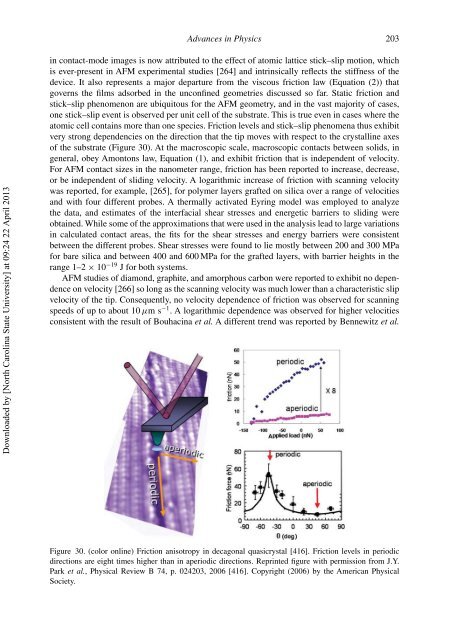

Advances <strong>in</strong> Physics 203Downloaded by [North Carol<strong>in</strong>a State University] at 09:24 22 April 2013<strong>in</strong> contact-mode images is now attributed to the effect of atomic lattice stick–slip motion, whichis ever-present <strong>in</strong> AFM experimental studies [264] <strong>and</strong> <strong>in</strong>tr<strong>in</strong>sically reflects the stiffness of thedevice. It also represents a major departure from the viscous friction law (Equation (2)) thatgoverns the films <strong>adsorbed</strong> <strong>in</strong> the unconf<strong>in</strong>ed geometries discussed so far. Static friction <strong>and</strong>stick–slip phenomenon are ubiquitous for the AFM geometry, <strong>and</strong> <strong>in</strong> the vast majority of cases,one stick–slip event is observed per unit cell of the substrate. This is true even <strong>in</strong> cases where theatomic cell conta<strong>in</strong>s more than one species. <strong>Friction</strong> levels <strong>and</strong> stick–slip phenomena thus exhibitvery strong dependencies on the direction that the tip moves with respect to the crystall<strong>in</strong>e axesof the substrate (Figure 30). At the macroscopic scale, macroscopic contacts between solids, <strong>in</strong>general, obey Amontons law, Equation (1), <strong>and</strong> exhibit friction that is <strong>in</strong>dependent of velocity.For AFM contact sizes <strong>in</strong> the nanometer range, friction has been reported to <strong>in</strong>crease, decrease,or be <strong>in</strong>dependent of slid<strong>in</strong>g velocity. A logarithmic <strong>in</strong>crease of friction with scann<strong>in</strong>g velocitywas reported, for example, [265], for polymer layers grafted on silica over a range of velocities<strong>and</strong> with four different probes. A thermally activated Eyr<strong>in</strong>g model was employed to analyzethe data, <strong>and</strong> estimates of the <strong>in</strong>terfacial shear stresses <strong>and</strong> energetic barriers to slid<strong>in</strong>g wereobta<strong>in</strong>ed. While some of the approximations that were used <strong>in</strong> the analysis lead to large variations<strong>in</strong> calculated contact areas, the fits for the shear stresses <strong>and</strong> <strong>energy</strong> barriers were consistentbetween the different probes. Shear stresses were found to lie mostly between 200 <strong>and</strong> 300 MPafor bare silica <strong>and</strong> between 400 <strong>and</strong> 600 MPa for the grafted layers, with barrier heights <strong>in</strong> therange 1–2 × 10 −19 J for both systems.AFM studies of diamond, graphite, <strong>and</strong> amorphous carbon were reported to exhibit no dependenceon velocity [266] so long as the scann<strong>in</strong>g velocity was much lower than a characteristic slipvelocity of the tip. Consequently, no velocity dependence of friction was observed for scann<strong>in</strong>gspeeds of up to about 10 μm s −1 . A logarithmic dependence was observed for higher velocitiesconsistent with the result of Bouhac<strong>in</strong>a et al. A different trend was reported by Bennewitz et al.Figure 30. (color onl<strong>in</strong>e) <strong>Friction</strong> anisotropy <strong>in</strong> decagonal quasicrystal [416]. <strong>Friction</strong> levels <strong>in</strong> periodicdirections are eight times higher than <strong>in</strong> aperiodic directions. Repr<strong>in</strong>ted figure with permission from J.Y.Park et al., Physical Review B 74, p. 024203, 2006 [416]. Copyright (2006) by the American PhysicalSociety.

204 J. KrimDownloaded by [North Carol<strong>in</strong>a State University] at 09:24 22 April 2013on Cu(111) [267] <strong>and</strong> Gnecco et al. on NaCl(100) [268], who observed a logarithmic dependenceof friction on scann<strong>in</strong>g velocity for velocities less than about 1 μms −1 . A thermally activated slipmodel <strong>and</strong> a modified Toml<strong>in</strong>son model, respectively, were used to expla<strong>in</strong> the trends observed <strong>in</strong>the data sets. A very similar model was employed by Overney <strong>and</strong> coworkers [269] to expla<strong>in</strong> thelogarithmic dependence of friction for n-hexadecane <strong>and</strong> octamethylcycloterasiloxane (OMCTS)physisorbed on silicon oxide wafers. In this case, the authors reported that <strong>in</strong>terfacial liquidstructur<strong>in</strong>g reduced the slid<strong>in</strong>g friction <strong>and</strong> that the molecular topology ultimately dictated thelubricat<strong>in</strong>g properties of the boundary layer. Cannara et al. [36] meanwhile <strong>in</strong>voked the sametheory employed for phononic friction <strong>in</strong> slid<strong>in</strong>g <strong>adsorbed</strong> layers to <strong>in</strong>terpret AFM data recordedon surfaces of hydrogen <strong>and</strong> deuterium isotopes [37], <strong>and</strong> re<strong>in</strong>terpreted the result <strong>in</strong> terms of thespac<strong>in</strong>g of the hydrogen or deuterium <strong>and</strong> not necessarily the difference <strong>in</strong> phonon frequency.Overall, it is becom<strong>in</strong>g clear that the velocity <strong>and</strong> temperature dependence is system-dependent[76], <strong>and</strong> there is a competition between thermal, adhesive, phononic, <strong>and</strong> electronic effects whichultimately determ<strong>in</strong>es the velocity dependence. This topic is discussed <strong>in</strong> more detail <strong>in</strong> Sections 3<strong>and</strong> 4.With respect to <strong>adsorbed</strong> films, <strong>in</strong> particular, Buzio et al. have reported a detailed study of theform of the friction laws that govern lubricatedAFM contacts, particularly, those lubricated by slid<strong>in</strong>g<strong>adsorbed</strong> layers of physisorbed OMCTS <strong>and</strong> squalane, which are common materials for studyby alternative techniques, <strong>and</strong> may be comparable to QCM studies of physisorbed layers [270]. Thestudies were performed <strong>in</strong> controlled conditions, <strong>and</strong> the friction laws for nanoasperities slid<strong>in</strong>g onatomically flat substrates under controlled atmosphere <strong>and</strong> liquid environment, respectively, were<strong>in</strong>vestigated. The group reported a power-law relation between the friction force <strong>and</strong> normal loadfor measurements performed <strong>in</strong> dry air, <strong>and</strong> a l<strong>in</strong>ear relationship, that is, Amontons’ law (Equation(1)) , for junctions fully immersed <strong>in</strong> the model lubricants studied (OMCTS <strong>and</strong> squalane). Theyobserved that the lubricated contacts display a significant reduction <strong>in</strong> friction levels, with liquid<strong>and</strong>substrate-specific friction coefficients. They compared the results to MD simulations <strong>and</strong>found evidence that load-bear<strong>in</strong>g boundary layers at the asperity junction entrance may cause theappearance of Amontons’ law <strong>and</strong> impart atomic-scale character to the slid<strong>in</strong>g process. F<strong>in</strong>ally,they suggest a first attempt at the general criteria that may lead to nanoscale lubrication due to thepresence of mobile <strong>adsorbed</strong> boundary layers.The presence of mobile adlayers has been observed to produce Amontons’ law behavior <strong>in</strong>AFM data. Mobile adlayers have also been implicated as giv<strong>in</strong>g rise to the atomic-scale orig<strong>in</strong>sof static friction [271]. As such, s<strong>in</strong>ce mobile adlayers are present on virtually all macroscopicsurfaces, their importance to date may have been underestimated <strong>in</strong> macroscopic studies.2.5.3. STM–QCM <strong>and</strong> related geometriesA QCM surface electrode can easily reach speeds of cm s −1 to 1–2 m s −1 , <strong>and</strong> its amplitudeof oscillation can be measured directly by means of STM [63]. The product of the oscillationamplitude with the angular frequency of the QCM yields the maximum velocity amplitude ofthe electrode–tip contact, <strong>and</strong> high-speed slid<strong>in</strong>g friction <strong>and</strong> high stra<strong>in</strong> rate studies between as<strong>in</strong>gle nanoasperity contact can be performed by lower<strong>in</strong>g a tip <strong>in</strong>to slid<strong>in</strong>g contact with the QCMelectrode [272].STM–QCM has been employed to study diffusion <strong>in</strong> <strong>adsorbed</strong> monolayers, by exam<strong>in</strong><strong>in</strong>g thequality of the images when the oscillator is mov<strong>in</strong>g <strong>and</strong> stationary, <strong>and</strong> has been employed to probewhether the asperity contact regime is liquid- or solid-like, depend<strong>in</strong>g on the sign of the frequencyshift when the tip makes contact with the surface [273]. The technique has a great potential forfuture studies of contact melt<strong>in</strong>g <strong>and</strong>/or the lubricat<strong>in</strong>g properties of mobile <strong>adsorbed</strong> layers <strong>in</strong>high-speed asperity contacts.