero-Flex ® and other<strong>Victaulic</strong> couplings provides positiveclamping of the pipe to resist torsionaland flexural loads.FLEXIBILITYThe <strong>Victaulic</strong> grooved end solutionaccommodates expansion/contraction/deflectionand enables designingthat takes advantage of these built-insystem features.ALIGNMENT EASEThe grooved system allows full rotationof the pipe and system componentsbefore tightening so that properalignment can be achieved eliminatingmate-up problems and field rework,which makes this system the idealsolution for deck or wall penetrations.ContractionDeflectionRigidity & FlexibilityDeflection Capabilities12 Shipbuilding and Marine Piping Systems

Green ShipbuildingGreen Shipbuilding is an inevitable trend in theindustry. <strong>Victaulic</strong> will help you to minimize thenegative effects on the environment and maximizethe efficient use of raw materials and energy.<strong>Victaulic</strong> can greatly improve work efficiency and secure operations at sea as our productsand the way they are installed have a low ecological footprint.PRODUCTION METHODGrooved products use recycled steel and the products aremanufactured using the natural elements of water, fire, sandand air. The manufacture of grooved products also requiresthe use of sand molds and 98% of the sand molds can bere-used. Dust emissions are far lower than the relevantnational environmental standards. Unlike spray painting,grooved products are painted by using a dip coatingapplication to create less wasted paint. Moreover, <strong>Victaulic</strong>’sproducts make use of water-soluble paint, which is moreenvironmental friendly and ensures the health and securityof the installation crew.FLAME FREE INSTALLATIONBy-products of weld and solder fumes can contain leadoxide, carbon monoxide, VOCs and hydrochloric acidin addition to many other harmful particles and gases.Reducing the particulate matter preserves indoor andoutdoorair quality leading to a safe and healthyenvironment. <strong>Victaulic</strong> no-weld pipe joining methodeliminates these harmful airborne pollutants normallyemitted into the environment during the welding process.REDUCING NOISE POLLUTIONThe elastomeric gasket used to seal pipe couplings alsocreates discontinuity in the piping system. This reducesnoise and vibration transmitted through piping from pumps,chillers and other components.PROTECTING THE MARINE ENVIRONMENTGrooved products can be used on various applications,such as ballast and bilge water treatment, exhaust emissionreduction and system retrofit, to effectively manage theenvironmental impact of maritime operations.Please refer to PB-303 "Designingfor Sustainability," the brochurewhich highlights all the solutionsoffered by <strong>Victaulic</strong> that supportsustainability standards.Click here to read the brochure.VISUAL CONFIRMATIONOF A PROPER INSTALLATIONOnce installed, mechanical systems are easily inspected.Our grooved systems provide for quality control throughvisual confirmation of proper installation. Metal-to-metal boltpad contact confirms that the joint is properly installed andno re-work is necessary. This eliminates the need of harmfullX-rays.REDUCING WEIGHTInstalling <strong>Victaulic</strong> couplings and valves instead of flangedassemblies leads to weight savings, thus also resulting inconsiderable fuel savings.Sustainable SolutionsShipbuilding and Marine Piping Systems 15

Meet or Beat Finite Project Schedules<strong>Victaulic</strong> will work with you in each phase ofthe project life cycle. Our services allow youto build, commission, test and turnover yourproject to meet or beat project schedules.Quicker, easier installations3 TO 5 TIMES FASTER TO INSTALLMAN HOURS PER JOINT<strong>Victaulic</strong> GroovedFlangedWelded121110987654321When reviewing the designfor your piping system, consider:• Welded systems demand 45% moreman-hours on average.•Hexavalent Chromium, produced bywelding stainless steel, is highly toxic.• Grooved-end valves have a smallerprofile and provide you with spacesavingadvantages over flanged valves.•<strong>Victaulic</strong> couplings require only twonuts and bolts compared to flangedsystems, and grooved productssignificantly weigh less, easinghandling in the shop and on board.2" 4" 6" 8" 10" 12"PIPE SIZEPlease refer to the PB-306 "Worksite Safety"the brochure which highlights how <strong>Victaulic</strong>can help you to manage safety-related costs.Click here to read the brochure.<strong>Victaulic</strong> benefits that save youtime and valuable resources:IMPROVED SAFETYNo flame joining methodLABOR SAVINGSEasier maintenance andreduced downtime16 Shipbuilding and Marine Piping Systems

Our Services<strong>Victaulic</strong> will increase project efficiencies andreduce on board installation man-hours fromstart to finish with value added services.VICTAULIC SERVICESINCLUDE:• Estimating• Pre-Planning and ProjectManagement• On Board Installation Training• Software Solutions• Construction Drawings• Pad equipment andpump layouts• Piping layouts• Fabrication spools• Laydown coordinationNUMBER OF MEN INSTALLINGShift MaximumManpower Line<strong>Victaulic</strong>Peak Man-PowerMECHANICAL CONSTRUCTION WEEKSWeldedPeak Man-PowerMeet or BeatProject ScheduleClick here for additional informationor to download our CAD files.Shipbuilding and Marine Piping Systems 17

ReferencesA broad variety of vessels and rigs all over the world havealready taken advantage of the benefits that come alongwith employing <strong>Victaulic</strong> products in a wide range ofapplications.City Wismar & Cape MolliniSTX Europe, formerly Aker Yards, is an international shipbuilding companybased in Norway. As the largest shipbuilding company in Europe and thefourth-largest firm in the world, STX requires that all vessels meet thehighest of global industry standards. In 2006, construction was completedon two containerships - Cape Mollini and City Wismar. Because <strong>Victaulic</strong>products meet stringent global approval standards, the <strong>Victaulic</strong> groovedpipe joining method was specified and installed on the ship’s galvanizedcarbon steel drinking water, sea cooling water and fire protection lines.Bohai Shi JiBOHAI SHI JI, a DNV classed Floating Production Storage Offloading(FPSO) vessel is located in the QHD32-6 field development in BohaiBay China, in a water depth of 20m. The mooring system is designed toproduce a total of 270,000 Barrels Per Day (BPD) of combined fluidsincluding 80,000 BPD of crude oil.<strong>Victaulic</strong> Style 07 rigid couplings and Style 77 flexible couplings areinstalled to connect six pipeline systems on FPSO. The contractor,Dalian Shipyard Offshore Co., Ltd., reported substantial time savings oninstalling <strong>Victaulic</strong> grooved couplings as compared to flanged products.Furthermore, the installation of <strong>Victaulic</strong> products provided a reliable andhigh quality solution for this vessel's 32"/813 mm seawater cooling system.La SuperbaOne of the world’s largest and fastest luxury cruise ferries, La Superbacan house 2,920 passengers and 1,000 vehicles. The owners of the ferrycruise needed a world class piping solution. Noise and vibration attenuation,as well as ease of installation and maintenance, made <strong>Victaulic</strong> anatural choice.18 Shipbuilding and Marine Piping Systems

Celebrity EclipseWhen one of the most luxurious cruise ships in the world, the CelebrityEclipse, operated by Celebrity Cruises, needed a quick upgrade in thePort of Malaga, the contractor, Servyman del Estrecho S.L., and systemprovider, Mahle – Industrial Filtration, relied on <strong>Victaulic</strong> piping solutions tomeet the operator’s demanding time schedule.With only a scheduled stop-over of 6 hours to install a new oil/waterfilter between two containers, Mahle went looking for a solution that waseasy and quick to install and enabled Servyman del Estrecho S.L. toprefabricate part of the installation before the ship arrived at the port.To work in the most efficient and cost effective way, Mahle chose toinstall <strong>Victaulic</strong> products and to rely on the experience of the <strong>Victaulic</strong>Construction Piping Services (CPS) division. By employing <strong>Victaulic</strong>couplings and fittings they were reassured of a smooth and fast installationand the detailed system drawings, made by the CPS division, wereused by Servyman del Estrecho S.L. as a blueprint to cut pipes to theexact required length and to prefabricate considerable segments of theinstallation in their workshop.Once boarded, Servyman del Estrecho S.L., finished the whole installationin three hours, which included cutting and grooving some pipes on board,resulting in plenty of time left to test the entire system. Installing <strong>Victaulic</strong>couplings and fittings proved to be the ideal solution to meet and evenbeat the deadline and allowed the Celebrity Eclipse to continue its journeyon the Mediterranean Sea with no delays, resulting in elaborate costsavings for Celebrity Cruises.• Click here for more references.Shipbuilding and Marine Piping Systems 19

www.victaulic.comThe <strong>Victaulic</strong> website is an information resourcethat can help you with your piping projects.Among the many resources available at the site:• Fully searchable product and project databases• Free product submittals• Free product literature• Piping software demos, modules and downloads• Information on new product innovations• Support services, and more. . .VICTAULIC LOCATIONSVICTAULIC GLOBAL CONTACT INFORMATIONUS & WORLD HEADQUARTERSINDIAEUROPEASIAP.O. Box 31Easton, PA 18044-0031 USA4901 Kesslersville RoadEaston, PA 18040 USASales:David Gibbons+1 610 559 3460dgibbons@victaulic.comSagar Tech PlazaA202-205 Andheri Kurla Rd.Sakinaka, India 400072Sales:Ravindra Deshpande+91 9922 423 544ravindra.deshpande@victaulic.bePrijkelstraat 369810 Nazareth, BelgiumSales:Didier Vassal+32 479 20 11 52didier.vassal@victaulic.beUnit 06-10, Floor 3AA Mansion 291 Fumin RoadShanghai, China 200031Sales:China: Peter Jiang+86 21 6170 1222pjiang@victaulic.comSingapore: HP Chan+65 9388 5665hpchan@victaulic.comCANADAUNITED KINGDOMMIDDLE EASTAUSTRALIA AND NEW ZEALAND123 Newkirk RoadRichmond Hill, ON L4C 3G5Sales:Scott McDonald+1 800 387 3815smcdonald@victaulic.comUnits B1 & B2, SG1 Industrial ParkCockerell CloseGunnels Wood RoadStevenageHertfordshire, SG1 2NB (UK)Sales:South: Shaun Hughes+44 7867 515 438shaun.hughes@victaulic.beP.O. Box 17683Unit XB 8Jebel Ali Free ZoneDubaiUnited Arab EmiratesSales:Parveez Saleem+9714 883 8870parveez.saleem@victaulic.be7 Chambers RoadUnit 1Altona North, VictoriaAustralia 3025Sales:Elan Avichzer+61 411 222 104eavichzer@victaulic.comwww.victaulic.comNorth: David Brownlie+44 7789 640 516david.brownlie@victaulic.beMB-560 0748 Rev EVICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY.© 2012 VICTAULIC COMPANY. ALL RIGHTS RESERVED.