Preventive Maintenance Pyris 1 TGA

Preventive Maintenance Pyris 1 TGA

Preventive Maintenance Pyris 1 TGA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

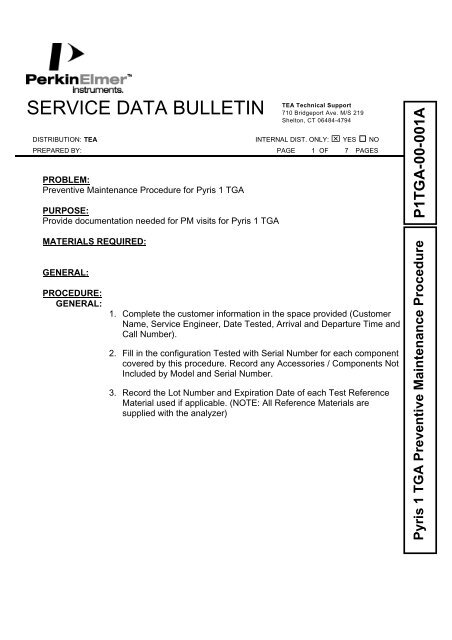

SERVICE DATA BULLETINTEA Technical Support710 Bridgeport Ave. M/S 219Shelton, CT 06484-4794DISTRIBUTION: TEAINTERNAL DIST. ONLY: ⌧ YES NOPREPARED BY: PAGE 1 OF 7 PAGESPROBLEM:<strong>Preventive</strong> <strong>Maintenance</strong> Procedure for <strong>Pyris</strong> 1 <strong>TGA</strong>PURPOSE:Provide documentation needed for PM visits for <strong>Pyris</strong> 1 <strong>TGA</strong>MATERIALS REQUIRED:GENERAL:PROCEDURE:GENERAL:1. Complete the customer information in the space provided (CustomerName, Service Engineer, Date Tested, Arrival and Departure Time andCall Number).2. Fill in the configuration Tested with Serial Number for each componentcovered by this procedure. Record any Accessories / Components NotIncluded by Model and Serial Number.3. Record the Lot Number and Expiration Date of each Test ReferenceMaterial used if applicable. (NOTE: All Reference Materials aresupplied with the analyzer)P1<strong>TGA</strong>-00-001A<strong>Pyris</strong> 1 <strong>TGA</strong> <strong>Preventive</strong> <strong>Maintenance</strong> Procedure

<strong>Preventive</strong> <strong>Maintenance</strong><strong>Pyris</strong> 1 <strong>TGA</strong>Company:Address:ServiceEngineer:Time arrived:Model:Serial Number:Firmwareversion:Softwareversion:Timedeparted:Date:Service ordernumber:Instrument configuration:Accessoriesinstalled:This <strong>Preventive</strong> <strong>Maintenance</strong> is to be performed on the PerkinElmer <strong>Pyris</strong> 1 <strong>TGA</strong>.Successful completion and acceptance of this maintenance confirms that the PerkinElmer<strong>Pyris</strong> 1 <strong>TGA</strong> operates in accordance with its intended usage.

Inspection checklist Yes No CommentAsk customer about unit’sperformance since last visit.Inspect and clean all fans and insuremagnetic sensors work.Clean exterior of the analyzerCheck all cable and gas connectionsCheck the <strong>TGA</strong> is level and adjust ifnecessary. Make sure the sample panis centered and at the correct heightinside the furnace.Check O Rings on balance cover, BallJoint and base of furnace.Clean furnace tube and check balljoint.Remove, inspect, clean and reformplatinum pans and stirrups. If using anA/S check ceramic pans and align ifneeded.Check Anti-Static operationRemove and clean quartz sleeve.Check and record purge gas, purge gasquality and pressure/flow settingsCheck exhaust line purge and flowrate, adjust as neededClean autosampler tray if applicableand exterior of A/SCheck auto-sampler alignments, alignand adjust as needed if applicableCheck incoming power and all powersupplies, record voltage and frequencyCheck units firmware and softwareversions recommend upgrade ifapplicableInspect and clean PC boardsCheck balance for drift and noiseCheck weight calibration using a 100mg Class 0 ASTM weightCheck Sample Temperature using twoCurie Point reference materials.Recalibrate Temperature if necessary.Inspect and clean <strong>TGA</strong> furnaceCheck Sample Temperature using twoCurie Points reference materials.Recalibrate Temperature and furnaceif necessary.

<strong>Preventive</strong> <strong>Maintenance</strong><strong>Pyris</strong> 1 <strong>TGA</strong>Company:Parts used covered under the <strong>Preventive</strong><strong>Maintenance</strong> planParts used not covered under the <strong>Preventive</strong> <strong>Maintenance</strong>planPartNumberDescription Qty PartNumberDescriptionQtyLaborhours:Laborhours:Comments:

<strong>Preventive</strong> <strong>Maintenance</strong><strong>Pyris</strong> 1 <strong>TGA</strong>Company:<strong>Preventive</strong> <strong>Maintenance</strong> Data sheetService Aids Required for Analyzer TestsReference Material Part Number Lot Number- serial numberSample Kit 02190071100 milligram ASTM Class 0Calibration weight09908397Analyzer TestsTest Performed Name Acceptable Range Actual ValueBaseline noise and driftCurie Point MagneticReference materialEnd point onset temperatureGas ChecksComments:ALUMELNICKELPERKALLOYIRONHISAT± 20 micrograms154.2 ± 2.0 °C355.3 ± 2.0 °C596.0 ± 2.0 °C780.0 ± 2.0 °C_____ ± 2.0 °CStandard weight 100 mg 100.0 ± 1%Input PressurePurge Gas Flow RatesBalance PurgeSample PurgeFTIR PurgeFurnace LiftBalance PurgeSample PurgeFTIR int. Purge20-40 psiN/A

<strong>Preventive</strong> <strong>Maintenance</strong>Company:<strong>Pyris</strong> 1 <strong>TGA</strong><strong>Preventive</strong> <strong>Maintenance</strong> Data sheetIncoming Line VoltageReference Voltage Tolerance Actual Value100/115/230 ± 10%Comments:This certifies that the above results and procedures were completed by a PerkinElmer Service EngineerPerkinElmer Service Engineer:Customer Signature:Date:Date: