Pilestredet Park - Statsbygg

Pilestredet Park - Statsbygg

Pilestredet Park - Statsbygg

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

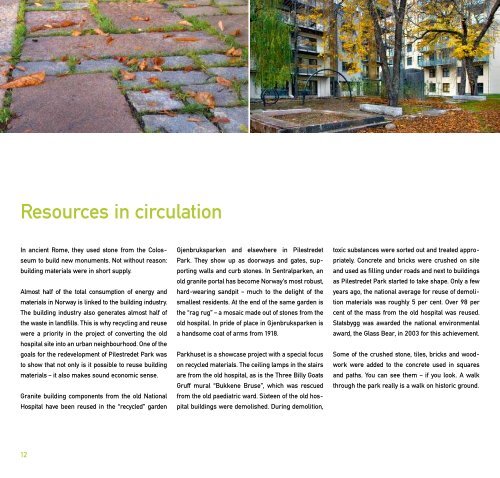

In Sentralparken, an old graniteportal has been turned into achildren’s sandpit.We built up new competenciesMarius Nygaard is an architect at ArkitektkontoretGASA. He was environmental coordinator for OBOS’sand Skanska’s projects (a total of 625 apartments).Resources in circulationIn ancient Rome, they used stone from the Colosseumto build new monuments. Not without reason:building materials were in short supply.Almost half of the total consumption of energy andmaterials in Norway is linked to the building industry.The building industry also generates almost half ofthe waste in landfills. This is why recycling and reusewere a priority in the project of converting the oldhospital site into an urban neighbourhood. One of thegoals for the redevelopment of <strong>Pilestredet</strong> <strong>Park</strong> wasto show that not only is it possible to reuse buildingmaterials – it also makes sound economic sense.Granite building components from the old NationalHospital have been reused in the “recycled” gardenGjenbruksparken and elsewhere in <strong>Pilestredet</strong><strong>Park</strong>. They show up as doorways and gates, supportingwalls and curb stones. In Sentralparken, anold granite portal has become Norway’s most robust,hard-wearing sandpit – much to the delight of thesmallest residents. At the end of the same garden isthe “rag rug” – a mosaic made out of stones from theold hospital. In pride of place in Gjenbruksparken isa handsome coat of arms from 1918.<strong>Park</strong>huset is a showcase project with a special focuson recycled materials. The ceiling lamps in the stairsare from the old hospital, as is the Three Billy GoatsGruff mural “Bukkene Bruse”, which was rescuedfrom the old paediatric ward. Sixteen of the old hospitalbuildings were demolished. During demolition,toxic substances were sorted out and treated appropriately.Concrete and bricks were crushed on siteand used as filling under roads and next to buildingsas <strong>Pilestredet</strong> <strong>Park</strong> started to take shape. Only a fewyears ago, the national average for reuse of demolitionmaterials was roughly 5 per cent. Over 98 percent of the mass from the old hospital was reused.<strong>Statsbygg</strong> was awarded the national environmentalaward, the Glass Bear, in 2003 for this achievement.Some of the crushed stone, tiles, bricks and woodworkwere added to the concrete used in squaresand paths. You can see them – if you look. A walkthrough the park really is a walk on historic ground.Concrete and bricks werecrushed on site and reused.The mural of the ThreeBilly Goats Gruff “BukkeneBruse” from the oldpaediatric ward has beengiven a new lease of life in<strong>Park</strong>huset.Concrete paving made ofrecycled materials.Photo: Halvor BjørngårdPhoto: Halvor BjørngårdPhoto: Halvor BjørngårdNygaard recalls how the requirements concerningreusing materials led to development of new methodsand new products. “All the toxic substanceswere removed from the old buildings, and the buildingmaterials were sorted and stored for reuse. Allthe materials and products were checked for toxicity andtheir environmental properties. Tests have shownthat this has ensured a good indoor climate. A newtype of concrete element made of recycled materialswas developed,” says Nygaard.“Everyone who worked on <strong>Pilestredet</strong> <strong>Park</strong> has hadto develop new competencies. These competencieshave benefitted individuals, companies and the buildingindustry in general,” he continues. “Together theyhave shown that ambitious environmental goals canbe met in large projects with normal requirementsconcerning progress and profits,” says Nygaard.The demolition process• The demolition mass came to 98,000 tonnes.• Toxic and hazardous substances were removedand delivered for appropriate disposal.Crushing and reuse• Concrete and bricks were crushed on site for reuse.• Dust pollution was reduced by spraying with water.• Noise was reduced by covering the crushingplant and only working at times of day that wouldnot disturb the neighbours unnecessarily.• The streets of Oslo were spared from 2300 lorry loads.• 82,500 tonnes of concrete and bricks were reused.12 13