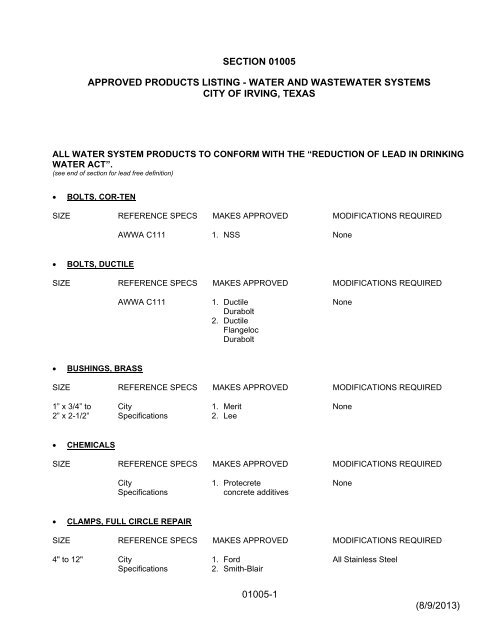

Approved Products List - City of Irving, Texas

Approved Products List - City of Irving, Texas

Approved Products List - City of Irving, Texas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

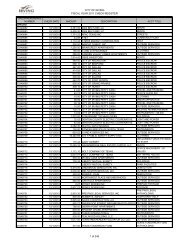

FITTINGS, ANCHOREDSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4” to 12” AWWA C153/ 1. GRADELOK NoneANSI A21.53,AWWA C104/ANSI A21.4FITTINGS, BRASSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3/4" to 2" AWWA C800 1. Mueller NoneASTM B-62 &2. Ford<strong>City</strong> 3. Cambridge Brass 3. Full port 3/4” & 1” angle meterSpecificationsstops not approved.4. A.Y. McDonald Mfg. Co. 4. Full port 3/4” & 1” angle meterstops not approved. 1 1/2” & 2”corporations not approved.5. Jones BrassFITTINGS, CAST IRON & DUCTILE IRONSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3" to 24" AWWA C110, 1. Tyler/Union All fittings shall be manufacturedC104, C111, 2. U.S. in the United States.C153 & <strong>City</strong>3. AmericanSpecifications4. GriffinFITTINGS, POLYVINYL CHLORIDESIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" to 15" SDR-35 PVC, 1. JM Eagle NoneSDR-26 PVC,2. RobintechASTM D3034,3. CertainteedD1869, F679 4. Clow5. North Star6. Vassallo7. Multi-Fittings8. Plastic Trends9. Flo-Control,Atlas Flexs18" and ASTM D1784, 10. JM Eagle “Perma-Loc” None01005-4(8/9/2013)

larger D2412 & D3212 11. Certainteed12. North StarFITTINGS, THREADED BRASS (ELLS, NIPPLES, TEES, ETC.)SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3/4” to 2” <strong>City</strong> 1. Merit NoneSpecifications2. Matco Norca3. Lee1-1/2” to 2” <strong>City</strong> 1. New Haven NoneSpecifications2. Midland3. CowtownFLANGED ADAPTERS (FLANGED JOINT RESTRAINT)SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4” to 24” ASTM A536, 1. Megaflange External PE wrapANSI/AWWA(EBBA Iron)C115/A21.15FLANGED COUPLING ADAPTERSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4” to 12” ASTM A536-71, 1. Ford-Ringwej NoneASTM D2000,2. Romac-FCA5013BA715, AWWA 3. Smith Blair 912C111-64 4. JCM - 301FLEXIBLE COUPLING ADAPTERSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3” to 12” <strong>City</strong> 1. Pipe Conx NoneSpecifications2. Mission Rubber3. Fernco4. Dallas Specialty5. NDS6” to 12” 6. Hymax 2000 SeriesFLEXIBLE EXPANSION JOINTSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4” to 36” AWWA/ANSI 1. Flex-Tend External PE wrap01005-5(8/9/2013)

C153/A21.53(EBBA Iron)MANHOLE INSERTSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED<strong>City</strong> 1. Parson NoneSpecificationsPlastics2. KnutsonMANHOLE REHAB MATERIALSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIREDN/A MS2A, MS2C 1. Strong Seal None2. QuadXMANHOLE RINGS AND LIDSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED30” 1. Bass & Hayes VRM-30 <strong>City</strong> <strong>of</strong> <strong>Irving</strong> Logo on all lids2. East Jordan Iron Works3. Tyler/UnionMANHOLES (FIBERGLASS)SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4' dia ASTM D3753-05, 1. HOBAS None& larger C581, D2584, 2. Containment SolutionsD695, D1790, & 3. Associated FiberglassAASHTO H-20EngineersMANHOLES (PRECAST CONCRETE)SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4' dia ASTM C-76 OR 1. Hanson Con mic Shield ® additive& larger C-478 & <strong>City</strong> 2. American InsustrialSpecificationsPrecast <strong>Products</strong>3. Hydro Conduit4. Concrete <strong>Products</strong>, Inc.5. Del Zotto <strong>Products</strong> <strong>of</strong> <strong>Texas</strong>, Inc.01005-6(8/9/2013)

6. The Turner CompanyMETER BOXSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED5/8” to 3/4” <strong>City</strong> Specifications 1. Brooks 36 Series Concrete Cover with CI Flip for 36Concrete BoxSeries Box with 1-7/8” holemodification for ERT, Old Castle Part#15001501” to 2” 2. Brooks 65 Series Concrete Cover with CI Flip for 65Concrete BoxSeries Box with 1-7/8” holemodification for ERT, Old Castle Part#1503210METER LOOPSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3/4” to 1” <strong>City</strong> 1. Ford NoneSpecifications2. MuellerMETER RESETERSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3/4” to 2” <strong>City</strong> 1. Ford NoneSpecifications2. Mueller1 1/2” to 2” 3. MacDonaldMETER, WATERSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3/4” to 2” <strong>City</strong> 1. Badger All meters must have ITRONSpecifications 2. Hersey Composite TERW--1300-202, 100W remoteread radios installed.3” to 12” 3. Mueller FM3/PD All meters must have ITRON4. Badger TERW--1300-202, 100W remote5. Sensus OMNI Fireline (F 2 ) read radios installed. All nuts andbolts to be stainless steel.01005-7(8/9/2013)

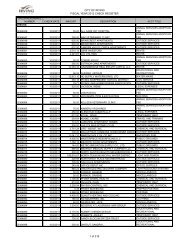

PIPE, WASTEWATERSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" to 16" SDR-26 PVC, 1. JM Eagle NoneASTM D2241,2. Vinyl TechClass 160 PVC 3. Certainteed4. Cresline(4”-8”)5. Diamond(4”-12”)6. NAPCO4" to 15" SDR-35 PVC, 7. JM Eagle NoneASTM D3034,8. Vinyl Tech& D18699. NAPCO10. Diamond11. Cresline(4”-12”)4” to 48” AWWA C111, C115 12. ACIPCO Ductile Iron Pipe only allowed with& C151written approval. PolybondPlusinterior lining.18" to 48” ASTM D1784, 13. JM Eagle “Perma-Loc” NoneD2412, F679, 14. NAPCO15. Diamond Plastics16. Vinyl Tech(18”-24”)12” to 96” SN46, SN72, 17. Hobas Pipe USA, Inc. NoneASTM D3262,D4161 & D2412PIPE, WASTEWATER (LINER)SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED6" to 24" ASTM F1216, 1. Insituform NoneASTM F1504, F1947 2. Miller Pipeline “ExFold And Form” pipePIPE SPACERS (ENCASED PIPELINES)SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" and <strong>City</strong> 1. Recon Pipe Corp. 1. For PVC pipe onlylarger Specifications raci2. Cascade Waterworks Mfg.Co.Style CCS, all stainless steel3. Advance <strong>Products</strong> & SystemsModel SSI, stainless steel4. Advance <strong>Products</strong> & Systems 4. For PVC pipe only01005-8(8/9/2013)

Model CI, Polyethylene5. Pipeline Seal & Insulator, Inc.S8G-2, stainless steel6. BWM CompanyModel SSPIPE, WATERSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" to 12" AWWA C900 PVC 1. JM Eagle NoneClass 305 DR 14 2. NAPCOClass 235 DR 18 3. Diamond Plastics4. Certainteed5. Vinyl Tech6. Plastic Trends6" to 12" AWWA C909 PVC 7. JM Eagle NoneClass 235Class 30514” to 24” AWWA C905 PVC 8. JM Eagle NoneClass 235 DR 18 9. NAPCO10. Diamond Plastics11. Certainteed(16” only)12. Vinyl Tech13. Plastic Trends>12" AWWA C303 RCCP 14. Hanson None(pretensioned)>4" AWWA C151 DIP, 15. American DIP only allowed with writtenC111 & C104 16. US Pipe approval from <strong>City</strong> EngineerClass 150 to 350PRESSURE TYPE VACUUM BREAKERSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED1/2” to 2” AWWA C510-89, 1. Conbraco NoneAWWA C511-89 4050302 to 40508022. Wilkins 720A3. Febco 7653/4” 4. Rainbird 0753/4” to 1” 5. Toro PVB3/4” to 2” 6. Watts 8001” 7. Rainbird 1001 1/4” 8. Rainbird PVB01005-9(8/9/2013)

1 1/2” 9. Rainbird PVB 1502” 10. Febco 775 (10) Air Inlet for use only with11. Rainbird PVB 200 approved double checkvalve assembly.2 1/2” to 10” 12. Cla-Val Model 273/4” and 1” 13. Febco 745REDUCED PRESSURE PRINCIPLE ASSEMBLIESSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED1/4” to 2”” AWWA C510-89 1. Wilkins 975XL NoneAWWA C5110-89 2. Conbraco40-204-02 40-208-023/4” to 3” 3. Watts 0093/4” and 1” 4. Conbraco 40-204-205-A2(Replaceable Seats)5. Conbraco 40-204-A2Z(U)3/4” to 1 1/2” 6. Cla-Val RP-23/4” to 2” 7. Badger #18. Hersey Model FRP-29. Flomatic RPZ3/4” to 4” 10. Watts 90911. Rainbird RPA-07512. Orion BRP13. Febco 825Y3/4” to 6” 14. Wilkins 5751” to 10” 15. Hersey 6C (15) Must be equipped with OS & Yshut<strong>of</strong>f valves if used on a fire1 1/2” to 10” 16. Febco 825 sprinkler system(16.) Must be equipped with OS & Y2” to 10” 17. Cla-Val RP-1 shut<strong>of</strong>f valves if used on a firesprinkler system2 1/2” to 6” 18. Ames 4000SS (17.) Must be equipped with OS & Y19. Febco 880V shut<strong>of</strong>f valves if used on a fire20. Hersey 6CM-Bronze sprinkler system2 1/2” to 8” 21. Febco 88001005-10(8/9/2013)

2 1/2” to 10” 22. Conbraco 40-20-A-C (22.) Must be equipped with OS & Y23. Hersey 6CM shut<strong>of</strong>f valve is used on a fire24. Wilkins 975XL sprinkler system3” to 10” 25. ITT Lawler RZ4” 26. Febco 8604” to 10” 27. Mueller H9506 (27.) Must be equipped with OS & Yshut<strong>of</strong>f valve if used on a firesprinkler system6” to 10” 28. Rainbird RPA-07529. Watts 90930. Febco 825YRESTRAINERS FOR CIP AND DIPSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4” to 12” ANSI B16.1, 1. UNIFLANGE NoneASTM A536 Series 200ANSI 4140400, 420, (castand D.I.P)3” to 48” 2. EBBA Iron Series 11004” to 24” 3. MJ Field Lok DIRESTRAINERS FOR PVCSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3” to 24” UNI-B-13, 1. Megalug (EBBA Iron), NoneASTM A536-80Series 2000PV,2000PEC, 2000SV4” to 12” 2. MJ Field Lok PV4” to 24” ANSI B16.1, 4140 3. Uniflange 1500CRETAINER GLANDSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4” to 12” <strong>City</strong> 1. Tyler/Union NoneSpecificationsSERVICE SADDLES ALL STAINLESS BAND TYPE01005-11(8/9/2013)

SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" to 12" <strong>City</strong> 1. Smith-Blair NoneSpecifications 2. JCM 103SERVICE SADDLES, DOUBLE STRAPSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED6" > O.D. AWWA C800 1. Smith-Blair Nylon coating with>3/4" tap ASTM B-62 2. Romac stainless straps or allsize ASTM A-98 3. Ford bronze, on all makes.<strong>City</strong> 4. JCM 406Specifications5. Muller DR2SSERVICE SADDLES, SINGLE STRAPSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED2" to 4" O.D. AWWA C800 1. Smith-Blair None1" tap ASTM B-62 2. FordASTM A-98 3. James Jones Includes sizes 2" to 12"<strong>City</strong> J-996Specifications 4. JCM 405WASTEWATER CLEANOUTSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4” residential ASTM F913 1. Stan Roberts CIG-1504 NoneASTM 3212Stan Roberts ATL-404ASTM D3034 2. Bass & Hays No. 404WASTEWATER DEGREASERSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIREDN/A <strong>City</strong> 1. Citrosolv - Oxford NoneSpecificationsChemical Co.2. Explode - VikingLabs, Inc.3. Grease-B-Gone -State Chemical Mfg. Co.4. Citra Solve W – K&L Supply5. Citro-Solv. – V&D Supply6. Formula P-88 – Selig7. Citra Solve – K&L SupplyWASTEWATER DEODORANT01005-12(8/9/2013)

SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIREDN/A <strong>City</strong> 1. Citrusan NoneSpecifications2. Zep-O-Ban3. Cherry Memories – K&L Supply4. Dubois Lake Charge – Dubois5. Selg-Lemon Breez – Selig6. Sewer Sweet – Allen’sSpecialty Shop7. HB – 140 Banish Cherry – H&BIndustriesWASTEWATER DIGESTERSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIREDN/A <strong>City</strong> 1. Sanfax 222 NoneSpecifications2. Red Hot – K&L Supply3. Seer Blaster – Allen’sSpecialty Shop4. Sewer Cleaner – V&DSupply5. Rout-R-Out – Last Group Ent.WASTEWATER LATERAL CONNECTION AND LINING (TRENCHLESS)SIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIREDN/A ASTM F-1216 LMK Technologies NoneBLD Services“Service Connection Seal + Lateral” None.WASTEWATER ROOT CONTROL CHEMICALSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIREDN/A <strong>City</strong> 1. Root X NoneSpecificationsSLEEVES, TAPPINGSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" to 12" AWWA C110 & 1. Mueller all stainless None<strong>City</strong>2. Romac-SST all stainlessSpecifications3. Ford-Fast all stainless4. JCM 432 all stainless5. Smith-Blair all stainless6. Tyler/Union> 12" 7. Requires Tapping sleeves & valvesspeciallarger than 12" require01005-13(8/9/2013)

approvalspecial approval on acase by case basis.VALVE, GATE RESILIENT SEATSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" to 12" AWWA C509, 1. Mueller A-2360 NoneC515, C550 & <strong>City</strong> 2. Clow 2640Specifications 3. American Flow AFC Series 25004. KenedyKen-seal II5. M & H6. U.S. Pipe Metroseal7. Stockham Resilient (7.) OZ All models shown – StemWedge 6-700,701changed to high strength.702,703,704-OZVALVES, AIR RELEASESIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED1" to 16" AWWA C512 & 1. APCO Per Project SpecificationsProject Specs.2. Crispin3. Val-MaticVALVES, BRASS WHEEL OPERATED GATESIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED1-1/2" to 2" <strong>City</strong> 1. Matco Norca NoneSpecifications2. WattsVALVES, BUTTERFLYSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED12" to 48" AWWA C504, C550 1. Mueller Internal epoxy coating& <strong>City</strong> 2. M & H (extra cost on allSpecifications 3. Kennedy makes.)4. Pratt-GroundhogVALVES, CHECK & DETECTOR CHECKSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" to 12" AWWA & <strong>City</strong> 1. Mueller NoneSpecifications2. AmericanDarling3. Kennedy (5a) Steel check valves4. Hersey must be epoxy5. Ames coated.01005-14(8/9/2013)

VALVES, CHECK BRASSSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED3/4" to 2" ASTM CDA 1. NIBCO NoneVALVES, CONTROLSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED4" to 30” Project 1. Ross Per Project SpecificationsSpecifications2. CLA-VAL3. Golden-Anderson4. APCO5. Muesco6. SingerVALVES, DOUBLE CHECK VALVE ASSEMBLIESSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED1/2” to 2 1/2” AWWA C510-89, 1. ConbracoAWWA C511-89 4010302 to 40108023/4” 2. ITT Lawler DC-33/4” to 1” 3. Watts 007MIQT4. Febco 805YR3/4” to 1 1/2” 5. CLA-VAL D23/4” to 2” 6. Rain Bird DCA-075 to 2007. Flomatic DCV8. Conbraco 40-104-A2T to40-108-A2T9. Wilkins 550 & 950XL10. Hersey FDC3/4” to 3” 11. Watts 007 & 0093/4” to 4” 12. Orion BDC3/4” to 10” 13. Febco 805 & 805Y 13.) 805 Must be equipped with14. Watts 709 OS&Y shut <strong>of</strong>f valves if used on a15. Wilkins 950 fire sprinkler system.14.) Must be equipped with OS&Yshut <strong>of</strong>f valves if used on a firesprinkler system.1” to 10” 16. Cla-Val D 16.) Must be equipped with OS&Yshut-<strong>of</strong>f valves if used on a fire1 1/4” to 2” 17. Buckner 24102 to 24104 sprinkler system.2” to 6” 18. Hersey F-7201005-15(8/9/2013)

2” to 10” 19. Hersey #12 1/2” to 6” 20. Ames 2000-SS-DCA 20.) Must be equipped with OS&Yshut-<strong>of</strong>f valves if used on a firesprinkler system.2 1/2” to 10”21. Febco 805YD3” to 6” 22. Wilkins 550 22.) Must be equipped with OS&Yshut-<strong>of</strong>f valves if used on a fire3” to 8” 23. Rain Bird DCA-250-800 sprinkler system.3” to 10” 24. Conbraco 40-100-10A-C 24.) Must be equipped with OS&Y25. Hersey #2 shut-<strong>of</strong>f valves if used on a firesprinkler system.4” to 6” 26. Febco 850, 87027. Hersey E-14” to 8” 28. Kennedy B-14” to 10” 29. Ames 2000-DCA 29.) Must be equipped with OS&Y30. Viking A-1 shut <strong>of</strong>f valves if used on a fire31. Kennedy B-2 sprinkler system.32. Mueller H9505 32.) Must be equipped with OS&Yshut <strong>of</strong>f valves if used on a firesprinkler system.VALVES, DOUBLE CHECK VALVES DETECTOR ASSEMBLIESSIZE REFERENCE SPECS MAKES APPROVED MODIFICATIONS REQUIRED2 1/2” to 6” AWWA C510-89, 1. Ames 3000-SS-DCDAAWWA C511-89 2. Apollo DCDA 4SG-6002 1/2” to 10” 3. Wilkins 950DA4. Watts 757DCDA3” 5. Watts 007DCDA3” to 10” 6. Watts 709DCDA7. Hersey DDC-II8. Febco 806, 806YD4” 9. Conbraco 40-60A-034” to 6” 10. Febco 8564” to 8” 11. Febco 8764” to 10” 12. Cla-Val Model 1613. Ames 3000-DCDA6” 14. Conbraco 40-60C-038” 15. Conbraco 40-60E-0301005-16(8/9/2013)

10” 16. Conbraco 40-60G-03For the purpose <strong>of</strong> these Specifications, the term ‘lead free’ means-A. Not containing more than 0.2 percent lead when used with respect to solder and flux; andB. Not more than a weighted average <strong>of</strong> 0.25 percent lead when used with respect to the wettedsurfaces <strong>of</strong> pipes, pipe fittings, plumbing fittings, and fixtures.The weighted average lead content <strong>of</strong> a pipe, pipe fitting, plumbing fitting, or fixture shall be calculated byusing the following formula: For each wetted component, the percentage <strong>of</strong> lead in the component shall bemultiplied by the ratio <strong>of</strong> the wetted surface area <strong>of</strong> that component to the total wetted surface area <strong>of</strong> theentire product to arrive at the weighted percentage <strong>of</strong> lead <strong>of</strong> the component. The weighted percentage <strong>of</strong>lead <strong>of</strong> each wetted component shall be added together, and the sum <strong>of</strong> these weighted percentages shallconstitute the weighted average lead content <strong>of</strong> the product. The lead content <strong>of</strong> the material used toproduce wetted components shall be used to determine compliance. For lead content <strong>of</strong> materials thatare provided as a range, the maximum content <strong>of</strong> the range shall be used.END OF SECTION01005-17(8/9/2013)