Manual Unheated - Applications for 1K High Viscosity Products

Manual Unheated - Applications for 1K High Viscosity Products

Manual Unheated - Applications for 1K High Viscosity Products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SALES GUIDEHIGH VISCOSITY PRODUCTSOver The past 50 years Kremlin Rexson havebeen working in the Fluid Handling business,offering a wide range of equipment toindustrial markets globally.TABLE OF CONTENTSAt Kremlin Rexson we pride ourselves on beinga complete supplier of equipment <strong>for</strong> bothSingle and Plural component materials.SUMMARYp1We are committed to Research Developmentand are always looking <strong>for</strong> new ways toimprove our equipment efficiency .Key to our equipment design is ease of use andsimplicity allowing materials to be pumpeddirectly from the pails with minimal wastage yearafter year.In the pages that follow you will findin<strong>for</strong>mation about our product range.For additional in<strong>for</strong>mation, please consult ourwebsite www.kremlin-rexson.com.ORDERING SECTION60.60 Single Post p2-5 (C1)60.60 Mini Twin Post p6-9 (C2)60.60 Double Post p10-13 (C3)34.106 Mini Twin Post p14-17 (C4)34.106 Twin Post p18-21 (C5)63.106 Mini Twin Post p22-25 (C6)63.106 Twin Post p26-29 (C7)32.207 Mini Twin Post p30-33 (C8)32.207 Twin Post p34-37 (C9)53.216 Mini Twin Post p38-41 (C10)53.216 Twin Post p42-45 (C11)82.216 Mini Twin Post p46-49 (C12)82.216 Twin Post p50-53 (C13)OUR EQUIPMENT MAINFEATURES AND BENEFITSp54THINGS TO KNOW ABOUTSELECTINGA ramA follower plateAn optional equipmentp56p57p58PRACTICALINFORMATIONp601GUIDE KREMLIN FR GB DER OK.indd 1 17/05/11 09:49

EXTRUSION UNIT 60.60 SINGLE POST RAM(20-30 LITRES DRUMS)C1COMPLETE PUMP UNITDescriptionSINGLE POST RAM FOR 60.60 PUMPDescriptionFOLLOWER PLATES FOR 60.60 PUMPDescription Type Follower plate Ø (mm) Follower plate Ø (inches) Part numberFollower plate - NitrileCART OPTIONDescriptionFILTER AND REGULATOR OPTIONSDescriptionHOSES AND FITTINGS KITS TO FEED THE GUNDescriptionFlat single sealMANUAL GUN AND ACCESSORIESDescriptionPart numberExtrusion gun 500 bar (equipped) 151.110.600Plastic disposable nozzles (x10) 151.110.290++++++DiameterFluid hose(mm)Length(m)Part number60.60 extrusion pump with PTFE/PE seals ( II2G IIB T3) 151.040.000Part numberSingle post ram with air control ( II2Gc) 151.080.000280 - 285 11 - 11,22 151.100.100305 12 151.100.200Part number4 wheel cart (L=1020mm - W=750mm - H=1100mm) 151.098.060Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987PartnumberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 12 151.260.9823GUIDE KREMLIN FR GB DER OK.indd 3 17/05/11 09:49

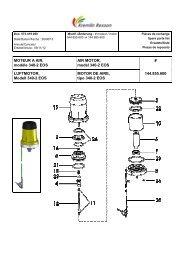

EXTRUSION UNIT 60.60 SINGLE POST RAM(20-30 LITRES DRUMS)3000 AIR MOTOR REPAIR KITDescription60CC FLUID SECTION REPAIR KITDescriptionPart numberAir motor seal kit 146.310.0902 air motor silencer kit 146.310.091Distributor kit 146.310.092Pneumatic kit 146.320.094Safety valve 6,5 bar 903.080.401Part numberStandard seal kit (PTFE + PE) 144.200.090Repair kit 144.200.091Cylinder kit 144.200.092Optional maintenance kit (graphite-fi lled PTFE) 144.200.093Optional maintenance kit (PU + graphite - fi lled PTFE) 144.200.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 280 - 285 mm (11" - 11,2") fl at seal 150.048.301Ø 305 mm (12") fl at seal 150.048.302SINGLE-POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.090.090Base outlet manometer kit 151.080.094Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.0933,8 bar valve kit 903.080.403FILTER MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Total weight : 89 kgREGULATOR MAINTENANCEDescriptionPart numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 500 bar extrusion gun 151.110.6954GUIDE KREMLIN FR GB DER OK.indd 4 17/05/11 09:49

NOTESC15GUIDE KREMLIN FR GB DER OK.indd 5 17/05/11 09:49

EXTRUSION UNIT 60.60MINI TWIN POST RAM(20-60 LITERS DRUMS)The 60.60 pump is specially designed <strong>for</strong> pumping liquid and thicks materials.KREMLIN REXSON equipment can process a wide range of materials includingoils, greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 400.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on20 to 60 liters pails (interior diameter 280 to 360mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator, 4 wheels cart to suit your application.Equipment compliant with ATEX Directive.FEATURESBENEFITSModular designWide range of options available to suitmost applicationsAir motor design enables precise controlDirect pumping from 20-60 liters pailChoice of double seal on follower plateShovel pump technologyPneumatic driven pumpThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsCan be used with a wide range ofmaterialsSafe <strong>for</strong> use with solvents and otherfl ammable materialsMotor air consumption(m 3 /min.) (Cubic feet/min).70.6 (2.00)61.7 (1.75)52.9 (1.50)44.1 (1.25)35.3 (1.00)6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi26.4 (0.75)17.6 (0.50)8.8 (0.25)0 15 30 45 60Pump cycles per minuteSPECIFICATIONSPressure ratio 60/1Motor type 3000Fluid volume per cycle (cc) 60Free flow rate at 60 cycles (L/mn) 3,6Fluid Output at 15 Cycles (l/mn) 0,9Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 30Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 360Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 19FITTINGSFitting Air Inlet F 3/4"G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 80Fluid OutletF 3/4'' G6GUIDE KREMLIN FR GB DER OK.indd 6 17/05/11 09:49

EXTRUSION UNIT 60.60 MINI TWIN POST RAM(20-60 LITERS DRUMS)C1C2COMPLETE PUMP UNITDescriptionMINI TWIN POST RAM FOR 60.60 PUMPDescriptionFOLLOWER PLATES FOR 60.60 PUMPDescriptionFollower plate - NitrileFollower plate PTFE coated- EPDMCART OPTIONDescriptionFILTER AND REGULATOR OPTIONSDescriptionHOSES AND FITTINGS KITS TO FEED THE GUNDescriptionTypeFlat single sealDouble seal 0'ringMANUAL GUN AND ACCESSORIESDescription++++++DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttingsPart number60.60 extrusion pump with PTFE/PE seals ( II2G IIB T3) 151.040.000Part numberMini twin post ram with air control and centering/hold-down clamps <strong>for</strong> 20-60 liters ( II2Gc) 151.080.500Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low-level alarm <strong>for</strong> 20-60 liters 151.098.010Follower plate Ø(mm)Follower plate Ø (inches) Part number280 - 285 11 - 11,22 151.100.100305 12 151.100.200315 12,4 151.100.300360 14,17 151.100.400280 11 151.102.100285 11,22 151.102.200305 12 151.102.300315 12,4 151.102.400360 14,17 151.102.500Part number4 wheel cart (L=1020mm - W=750mm - H=1100mm) 151.098.060Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.9871/2 + 3/8 12 151.260.982Part numberExtrusion gun 500 bar (equipped) 151.110.600Plastic disposable nozzles (x10) 151.110.2907GUIDE KREMLIN FR GB DER OK.indd 7 17/05/11 09:49

EXTRUSION UNIT 60.60 MINI TWIN POST RAM(20-60 LITERS DRUMS)3000 AIR MOTOR REPAIR KITDescription60CC FLUID SECTION REPAIR KITDescriptionPart numberAir motor seal kit 146.310.0902 air motor silencer kit 146.310.091Distributor kit 146.310.092Pneumatic kit 146.320.094Safety valve 6,5 bar 903.080.401Part numberStandard seal kit (PTFE + PE) 144.200.090Repair kit 144.200.091Cylinder kit 144.200.092Optional maintenance kit (graphite-fi lled PTFE) 144.200.093Optional maintenance kit (PU + graphite - fi lled PTFE) 144.200.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 280 - 285 mm (11" - 11,2") fl at seal 150.048.301Ø 305 mm (12") fl at seal 150.048.302Ø 315 mm (12,4") fl at seal 150.048.303Ø 360mm (14.17") fl at seal 150.048.304Ø 280 - 285 mm (11") EPDM seal 150.048.306Ø 305 mm (12") EPDM seal 150.048.307Ø 315 mm (12.4") EPDM seal 150.048.308Ø 360 mm (14.17") EPDM seal 150.048.309MINI TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403FILTER MAINTENANCEDescriptionREGULATOR MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Part numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904Total weight : 87 kgEXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 500 bar extrusion gun 151.110.6958GUIDE KREMLIN FR GB DER OK.indd 8 17/05/11 09:49

NOTESC29GUIDE KREMLIN FR GB DER OK.indd 9 17/05/11 09:49

EXTRUSION UNIT 60.60 TWIN POST RAM(200 LITERS DRUMS)The 60.60 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 400.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on200 liter pails (interior diameter 571 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator to suit your application.Equipment compliant with ATEX Directive.FEATURESBENEFITSModular designWide range of options available to suitmost applicationsAir motor design enables precise controlDirect pumping from 200 lts drumShovel pump technologyChoice of double seal on follower platePneumatic driven pumpThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materialsMotor air consumption(m 3 /min.) (Cubic feet/min).70.6 (2.00)61.7 (1.75)52.9 (1.50)44.1 (1.25)35.3 (1.00)6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi26.4 (0.75)17.6 (0.50)8.8 (0.25)0 15 30 45 60Pump cycles per minuteSPECIFICATIONSPressure ratio 60/1Motor type 3000Fluid volume per cycle (cc) 60Free flow rate at 60 cycles (L/mn) 3,6Fluid Output at 15 Cycles (l/mn) 0,9Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 30Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 360Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 19FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 80Fluid OutletF 3/4'' G10GUIDE KREMLIN FR GB DER OK.indd 10 17/05/11 09:49

EXTRUSION UNIT 60.60 TWIN POST RAM(200 LITERS DRUMS)+C3COMPLETE PUMP UNITDescriptionMINI TWIN POST RAM FOR 60.60 PUMPDescriptionFILTER AND REGULATOR OPTIONSDescriptionHOSES AND FITTINGS KITS TO FEED THE GUNDescriptionMANUAL GUN AND ACCESSORIESDescription++DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttingsPart number60.60 extrusion pump with PTFE/PE seals ( II2G IIB T3) 151.040.000Part numberDouble post ram with air control <strong>for</strong> 200 liters drums and centering/hold-down clamps ( II2Gc) 151.090.500Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low level alarm <strong>for</strong> 200 liters drums 151.098.020Drum roller unit <strong>for</strong> 200 litres drum 151.098.100+FOLLOWER PLATES FOR 60.60 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part numberFollower plate - Nitrile Single fl at seal 571 22,48 151.100.500Follower plate PTFE coated-EPDMDouble seal O'ring 571 22,48 151.102.600Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987++1/2 + 3/8 12 151.260.982Part numberExtrusion gun 500 bar (equipped) 151.110.600Plastic disposable nozzles (x10) 151.110.29011GUIDE KREMLIN FR GB DER OK.indd 11 17/05/11 09:49

NOTESC313GUIDE KREMLIN FR GB DER OK.indd 13 17/05/11 09:50

EXTRUSION UNIT 34.106MINI TWIN POST RAM(20-60 LITERS DRUMS)The 34.106 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 300.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on20 to 60 liter pails (interior diameter 280 to 360 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator, 4 wheel cart to suit your application.Equipment compliant with ATEX Directive.FEATURESBENEFITSModular designWide range of options available to suitmost applicationsAir motor design enables precise controlDirect pumping from 20-60 liters pailShovel pump technologyChoice of double seal on follower platePneumatic driven pumpThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materialsMotor air consumption(m 3 /min.) (Cubic feet/min).70.6 (2.00)61.7 (1.75)52.9 (1.50)44.1 (1.25)35.3 (1.00)6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi26.4 (0.75)17.6 (0.50)8.8 (0.25)0 15 30 45 60Pump cycles per minuteSPECIFICATIONSPressure ratio 34/1Motor type 3000Fluid volume per cycle (cc) 106Free flow rate at 60 cycles (L/mn) 6,3Fluid Output at 15 Cycles (l/mn) 1,6Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 30Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 204Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 21FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 80Fluid OutletF 3/4'' G14GUIDE KREMLIN FR GB DER OK.indd 14 17/05/11 09:50

EXTRUSION UNIT 34.106 MINI TWIN POST RAM(20-60 LITERS DRUMS)+COMPLETE PUMP UNITDescriptionMINI TWIN POST RAM FOR 34.106 PUMPDescriptionFILTER AND REGULATOR OPTIONSDescriptionHOSES AND FITTINGS KITS TO FEED THE GUNDescriptionMANUAL GUN AND ACCESSORIESDescription++DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttingsPart number34.106 PUMP PTFE/PE Seals ( II2G IIB T3) 151.050.000Part numberMini twin post ram with air control and centering/hold-down clamps <strong>for</strong> 20-60 liters ( II2Gc) 151.080.500Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low-level alarm <strong>for</strong> 20-60 liters 151.098.010FOLLOWER PLATES FOR 34.106 PUMPDescriptionFollower plate - NitrileFollower plate PTFE coated- EPDMCART OPTIONDescriptionTypeFlat single sealDouble seal 0'ringFollower plate Ø(mm)Follower plate Ø (inches) Part number280 - 285 11 - 11,22 151.100.100305 12 151.100.200315 12,4 151.100.300360 14,17 151.100.400280 11 151.102.100285 11,22 151.102.200305 12 151.102.300315 12,4 151.102.400360 14,17 151.102.500Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987++Part number4 wheel cart (L=1020mm - W=750mm - H=1100mm) 151.098.0601/2 + 3/8 12 151.260.982Part number250 bar extrusion gun 151.110.200Straight swivel fi tting 105.485Adaptor <strong>for</strong> plastic nozzles 150.103.539Plastic disposable nozzles (x10) 151.110.290++C415GUIDE KREMLIN FR GB DER OK.indd 15 17/05/11 09:50

EXTRUSION UNIT 34.106 MINI TWIN POST RAM(20-60 LITERS DRUMS)3000 AIR MOTOR REPAIR KITDescription60CC FLUID SECTION REPAIRDescriptionPart numberAir motor seal kit 146.310.0902 air motor silencer kit 146.310.091Pneumatic kit 146.320.094Distributor kit 146.310.092Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.210.090Repair kit 144.210.091Cylinder kit 144.210.092Optional maintenance kit (graphite-fi lled PTFE) 144.210.093Optional maintenance kit (PU + graphite-fi lled PTFE) 144.210.094FOLLOWER PLATES REPAIR SEALSDescriptionPart numberØ 280 - 285 mm (11" - 11,2") fl at seal 150.048.301Ø 305 mm (12") fl at seal 150.048.302Ø 315 mm (12,4") fl at seal 150.048.303Ø 360mm (14.17") fl at seal 150.048.304Ø 280 - 285 mm (11") EPDM seal 150.048.306Ø 305 mm (12") EPDM seal 150.048.307Ø 315 mm (12.4") EPDM seal 150.048.308Ø 360 mm (14.17") EPDM seal 150.048.309MINI TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403FILTER MAINTENANCEDescriptionREGULATOR MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Part numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904Total weight : 86 kgEXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 250 bar extrusion gun 151.110.69016GUIDE KREMLIN FR GB DER OK.indd 16 17/05/11 09:50

NOTESC12C417GUIDE KREMLIN FR GB DER OK.indd 17 17/05/11 09:50

EXTRUSION UNIT 34.106 TWIN POST RAM(200 LITERS DRUMS)The 34.106 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 300.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on200 liters pails (interior diameter 571 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator to suit your application.Equipment compliant with ATEX Directive.FEATURESBENEFITSModular designWide range of options available to suitmost applicationsAir motor design enables precise controlDirect pumping from 200 lts drumShovel pump technologyChoice of double seal on follower platePneumatic driven pumpThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materialsMotor air consumption(m 3 /min.) (Cubic feet/min).70.6 (2.00)61.7 (1.75)52.9 (1.50)44.1 (1.25)35.3 (1.00)6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi26.4 (0.75)17.6 (0.50)8.8 (0.25)0 15 30 45 60Pump cycles per minuteSPECIFICATIONSPressure ratio 34/1Motor type 3000Fluid volume per cycle (cc) 106Free flow rate at 60 cycles (L/mn) 6,3Fluid Output at 15 Cycles (l/mn) 1,6Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 30Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 204Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 21FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 80Fluid OutletF 3/4'' G18GUIDE KREMLIN FR GB DER OK.indd 18 17/05/11 09:50

EXTRUSION UNIT 34.106 TWIN POST RAM(200 LITERS DRUMS)+COMPLETE PUMP UNITDescriptionMINI TWIN POST RAM FOR 34.106 PUMPDescriptionFILTER AND REGULATOR OPTIONSDescription+++Part number34.106 PUMP PTFE/PE Seals ( II2G IIB T3) 151.050.000Part numberDouble post ram with air control <strong>for</strong> 200 liters drums and centering/hold-down clamps ( II2Gc) 151.090.500Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low-level alarm <strong>for</strong> 20-60 liters 151.098.010Drum roller unit <strong>for</strong> 200 litres drum 151.098.100FOLLOWER PLATES FOR 34.106 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part numberFollower plate - Nitrile Single fl at seal 571 22,48 151.100.500Follower plate PTFE coated-EPDMDouble seal O'ring 571 22,48 151.102.600Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS TO FEED THE GUNDescriptionDiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings+1/2 + 3/8 12 151.260.982C5MANUAL GUN AND ACCESSORIESDescription+Part number250 bar extrusion gun 151.110.200Straight swivel fi tting 105.485Adaptor <strong>for</strong> plastic nozzles 150.103.539Plastic disposable nozzles (x10) 151.110.29019GUIDE KREMLIN FR GB DER OK.indd 19 17/05/11 09:50

EXTRUSION UNIT 34.106 TWIN POST RAM(200 LITERS DRUMS)3000 AIR MOTOR REPAIR KITDescriptionPart numberAir motor seal kit 146.310.0902 air motor silencer kit 146.310.091Distributor kit 146.310.092Pneumatic kit 146.320.094Safety valve 6,5 bar 903.080.401106CC FLUID SECTION REPAIR KITDescriptionPart numberStandard maintenance kit (PTFE + PE) 144.210.090Repair kit 144.210.091Cylinder kit 144.210.092Optional maintenance kit (graphite-fi lled PTFE) 144.210.093Optional maintenance kit (PU + graphite-fi lled PTFE) 144.210.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 571 mm (22.48") Flat single seal 150.048.305Ø 571 mm (22.48") EPDM seal 150.048.310TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403FILTER MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Total weight : 214 kgREGULATOR MAINTENANCEDescriptionPart numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 250 bar extrusion gun 151.110.69020GUIDE KREMLIN FR GB DER OK.indd 20 17/05/11 09:50

NOTESC521GUIDE KREMLIN FR GB DER OK.indd 21 17/05/11 09:50

EXTRUSION UNIT 63.106MINI TWIN POST RAM(20-60 LITERS DRUMS)The 63.106 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 600.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on20 to 60 liters pails (interior diameter 280 to 360 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator, 4 wheel cart to suit your application.Equipment compliant with ATEX Directive.FEATURESBENEFITSModular designWide range of options available to suitmost applicationsAir motor design enables precise controlDirect pumping from 20-60 liters pailShovel pump technologyChoice of double seal on follower platePneumatic driven pumpThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materialsMotor air consumption(m 3 /min.) (Cubic feet/min).141 (4.0)124 (3.5)106 (3.0)88.3 (2.5)6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi70.6 (2.0)52.9 (1.5)35.3 (1.0)17.6 (0.5)0 10 20 30 40 50 60Pump cycles per minuteSPECIFICATIONSPressure ratio 63/1Motor type 5000Fluid volume per cycle (cc) 106Free flow rate at 60 cycles (L/mn) 6,3Fluid Output at 15 Cycles (l/mn) 1,6Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 66Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 378Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 30FITTINGSFitting Air Inlet F 3/4" G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 80Fluid OutletF 3/4'' G22GUIDE KREMLIN FR GB DER OK.indd 22 17/05/11 09:50

EXTRUSION UNIT 63.106 MINI TWIN POST RAM(20-60 LITERS DRUMS)+COMPLETE PUMP UNITDescriptionMINI TWIN POST RAM FOR 63.106 PUMPDescriptionFILTER AND REGULATOR OPTIONSDescriptionMANUAL GUN AND ACCESSORIESDescription+++Part number63.106 pump with PTFE/PE seals ( II2G IIB T3) 151.050.500Part numberMini twin post ram with air control and centering/hold-down clamps <strong>for</strong> 20-60 liters ( II2Gc) 151.080.500Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low-level alarm <strong>for</strong> 20-60 liters 151.098.010FOLLOWER PLATE REFERENCE FOR 63.106 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part number280 - 285 11 - 11,22 151.100.100Follower plate - Nitrile Flat single seal305 12 151.100.200315 12,4 151.100.300360 14,17 151.100.400Follower plate PTFE coated- EPDMCART OPTIONDescriptionPart numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS KITS TO FEED THE GUNDescriptionDouble seal 0'ring+DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings280 11 151.102.100285 11,22 151.102.200305 12 151.102.300315 12,4 151.102.400360 14,17 151.102.5001/2 + 3/8 12 151.260.982Part numberExtrusion gun 500 bar (equipped) 151.110.600Plastic disposable nozzles (x10) 151.110.290++Part number4 wheel cart (L=1020mm - W=750mm - H=1100mm) 151.098.060C623GUIDE KREMLIN FR GB DER OK.indd 23 17/05/11 09:50

EXTRUSION UNIT 63.106 MINI TWIN POST RAM(20-60 LITERS DRUMS)5000 AIR MOTOR REPAIR KITDescription106 CC FLUID SECTION REPAIR KITDescriptionPart numberSeal motor kit 146.320.090Silencer kit 146.320.091Distributor kit 146.320.092Distributor seal kit 146.320.093Pneumatic kit 146.320.094Piston rod seal kit 146.320.095Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.210.090Repair kit 144.210.091Cylinder kit 144.210.092Optional maintenance kit (graphite-fi lled PTFE) 144.210.093Optional maintenance kit (PU + graphite-fi lled PTFE) 144.210.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 280 - 285 mm (11" - 11,2") fl at seal 150.048.301Ø 305 mm (12") fl at seal 150.048.302Ø 315 mm (12,4") fl at seal 150.048.303Ø 360mm (14.17") fl at seal 150.048.304Ø 280 - 285 mm (11") EPDM seal 150.048.306Ø 305 mm (12") EPDM seal 150.048.307Ø 315 mm (12.4") EPDM seal 150.048.308Ø 360 mm (14.17") EPDM seal 150.048.309MINI TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403Total weight : 98 kgFILTER MAINTENANCEDescriptionREGULATOR MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Part numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 500 bar extrusion gun 151.110.69524GUIDE KREMLIN FR GB DER OK.indd 24 17/05/11 09:50

NOTESC625GUIDE KREMLIN FR GB DER OK.indd 25 17/05/11 09:50

EXTRUSION UNIT 63.106 TWIN POST RAM(200 LITERS DRUMS)The extrusion unit 63.106 is specially designed <strong>for</strong> pumping viscous materials.KREMLIN REXSON equipment can process a wide range of materials includingoils, greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 600.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on200 liter pails (interior diameter 571 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator to suit your application.Equipment compliant with ATEX Directive.FEATURESModular designAir motor design enables precise controlDirect pumping from 200 lts drumShovel pump technologyChoice of double seal on follower platePneumatic driven pumpBENEFITSWide range of options available to suitmost applicationsThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materials141 (4.0)124 (3.5)106 (3.0)88.3 (2.5)70.6 (2.0)52.9 (1.5)35.3 (1.0)17.6 (0.5)Motor air consumption(m 3 /min.) (Cubic feet/min).6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi0 10 20 30 40 50 60Pump cycles per minuteSPECIFICATIONSPressure ratio 63/1Motor type 5000Fluid volume per cycle (cc) 106Free flow rate at 60 cycles (L/mn) 6,3Fluid Output at 15 Cycles (l/mn) 1,6Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 66Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 378Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 30FITTINGSFitting Air Inlet F 3/4"' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 80Fluid OutletF 3/4'' G26GUIDE KREMLIN FR GB DER OK.indd 26 17/05/11 09:50

EXTRUSION UNIT 63.106 TWIN POST RAM(200 LITERS DRUMS)+COMPLETE PUMP UNITDescriptionTWIN POST RAM FOR 64.106 PUMP - PTFE/PE SEALSDescription++Part number63.106 pump with PTFE/PE seals ( II2G IIB T3) 151.050.500Part numberDouble post ram with air control <strong>for</strong> 200 liters drums and centering/hold-down clamps ( II2Gc) 151.090.500Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low level alarm <strong>for</strong> 200 liters drums 151.098.020Drum roller unit <strong>for</strong> 200 litres drum 151.098.100FOLLOWER PLATES FOR 63.106 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part numberFollower plate - Nitrile Single fl at seal 571 22,48 151.100.500Follower plate PTFE coated-EPDMDouble seal O'ring 571 22,48 151.102.600+C7FILTER AND REGULATOR OPTIONSDescriptionMANUAL GUN AND ACCESSORIESDescription+Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS TO FEED THE GUNDescription+DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 12 151.260.982Part numberExtrusion gun 500 bar (equipped) 151.110.600Plastic disposable nozzles (x10) 151.110.29027GUIDE KREMLIN FR GB DER OK.indd 27 17/05/11 09:50

EXTRUSION UNIT 63.106 TWIN POST RAM(200 LITERS DRUMS)5000 AIR MOTOR REPAIR KITDescription106 CC FLUID SECTION REPAIR KITDescriptionPart numberSeal motor kit 146.320.090Silencer kit 146.320.091Distributor kit 146.320.092Distributor seal kit 146.320.093Pneumatic kit 146.320.094Piston rod seal kit 146.320.095Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.210.090Repair kit 144.210.091Cylinder kit 144.210.092Optional maintenance kit (graphite-fi lled PTFE) 144.210.093Optional maintenance kit (PU + graphite-fi lled PTFE) 144.210.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 571 mm (22.48") Flat single seal 150.048.305Ø 571 mm (22.48") EPDM seal 150.048.310TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403FILTER MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Total weight : 226 kgREGULATOR MAINTENANCEDescriptionPart numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 500 bar extrusion gun 151.110.69528GUIDE KREMLIN FR GB DER OK.indd 28 17/05/11 09:50

NOTESC729GUIDE KREMLIN FR GB DER OK.indd 29 17/05/11 09:50

EXTRUSION UNIT 32.207MINI TWIN POST RAM(20-60 LITRES DRUMS)The 32.207 extrusion unit is specially designed <strong>for</strong> pumping viscous materials.KREMLIN REXSON equipment can process a wide range of materials includingoils, greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 300.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on20 to 60 liter pails (interior diameter 280 to 360 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator, 4 wheel cart to suit your application.Equipment compliant with ATEX Directive.FEATURESModular designAir motor design enables precise controlDirect pumping from 20-60 liters pailShovel pump technologyChoice of double seal on follower platePneumatic driven pumpBENEFITSWide range of options available to suitmost applicationsThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materials141 (4.0)124 (3.5)106 (3.0)88.3 (2.5)70.6 (2.0)52.9 (1.5)35.3 (1.0)17.6 (0.5)Motor air consumption(m 3 /min.) (Cubic feet/min).6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi0 10 20 30 40 50 60Pump cycles per minuteSPECIFICATIONSPressure ratio 32/1Motor type 5000Fluid volume per cycle (cc) 207Free flow rate at 60 cycles (L/mn) 12,4Fluid Output at 15 Cycles (l/mn) 3,1Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 66Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 192Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 31,5FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 80Fluid OutletF 3/4'' G30GUIDE KREMLIN FR GB DER OK.indd 30 17/05/11 09:50

EXTRUSION UNIT 32.207 MINI TWIN POST RAM(20-60 LITRES DRUMS)COMPLETE PUMP UNITDescriptionFILTER AND REGULATOR OPTIONSDescriptionMANUAL GUN AND ACCESSORIESDescription+MINI TWIN POST RAM FOR 32.207 PUMP - PTFE/PE SEALSDescription++Part number32.207 extrusion pump with PTFE/PE seals ( II2G IIB T3) 151.060.000Part numberMini twin post ram with air control and centering/hold-down clamps <strong>for</strong> 20-60 liters ( II2Gc) 151.080.500Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low-level alarm <strong>for</strong> 20-60 liters 151.098.010FOLLOWER PLATE REFERENCE FOR 32.207 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part number280 - 285 11 - 11,22 151.100.100Follower plate - Nitrile Flat single seal305 12 151.100.200315 12,4 151.100.300360 14,17 151.100.400Follower plate PTFE coated- EPDMCART OPTIONDescriptionPart numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS KITSDescriptionDouble seal 0'ring+DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings280 11 151.102.100285 11,22 151.102.200305 12 151.102.300315 12,4 151.102.400360 14,17 151.102.5001/2 + 3/8 12 151.260.982Part number250 bar extrusion gun 151.110.200Straight swivel fi tting 105.485Plastic disposable nozzles (x10) 151.110.290Adaptor <strong>for</strong> plastic nozzles 150.103.539++Part number4 wheel cart (L=1020mm - W=750mm - H=1100mm) 151.098.060C831GUIDE KREMLIN FR GB DER OK.indd 31 17/05/11 09:50

EXTRUSION UNIT 32.207 MINI TWIN POST RAM(20-60 LITRES DRUMS)3000 AIR MOTOR REPAIR KITDescription207 CC FLUID SECTION REPAIR KITDescriptionPart numberSeal motor kit 146.320.090Silencer kit 146.320.091Distributor kit 146.320.092Distributor seal kit 146.320.093Pneumatic kit 146.320.094Piston rod seal kit 146.320.095Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.220.090Repair kit 144.220.091Cylinder kit 144.220.092Optional maintenance kit (graphite-fi lled PTFE) 144.220.093Optional maintenance kit (pu + graphite-fi lled PTFE) 144.220.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 280 - 285 mm (11" - 11,2") fl at seal 150.048.301Ø 305 mm (12") fl at seal 150.048.302Ø 315 mm (12,4") fl at seal 150.048.303Ø 360mm (14.17") fl at seal 150.048.304Ø 280 - 285 mm (11") EPDM seal 150.048.306Ø 305 mm (12") EPDM seal 150.048.307Ø 315 mm (12.4") EPDM seal 150.048.308Ø 360 mm (14.17") EPDM seal 150.048.309MINI TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403Total weight : 100 kgFILTER MAINTENANCEDescriptionREGULATOR MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Part numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 250 bar extrusion gun 151.110.69032GUIDE KREMLIN FR GB DER OK.indd 32 17/05/11 09:51

NOTESC833GUIDE KREMLIN FR GB DER OK.indd 33 17/05/11 09:51

EXTRUSION UNIT 32.207TWIN POST RAM(200 LITRES DRUMS)The 32.207 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 300.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on200 liter pails (interior diameter 571 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator to suit your application.Equipment compliant with ATEX Directive.FEATURESModular designAir motor design enables precise controlDirect pumping from 200 lts drumShovel pump technologyChoice of double seal on follower platePneumatic driven pumpBENEFITSWide range of options available to suitmost applicationsThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materials141 (4.0)124 (3.5)106 (3.0)88.3 (2.5)70.6 (2.0)52.9 (1.5)35.3 (1.0)17.6 (0.5)Motor air consumption(m 3 /min.) (Cubic feet/min).6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi0 10 20 30 40 50 60Pump cycles per minuteSPECIFICATIONSPressure ratio 32/1Motor type 5000Fluid volume per cycle (cc) 207Free flow rate at 60 cycles (L/mn) 12,4Fluid Output at 15 Cycles (l/mn) 3,1Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 66Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 192Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 31,5FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 80Fluid OutletF 3/4'' G34GUIDE KREMLIN FR GB DER OK.indd 34 17/05/11 09:51

EXTRUSION UNIT 32.207 TWIN POST RAM(200 LITRES DRUMS)+COMPLETE PUMP UNITDescriptionTWIN POST RAM FOR PUMP 32.207- PTFE/PE SEALSDescriptionFILTER AND REGULATOR OPTIONSDescriptionMANUAL GUN AND ACCESSORIESDescription+++Part number32.207 extrusion pump with PTFE/PE seals ( II2G IIB T3) 151.060.000Part numberDouble post ram with air control <strong>for</strong> 200 liters drums and centering/hold-down clamps ( II2Gc) 151.090.500Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low level alarm <strong>for</strong> 200 liters drums 151.098.020Drum roller unit <strong>for</strong> 200 litres drum 151.098.100FOLLOWER PLATES FOR 32.207 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part numberFollower plate - Nitrile Single fl at seal 571 22,48 151.100.500Follower plate PTFE coated-EPDMDouble seal O'ring 571 22,48 151.102.600Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS KITSDescription+DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings+1/2 + 3/8 12 151.260.982Part number250 bar extrusion gun 151.110.200Straight swivel fi tting 105.485Plastic disposable nozzles (x10) 151.110.290Adaptor <strong>for</strong> plastic nozzles 150.103.539C935GUIDE KREMLIN FR GB DER OK.indd 35 17/05/11 09:51

EXTRUSION UNIT 32.207 TWIN POST RAM(200 LITRES DRUMS)5000 AIR MOTOR REPAIR KITDescription207 CC FLUID SECTION REPAIR KITDescriptionPart numberSeal motor kit 146.320.090Silencer kit 146.320.091Distributor kit 146.320.092Distributor seal kit 146.320.093Pneumatic kit 146.320.094Piston rod seal kit 146.320.095Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.220.090Repair kit 144.220.091Cylinder kit 144.220.092Optional maintenance kit (graphite-fi lled PTFE) 144.220.093Optional maintenance kit (pu + graphite-fi lled PTFE) 144.220.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 280 - 285 mm (11" - 11,2") fl at seal 150.048.301Ø 305 mm (12") fl at seal 150.048.302DOUBLE POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403FILTER MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Total weight : 227 kgREGULATOR MAINTENANCEDescriptionPart numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 250 bar extrusion gun 151.110.69036GUIDE KREMLIN FR GB DER OK.indd 36 17/05/11 09:51

NOTESC937GUIDE KREMLIN FR GB DER OK.indd 37 17/05/11 09:51

EXTRUSION UNIT 53.216MINI TWIN POST RAM(20-60 LITRES DRUMS)The 53.216 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 500.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on20 to 60 liter pails (interior diameter 360 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator, to suit your application.Equipment compliant with ATEX Directive.FEATURESModular designAir motor design enables precise controlDirect pumping from 20-60 liters pailShovel pump technologyChoice of double seal on follower platePneumatic driven pumpBENEFITSWide range of options available to suitmost applicationsThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materials141 (4.0)124 (3.5)106 (3.0)88.3 (2.5)70.6 (2.0)52.9 (1.5)35.3 (1.0)17.6 (0.5)Motor air consumption(m 3 /min.) (Cubic feet/min).6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi0 10 20 30 40 50 60Pump cycles per minuteSPECIFICATIONSPressure ratio 53/1Motor type 7000Fluid volume per cycle (cc) 216Free flow rate at 60 cycles (L/mn) 12,9Fluid Output at 15 Cycles (l/mn) 3,3Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 102Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 318Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 51FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 105Fluid OutletF 1'' G38GUIDE KREMLIN FR GB DER OK.indd 38 17/05/11 09:51

EXTRUSION UNIT 53.216 MINI TWIN POST RAM(20-60 LITRES DRUMS)+COMPLETE PUMP UNITDescriptionFILTER AND REGULATOR OPTIONSDescriptionMANUAL GUN AND ACCESSORIESDescription+MINI TWIN POST RAM FOR 53.216 PUMP - PTFE/PE SEALSDescription++Part number53.216 extrusion pump with PTFE seals ( II2G IIB T3) 151.070.000Part numberMini twin post ram with air control and centering/hold-down clamps <strong>for</strong> 20-60 liters ( II2Gc) 151.080.500Option : Runaway valve - to be fi tted on the air inlet (3/4" NPT) 151.098.070Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low-level alarm <strong>for</strong> 20-60 liters 151.098.010FOLLOWER PLATE REFERENCE FOR 53.216 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part number280 - 285 11 - 11,22 151.100.100Follower plate - Nitrile Flat single seal305 12 151.100.200315 12,4 151.100.300360 14,17 151.100.400Follower plate PTFE coated- EPDMPart numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS KITSDescriptionDouble seal 0'ring+DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings280 11 151.102.100285 11,22 151.102.200305 12 151.102.300315 12,4 151.102.400360 14,17 151.102.5001/2 + 3/8 12 151.260.982Part number250 bar extrusion gun 151.110.200Straight swivel fi tting 105.485Plastic disposable nozzles (x10) 151.110.290Adaptor <strong>for</strong> plastic nozzles 150.103.539+C1039GUIDE KREMLIN FR GB DER OK.indd 39 17/05/11 09:51

EXTRUSION UNIT 53.216 MINI TWIN POST RAM(20-60 LITRES DRUMS)7000 AIR MOTOR REPAIR KITDescription207 CC FLUID SECTION REPAIR KITDescriptionPart numberSeal Motor kit 146.330.090Silencer kit 146.320.091Distributor kit 146.320.092Distributor seal kit 146.320.093Pneumatic kit 146.320.094Piston rod seal kit 146.320.095Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.230.090Repair kit 144.230.091Cylinder kit 144.230.092Optional maintenance kit (graphite-fi lled PTFE) 144.230.093Optional maintenance kit (pu + graphite-fi lled PTFE) 144.230.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 280 - 285 mm (11" - 11,2") fl at seal 150.048.301Ø 305 mm (12") fl at seal 150.048.302Ø 315 mm (12,4") fl at seal 150.048.303Ø 360mm (14.17") fl at seal 150.048.304Ø 280 - 285 mm (11") EPDM seal 150.048.306Ø 305 mm (12") EPDM seal 150.048.307Ø 315 mm (12.4") EPDM seal 150.048.308Ø 360 mm (14.17") EPDM seal 150.048.309MINI TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403Total weight : 119 kgFILTER MAINTENANCEDescriptionREGULATOR MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Part numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 250 bar extrusion gun 151.110.69040GUIDE KREMLIN FR GB DER OK.indd 40 17/05/11 09:51

NOTESC1041GUIDE KREMLIN FR GB DER OK.indd 41 17/05/11 09:51

EXTRUSION UNIT 53.216TWIN POST RAM(200 LITRES DRUMS)The 53.216 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 500.000 centipoises depending on specifi cation.The system pumps directly from the original material container and is used on200 liter drums (interior diameter 571 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator to suit your application.Equipment compliant with ATEX Directive.FEATURESModular designAir motor design enables precise controlDirect pumping from 200 lts drumShovel pump technologyChoice of double seal on follower platePneumatic driven pumpBENEFITSWide range of options available to suitmost applicationsThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materials141 (4.0)124 (3.5)106 (3.0)88.3 (2.5)70.6 (2.0)52.9 (1.5)35.3 (1.0)17.6 (0.5)Motor air consumption(m 3 /min.) (Cubic feet/min).6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi0 10 20 30 40 50 60Pump cycles per minuteSPECIFICATIONSPressure ratio 53/1Motor type 7000Fluid volume per cycle (cc) 216Free flow rate at 60 cycles (L/mn) 12,9Fluid Output at 15 Cycles (l/mn) 3,3Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 102Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 318Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 51FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 105Fluid OutletF 1'' G42GUIDE KREMLIN FR GB DER OK.indd 42 17/05/11 09:51

EXTRUSION UNIT 53.216 TWIN POST RAM(200 LITRES DRUMS)+COMPLETE PUMP UNITDescriptionTWIN POST RAM FOR 53.216 PUMP - PTFE/PE SEALSDescriptionFILTER AND REGULATOR OPTIONSDescriptionMANUAL GUN AND ACCESSORIESDescription+++Part number53.216 extrusion pump with PTFE seals ( II2G IIB T3) 151.070.000Part numberDouble post ram with air control <strong>for</strong> 200 liters drums and centering/hold-down clamps ( II2Gc) 151.090.500Option : Runaway valve - to be fi tted on the air inlet (3/4" NPT) 151.098.070Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low level alarm <strong>for</strong> 200 liters drums 151.098.020Drum roller unit <strong>for</strong> 200 litres drum 151.098.100FOLLOWER PLATES FOR 53.216 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part numberFollower plate - Nitrile Single fl at seal 571 22,48 151.100.500Follower plate PTFE coatedDouble seal O'ring- EPDM571 22,48 151.102.600Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS KITSDescription+DiameterFluid hose(")Length(m)Part numberØ 3/8" PTFE hose 3/4" JIC fi tting, lg 5m with all required fi ttings 3/8 5 151.260.980Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 7 151.260.981Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 7 151.260.983Ø 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings3/4 + 3/8 12 151.260.984Ø 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttings1/2 + 3/8 12 151.260.982Part number250 bar extrusion gun 151.110.200Straight swivel fi tting 105.485Plastic disposable nozzles (x10) 151.110.290Adaptor <strong>for</strong> plastic nozzles 150.103.539+C1143GUIDE KREMLIN FR GB DER OK.indd 43 17/05/11 09:51

EXTRUSION UNIT 53.216 TWIN POST RAM(200 LITRES DRUMS)7000 AIR MOTOR REPAIR KITDescription216 CC FLUID SECTION REPAIR KITDescriptionPart numberSeal Motor kit 146.330.090Silencer kit 146.320.091Distributor kit 146.320.092Distributor seal kit 146.320.093Pneumatic kit 146.320.094Piston rod seal kit 146.320.095Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.230.090Repair kit 144.230.091Cylinder kit 144.230.092Optional maintenance kit (graphite-fi lled PTFE) 144.230.093Optional maintenance kit (pu + graphite-fi lled PTFE) 144.230.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 571 mm (22.48") Flat single seal 150.048.305Ø 571 mm (22.48") EPDM seal 150.048.310TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403FILTER MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Total weight : 247 kgREGULATOR MAINTENANCEDescriptionPart numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 250 bar extrusion gun 151.110.69044GUIDE KREMLIN FR GB DER OK.indd 44 17/05/11 09:51

NOTESC11C345GUIDE KREMLIN FR GB DER OK.indd 45 17/05/11 09:51

EXTRUSION UNIT 82.216MINI TWIN POST RAM(20-60 LITERS DRUM)The 82.216 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 1 million centipoises depending on specifi cation.The system pumps directly from the original material container and is used on20 to 60 liter pails (interior diameter 280 to 360 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulato to suit your application.Equipment compliant with ATEX Directive.FEATURESModular designAir motor design enables precise controlDirect pumping from 20-60 liters pailShovel pump technologyChoice of double seal on follower platePneumatic driven pumpBENEFITSWide range of options available to suitmost applicationsThe unique air motor design ensures aconstant controllled fl ow rate with lownoise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materialsMotor air consumption(m 3 /min.) (Cubic feet/min).141 (4.0)124 (3.5)106 (3.0)88.3 (2.5)70.6 (2.0)52.9 (1.5)35.3 (1.0)17.6 (0.5)6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi0 10 20 30 40 50 60Pump cycles per minuteSPECIFICATIONSPressure ratio 82/1Motor type 9000Fluid volume per cycle (cc) 216Free flow rate at 60 cycles (L/mn) 12,9Fluid Output at 15 Cycles (l/mn) 3,3Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 102Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 492Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 62FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 105Fluid OutletF 1'' G46GUIDE KREMLIN FR GB DER OK.indd 46 17/05/11 09:51

EXTRUSION UNIT 82.216 MINI TWIN POST RAM(20-60 LITERS DRUM)+COMPLETE PUMP UNITDescriptionFILTER AND REGULATOR OPTIONSDescriptionMANUAL GUN AND ACCESSORIESDescription+MINI TWIN POST RAM FOR 82.216 PUMP - PTFE/PE SEALSDescription++Part number82.216 extrusion pump with PTFE/PE seals ( II2G IIB T3) 151.070.500Part numberMini twin post ram with air control and centering/hold-down clamps <strong>for</strong> 20-60 liters ( II2Gc) 151.080.500Option : Runaway valve - to be fi tted on the air inlet (3/4" NPT) 151.098.070Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low-level alarm <strong>for</strong> 20-60 liters 151.098.010FOLLOWER PLATE FOR 82.216 PUMPDescriptionFollower plate - NitrileFollower plate PTFE coated- EPDMPart numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS KITSDescriptionTypeFlat single sealDouble seal 0'ringØ 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttingsØ 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttingsØ 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttingsØ 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttingsFollower plate Ø(mm)Follower plate Ø (inches) Part number280 - 285 11 - 11,22 151.100.100305 12 151.100.200315 12,4 151.100.300360 14,17 151.100.400280 11 151.102.100285 11,22 151.102.200305 12 151.102.300315 12,4 151.102.400360 14,17 151.102.500+DiameterFluid hose(")Length(m)Part number1/2 + 3/8 7 151.260.9813/4 + 3/8 7 151.260.9831/2 + 3/8 12 151.260.9823/4 + 3/8 12 151.260.984Part numberExtrusion gun 500 bar (equipped) 151.110.600Plastic disposable nozzles (x10) 151.110.290+C1247GUIDE KREMLIN FR GB DER OK.indd 47 17/05/11 09:51

EXTRUSION UNIT 82.216 MINI TWIN POST RAM(20-60 LITERS DRUM)9000 AIR MOTOR KITDescription216 CC FLUID SECTION REPAIR KITDescriptionPart numberAir motor seal kit 146.340.090Silencer kit 146.320.091Distributor kit 146.320.092Distributor seal kit 146.320.093Pneumatic kit 146.320.094Piston rod seal kit 146.320.095Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.230.090Repair kit 144.230.091Cylinder kit 144.230.092Optional maintenance kit (graphite-fi lled PTFE) 144.230.093Optional maintenance kit (pu + graphite-fi lled PTFE) 144.230.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 280 - 285 mm (11" - 11,2") fl at seal 150.048.301Ø 305 mm (12") fl at seal 150.048.302Ø 315 mm (12,4") fl at seal 150.048.303Ø 360mm (14.17") fl at seal 150.048.304Ø 280 - 285 mm (11") EPDM seal 150.048.306Ø 305 mm (12") EPDM seal 150.048.307Ø 315 mm (12.4") EPDM seal 150.048.308Ø 360 mm (14.17") EPDM seal 150.048.309MINI TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403Total weight : 130 kgFILTER MAINTENANCEDescriptionREGULATOR MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Part numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 500 bar extrusion gun 151.110.69548GUIDE KREMLIN FR GB DER OK.indd 48 17/05/11 09:51

NOTESC1249GUIDE KREMLIN FR GB DER OK.indd 49 17/05/11 09:52

EXTRUSION UNIT 82.216TWIN POST RAM(200 LITERS DRUM)The 82.216 pump is specially designed <strong>for</strong> pumping viscous materials. KREMLINREXSON equipment can process a wide range of materials including oils,greases, adhesives and sealants.This equipment has proved itself over the years to be strong and reliable andcan process products up to 1 million centipoises depending on specifi cation.The system pumps directly from the original material container and is used on200 liter pails (interior diameter 571 mm).The modular conception allows you to select an extrusion system comprisingof a pump, elevator, follower plate, gun and hoses + optional extras includingfi lter, regulator to suit your application.Equipment compliant with ATEX Directive.FEATURESModular designAir motor design enables precise controlDirect pumping from 200 lts drumShovel pump technologyChoice of double seal on follower platePneumatic driven pumpBENEFITSWide range of options available to suitmost applicationsThe unique air motor designensures a constant controllled fl ow ratewith low noise and minimum icing riskClean wipe of the material drum savingmaterialsCan be used with a wide range ofmaterialsRecommended <strong>for</strong> high viscosity andmoisture-sensitive materialsSafe <strong>for</strong> use with solvents and otherfl ammable materials141 (4.0)124 (3.5)106 (3.0)88.3 (2.5)70.6 (2.0)52.9 (1.5)35.3 (1.0)17.6 (0.5)Motor air consumption(m 3 /min.) (Cubic feet/min).6 bar - 87 psi4 bar - 58 psi2 bar - 29 psi0 10 20 30 40 50 60Pump cycles per minuteSPECIFICATIONSPressure ratio 82/1Motor type 9000Fluid volume per cycle (cc) 216Free flow rate at 60 cycles (L/mn) 12,9Fluid Output at 15 Cycles (l/mn) 3,3Air consumption (m 3 /h) at 30 cycles/mn at 4 bar 102Maximum air inlet pressure (bar) 6Maximum fluid pressure (bar) 492Maximum Fluid Temperature (°C) 60Seal packingsPTFE + PEWetted partsCarbon steelWeight (kg) - bare pump 62FITTINGSFitting Air Inlet F 3/4'' G (1)(1) Recommended air supply hose diameter 1/2"Fluid Inlet Ø 105Fluid OutletF 1'' G50GUIDE KREMLIN FR GB DER OK.indd 50 17/05/11 09:52

EXTRUSION UNIT 82.216 TWIN POST RAM(200 LITERS DRUM)+COMPLETE PUMP UNITDescriptionTWIN POST RAM FOR 82.216 PUMP - PTFE/PE SEALSDescriptionFILTER AND REGULATOR OPTIONSDescriptionMANUAL GUN AND ACCESSORIESDescription+++Part number82.216 extrusion pump with PTFE/PE seals ( II2G IIB T3) 151.070.500Part numberDouble post ram with air control <strong>for</strong> 200 liters drums and centering/hold-down clamps ( II2Gc) 151.090.500Option : Runaway valve - to be fi tted on the air inlet (3/4" NPT) 151.098.070Option : Pneumatic two-hand safety control 151.098.050Option : Pneumatic low level alarm <strong>for</strong> 200 liters drums 151.098.020Drum roller unit <strong>for</strong> 200 litres drum 151.098.100FOLLOWER PLATES FOR 82.216 PUMPDescriptionTypeFollower plate Ø(mm)Follower plate Ø (inches) Part numberFollower plate - Nitrile Single fl at seal 571 22,48 151.100.500Follower plate PTFE coated-EPDMDouble seal O'ring 571 22,48 151.102.600Part numberOption A : Regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.985Option B : Filter with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.986Option C : Filter and regulator with fi tting and mounting accessories (plate, fi ttings, hose...) 151.260.987HOSES AND FITTINGS KITSDescriptionØ 1/2" PTFE hose 7/8" JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttingsØ 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 5m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttingsØ 1/2" PTFE hose 7/8" JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg 2mwith all required fi ttingsØ 3/4" PTFE hose 1" 1/16 JIC fi tting, lg 10m and PTFE Ø 3/8" whip end 3/4" JIC fi tting, lg2m with all required fi ttings+DiameterFluid hose(")Length(m)Part number1/2 + 3/8 7 151.260.9813/4 + 3/8 7 151.260.9831/2 + 3/8 12 151.260.9823/4 + 3/8 12 151.260.984Part numberExtrusion gun 500 bar (equipped) 151.110.600Plastic disposable nozzles (x10) 151.110.290+C1351GUIDE KREMLIN FR GB DER OK.indd 51 17/05/11 09:52

EXTRUSION UNIT 82.216 TWIN POST RAM (200LITERS DRUM)9000 AIR MOTOR REPAIR KITDescription216 CC FLUID SECTION REPAIR KITDescriptionPart numberAir motor seal kit 146.340.090Silencer kit 146.320.091Distributor kit 146.320.092Distributor seal kit 146.320.093Pneumatic kit 146.320.094Piston rod seal kit 146.320.095Safety valve 6,5 bar 903.080.401Part numberStandard maintenance kit (PTFE + PE) 144.230.090Repair kit 144.230.091Cylinder kit 144.230.092Optional maintenance kit (graphite-fi lled PTFE) 144.230.093Optional maintenance kit (pu + graphite-fi lled PTFE) 144.230.094FOLLOWER PLATE REPAIR SEALSDescriptionPart numberØ 571 mm (22.48") Flat single seal 150.048.305Ø 571 mm (22.48") EPDM seal 150.048.310TWIN POST RAM ELEVATOR MAINTENANCE KITDescriptionPart numberSeal kit 151.080.090Manometer outlet back kit 151.080.091Command button kit 151.080.092Pushbutton kit 151.080.093Base outlet manometer kit 151.080.0943,8 bar valve kit 903.080.403FILTER MAINTENANCEDescriptionPart numberFKM (Viton) O'ring seal 80.032Cartridge fi lter (25 mesh - 710 μ) 601.084Cartridge fi lter (50 mesh - 350 μ) 601.092Cartridge fi lter (80 mesh - 201 μ) 601.287Total weight : 258 kgREGULATOR MAINTENANCEDescriptionPart numberRepair Kit 8 mm 155.750.9018mm Cartridge 155.750.904EXTRUSION GUN REPAIR KITDescriptionPart numberRepair kit <strong>for</strong> 500 bar extrusion gun 151.110.69552GUIDE KREMLIN FR GB DER OK.indd 52 17/05/11 09:52

NOTESC1353GUIDE KREMLIN FR GB DER OK.indd 53 17/05/11 09:52

MAIN FEATURES AND BENEFITS FOR THOR AIRMOTOR: THE POWER HOUSEKremlin Rexson manufactures a full range of motors to ensure optimised air fluid ratios. It is importantto be sure you always have sufficient material pressure to move the material being processed to thedispensing valve. The restriction to your flow is called Back Pressure and is due to material viscosityor hose size.Hence the power of the motor/ pump combination, is key to your successS1 (AIR MOTOR PISTON SURFACE AREA)S2 (PUMP PISTON SURFACE AREA)= PUMP PRESSURE RATIOThis pump pressure ratio determines the maximum possible PUMP MATERIAL OUTLET PRESSURE.PUMP PRESSURE RATIO x inbound driving air pressure (max. 6 bar) = STALLED FLUIDOUTLET PRESSUREExample: Pump 63.106 = 63 (ratio) x 6 (air pressure) = 378 barThe unique design of the Kremlin Rexson air motor is based on many years of developmentThis has resulted in a simple reliable design. All THOR air motors are built using the same features.MAIN ADVANTAGES OF A THOR AIR MOTOR DESIGN• Very quiet running• Thru shaft air motor giving perfectsupport to the piston shaft• Balanced volumes on the top andbottom of the air cylinder givingequal thrust• Large diameter exhaust port minimisingicing risksAir supplyTHE SIMPLICITY OF THE THOR AIR MOTORAir reversingvalveUppersensorLowersensor• Existing pneumatic connectionsmaking remote stop start easy tofit• Air supply to reversing valveseither regulated or full air pressureLarge airexhaust• Externally fitted air reversing valvesFluid pump54GUIDE KREMLIN FR GB DER OK.indd 54 17/05/11 09:52

MAIN FEATURES AND BENEFITS FOR CHOPCHECK PUMP: THE HEART OF THE SYSTEMKremlin Rexson Manufactures a full range of extrusionpumps to handle most high viscosity products.These pumps are double acting reciprocatingpumps and are recommended <strong>for</strong> useon materials over 5000cps or <strong>for</strong> use on productsthat do not self level.Key features• Low shear when the material beinghandled, resulting in minimal materialdegradation during processing• Large internal fluid passage waysoptimising material flow• Pumps designed with as few parts aspossible to give simplicity in construction• Pump designed and manufactured <strong>for</strong>severe duty applications• Pump fitted with Pe – Ptfe seals asstandard with Ptfe G and PU sealkits available as an optionEfficiencyAll Kremlin Rexson pneumatic pumps are able tostop when the dispensing valve is closed. This iscalled 'stalling'. As soon as the dispensing valve isreopened, the pump will automatically restart.DOUBLE-ACTING RECIPROCATING PUMPPneumatic Air MotorPISTONDOWNSTROKE…Check valve (green)closed against the seatand the material in chamberV2 is displaced out ofthe pump by the pumpdisplacement rod.PISTON UPSTROKE…Check valve (green)opens and material is<strong>for</strong>ced into chamberV2 by the primingpiston. The top check(red) closes andmaterial is pulled fromchamber V1.• Modular pump design usingthe minimum number ofcomponents• Hard chrome fi nish to pumpshatf and cylinder• New type guard (with integratedlarge diameter wetcup) compliant to EU norms• Simple design using externalreversing valves• Very fast changeover• Large diameter exhaustmaking <strong>for</strong> quiet runningand minimum icing riskVolume V3 > Volume V2Volume V2Volume V1 =255GUIDE KREMLIN FR GB DER OK.indd 55 17/05/11 09:52