Download the pdf! - timberDESIGN Magazine

Download the pdf! - timberDESIGN Magazine

Download the pdf! - timberDESIGN Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3_AHEC.indd 1 29/6/07 1:31:01

CONTACT USEDITOR & PUBLISHERTony Neilson – tony@timberdesignmag.comSUB-EDITORMichael SmithADVERTISING ENQUIRIESAustraliaTony Neilson – tony@neilsonpromotions.comMob: 0408 166 543New ZealandDon Wilson – don_wilson@xtra.co.nzTel: 09 535 7275DESIGNEffigy CreativePRINTERSentra PrintSUBSCRIPTIONSinfo@timberdesignmag.com<strong>timberDESIGN</strong> is an independent magazine publishedquarterly by Neilson Promotions Pty Ltd, targeting designand build professionals throughout Australia andNew Zealand. Available by subscription or special delivery.All rights reserved. No part of this publication may bereproduced, stored in a retrieval system or transmittedin any form or by any means, electronic, mechanical,photocopying, recording, internet or o<strong>the</strong>rwise without <strong>the</strong>prior written permission of <strong>the</strong> publishers.While every effort has been made to ensure <strong>the</strong> accuracyof <strong>the</strong> information contained in this publication,<strong>the</strong> publishers accept no responsibility or liability for anyerrors, omissions or resultant consequences, includingany loss or damage, from reliance on information in thispublication. Opinions expressed in <strong>timberDESIGN</strong> arethose of <strong>the</strong> contributors and not necessarily those of<strong>the</strong> publisher. All letters or o<strong>the</strong>r material forwarded to<strong>the</strong> magazine are assumed to be intended for publicationunless clearly marked ‘not for publication’.ISSN-1178-881XNeilson Promotions Pty LtdAustralia address:PO Box 7611 East Brisbane, QLD 4169Mob: 0408 166 543New Zealand address:PO Box 17124 Greenlane, Auckland 1546Ph: +64 9 269 4531Fax: +64 9 520 3487Email: info@timberdesignmag.comWOOL ANALOGIES AND ECUADORI confess to raising a cynical eyebrowwhen a media release claiming “livingin a solid wood house is comparableto wearing merino wool” came acrossmy desk. So I ‘filed’ it for fur<strong>the</strong>rconsideration; <strong>the</strong> spin (pardon <strong>the</strong> pun)was just too slick not to go unchallenged.Putting aside <strong>the</strong> inevitable sheep jokes(yes, <strong>the</strong> Kiwis are behind this project)in favour of more puns, <strong>the</strong>re definitelyseems to be a fibre of truth in this one;maybe a skein of it.Everybody knows that wood is agreat insulator, but Lincoln University(Christchurch) research engineers LarryBellamy and Don MacKensie have beenlooking at it’s <strong>the</strong>rmal properties andability to absorb moisture from <strong>the</strong>environment – concluding that housesbuilt from solid wood demonstrate similar‘breathing’ properties to wool, withattendant comfort and health benefits.While that might be good news for loghome and Lockwood-style builders,I asked Dr Bellamy how <strong>the</strong> ‘merino-effect’can be achieved cost-efficiently andwithout consuming vast quantitiesof timber?“The humidity buffering effect of solidwood works best when <strong>the</strong>re is asignificant surface area exposed to <strong>the</strong>indoor air. [Our] research focused onhumidity buffering that might be achievedwith 60 mm thick solid wood internal andexternal walls. But we expect significantbuffering can be achieved with thinnerwood walls and/or ceilings.”The Lincoln scientists’ work also seemsto hit for six <strong>the</strong> <strong>the</strong>ory that brick andconcrete have superior insulation andpassive solar heating properties.Pound-for-pound it appears solid woodactually has 2.5 times <strong>the</strong> <strong>the</strong>rmal mass ofconcrete. If you want to know more aboutthis work, try: bellamy@clear.net.nzHere’s a blast from <strong>the</strong> past: we nowhave a subscriber in Quito! For <strong>the</strong>geographically-challenged, it is <strong>the</strong> capitalof Ecuador – full name San Francisco deQuito. I was lucky enough to be <strong>the</strong>re afew years ago on my way to <strong>the</strong> GalapagosIslands and it literally took my breathaway. Never run for a taxi at 2850 m abovesea level until you’ve acclimatised.Muchas gracias, Jose from Moldec(solidwood and mouldings). Maybe youcan tell me why <strong>the</strong>y paint white ringsaround <strong>the</strong> cedars in <strong>the</strong> city parks?Nobody else can.Which reminds me, it is time we thanked<strong>the</strong> people who help us with <strong>the</strong>increasingly outrageous cost of posting<strong>timberDESIGN</strong> to thousands of architectsand specifiers each quarter. In Australia,our major help comes from Forest &Wood Products Australia, VicForests andTimber Queensland, and in New Zealandit is <strong>the</strong> American Hardwood ExportCouncil (yep, that’s right) and <strong>the</strong> TimberDesign Society. Our common interest issustainable timber design.Watch out for <strong>the</strong> new website and o<strong>the</strong>rproducts in <strong>the</strong> next quarter.For comment or information about any aspect of this edition,please email us at: info@timberdesignmag.comCONTRIBUTORSPeter Harington – page 20Peter is a director of New Zealand wood marketing companyWoodmetrics and a lecturer, professional presenter and writer inhis spare time. He is a regular contributor to our sister publication,in-wood.peter@peterharington.comColin MacKenzie – page 42Colin works for Timber Queensland and is a widely respected woodtechnology expert, researcher and author. His flooring series(in conjunction with <strong>the</strong> ATFA) continues in this issue.colin@timberqueensland.com.auGREGORY NOLAN – page 39Greg is Associate Professor at <strong>the</strong> University of Tasmania where he isdirector of <strong>the</strong> Centre for Sustainable Architecture (CSAW) and writesregularly for <strong>timberDESIGN</strong>.gnolan@utas.edu.auTracy Wakefield – page 34Dr Wakefield is a Canadian-born materials science engineer andrecently completed a Masters in Fire Safety Engineering. She runs herown heavy timber structures company and has some good advice for‘bush building’. wakefieldp@bigpond.com

24PROJECTS4 IN THE BEST LIGHTIt looks like a wooden jetty – seeminglyincongruous in its landlocked setting –and that is not all that makes KielderObservatory a unique structure.8 CONVERSION THAT WASN’TA story of a ‘conversion’ that became a newbuild project by accident, and finished upwinning a best-private-house award.14 PUBLIC SCULPTUREIn <strong>the</strong> concrete-dominated zoo of Canberra’smajor institutional architecture sit two newkiosks that bring welcome relief – in moreways than one.16 PODS OF PINEA 1930s Auckland substation now doubles asa swanky and innovative ‘aspirational’ centrefor a major New Zealand business.18 WARMING REDSIt stood, robustly, on <strong>the</strong> edge of Lake BurleyGriffin for nearly a century – now it makes amajor contribution to Canberra’s reputation asa glass arts centre.22 FIT FOR PURPOSEAn unassuming timber-built ticket office at<strong>the</strong> base of a medieval English castle wasjudged ‘best small project’ at <strong>the</strong> latest UKWood Awards.24 GRAPHIC ERUPTIONThey say it is <strong>the</strong> ‘Holy Grail for institutionalfacilities’. Go to <strong>the</strong> centre spread and judgefor yourself.27 CONNECTED TO THE LANDSCAPEIt was a sawmill site, now a sewer andwastewater management system,and winner of <strong>the</strong> 2008 Wood WORKS! greenbuilding award.ACKNOWLEDGEMENTSWe gratefully acknowledge <strong>the</strong> special assistance of <strong>the</strong> following organisations with <strong>the</strong> distribution of <strong>timberDESIGN</strong> to leading designand build professionals throughout Australia and New Zealand:American Hardwood Export Council – representing producers of lumber species from sustainable American hardwood forests.Forest & Wood Products Australia – a not-for-profit company increasing awareness of <strong>the</strong> many advantages of wood.New Zealand Timber Design Society – fostering <strong>the</strong> designed use of timber.Timber Queensland – commercially-minded not-for-profit industry association.VicForests – <strong>the</strong> leading native forest timber harvesting & sales business in Victoria.

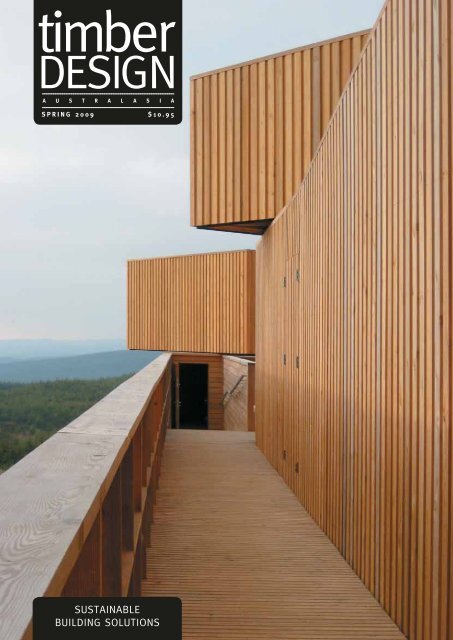

S P R I N G 2 0 0 9 $ 1 0 . 9 5CASE STUDY3048243418123642162214FEATURES & INTERVIEWS12 AMERICA’S BEST-KEPT SECRETContinuing our series profiling importantcommercial timber species – this time it isAmerican red oak.20 HIGHER ASPIRATIONSWood is beating at <strong>the</strong> door of a traditionalconcrete and steel stronghold in multi-storeyconstruction, and <strong>the</strong> ‘intruder’ is LVL.30 LIFE CYCLE PARALYSISThe Green Star rating system continues tochallenge logic and justice, and marginalisegood wood.31 NEW LVL FOR DOMESTIC FRAMINGClaims of greater stability and straightnessaccompany <strong>the</strong> release in Australia and NewZealand of a new LVL framing product.32 A SENSE OF LIFETimber is enjoying something of a renaissancein Japan – particularly preservative-treatedlocal species.34 BEATING THE FLAME ZONEA special report from fire safety engineeringexpert Dr Tracy Wakefield contains good newsfor wood in bushfire-prone areas.37 TOUCHING THE SOULDave Jones knows more than most aboutAustralia’s mineral riches – but <strong>the</strong>re isano<strong>the</strong>r, greater natural treasure.39 CLASS STRUCTURESThe ‘fundamentals’ seem right to considergreater use of timber in educational buildings.42 TIMBER FLOORINGAchieving a great result with wood and whatyou should know about timber types andfinishes.46 WOOD GUIDEOur new wood products and servicesreference for specifiers.IBC SUBSCRIPTIONSTake this opportunity to order your own copyof <strong>timberDESIGN</strong> and get FREE access to backcopies and <strong>the</strong> e-magazine.timberdesigna u s t r a l a s i aADVERTISERS’ INDEXAmerican Hardwood Export Council IFC & 12, Australian Forestry Standard Ltd 30, Arch Wood Protection 32 & 33, Hyne OBC,Juken New Zealand Ltd 11 & 31, Nelson Pine 7, Wespine 41.Wood Guide: AHEC, Craftbuilt Industries, Dave Jones Furniture, Hyne, Kennedys Aged Timbers, Lindsay & Dixon, Nelson Pine,New Zealand Douglas Fir Association, Outdoor Structures Australia, Resene, Rosenfeld Kidson, Sou<strong>the</strong>rn Lumber Company,Timberbond Industries, Watsons Ironbark Timber Products, Wood, Naturally Better.sustainablEbuilding solutionsCOVER: Kielder Observatory, UK – <strong>the</strong> timber choice enabled a sizeable structure at minimum environmental cost.PHOTOGRAPH: Courtesy Charles Barclaywww.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 3

PUBLIC ACCESS“The original design competitionrequired a building with exemplary ‘eco’credentials, and <strong>the</strong> architects say usingtimber enabled <strong>the</strong> construction of a sizeablestructure at minimal environmental cost,with carbon locked up in <strong>the</strong> material itself.”6www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

PUBLIC ACCESSwhitewood for <strong>the</strong> enclosed frame elements.Spruce and birch plywoods were used for <strong>the</strong>wall linings and stressed skin elements.The timber has been allowed to wea<strong>the</strong>rnaturally but was pre-treated with fire retardantNon-Com by Arch Timber Protection to give <strong>the</strong>building some protection against fire.Detailing includes a broad handrail thatserves as a datum for <strong>the</strong> structure, like a giantspirit level in <strong>the</strong> landscape. The cladding aboveit is vertical board-on-board, with horizontalshiplap below, emphasising <strong>the</strong> continuoushorizontal line for <strong>the</strong> building’s 42 m length.The original design competition required abuilding with exemplary ‘eco’ credentials, and<strong>the</strong> architects say using timber enabled <strong>the</strong>construction of a sizeable structure at minimalenvironmental cost, with carbon locked up in<strong>the</strong> material itself.The observatory building is entirely selfpowered,with a battery system run off a2.5 kW wind turbine and photovoltaic cells.There is a composting toilet, a wood-burningstove provides heat in a ‘warm room’ andastronomers bring <strong>the</strong>ir own water and campingstoves to brew up in <strong>the</strong> kitchen (water cannotbe stored on site because of <strong>the</strong> sub-zerowinter temperatures).Global warming has brought increasedhigh level cloud that obscures <strong>the</strong> night sky,so minimising <strong>the</strong> carbon footprint of <strong>the</strong>observatory was a priority for <strong>the</strong> astronomers.Rotating architectureThe traditional domed form of telescopeenclosures was rejected in favour of utilising<strong>the</strong> self-transforming possibilities of rotatingarchitecture. The turrets sit square to <strong>the</strong>building when not in use. When closed <strong>the</strong>building is not obviously an observatory, butresembles an austere, modernist pavilionor belvedere. However, when in use <strong>the</strong>observatory becomes expressive, with <strong>the</strong>turrets rotated and shutters open, alive withstrange geometries and altered orientations.The turrets are built off steel octagons wi<strong>the</strong>ight wheels that bear on a circular track, itselfsupported on a stationary steel octagon built ontimber framing below. The turning mechanismis a rack-and- pinion, hand-operated by a largestainless steel wheel and handle, with a gearboxto move <strong>the</strong> six-tonne turrets. The telescopeshave concrete-filled tubular steel columnmounts – entirely separate from <strong>the</strong> timberstructure to ensure <strong>the</strong>y are vibration-free.Computer-controlled electro-hydraulic servoscontrol <strong>the</strong> opening and closing sequences of <strong>the</strong>observatory shutters.The windy site’s normal power needs are metby <strong>the</strong> 2.5 kW wind turbine. In calm conditions,10 130 pW photovoltaic panels keep <strong>the</strong> 24 deepcellbatteries powered up. There is a dual whiteand red lighting system, with <strong>the</strong> red light usedduring observation to preserve night vision.OPPOSITE TOP The observatory’s 20-inch split-ringequatorial telescope is accessed via a circularnon-slip timber rampOPPOSITE BOTTOM The building serves as a belvederefor viewing <strong>the</strong> unique landscape during <strong>the</strong> dayOPPOSITE RIGHT Douglas fir frame and larch claddingare reminders of surrounding Kielder Forest, andtimber structures of a past local mining industryPROJECT Kielder ObservatoryCLIENT Kielder Water and Forest Park,Northumberland, UKARCHITECT Charles Barclay ArchitectsSTRUCTURAL ENGINEERS Michael HadiAssociatesASTRONOMY ADVISER Charles Barclay(Blackett Observatory)WOOD PRODUCTS Siberian larch, AmericanDouglas fir, European whitewood, spruceand birch plywoodPHOTOGRAPHY Charles BarclayAWARDS UK Wood Awards 08 (commercial& public access h/c), RIBA 2009 and TheCivic Trust (recognised), inaugural WorldArchitectural Festivalwww.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 7

UK AWARDS“The original scheme was to retain <strong>the</strong> basic footprint of Winter’s house, but in removing <strong>the</strong> faultyroof structure, an overenthusiastic demolition contractor knocked all <strong>the</strong> existing walls off plumb…””12 3 12 3 14 44 14551174441097 84109 1 Coutyard 111182 Garage3 Utility4 Bedroom5 Kitchen/Dining6 Study7 Living8 Conservatory9 Pond10 Bridge11 Garden1 Coutyard2 Garage3 Utility4 Bedroom5 Kitchen/Dining6 Study7 Living8 Conservatory9 Pond10 Bridge11 Garden66660 2.0m0 2.0mTHE CONVERSIONTHAT WASN’TThis is <strong>the</strong> story of a ‘conversion’ project that became a new build project by ‘accident’ andfinished up winning <strong>the</strong> best private house award at <strong>the</strong> 2008 British Wood Awards.Britain’s first Christian martyr was beheaded at St Albans. Now <strong>the</strong>Hertfordshire city is a sought-after dormitory town in <strong>the</strong> Londoncommuter belt.Marshalls Drive, a long and typically suburban St Albans road, is linedwith large detached houses, all of traditional design and pitched roofs.The site at number 65 is 15 m wide and 80 m deep and was part of amuch larger adjacent plot – sold off with a covenant that any new houseshould be single storey and flat roofed.In <strong>the</strong> 1960s, young architect John Winter was commissioned to designa small but ‘modern’ house. The result was a simple, single storey,two bedroom, brick and glass pavilion, with a small courtyard garden to<strong>the</strong> south to provide a buffer to <strong>the</strong> road frontage.But time had done <strong>the</strong> house few favours, because of a complete lackof maintenance, poor original build quality and virtually non-existent<strong>the</strong>rmal standards.New owners with an interest in contemporary design engagedSimon Condor to expand <strong>the</strong> house, adding a kitchen/dining room, large livingroom, conservatory, two studies, four bedrooms, utility room and garage.They wanted a simple, durable, light and airy house with <strong>the</strong> mainspaces having direct access to external spaces. They also required privacyand all for around £300,000.Design solutionThe scale of <strong>the</strong> new accommodation, site width and <strong>the</strong> limitations ofsingle-storey development led to a simple courtyard layout. At <strong>the</strong> front of<strong>the</strong> property <strong>the</strong>y are a buffer to <strong>the</strong> public realm, while <strong>the</strong> central partof <strong>the</strong> house opens up to provide light, ventilation and external spaces torooms that would o<strong>the</strong>rwise be entirely internal.The height of <strong>the</strong> two main living spaces was increased to create amore generous sense of space, with clearstorey glazing to catch <strong>the</strong>morning and evening sun.8www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

UK AWARDSwww.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 9

UK AWARDSThe fabric of <strong>the</strong> new building was a simple cost-driven combination ofblock walls and European redwood joisted roof structure. External wallswere finished in a white insulated render. Internally <strong>the</strong> walls were plasteredand <strong>the</strong> floor was power floated concrete. Fixed double-glazed units weresimply silicone bonded on to <strong>the</strong> softwood glazing frames and naturalventilation was achieved by a series of panels formed from solid core doorblanks. The roof finish is a single-ply membrane.The car parking area on <strong>the</strong> road frontage is screened from <strong>the</strong> front of<strong>the</strong> house by a high iroko (African hardwood) trellis structure, which intime will become a ‘green wall’.The purpose-designed kitchen units and extensive built-in storage unitswere constructed in birch ply and finished externally in white Formica.The original scheme was to retain <strong>the</strong> basic footprint of Winter’s house,but in removing <strong>the</strong> faulty roof structure, an overenthusiastic demolitioncontractor knocked all <strong>the</strong> existing walls off plumb, resulting in <strong>the</strong> fulldemolition of <strong>the</strong> original house.PREVIOUS TOP A simple cost-driven combination of block walls and redwoodjoisted roof structurePREVIOUS BOTTOM Height restriction led to simple courtyard layoutTOP LEFT Contemporary flat roof surrounded by ‘pitched and detached’BOTTOM LEFT Height of main living spaces increased to create a more generoussense of spaceABOVE Iroko hardwood trellis screening will become a ‘green wall’LOCATION St Albans, Hertfordshire, EnglandARCHITECT Simon Conder AssociatesBUILDER / MAIN CONTRACTOR Dunworth BuildersSTRUCTURAL ENGINEERS BuiltWOOD PRODUCTS European redwood (Scandinavia), iroko fencing anddecking, birch plywoodPHOTOGRAPHY Stephen Ambrose/Simon Conder Associates/Christobel PalmaAWARDS Best private house 2008 UK Wood Awards10www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

STRAIGHT,STRONG& TRUEThe new framingtimber that has it all.J-Frame is an engineered structural LVLframing timber manufactured by JukenNew Zealand Ltd from 100% renewableplantation forest resources.A reliable, straight and durable product.J-Frame can be used across a wide rangeof applications, including residential andcommercial framing and truss systems.Juken WOOD New FOR Zealand LIFELtdAvailable inNew Zealandand Australia.J-FRAMEFor fur<strong>the</strong>r information contact:Juken New Zealand Ltd, Wairarapa Mill, PO Box 535, Masterton 5840, New ZealandPhone: +64 6 370 0650 | Email: sales@jnl-ms.co.nz"Better by Design"J-FRAME is a gpurpose Structu

SPECIES PROFILEAMERICA’SBEST-KEPTSECRETRed oak – a warm anddistinctive performerWe continue our seriesprofiling important commercialtimber species availablein Australasia.“In flooring, its distinctive grainpattern is less likely to show wearand tear than many o<strong>the</strong>r speciesused today.”There is much discussion about <strong>the</strong> originsof <strong>the</strong> name American red oak. Some say it isbecause <strong>the</strong> leaves turn red in <strong>the</strong> autumn,o<strong>the</strong>rs contend that <strong>the</strong>re is a reddish tinge to<strong>the</strong> o<strong>the</strong>rwise dominant brown.William A. Lincoln* says it ranges from“biscuit coloured to pink”.Whatever, red oak is well suited to a wholerange of applications from flooring to furnitureand cabinets; and every type of joinery fromdoors to decorative panels.White oak is <strong>the</strong> leading US hardwoodimported into Australia – probably becauseimporters have, in <strong>the</strong> past, been unable tointerest furniture makers and interior joinerymanufacturers in what is now regarded asone of <strong>the</strong> world’s most sustainable of alltemperate hardwoods.American red oak is a true Quercus – mainlyQuercus rubra (Nor<strong>the</strong>rn red oak) and Quercusfalcata (Sou<strong>the</strong>rn red oak) but <strong>the</strong>re are manyo<strong>the</strong>rs subspecies such as Spanish oak,cherrybark oak and shummard oak. They allexhibit much <strong>the</strong> same technical and workingproperties but, as with most US hardwoods,can vary in colour and grain from region toregion. Red oak is native only to North America,although it has mainly been planted as anurban or garden tree outside America.There is a relatively large percentage ofheartwood in red oak, particularly in nor<strong>the</strong>rngrownmaterial. So, as usual when specifyingAmerican hardwoods, it is best to find outabout your source, especially if reducedsapwood and physical properties are moreimportant than aes<strong>the</strong>tics. Most Australianspecialist hardwood importers know <strong>the</strong>different characteristics accordingto provenance.Red oak represents about 35% of <strong>the</strong> totalAmerican hardwood forest – hence its sustainedpromotion by <strong>the</strong> American Hardwood ExportCouncil (AHEC), now active in Australia atexhibitions like DesignEx.The wood is particularly easy to slice andpeel for veneer and plywood, and is readilyavailable. As a result it is widely used for doorsand panelling, where its individual characteroffers decorative options for interiors todesigners and architects. The tree grows largeand tall, giving much better specifications thanmost o<strong>the</strong>r types of oak.12www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

AMENITIES“A ‘singular’ quality is created by using spotted gum claddingon all surfaces, and in avoiding any predominant grids orsub-geometries that would diminish <strong>the</strong> ‘monumental’ effect.”PUBLIC SCULPTURETimber ‘boxes’ break <strong>the</strong> Canberra mouldFrom a distance it is almost invisible, but in <strong>the</strong> concrete-dominated architectural zoo ofCanberra’s major institutional buildings, <strong>the</strong> Commonwealth Place Kiosks are a welcome relief– in more ways than one.Australia’s Parliament House and adjacentmajor public buildings present as an imposing,robust and earnest collection in concrete.So when architects Terroir were commissionedby <strong>the</strong> National Capital Authority (NCA) to build apublic toilet and ice-cream kiosk in <strong>the</strong> immediateforeground on <strong>the</strong> edge of Lake Burley Griffin,it seemed time for an alternative material.The new amenity buildings would besmall (less than 50m 2 ) and of ‘prosaic’ usewhen compared with <strong>the</strong> presumably loftieraspirations of those using adjacent structures.So, how does one install a toilet and kiosk justmetres from <strong>the</strong> central axis connecting <strong>the</strong>Parliament and lake?The NCA’s decision to locate a publicamenity in <strong>the</strong> context of so much architecturalmuscle was a positive gesture intended toincrease daily use of <strong>the</strong> Parliamentary Zone.To soften <strong>the</strong> structure’s impact on its augustand conservative surroundings, <strong>the</strong> architectsdesigned <strong>the</strong> kiosks as a ‘public sculpture’:blank timber boxes installed within this largestof sculptured parks.“The design is an essay in a sort of hyperformality,responding to nuances in Griffin’sgeometry at an urban scale, yet realised ina taut, blunt form,” Terroir associate TamaraDonnellan told <strong>timberDESIGN</strong>.Wood was chosen to separate <strong>the</strong> kiosksfrom <strong>the</strong> surrounding national institutions,and because of <strong>the</strong>ir proximity to a timber jetty.A ‘singular’ quality is created by using spottedgum cladding on all surfaces, and in avoidingany predominant grids or sub-geometries thatwould diminish <strong>the</strong> ‘monumental’ effect.“That is why <strong>the</strong> movement joints betweentimber elements were arranged in an informalmanner, so as not to subdivide <strong>the</strong> blockforms into smaller pieces. Instead, <strong>the</strong> effectis of a single form with a series of randomlines that do not suggest fur<strong>the</strong>r subdivision,”says Donnellan.To achieve <strong>the</strong> desired degree of ‘invisibility’in <strong>the</strong> larger context, a grey finish was chosen,which unifies <strong>the</strong> kiosks with <strong>the</strong> surroundingconcrete paving and makes <strong>the</strong>m all butdisappear when viewed from a distance.Spotted gum was selected because it waslocal and for its natural properties of hardnessand durability, lower tannin than o<strong>the</strong>r eucalyptsand termite resistance. Because <strong>the</strong> structurewas being build for a public authority, <strong>the</strong> greyeffect was required from day one, and Cabot’shacienda grey decking stain was chosen.A key detailing consideration was <strong>the</strong>decision to increase <strong>the</strong> number of movementjoints – to improve cladding longevity andto achieve a random pattern of joints, usingblack silicone. But <strong>the</strong> biggest challenge wasin <strong>the</strong> corner detailing where <strong>the</strong> desire for <strong>the</strong>buildings to read as a single block required allcorner junctions to be mitred.Donnellan says Canberra’s ‘variable’climate is often used as a reason to avoidtimber. “But <strong>the</strong> equally variable Scandinavianclimate has not prohibited a continual andsubstantial use of timber on many public andcommercial projects.“Timber was chosen very much to satisfyan urban design aim and not for reasons of<strong>the</strong> material’s inherent qualities. Also, <strong>the</strong>expectations for a public building in Canberrademand an extreme formality and, thus,<strong>the</strong> client did not want a ‘relaxed’ approachto timber expression and detailing.“That iswhy <strong>the</strong> detailing and finishing of <strong>the</strong> timber‘dematerialises’ it to some extent – as opposed toa celebration of timber and its inherent figuring,colour, texture and so on. We are, however,using this approach on a house underconstruction where timber is being used onnearly all surfaces inside and out, and where itsinherent characteristics are brought to <strong>the</strong> fore.“Like a giant piece of timber furniture, thishouse will be remembered for <strong>the</strong> look, feel andsmell of <strong>the</strong> material – in complete oppositionto our approach with <strong>the</strong> Canberra kiosks,”says Donnellan.TOP The timber finish links and merges with <strong>the</strong>immediate surroundingsMIDDLE LEFT Extra movement joints were added toimprove cladding longevity and achieve a randompatternMIDDLE RIGHT Hidden system of coloured lightfilteringtubes represent autumn <strong>the</strong> tonal rangeBOTTOM Spotted gum-clad toilet and <strong>the</strong> ice creamkiosks flank Canberra’s architectural heavyweightsPROJECT Commonwealth Place Kiosks,CanberraCLIENT National Capital AuthorityARCHITECTS Terroir Pty LtdFACILITATORS Steenson Varming (Australia)STRUCTURAL ENGINEERS Hughes TruemanBUILDER Manteena Pty LtdWOOD PRODUCTS Spotted gum claddingAWARDS 2008 Dulux Colour Awards(winner: commercial exterior); 2008 RAIA(ACT Chapter) (commendation: urban design)PHOTOGRAPHY Brett Boardman14www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

AMENITIESwww.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 15

FIT-OUT“The warmth of <strong>the</strong> beautifullyfinished, low-formaldehydehoop pine is a nice contrastwith <strong>the</strong> concrete and steelsubstation space.”PODS OF PINESubstation becomes innovation centreA 1930s substation building through which a third of Auckland’spower still runs now doubles as a very swanky and innovativefacility uniting <strong>the</strong> aspirations of <strong>the</strong> businesses of one of NewZealand’s biggest infrastructure providers.16www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

FIT-OUTKnown as The Substation and createdfor Vector Ltd, it was conceived as a placeto explore, integrate and display newtechnology, and to encourage <strong>the</strong> developmentof sustainable business models and <strong>the</strong>irexpedition to market.The resulting multifunctional and modularsolution is based on four bespoke timber pods,inserted into a raw industrial environment.“Drawing <strong>the</strong>ir formal language from ideasof circuitry, <strong>the</strong>y delineate a series of spaces inwhich innovation, experimentation and displayare integrated into a cohesive yet adaptableexperience,” says architect Mat<strong>the</strong>w Waterfall.Vector is a major player in fibre optics,renewable energy resources, gas, meteringand traditional electricity supply, and each podis supposed to represent four different uses:Connect, Manage, Use and Understand.“But <strong>the</strong>y are primarily a mechanism to allow<strong>the</strong> client to use <strong>the</strong> spaces flexibly,” Waterfalltold <strong>timberDESIGN</strong>. “We needed spaces thatcould be understood and easily adapted andused by <strong>the</strong> sub-companies.“The first pod [Connect] is a kitchen-type spacewith all <strong>the</strong> necessary management controls for<strong>the</strong> home of <strong>the</strong> future, including computers,metering, internal gas power and microgeneration.The second pod [Manage] was set out as ahome office with access to experimental energymanagement systems. The third is a small loungetypearea but is primarily focused outwardstowards <strong>the</strong> main exhibition and [communications]area, and <strong>the</strong> fourth pod [Understand] is aconference and presentation area.”Space behind <strong>the</strong> pods is deliberately moreindustrial, allowing for easy adaptability to newtechnology, experimentation and metering ofinstalled technologies.The roof space is occupied by two windturbines – generating electricity for <strong>the</strong> pods –and a solar array using photovoltaics and hotwater technology.New Zealand pine was used for <strong>the</strong> mainstructural elements and plantation-grownhoop pine from Australia was chosen for <strong>the</strong>pod cladding. “The warmth of <strong>the</strong> beautifullyfinished, low-formaldehyde hoop pine is a nicecontrast with <strong>the</strong> concrete and steel substationspace,” says Waterfall.Unusually severe dryness within <strong>the</strong> buildingcaused considerable movement of framingtimber. “At one point <strong>the</strong> internal moisturelevels of <strong>the</strong> framing were down to 4 percentand was constantly planed and re-fixed toachieve a suitable quality level for finishing.”The hoop ply sheets were butt joined andsecured with concealed fixings. “Initially,we looked at mitred corners, but with <strong>the</strong> lowmoisture and high <strong>the</strong>rmal gain of <strong>the</strong> existingstructure in summer, we decided to do smalltimber fillets on <strong>the</strong> corners to accommodatesome movement,” he says.OPPOSITE Space behind <strong>the</strong> pods is more industrialbut easily adaptable to new technologyBELOW Low moisture levels presented finishing anddetailing challengesPROJECT The Substation, Auckland,New ZealandCLIENT Vector LtdARCHITECT Mat<strong>the</strong>w WaterfallWOOD PRODUCTS Hoop pine ply, radiata pinestructuralAWARDS NZ Timber Design 2008,sustainability (joint) and fit-out(highly commended)PHOTOGRAPHY Greg Brookeswww.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 17

CONVERSIONWARMINGHardwoods bring colour and contrastto glassworksREDSThe Kingston Powerhouse has stood, robustly,on <strong>the</strong> south-eastern edge of Lake Burley Griffinin Canberra for some 94 years – but it wasn’tsupposed to.The federal capital’s first permanent public building – <strong>the</strong> powerhouse,designed by John Smith Murdoch to provide coal-generated electricityto <strong>the</strong> burgeoning new community from 1915 – was originally intendedto be a temporary structure. But its final sturdy proportions ensuredgreater longevity.In 2004, after 15 years of lobbying by Canberra’s glass artists, <strong>the</strong> ACTGovernment announced funding to convert <strong>the</strong> disused powerhouse into aglass centre – a landmark project, building on <strong>the</strong> international success of<strong>the</strong> Glass Workshop at <strong>the</strong> Canberra School of Art.“It was to reflect <strong>the</strong> synergies between <strong>the</strong> creative art glass industryand <strong>the</strong> history of energy supply in Canberra,” says Jocelyn Jackson ofproject-winning Tanner Architects.The resulting design is an innovative solution that meets <strong>the</strong> functionalrequirements of an accessible glass centre, respects <strong>the</strong> existing structureand heritage significance, and allows <strong>the</strong> public to appreciate <strong>the</strong>building’s various uses.Jackson says <strong>the</strong> project brief and <strong>the</strong> building were an excellentmatch. “The interior surfaces and finishes [unpainted and painted offformconcrete] were rough, irregular and with details suited to its originalindustrial use. The requirements for <strong>the</strong> glassworks could be seen as anew contemporary industrial use, well suited to <strong>the</strong> fabric condition of <strong>the</strong>old powerhouse,” she told <strong>timberDESIGN</strong>.Repairs and reinstatement of some historic fabric was required(e.g. steel-framed windows) but a full restoration and reconstructionwere not part of <strong>the</strong> brief.The end result minimises intervention, with much of <strong>the</strong> historic fabricand space retained and given fresh life. New materials of glass, timber andsteel marry with <strong>the</strong> old. For <strong>the</strong> interior finish, recycled ‘red’ hardwoodswere specified ¬– providing colour and warmth, and visual synergy next to<strong>the</strong> rusting red steel of <strong>the</strong> riveted columns and coal hoppers.The same hardwood is used for <strong>the</strong> lift shaft lining, <strong>the</strong> circular screenaround <strong>the</strong> foyer retail shop, public viewing seats and handrails,flooring to <strong>the</strong> smokestack installation space and on <strong>the</strong> new stairs.The lift shaft lining battens are 32 x 19 mm, evenly spaced with5 mm gaps and secret nail-fixed over black fabric/screen to steel furringchannels on <strong>the</strong> concrete block lift shaft.The circular vertical timber screen in <strong>the</strong> foyer uses recycled karri.Alternating battens are 41 x 41 mm (1400 mm long) and 41 x 115 mm (2700mm long), spaced 15 mm apart and secret nailed from <strong>the</strong> internal faceto a curved steel framework of steel studs. The wood was selected tominimise colour differences and is clear finished.Seats in <strong>the</strong> mezzanine viewing area are Oregon planks that servedas walkways above <strong>the</strong> old condensing pits (not reused for rainwaterstorage), salvaged and reworked in lengths up to 8.5 metres.18www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

CONVERSION“For <strong>the</strong> interior finish, recycled‘red’ hardwoods were specified –providing colour and warmth, anda visual synergy next to <strong>the</strong> rustingred steel of <strong>the</strong> riveted columns andcoal hoppers.”OPPOSITERecycled karri battens – colour matched and clearfinishedABOVE LEFTRed hardwoods provide colour and warmth next to<strong>the</strong> riveted columnsLEFT MIDDLENew lease on life for <strong>the</strong> Kingston PowerhouseLEFTAlthough not used widely in <strong>the</strong> original building,timber adds warmth and colour throughout <strong>the</strong>conversionPROJECT Canberra GlassworksCLIENT ACT GovernmentARCHITECT Tanner ArchitectsSTRUCTURAL ENGINEER NorthropESD CundallARCHAEOLOGIST Navin OfficerWOOD PRODUCTS Recycled red hardwoods(including karri), Oregon (salvaged)PHOTOGRAPHY Tyrone Branigan PhotographyAWARDS 2008 ACT Heritage ArchitectureAwardwww.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 19

RESEARCH“This is about big-span structures so it is not limiting woodto just domestic buildings and opens up opportunitiesworldwide into <strong>the</strong> commercial sector.”HIGHER ASPIRATIONSMulti-storey LVL system a world firstWood is about to start beating at <strong>the</strong> door of a traditional cement and steel stronghold –<strong>the</strong> multi-storey building. And <strong>the</strong> irony is that <strong>the</strong> core technology on which this exciting newdevelopment is based comes from <strong>the</strong> concrete industry.Researchers at <strong>the</strong> University of Canterburyin New Zealand have recently designed andconstructed <strong>the</strong> world's first large-scalepre-stressed timber test building – withinternationally significant results.The two-storey patented Pres-Lam buildingsystem has been constructed in a laboratoryat <strong>the</strong> university and consists of a skeleton ofpost-tensioned frames in one direction andpost-tensioned coupled structural walls in<strong>the</strong> o<strong>the</strong>r, with a timber-concrete compositefloor system.The research is being funded as part of afive-year Australasian programme to developnew forms of multi-storey timber buildings.Professor of Timber Design and projectleader Dr Andy Buchanan says <strong>the</strong> latestconstruction techniques using pre-stressedtimber technology are being used and <strong>the</strong> LVLbeams, columns and walls are all held to eacho<strong>the</strong>r with steel tendons, as in modern prestressedconcrete structures.When <strong>timberDESIGN</strong> spoke to Buchanan,a two-thirds scale building had been erectedin <strong>the</strong> structural engineering laboratory andwas being subjected to a range of earthquakeloadings in various conditions.The Pres-Lam system is expected to offerarchitects and structural engineers <strong>the</strong> chanceto design large, open-plan, multi-storeybuildings with great flexibility for changesof use. Long-span post-tensioned timberbeams will offer more attractive and desirableworkplaces because <strong>the</strong>y require fewerinternal columns and walls – including crosslaminatedtimber (CLT).Buchanan says ano<strong>the</strong>r benefit of posttensioningis that a large number of strong butductile moment-resisting connections can bemade in one stressing operation at each level ofeach frame, avoiding <strong>the</strong> need for hundreds ofnails or screws in traditional timber connections.In frames, <strong>the</strong> full-length horizontal tendonspass through ducts along <strong>the</strong> beams andthrough holes in <strong>the</strong> columns, providingmoment-resistance at each beam columnconnection. In timber walls, <strong>the</strong> tendons orthreaded bars are placed vertically from <strong>the</strong>foundation to an anchor plate at <strong>the</strong> top of<strong>the</strong> multi-storey wall panels. Vertical posttensioningin columns is also possible to20www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

RESEARCHimprove <strong>the</strong> overall system re-centring capacityand to act as hold-down systems.Because wood is lighter than o<strong>the</strong>rmaterials, cranes can lift longer beams orlarger prefabricated components than o<strong>the</strong>rmaterials, significantly reducing on-site costsand speeding up construction time.The research team is also looking at <strong>the</strong>relative carbon footprint of wood-basedbuildings, plus fire resistance, <strong>the</strong>rmalperformance and durability.A possible outcome for <strong>the</strong> Pres-Lamsystem is prefabricated kitset multi-storeybuildings for export. Early indications are thatstructures built this way will be competitivewith concrete, and have earthquake andenvironmental advantages.“For earthquake areas, we know this systemwill have a big edge with its lower seismicmass,” says Nelson Pine LVL product engineerAndy van Houtte, “but we are hoping it will<strong>the</strong>n spread to all areas because of itso<strong>the</strong>r advantages.”The company provided product for <strong>the</strong>research project and van Houtte says <strong>the</strong>y arelearning more about <strong>the</strong> advantages of <strong>the</strong>setimber structures all <strong>the</strong> time. “They are highstrength,lightweight, easily machined, gluedand adapted.”New Zealand Timber Design Society (TDS)president and University of Auckland lecturerHugh Morris believes this is <strong>the</strong> most significantstructural research project in <strong>the</strong> industry forsome time. “It is of world scale interest andthose behind it should be proud of it. This isabout big-span structures so it is notlimiting wood to just domestic buildings andopens up opportunities worldwide into <strong>the</strong>commercial sector.”The research is funded by <strong>the</strong> StructuralTimber Innovation Company (STIC) –a consortium of Australian and New Zealandcompanies and universities, and <strong>the</strong> NewZealand Government.PETER HARINGTONABOVE The world's first large-scale pre-stressedtimber test buildingwww.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 21

UK AWARDSFIT FORPURPOSEA medieval castle’s new ticket hutFor centuries Lindisfarne Castle on <strong>the</strong> Northumberland coast ofEngland has withstood <strong>the</strong> ravages of time, North Sea wea<strong>the</strong>rand Norse and Scottish raiders. Nowadays, <strong>the</strong> romantic 16thcentury fort is more likely to be overrun by tourists.A new timber-built ticket hut completed for<strong>the</strong> National Trust property on <strong>the</strong> highest pointof Holy Island – reachable from <strong>the</strong> mainlandonly at low tides by a mile-long causeway –was judged ‘best small project’ in <strong>the</strong> 2008UK Wood Awards.Although medieval in origin, <strong>the</strong> castle wassubstantially remodelled by Sir Edwin Lutyensin <strong>the</strong> early 20th century and now attracts amultitude of visitors every year.Admissions were originally dealt with in<strong>the</strong> castle entrance hall, accessed via a longexternal ramp and staircase. To better manage<strong>the</strong> ever-increasing visitor numbers andaccommodate some modest interpretationdisplays, <strong>the</strong> National Trust commissionedarchitects Simpson & Brown to design apurpose-built ticket hut and reception building.It sits on a very sensitive and exposedsite adjacent to much-photographed andrecognisable storage sheds built from three‘sawn-off’ and upturned boat hulls.22 www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

UK AWARDSWhile <strong>the</strong> design deliberately eschews<strong>the</strong> opportunity to build a fourth upturnedhull, it does attempt to respond to its uniquesetting between <strong>the</strong> tall, harsh, angular stonerevetments of <strong>the</strong> castle and <strong>the</strong> low, softlycurved profiles of <strong>the</strong> sheds.The result is a wedge-shaped building witha sculptural black ‘crinkly tin’ roof that dipstowards <strong>the</strong> rear as <strong>the</strong> plan form widens.French oak was chosen as <strong>the</strong> main materialfor internal and external detailing because ofits durability and long life, and <strong>the</strong> cohesiveaes<strong>the</strong>tic it brings to <strong>the</strong> different designelements.The building is framed in timber and cladwith untreated, graduated oak boards,which unfurl to create louvred screens over <strong>the</strong>windows. The large outer door swivels on acentral pivot. When closed it provides securityand shelter to <strong>the</strong> exposed lobby area. Whenopen it engages with <strong>the</strong> distinctive riven oakfencing, inviting visitors into <strong>the</strong> hut on oneside as <strong>the</strong>y approach, and directing <strong>the</strong>mtowards <strong>the</strong> castle on <strong>the</strong> o<strong>the</strong>r side once <strong>the</strong>yhave purchased <strong>the</strong>ir tickets.The pivot door is designed with spacingsto allow <strong>the</strong> coastal winds to pass through<strong>the</strong> graduated oak boards, facilitating openingin <strong>the</strong> exposed island location. Glazing above<strong>the</strong> pivot door stops swallows returning infollowing years and taking up home in <strong>the</strong>lobby roof purlins.The oak wall claddings and fittings provide alow-maintenance interior – simple, workmanlikeand unpretentious. Roof purlins are leftexposed, showing <strong>the</strong> scarf jointing requiredbecause of a scarcity of bigger oak sizes.And <strong>the</strong> sweeping oak ticket desk and storagecupboards maximise <strong>the</strong> space and provide aninformation point for tourists.(Footnote: in 2005, two of Lutyens’ originalherring buss sheds were destroyed by arson.They were replaced in 2006 and a third has beenrenovated. Spanish architect Enric Miralles laterused Lutyens’ idea as inspiration for his design of<strong>the</strong> Scottish Parliament Building in Edinburgh.)OPPOSITE LEFTUntreated French oak chosen for durability andcohesive aes<strong>the</strong>ticOPPOSITE RIGHTLindisfarne Castle on Holy Island was built in 1550and much-altered by Lutyens in <strong>the</strong> early 1900s(Photo: Wikimedia)LEFTGraduated oak boards unfurl to create louvredscreens over <strong>the</strong> windowsABOVEThe ticket office’s swivel door ‘engages’ with <strong>the</strong>split oak fencingCLIENT The National TrustARCHITECT Simpson & Brown Architects,EdinburghSTRUCTURAL ENGINEER Patrick Parsons,Newcastle-Upon-TyneCONTRACTOR Historic Property RestorationLtd, North ShieldsWOOD SPECIES French oakAWARDS UK Wood Awards, Best SmallProject 2008www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 23

EDUCATIONGRAPHICERUPTIONColour and style on <strong>the</strong> Deakin campusThe designers describe it as <strong>the</strong> “Holy Grailfor institutional facilities” – a trifle immodestperhaps, but <strong>the</strong>re is no denying <strong>the</strong> newInternational Centre and Business Building(ICBB) at Deakin University’s Melbourne campusis an aes<strong>the</strong>tic icon.The first buildings at <strong>the</strong> university’s Elgar Road site in Burwood, <strong>the</strong>ICBB consists of parallel, low-rise, large floor plate buildings joined bya bridge and accessed from a central pedestrian ‘street’. Cafes, lecture<strong>the</strong>atre, foyers and reception areas create a dynamic street environmentwith universal access at <strong>the</strong> ground plane.The brief required practical and flexible accommodation of Deakin’simmediate and future needs, and <strong>the</strong> result is a distinctive andcontemporary curved form.The design incorporates a strong environmental commitment, withsheltered atriums enlivened by textured recycled brick walls and lightcourts edged with graduated ‘seasonal’-coloured timber-panelled walls –providing <strong>the</strong> sustainable lungs for fresh air to <strong>the</strong> complex.A relatively ‘hard-faced’ prefabricated patterned aluminium skin overprecast concrete panels is offset by <strong>the</strong> natural qualities of substantialtimber louvres, timber panelling and bricks recovered from sitedemolition works. All of <strong>the</strong> materials have a deliberate relationshipwith <strong>the</strong> landscape.24www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

EDUCATION“Use of cedar… communicates that <strong>the</strong> buildingis different from o<strong>the</strong>r institutional buildings andmay represent a more responsive characteristicfor education delivery.”www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 25

EDUCATIONAn important external feature is <strong>the</strong> panelledcedar-finned western facade, extending to<strong>the</strong> main building entrance – designed with afully accessible service gap to improve passiveshading and allow maintenance access to <strong>the</strong>enclosed glass facade.Creating something of a graphic eruption,<strong>the</strong> timber elements also succeed in softening<strong>the</strong> hard-edged facade materials and‘de-institutionalise’ <strong>the</strong> most important publicface of <strong>the</strong> buildings. The exterior fins alsoscreen end-located glazed stairs and link <strong>the</strong>structure with its creek-edge location.“Use of western red cedar on <strong>the</strong>se importantand highly visible facades also communicatesthat <strong>the</strong> building is different from o<strong>the</strong>rinstitutional buildings and may represent amore responsive characteristic for educationdelivery,” <strong>the</strong> architects say.They add that manufacturing <strong>the</strong> timber panelmodules off-site made for faster assembly and,better construction quality, minimising waste andmaintenance.Inside, ‘light courts’ slash through <strong>the</strong> centreof both buildings – functioning as conduits forair, light and occupant movement. Victorian ashveneered plywood feature walls, stained andsealed in vibrant feature colours, face stackedbalconies and <strong>the</strong>ir cedar balustrades.The International Building interior isshea<strong>the</strong>d in yellow and red tones to reflect <strong>the</strong>summer and autumn seasons and <strong>the</strong> BusinessBuilding sports blue and green summer/winterhues. The feature panels also harmonise with<strong>the</strong> recycled brick.This project won <strong>the</strong> best use of decorativeveneer and best use of western red cedar awardsat <strong>the</strong> 2008 Australian Timber Design Awards.PREVIOUS PAGE TOP LEFTCedar louvres allow for maintenance accessto glass behindPREVIOUS PAGE TOP RIGHTPrefabricated patterned aluminium skin overprecast concrete, softened with timber featuresPREVIOUS PAGE BOTTOMTimber screen softens and ‘de-institutionalises’<strong>the</strong> main building entranceTHIS PAGE TOPRed and yellow stained Victorian ash panels reflectsummer and autumn coloursTHIS PAGE BOTTOMLight courts edged with graduated colour representsustainable ‘lungs’PROJECT Deakin University ICBBARCHITECT/INTERIOR DESIGN H2o Architects,Collingwood VICDESIGN & PROJECT MANAGEMENT DeakinUniversity FMSDSTRUCTURAL ENGINEERS Deakin FMSDWOOD PRODUCTS Victorian ash veneer onplantation ply, panelled western red cedarlouvresPHOTOGRAPHY Trevor Mein26www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

CANADIAN AWARDSCONNECTED TOTHE LANDSCAPEOld sawmill ‘lives’ againThe operations buildings for a sewer andwasterwater management project built onan old sawmill site in New Westminster,British Columbia was <strong>the</strong> winner of <strong>the</strong> 2008Wood WORKS! BC green building award.www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 27

CANADIAN AWARDS“The material is flexible and reliable for exploring design and structural ideas, and for meeting budget realities.We work with several soft and hardwood species, depending on <strong>the</strong> given design situation.”The Combined Sewer Overflow (CSO) operations building locatedon <strong>the</strong> north bank of <strong>the</strong> giant Fraser River was a partnership projectbetween <strong>the</strong> city fa<strong>the</strong>rs and Metro Vancouver. It was commissioned tominimise untreated storm water overflows into <strong>the</strong> Fraser, which, at nearly1400 km, is <strong>the</strong> province’s longest.As a public park facility, community interaction and environmentalawareness were also to be encouraged. (Phase 2 of <strong>the</strong> project includesdevelopment of Poplar Landing Park and <strong>the</strong> continuation of <strong>the</strong> city'swaterfront esplanade. A housing site is also anticipated to offset totalproject costs.)The operations building is a single-storey, 250 m 2 structure that containsliquid, air and electrical equipment necessary to run <strong>the</strong> complex facility,and provides direct access to a huge underground storage tank. Publicwashrooms and a covered plaza for educational displays are also provided.To minimise its environmental impact, <strong>the</strong> building relies heavily onmaterials reclaimed from a local deconstructed sawmill, with minimal useof new materials.Wood products used on <strong>the</strong> project include:• reclaimed Douglas fir heavy timber trusses,posts and beams for <strong>the</strong> mechanical room’s structural frame• reclaimed glulam beams supporting <strong>the</strong> green roof/plaza and <strong>the</strong>curved control room roof• tongue and groove Douglas fir horizontal siding used to clad <strong>the</strong>mechanical room• tongue and groove Douglas fir timber roof decking for all roofs(80% reclaimed)• re-sawn Douglas fir veneer plywood with cedar batten cladding• wood stud heavy timber infill walls.Unlike typical infrastructure projects, aes<strong>the</strong>tics were an integralcomponent of client objectives to ensure a facility that integrates with<strong>the</strong> public and its surroundings. The mixture of materials, textures andbuilding forms helps mitigate <strong>the</strong> imposition of a large operating municipalfacility on <strong>the</strong> public outdoor space. And, <strong>the</strong> warmth and scale of woodencourages <strong>the</strong> use of a public space that is inviting, and informative.As part of a larger sewer management system, <strong>the</strong> building reducesupgrade and maintenance requirements on all downstream infrastructure.Designed to improve <strong>the</strong> quality of future overflows, a unique flushingsystem cleans <strong>the</strong> tank automatically, using very little power when inoperation and incurring virtually no costs while off-line. The facility isdesigned to reduce noise and incorporates a unique, cost-effective andenergy-efficient odour control system.Environmental performance is enhanced by highly reflective, energyefficientmetal roofing, reclaimed steel components, high-volume fly-ashconcrete, and landscaped green roof.The wood connectionWhen asked why <strong>the</strong>y specified wood, <strong>the</strong> designers specified woodbecause it is “embedded” in Canadian culture and identity – both nativeand European. “Building with wood connects us to our landscape and <strong>the</strong>cycles of nature. It is an accessible material available everywhere.“The material is flexible and reliable for exploring design and structuralideas, and for meeting budget realities. We work with several soft andhardwood species depending on <strong>the</strong> given design situation. Western redcedar is durable for exteriors; Douglas fir is very strong for framing; birchand maple have attractive grain for cabinetry and millwork. Plywood ando<strong>the</strong>r remanufactured products provide o<strong>the</strong>r opportunities for use ofwood in architecture.”28 www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

CANADIAN AWARDSMany Northwest Pacific architects say wood is more conducive toexploring contemporary aes<strong>the</strong>tic ideas in architecture than masonryor steel. “Perhaps it’s <strong>the</strong> quality of light, our tempered [often grey]climate, closeness of <strong>the</strong> ocean and forest, and our ‘young’ history,but our buildings tend to be more open and expressive; engaging <strong>the</strong>landscape and new ideas wherever possible. We are less committed to<strong>the</strong> traditional architectural elements found in older cities.OPPOSITE PAGE LEFTThe operations building provides direct access to a huge underground storagetank (see perspective)OPPOSITE PAGE RIGHTThe design makes substantial use of materials reclaimed from a localdeconstructed sawmillTOP RIGHTEnvironmental performance is enhanced by reclaimed steel components,high-volume fly-ash concrete and landscaped green roofBOTTOM RIGHTThe structural frame trusses, posts and beams are reclaimed Douglas firARCHITECTS Eric Pattison Architect, BCENGINEER Associated EngineeringBUILDER Westport Construction GroupWOOD PRODUCTS Reclaimed Douglas fir trusses, horizontal siding,roof decking (80% reclaimed), resawn veneer plywood, reclaimedglulam beams, cedar battens, wood stud infill walls.www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 29

COMMENTLIFE CYCLE PARALYSISThe Green Star rating system for buildings continues to challenge logic and justice, yet seems tobe sweeping <strong>the</strong> globe at a similar pace to swine flu.How can a sustainable building certificationsystem that rewards a bike rack with <strong>the</strong> samenumber of credits as can be earned for usingcertified, carbon-storing wood throughouthave any credibility with thinking architects,politicians or <strong>the</strong> public at large?Well, it does. And as things stand, <strong>the</strong>re isnothing to indicate that such absurdly skewedproduct evaluation criteria will result in <strong>the</strong> GreenBuilding Council succumbing to logic or equity.The Green Building phenomenon has takenoff in Australia like nowhere else outside <strong>the</strong>US, with New Zealand not far behind. Architectsand politicians everywhere seem captivatedby <strong>the</strong> feel-good factors associated with <strong>the</strong>accumulation of Green Star ratings.But for <strong>the</strong> wood industry, <strong>the</strong> system isjust as widely seen as a rort: wood mustprove its sustainability, when most competingbuilding materials do not; <strong>the</strong> GBCA and NZGBConly recognise FSC-certified wood for GreenStar rating points; lifecycle analysis and itsembodied carbon-storage data are dismissedas ‘too hard’; and attempts to redress <strong>the</strong>situation are in <strong>the</strong> grip of inertia.Timber interests and <strong>the</strong> AustralianCompetition & Consumer Commission (ACCC)have complained that it is anti-competitive for<strong>the</strong> GBCA to unconditionally accredit only oneforest products certification system.After a year’s deliberation by a ‘timber expert’reference panel <strong>the</strong> GBCA released a new ‘draftframework’ review of <strong>the</strong> timber credit at <strong>the</strong>end of June, with <strong>the</strong> promise that new criteriawould be announced by <strong>the</strong> end of July. (By <strong>the</strong>end of August <strong>the</strong>re was still no news.)For currently marginalised forest certificationand chain-of-custody (CoC) schemes like <strong>the</strong>Australian Forestry Standard (AFS) and PEFC(<strong>the</strong> world’s biggest CoC certifier), <strong>the</strong> review ispotentially good news. Or is it?Speaking at an AFSL forum in Brisbane in lateJuly, GBCA Queensland and Nor<strong>the</strong>rn TerritoryGreen Star rating tool manager Andrew Aitkensignalled that AFS/PEFC and FSC would achieve‘best practice’ recognition. However, <strong>the</strong>re isnervousness that <strong>the</strong> GBC’s global enchantmentwith FSC will still see <strong>the</strong> scheme emerge with<strong>the</strong> upper hand.The nub of <strong>the</strong> problem is <strong>the</strong> GBCA’s desireto be <strong>the</strong> final arbiter on what constitutes afull-points-earning timber certification process– requiring <strong>the</strong> world’s leading independentforestry and CoC certification schemes to‘prove’ <strong>the</strong>mselves to an organisation with littleor no expertise in <strong>the</strong> matter.“PEFC and FSC are <strong>the</strong> most recognised globalcertification schemes; rigorously reviewed andwith impeccable credentials. And for <strong>the</strong> GBCAto want to change <strong>the</strong> benchmarks and put <strong>the</strong>mthrough <strong>the</strong> hoops again is ridiculous,” saysAFSL chief executive Kayt Watts.Under <strong>the</strong> proposed new criteria, timbercertification schemes will have to re-accredit with<strong>the</strong> GBCA, and if approved, <strong>the</strong>y will be rewardedwith one Green Star point. But to get <strong>the</strong> secondpoint, <strong>the</strong> schemes will have to be separatelyticked off by <strong>the</strong> GBCA’s board of directors!Now <strong>the</strong>re’s a detail-devil if ever <strong>the</strong>re was one.While Aitken says <strong>the</strong> GBCA only wants tokeep illegal timber out of buildings – not woodper se, he concedes that as things stand, it ispossible to use illegal timber or shunned PVCand still get a 6-star rating.TONY NEILSON – EditorMAKE A DIFFERENCE TODAY!SOURCE ONLY CERTIFIED WOOD AND WOOD PRODUCTSSetting <strong>the</strong> standard for sustainable forest management in AustraliaAustrAliAn Forest CertiFiCAtion sCheme (AFCs)www.forestrystandard.org.au Phone: +61 (0) 2 6232 5356 Email: info@forestrystandard.org.au30www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

SPECIAL FEATURENEW LVL FRAMINGImproved stability and straightnessWhen we report on a new product in <strong>timberDESIGN</strong> it is usually <strong>the</strong> manufacturer who approachesus. But in this case, we heard about J-Frame from a builder enthusiastically telling his neighbour(one of our team, as it happened) about this wonderful new building product he had “found”.“I loved it on <strong>the</strong> job we have just finished and have specified it for ournext two jobs,” Wok Stehr (co-owner, Stehr Bro<strong>the</strong>rs builders in Auckland)told us later. “What we love most about J-Frame is that it doesn’t move,everything is straight and plumb at <strong>the</strong> end of <strong>the</strong> job.”Stehr Bro<strong>the</strong>rs builds houses in <strong>the</strong> upper end of <strong>the</strong> market (<strong>the</strong>ir nexttwo are NZ$1 million and NZ$3 million jobs) – clients who won’t toleratewalls that are not straight.J-Frame costs slightly more than conventional pine framing, but Stehrsays he easily recovers <strong>the</strong> extra with reduced labour costs. “On <strong>the</strong> jobwe just finished it cost <strong>the</strong> equivalent of a couple of man-days extra touse <strong>the</strong> J-Frame. But we probably saved at least a week’s labour. Forinstance, <strong>the</strong> cabinetry fitted straight in without having to straightenanything.” Supplier for <strong>the</strong> Stehr job was Smith Timber ITM.J-Frame is made at <strong>the</strong> Masterton (lower North Island) factory of JukenNew Zealand Ltd (JNL). It is an LVL framing product made for standarddomestic building applications.JNL assistant mill manager Paul Jordan says <strong>the</strong>y had planned J-Frameas an engineered wood solution for applications where straightness andstability were critical and sawn timber was loosing market share tonon-wood competitors.“We are confident J-Frame will compete head-on with steel framingonce people realise every stick is guaranteed fit-for-purpose. It is alsowood and, <strong>the</strong>refore, naturally better.”The product is available in fixed lengths from 2.4 to 6 m and in a seriesof cut-to-length standard stud sizes to 0.5 mm tolerance so <strong>the</strong>y can beused as studs without re-cutting. Offering accurately pre-cut studs alsoreduces waste generated at <strong>the</strong> frame plants.Every piece is machine stress graded to MSG8 or MSG10 to ensure aguaranteed consistent stiffness.Juken has overcome traditional problems with LVL, like nail-splittingalong <strong>the</strong> glue lines. No problems ei<strong>the</strong>r with <strong>the</strong> product drying whenwet. In Auckland’s wet winter, Stehr says <strong>the</strong> LVL actually seemed toresist water and stayed dryer (than solid pine framing), with no delays tolining <strong>the</strong> house.Jordan says lessons learned over 18 years supplying <strong>the</strong> highlydiscerning Japanese market are behind this product break-through.“We have done a lot of work with <strong>the</strong> bonding material and controllingmoisture content. Both are critical to preventing splitting.“The product leaves <strong>the</strong> factory between 14 and 18% moisture contentand is plastic-wrapped to maintain that level. Combine that with goodbuilding practices and you don’t have problems”JNL has also improved LVL uptake of preservative treatments byrefining its boron and CCA schedules to ensure <strong>the</strong> frames exceeded<strong>the</strong> standards. Treatment is to ei<strong>the</strong>r H1.2 or H3.2 in accordance withASNZS1604.4 and NZ3604 standards and is AsureQuality certified.The emphasis at JNL is on producing both high quality andenvironmentally sustainable products. J-Frame is made entirely of FSCcertifiedtimber grown in JNL’s own forests in <strong>the</strong> Masterton area, closeto <strong>the</strong> mill.TOP LEFT Every piece of J-Frame is machine stress graded to MSG8 or MSG10,ensuring consistent stiffnessTOp RIGHT Wok Stehr says J-Frame simply doesn’t movewww.timberdesignmag.com timberDesign AUSTRALASIA SPRING 200931

SPECIAL FEATUREA SENSEOF LIFERenaissance for outdoortimber in Japan"Wooden structures areassociated with <strong>the</strong> sense oflife and death lying in <strong>the</strong> heartof <strong>the</strong> Japanese."ABOVE Replication of a centuries-old candle-powered lighthouse – typical of timber’s traditional importance in JapanOPPOSITE TOP Sugi and o<strong>the</strong>r treated timbers are popular for ‘rest houses’ in <strong>the</strong> countrysideOPPOSITE BOTTOM Tokyo park pedestrian bridge in treated hinoki – end-grain protection is made into a feature (Feature photography courtesy Xyence Corporation)32www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

SPECIAL FEATUREThe words (opposite page) of Professor UEDA Atshushi of Kyoto SeikaUniversity are reflective of <strong>the</strong> rich traditions and history associatedwith <strong>the</strong> use of wood in Japanese society where it is much more than abuilding material; highly valued for its association with nature and for itscolour and texture.Although images of concrete and steel appear to dominate <strong>the</strong> crowdedand busy spaces that typify modern Japan, timber is quietly making acomeback – particularly outdoors.Treated timber, traditionally reserved for <strong>the</strong> dodai (sill plate) in domestichousing, is gaining wider acceptance as government agencies, keen toutilise vast domestic plantation resources, promote wood as a sustainableconstruction material.Historically, <strong>the</strong> use of indigenous Japanese timbers has been restricted,but with <strong>the</strong> new drive to use native sugi (a cypress) ra<strong>the</strong>r than importedtimbers such as American hemlock and Douglas fir, new opportunities arebeing created.Sugi is <strong>the</strong> national timber of Japan and as such is often seen aroundtemples. But it is much more abundant in <strong>the</strong> countryside where <strong>the</strong>reare some 4.5 million ha in plantations. The wood is reddish pink, scented,lightweight, strong, water and decay-resistant.Preservative treated sugi is gaining wide acceptance for its versatility anddecay and insect resistance in indoor and outdoor situations, particularly insou<strong>the</strong>rn regions of Japan where termites were inadvertently introduced afterWorld War II during <strong>the</strong> reconstruction process.Because modern wood preservatives such as Tanalith CY (Copper Azol),ACQ, DDAC and oil-borne products for house framing are recognised as saferthan some earlier formulations, treated timber is being specified across awider spectrum of <strong>the</strong> building industry. This is helped by <strong>the</strong> high standardof Japanese carpentry, where careful attention is paid to detailing such asend-grain protection and natural water shedding to avoid creating decayspots. In wea<strong>the</strong>r-exposed situations (particularly near <strong>the</strong> sea) Japanesebuilders also use corrosion-resistant fasteners such as stainless steel.To illustrate something of <strong>the</strong> renaissance of outdoor timber use in Japan,we have featured three recently completed projects, each with <strong>the</strong> assistanceof Xyence Corporation.Park bridgeThis contemporary interpretation of Japanese bridging in a Tokyo parkwas designed by Xyence Corporation and build with Tanalith CY-treatedhinoki. Bevelled and copper-capped posts assist with natural water sheddingand extend <strong>the</strong> life of <strong>the</strong> timber.Rest houseThis style of shelter is commonly seen on walking tracks in <strong>the</strong> Japanesecountryside and <strong>the</strong> design is reflective of old-style housing. The use of woodin Japan today directly reflects centuries of wood-based building and a highstandard of design and carpentry are typified by attention to detail.LighthouseAt 670 square km, lake Biwa is <strong>the</strong> biggest in Japan and it is dotted withnumerous shoreline parks for visitors to enjoy fishing, camping, walking andwater sports. Each park will typically have its own wooden facilities, includingstructures like <strong>the</strong> ‘lighthouse’ (opposite), made with preservative-treatedsugi and replicating <strong>the</strong> real candle-powered version from <strong>the</strong> Edo shogunera (circa 1603 – 1868).This feature is supported by Arch Wood Protection to highlightano<strong>the</strong>r environmentally responsible project using preservativetreatedwood products.For fur<strong>the</strong>r information about <strong>the</strong> featured projects or woodtreatment in Japan, please contact our Japan Manager, Ken Yahara:kyahara@archchemicals.comFor more general inquiries, please contact Arch Wood Protection at:Australia +61 2 9954 5433New Zealand +64 9 276 3646Asia +60 3 7981 4002www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 33

BUSH BUILDINGBEATING THEFLAME ZONEWood breaks through in bushfire-prone areasUntil recently timber buildings were not considered suitablefor <strong>the</strong> Flame Zone category of bushfire risk, and fire-retardantcoatings could not be used as a means to gain compliance.But as fire safety engineering expert and log home builderDr Tracy Wakefield writes, that has all changed.For many years now, my company(Appalachian Log Homes) has been buildingsolid timber homes in bushfire-prone areasaround Australia, and has struggled toovercome <strong>the</strong> misconception that timberbuildings cannot perform in such areas.But <strong>the</strong> good news is that heavy timbercan perform as an excellent wall system forbushfire-prone areas – ei<strong>the</strong>r in a solid wallsystem or through <strong>the</strong> use of heavy claddingproducts without specific treatments.Timber is one of <strong>the</strong> most renewable,sustainable and lowest carbon-emitting buildingmaterials we can use to address greenhousegas emissions in residential construction. It isalso a combustible material and much malignedby people with limited understanding of how itburns, especially in <strong>the</strong> Flame Zone category ofbushfire risk.But with <strong>the</strong> introduction of Australian testingstandards in 2007 to provide performancesolutions for building in bushfire-prone areas,we have finally been able to prove timber’s34www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009

BUSH BUILDINGsustainability as a building material, even in <strong>the</strong>Flame Zone.Removing carbon from <strong>the</strong> atmosphere,ra<strong>the</strong>r than simply reducing our additions, is<strong>the</strong> ultimate way of addressing climate change.Growing trees is <strong>the</strong> obvious answer, which iswhy timber is considered carbon positive,as <strong>the</strong> carbon taken from <strong>the</strong> atmosphere isstored in wood and in long-life constructions.The Building Code focuses on operationalenergy of buildings, but as <strong>the</strong>y become moreenergy-efficient, <strong>the</strong> embodied or lifecycleenergy of materials used in construction takeson more meaning. For example, using solidtimber (logs) or timber cladding on timberframes instead of conventional buildingmaterials can result in an 88% reduction ingreenhouse gas emissions. The differencein GHG emissions between constructing aresidential home in timber as opposed to brickand steel-frame is <strong>the</strong> equivalent of running acar for 17 years, or heating and lighting a homefor 25 years.New opportunitiesIn 1991 <strong>the</strong> first Australian Standard 3959 -Construction in Bushfire Prone Areas (AS3959)was published, and life in timber buildingbecame quite complicated, especially with <strong>the</strong>majority of our building projects located in <strong>the</strong>Blue Mountains west of Sydney. Updated in1999 and 2009, AS3959 has evolved to becomea more performance-based standard, whichis opening up opportunities for engineeredsolutions in timber.Two new testing standards – AS1530.8.1-2007 (up to BAL-40) and AS1530.8.2-2007 (forBAL-FZ) – provide performance solutions forbuilding in bushfire-prone areas. This means<strong>the</strong> excellent fire properties of heavy (<strong>the</strong>rmallythick) timber can finally be demonstrated in atrue performance scenario.Solid timber construction refers to a singleskin of 90 mm thick tongue and groove‘logs’ stacked to form a wall without <strong>the</strong> useof framing. Conventional construction ofwea<strong>the</strong>rboard fixed to timber stud framing canbe used in higher levels of bushfire attack(but not Flame Zone) if <strong>the</strong> cladding is a“fire-retardant treated” timber. AS3959-1999defines fire-retardant treated as tested toAS3837 with specific performance criteriafollowing an accelerated wea<strong>the</strong>ring process.Hardwoods such as spotted gum, merbau(kwila), blackbutt, silver top ash, red ironbark orred river gum comply with this definition withoutneeding special treatments. There is also anopaque paint process known as Ceasefire FR,which complies with <strong>the</strong> required testing and canbe used to coat wea<strong>the</strong>rboards or solid timber torender it “fire-retardant treated”.Performance testsThe pyrolysis (<strong>the</strong>rmal degradation) processcreates a char layer on <strong>the</strong> timber surface,which has a low <strong>the</strong>rmal conductivity that helpsinsulate unburnt timber from heat, <strong>the</strong>rebyslowing <strong>the</strong> combustion process.www.timberdesignmag.com timberDesign AUSTRALASIA SPRING 2009 35