Chapter 16 - Pipe Brusting - Plastics Pipe Institute

Chapter 16 - Pipe Brusting - Plastics Pipe Institute

Chapter 16 - Pipe Brusting - Plastics Pipe Institute

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

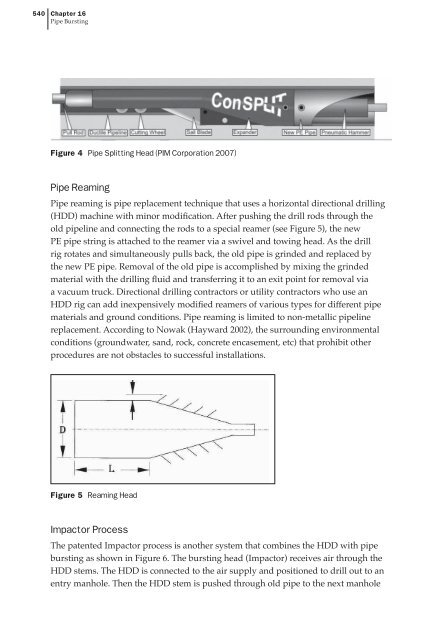

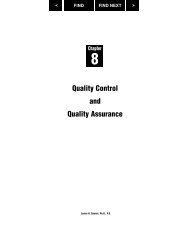

540<strong>Chapter</strong> <strong>16</strong><strong>Pipe</strong> BurstingFigure 4 <strong>Pipe</strong> Splitting Head (PIM Corporation 2007)<strong>Pipe</strong> Reaming<strong>Pipe</strong> reaming is pipe replacement technique that uses a horizontal directional drilling(HDD) machine with minor modification. After pushing the drill rods through theold pipeline and connecting the rods to a special reamer (see Figure 5), the newPE pipe string is attached to the reamer via a swivel and towing head. As the drillrig rotates and simultaneously pulls back, the old pipe is grinded and replaced bythe new PE pipe. Removal of the old pipe is accomplished by mixing the grindedmaterial with the drilling fluid and transferring it to an exit point for removal viaa vacuum truck. Directional drilling contractors or utility contractors who use anHDD rig can add inexpensively modified reamers of various types for different pipematerials and ground conditions. <strong>Pipe</strong> reaming is limited to non-metallic pipelinereplacement. According to Nowak (Hayward 2002), the surrounding environmentalconditions (groundwater, sand, rock, concrete encasement, etc) that prohibit otherprocedures are not obstacles to successful installations.Figure 5 Reaming Head!Impactor ProcessThe patented Impactor process is another system that combines the HDD with pipebursting as shown in Figure 6. The bursting head (Impactor) receives air through theHDD stems. The HDD is connected to the air supply and positioned to drill out to anentry manhole. Then the HDD stem is pushed through old pipe to the next manhole