Wenzel exaCT XS - Exact Metrology

Wenzel exaCT XS - Exact Metrology

Wenzel exaCT XS - Exact Metrology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Operating concept and fields of application of the <strong>exaCT</strong> ® <strong>XS</strong>Beautifully simple and well conceivedAbove all, the performance and the userfriendliness of the integrated applicationsoftware ensure that the full extent ofthe innovative device concept of the<strong>exaCT</strong> ®<strong>XS</strong> is brought to bear. The<strong>exaCT</strong> ®control data acquisition softwarefor optimised control of the computertomograph and the <strong>exaCT</strong> ®Volumereconstruction software for precisecalculation of the volume data wasdeveloped by WENZEL Volumetrik. Theevaluation software of the <strong>exaCT</strong> ®<strong>XS</strong> has adirect link to the proven software productsof Metrosoft QUARTIS from WENZELMetromec and PointMaster from WENZELKnotenpunkt. The applications for the<strong>exaCT</strong> ®<strong>XS</strong> are measurement and testingtechnology where 3D data of complex innerstructures are required. Based on a singlemeasurement comprehensive evaluationsare possible e.g. material analysis,dimensional measurements, nominal-toactualcomparisons with CAD data, reverseengineering and tool optimizations.CT control and reconstructionYou don‘t need to be a computed tomography specialist to operate the <strong>exaCT</strong> ®<strong>XS</strong>. Intuitive user guidance allows excellent measurementsto be generated after a short training period. The <strong>exaCT</strong> ®<strong>XS</strong> thinks too: Measurement parameters are automatically optimised by the system.Specially developed for industrial use, the CT control unit and reconstruction software ensure high precision and high quality results.In contrast to other manufacturers, the entire image processing chain and 3D reconstruction are carried out with our own software. Thisallows the components to be optimised and finely matched to one another, thus achieving the high quality standards.Dimensional measurementThe decades of experience gained by WENZEL Metromec in 3-dimensional coordinate measurement technology is underlined in the keyadvantages that the Metrosoft QUARTIS measurement software also offers its users in the field of computed tomography:• Non-destructive and non contact metrological evaluation of all contours and surfaces of a component as well as the internalstructures of workpieces• Clear, flexible and results-oriented user interface with proven construction and alignment functions• Full functionality for evaluation of shape, position and dimension with simple display of the measurements in meaningfulmeasurement reports• Intuitive measurement programming for the automation of measurement sequencesNominal-to-actual comparison and reverse engineeringThe PointMaster software from WENZEL Knotenpunkt is one of the world’s best surface generation tools which can be used to generateand process exact free-form surfaces from CT data. PointMaster also fulfils important functions for CT evaluations:• Can be used for reverse engineering• Nominal-to-actual comparisons against 3D CAD models, display using colour rendering• Innovative functions for iterative compensation of material shrinkage in injection and casting mouldsProduct advantagesThe excellent price-performance ratio of<strong>exaCT</strong> ®<strong>XS</strong> makes computed tomographyaffordable even for small companies. Thetechnical advantages are numerous. Thestable and maintenance-free X-ray sourcein combination with the industrial detectorfrom own production and the highprecisionrotary table provide an excellentbasis for metrological applications.The type-approval certificate underGerman law eliminates the authorizationprocess in Germany. This ensures both thequick startup and the flexible modificationof the installation site. You only needspace on the desk and an electrical outletfor operation. The data is exchanged via afast network connection.Safety includedThe new <strong>exaCT</strong> ®<strong>XS</strong> has a type-approvalcertificate under German law. The fullyprotected device based on the strict legalrequirements of the German X-ray Directiveand DIN 54113.Its use is non-hazardous for the operator.There is also no danger from componentsthat have been exposed to X-ray.

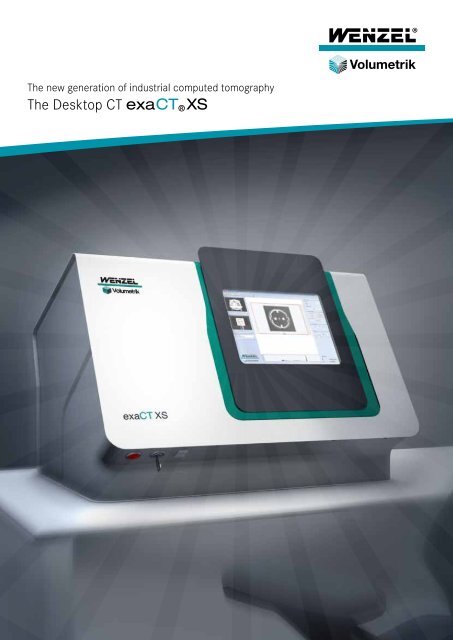

Simply <strong>exaCT</strong>Computed tomography on the deskThe highly compact desktop CT <strong>exaCT</strong> ®<strong>XS</strong>is the ideal solution for the volumemeasurement of small plastic parts andcomponents with low density. Thanksto its optimized dimensions and lowweight, it can be placed on desktopsor portable trolleys easily. The device iscontrolled by a modern touch-screenmonitor. The innovative and user-friendlyoperating concept allows to setup ameasurement within a few minutes.All components of the <strong>exaCT</strong> ®<strong>XS</strong> areintegrated in one unit. This ensures a verysmall footprint.TECHNICAL DATAWORK Piece diMenSiOnS:Mechanics:Maximum scan diameterMaximum scan height(depending on the component diameter)X-ray source:Maximum accelerationvoltagePHYSICAL DIMENSIONS:75 mm45 mm80 kVTurntable bearingsPosition measuringsystemsCalibration andmonitoringRadiation protectionSetupHigh-precision roller bearingHigh-resolution precisionmeasuring systemsCalibration and test artifact acc. toVDI/VDE 2630 (draft)Full radiation protection chamber,type-approval certificate underGerman lawTable top installationLength x Width x Height600 mm x 520 mm x 430 mm

<strong>exaCT</strong> ® Volume scanning technologyOne measurement – multiple evaluationsThe strengths of the <strong>exaCT</strong> ®<strong>XS</strong> arerevealed in the specific application.The possible applications are, however,too numerous to mention them all. Forthis reason we have shown examplesof specific applications here to makeour advantages clear. As with the<strong>exaCT</strong> ®volume scanning technology,both material and geometry data arepresent, so multiple evaluations canbe carried out on the basis of a singlemeasurement. Because of the non contactand non destructive measurement,components that are not suitable forother measurement techniques, such astactile or optical coordinate measurementmachines can be examined. Fast andcomplete digitising of objects can beperformed by scanning the overallgeometry in a single measurement step.VM_EXACT_<strong>XS</strong>_GB_01 | Version September 2011© WENZEL Volumetrik GmbH | Technical data are subject to change.In part the described features are optionally available.Dimensional measurement and material analysison a plastic injection moulding partInjection moulding part with complex internalstructuresThe CT scan generates a complete 3D surface model ofthe part. This includes internal and external geometries.The nominal to actual comparison shows deviationsbetween the manufactured part and the CAD model.Local variations can be indicated by measuring flags atselected points.3D-Porosity analysis on a plastic injection mouldingpart: In this example cavities are classified insize, extent and volume.Using a semi-automatic process, it is possible to createa CAD model from the scan data (Reverse Engineering).With the software Metrosoft QUARTIS, internal andexternal structures can be measured such as with acoordinate measuring machine.WENZEL Volumetrik GmbHMaggistraße 778224 Singen / HohentwielGermanyPhone: +49-7731-14436-0Fax: +49-7731-14436-299info@wenzel-volumetrik.comwww.wenzel-volumetrik.com