brozura tapone - EN 2012.indd - Coastone Oy

brozura tapone - EN 2012.indd - Coastone Oy

brozura tapone - EN 2012.indd - Coastone Oy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

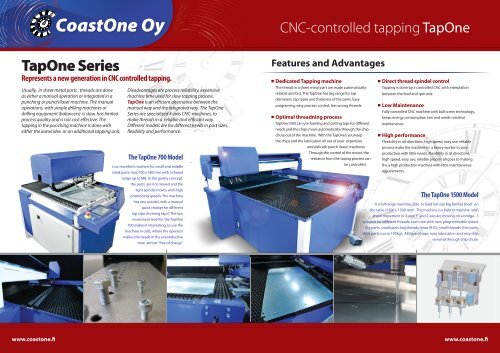

CoastOne <strong>Oy</strong>CNC-controlled tapping TapOneTapOne SeriesRepresents a new generation in CNC controlled tapping.Usually, in sheet metal parts , threads are doneas either a manual operation or integrated in apunching or punch/laser machine. The manualoperations, with simple drilling machines ordrilling equipment (balancers) is slow, has limitedprocess quality and is not cost effective. Thetapping in the punching machine is done witheither the autoindex or an additional tapping unit.Disadvantages are process reliability, expensivemachine time used for slow tapping process.TapOne is an efficient alternative between themanual way and the integrated way. The TapOneSeries are specialized 4-axis CNC-machines, tomake threads in a reliable and efficiant way.Different models are for different needs in part sizes,flexibility and performance.The TapOne 700 Modelis an excellent machine for small and middlesized parts; max 700 x 580 mm with a threadrange up to M8. In the gantry concept,the parts are not moved and thelight spindel moves with highpositioning speeds. The machinehas one spindel, with a manualquick change for differenttap sizes (forming taps). The lowinvestment level for the TapOne700 makes it interesting, to use themachine in cells, where the operatormakes the treads in the unproductivetime almost ”free of charge”.Features and AdvantagesDedicated Tapping machineThe thread in a sheet metal part are made automatically,reliable and fast. The TapOne has big range for tapdiameters, tap types and thickness of the parts. Easyprograming, easy process control, less wrong threads.Optimal threadning processTapOne1500 can use forming and cutting taps for differentneeds and the chips move automatically, through the chipchute out of the machine. With the TapOne’s you keepthe chips and the lubrication oil out of your expensiveand delicate punch (laser) machines.Through the control of the motor, theresitance from the taping process canbe controlled.Direct thread spindel controlTapping is done by a controlled CNC with interplationbetween the feed and rpm axis.Low MaintenanceFully controlled CNC machine with ball screw technology,keeps energy consumption low and needs minimalmaintenance.High performanceFlexibility in all directions, high speed, easy use, reliableprocess make the machine to a heavy worker in yourproduction with little needs. Flexibility in all directions,high speed, easy use, reliable process all goes to makingthe a high production machine with little maintainencerequirements.The TapOne 1500 ModelIs a full range machine, able to load full size big format sheet onthe table (1500 x 1500 mm). The machine is a hybrid machine withsheet movement in X axis; Y and Z axis are moving on a bridge. 3spindels for different threads; each one with own programmable speed.Big parts, small parts, big threads (max M10), small threads, thin parts,thick parts (up to 100kg). All type of taps, easy lubrication and easy chipremoval through chip chute.www.coastone.fiwww.coastone.fi

CoastOne <strong>Oy</strong>CNC-CONTROLLED TAPPINGCoastOne <strong>Oy</strong>CNC-CONTROLLED TAPPINGTECHNICAL DATATECHNICAL DATA DIM<strong>EN</strong>SIONS TAPONE700 TAPONE1500Tap diameter range mm M2.5 - M8 M2.5 - M10Taps/min (M5, pith 20 mm) 60 50Tapping spindles 1 3X-axis mm 700 1500Y axis mm 580 1500 (1290)Z-axis mm 60 120X-axis speed mm/s 800 800Y axis speed mm/s 800 800Z-axis speed mm/s 300 300Spindel speed U axis rpm 0…2000 0…2000Tapping principle CNC (U,Z, interpol.) CNC (U,Z, interpol.)Positioning accuracy (X, Y) mm +/- 0.05 +/- 0.05Tap type forming forming/cuttingOil spray lubrication programmable programmableChip chute not available includedtable brush brushmax table load kg 35 100Table height mm 900 900Power consumption kW 1 1,5Power connection 400V/16A 400V/16AAir pressure bar 6 6Dimensions LxWxH cm 870x156x135 258x227x165Weight kg 350 800Control Omron OmronControl touch screen touch screenJetcam Programing option optionNetwork connection (Option) included includedwww.coastone.fiCoastOne <strong>Oy</strong>Tuottajantie 27 A 160100 Seinäjoki, Finlandwww.coastone.fi