General Principles of Food Hygiene, Composition and Labelling

General Principles of Food Hygiene, Composition and Labelling

General Principles of Food Hygiene, Composition and Labelling

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

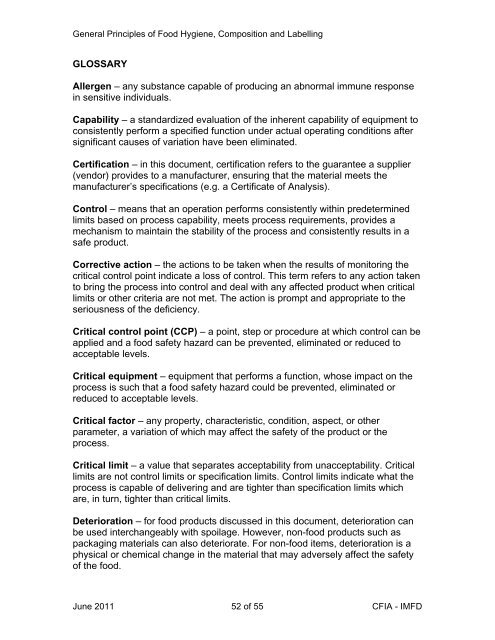

<strong>General</strong> <strong>Principles</strong> <strong>of</strong> <strong>Food</strong> <strong>Hygiene</strong>, <strong>Composition</strong> <strong>and</strong> <strong>Labelling</strong>GLOSSARYAllergen – any substance capable <strong>of</strong> producing an abnormal immune responsein sensitive individuals.Capability – a st<strong>and</strong>ardized evaluation <strong>of</strong> the inherent capability <strong>of</strong> equipment toconsistently perform a specified function under actual operating conditions aftersignificant causes <strong>of</strong> variation have been eliminated.Certification – in this document, certification refers to the guarantee a supplier(vendor) provides to a manufacturer, ensuring that the material meets themanufacturer’s specifications (e.g. a Certificate <strong>of</strong> Analysis).Control – means that an operation performs consistently within predeterminedlimits based on process capability, meets process requirements, provides amechanism to maintain the stability <strong>of</strong> the process <strong>and</strong> consistently results in asafe product.Corrective action – the actions to be taken when the results <strong>of</strong> monitoring thecritical control point indicate a loss <strong>of</strong> control. This term refers to any action takento bring the process into control <strong>and</strong> deal with any affected product when criticallimits or other criteria are not met. The action is prompt <strong>and</strong> appropriate to theseriousness <strong>of</strong> the deficiency.Critical control point (CCP) – a point, step or procedure at which control can beapplied <strong>and</strong> a food safety hazard can be prevented, eliminated or reduced toacceptable levels.Critical equipment – equipment that performs a function, whose impact on theprocess is such that a food safety hazard could be prevented, eliminated orreduced to acceptable levels.Critical factor – any property, characteristic, condition, aspect, or otherparameter, a variation <strong>of</strong> which may affect the safety <strong>of</strong> the product or theprocess.Critical limit – a value that separates acceptability from unacceptability. Criticallimits are not control limits or specification limits. Control limits indicate what theprocess is capable <strong>of</strong> delivering <strong>and</strong> are tighter than specification limits whichare, in turn, tighter than critical limits.Deterioration – for food products discussed in this document, deterioration canbe used interchangeably with spoilage. However, non-food products such aspackaging materials can also deteriorate. For non-food items, deterioration is aphysical or chemical change in the material that may adversely affect the safety<strong>of</strong> the food.June 2011 52 <strong>of</strong> 55 CFIA - IMFD