Climax Mine - Leadville Today

Climax Mine - Leadville Today

Climax Mine - Leadville Today

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

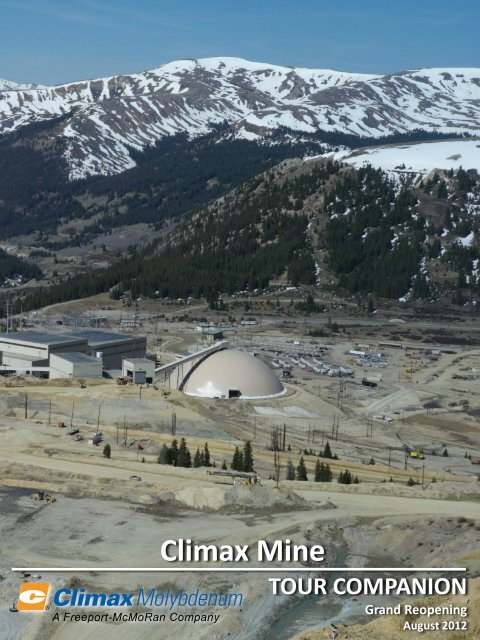

<strong>Climax</strong> <strong>Mine</strong>TOUR COMPANIONGrand ReopeningAugust 2012

WelcomeWelcome to the <strong>Climax</strong> <strong>Mine</strong>. Freeport-McMoRan Copper & Gold isthe world’s largest producer of molybdenum. We producemolybdenum at our <strong>Climax</strong> and Henderson mines in Colorado and asa by-product at several of our copper operations in North and SouthAmerica.<strong>Climax</strong> <strong>Mine</strong>, located a short distance from Henderson operations, isbelieved to be the world’s largest, highest-grade and lowest-costundeveloped molybdenum ore body in the world.Safety is our highest priority, and we will provide you with personalsafety equipment as you tour the facilities.Table of ContentsLocation 3History 4-5Fast Facts 6Operations Overview 7Reserves and Resources 8Exploration 9<strong>Climax</strong> <strong>Mine</strong> Site Map 10-11<strong>Mine</strong> 12-13Mill 14-15Tailings & Water Treatment Plant 16Environmental 17Workforce 17Safety 18Community Development 19Who is Freeport-McMoRan Copper & Gold? 20Molybdenum Fast Facts 21<strong>Climax</strong> Molybdenum Company 22-232

LocationCopperMountainConferenceCenterNUtahArizonaPhoenixMill9 Denver91DillonHenderson<strong>Mine</strong>6Keystone<strong>Climax</strong><strong>Mine</strong><strong>Leadville</strong>ColoradoNewMexico<strong>Climax</strong><strong>Mine</strong>40EmpireTownOperation10 milesN<strong>Climax</strong> <strong>Mine</strong> is located 13miles northeast of <strong>Leadville</strong>,Colorado, off Colorado StateHighway 91 at the top ofFremont Pass. The mine isaccessible by paved roads andis located in a mountainregion. The highest benchelevation is approximately4,050 meters (13,290 feet),and the ultimate pit bottom isexpected to be approximately3,100 meters (10,170 feet).This region experiencessignificant snowfall during thewinter (23 feet/year onaverage). The operationsencompass about 14,339acres.3

HistoryThe roots of <strong>Climax</strong> <strong>Mine</strong> run deep, tracing its name and origin to the early mining days in the highmountains of Colorado. The name “<strong>Climax</strong>” derives from the <strong>Climax</strong> railroad station which was built at thetop of the Continental Divide as a place to uncouple helper locomotives after the long climb from Denverto the mining town of <strong>Leadville</strong>.1778 Swedish scientist, Carl Wilhelm Scheele, positivelyidentifies molybdenum.1879 A large, gray, mineralized outcropping was discoveredby Charles Senter on the western slope of BartlettMountain.1891 French company first uses molybdenum as an alloyingelement in the production of armor plate; with adensity of half that of tungsten, molybdenum is aneffective replacement for tungsten in numerous steelalloy applications.1895 Colorado School of <strong>Mine</strong>s Professor Rudolph George identified the Bartlett Mountain samples asmolybdenite (molybdenum disulfide).1916 Max Schott, a miner and businessman, formed <strong>Climax</strong> Molybdenum Company to recover and processthe metal.1917 World War I caused tungsten demand to soar and severely strain its supply, and as a result,molybdenum was substituted for tungsten in many hard and impact resistant steels; developmentbegins at <strong>Climax</strong> in response.1918 <strong>Climax</strong> mine begins production; on April 2, <strong>Climax</strong> ships first concentrate totaling 21,000 pounds witha market value of $100,000; <strong>Climax</strong> is a major contributor to the allied war effort; <strong>Climax</strong> ceasesoperations after World War I because of the reduction in molybdenum demand; decrease in demandtriggers research and development program to develop civilian applications for molybdenum.1924 <strong>Climax</strong> reopens and runs almost continuously through 1982.1941 <strong>Climax</strong> supplies the Allied molybdenum throughout World War II.1945 <strong>Climax</strong> becomes the world’s largest underground mine.<strong>Climax</strong> Management, 1917<strong>Climax</strong> <strong>Mine</strong>, ~194041957 <strong>Climax</strong> and American Metal TradingCompany merge to become AMAX.1961 <strong>Climax</strong> Molybdenum Companyoptions the URAD <strong>Mine</strong> on RedMountain, which ceased productionin 19451962 Feasibility study commences on theURAD deposit.1963 Development begins at the URAD<strong>Mine</strong>.1964 Through deep exploratory drillingfrom the URAD mine, RobertHenderson discovers the Hendersonore body.

1967 First ore reserve estimation of Henderson completed.1968 Henderson shaft sinking begins.1969 Henderson underground development initiated.1971 Excavation of the 10-mile haulage tunnel begins.1973 Open pit production begins at <strong>Climax</strong> at the rateof 4,000 t/d.1975 <strong>Climax</strong> production from the Storke Level, 600 Level & the open pit hits 60 million pounds of moly.1976 <strong>Climax</strong> <strong>Mine</strong> sets an all time record of 61 million pounds produced; on July 7, Henderson beginsproduction at the rate of 10,000 tons per day via panel caving from the 8,100 ft level.1979 <strong>Climax</strong> <strong>Mine</strong> reaches the 400 million ton milestone.1980 <strong>Climax</strong> and Henderson mines produce a record 100 million pounds of molybdenum; employmentpeaks at 3,000 at <strong>Climax</strong> and at 2,000 at Henderson.1982 <strong>Climax</strong> and Henderson mines suspend production as a result of economic downturn.1984 <strong>Climax</strong> and Henderson mines resume production.1987 <strong>Climax</strong> ceases operations due to poor economic conditions and a weak molybdenum market.1989 <strong>Climax</strong> operates at reduced rates until 1991.1991 At Henderson, panel caving commences from the 7,700-foot level.1993 Cyprus <strong>Mine</strong>rals and AMAX merge becoming Cyprus AMAX.1995 With increased molybdenum demand, <strong>Climax</strong> reopens for 5 months and then ceases operations;Henderson produces 39 million pounds.1996 Project at Henderson commences to replace train with an underground crusher and 15 mile longconveyor system.1999 Phelps Dodge purchases Cyprus AMAX; conversion from train haulage to conveyor system completed.2000 Henderson modernization is completed with over 1 million man hours worked without a lost timeaccident; conveyor system successfully operating, yielding highest efficiencies ever achieved atHenderson.2003 At Henderson, development of the 7,210-foot level begins.2004 Initiation of the 7,210-foot level begins at Henderson.2005 7,210-foot level production begins atHenderson.2007 FCX acquires Phelps Dodge; FCX announcesrestart of <strong>Climax</strong>.2008 With change in market conditions, FCX defersrestart of <strong>Climax</strong>.2010 Construction activities are advanced for restartof <strong>Climax</strong>.2011 Construction activities continue at <strong>Climax</strong>.2012 Commercial operations starts at <strong>Climax</strong> withfirst shipment of molybdenum in May.5<strong>Climax</strong> <strong>Mine</strong>

Fast Facts<strong>Climax</strong> <strong>Mine</strong>FCX’s interest 100%Reserves*578 million lbs molyProduction20 million lbs in 201330 million lbs/year at full rateswith potential to double**OperationsOpen-pit mine andConcentratorUnit Cash Costs(per lb molybdenum)~$6(projected)Project CapitalImplied Reserve Life(Reserves/Full Production)Employees$760 millionwith ramp-upin 201219 years400 (full rates);1,000 contractors at peakduring construction* as of 12/31/11 using a long-term molybdenum price of $10; there is substantial upside with higher price assumptions** <strong>Climax</strong> is currently ramping up in 2012; depending on market conditions, <strong>Climax</strong> may increase to 30 million lbs/year6

Operations OverviewAt the <strong>Climax</strong> <strong>Mine</strong>, ore from the mine is processed in the concentrator (mill) toproduce a molybdenum concentrate.OPEN PIT MINE(drill & blast, load & haul)Ore tothe millMILL/CONCENTRATOR(crushing & conveying, concentrating)CrushedOreGrindingSlurryFlotationConcentrateTailingsMolybdenumConcentrateTailings toTailings DamThis molybdenum concentrate is sent to other facilities for additional processinginto saleable products. Please refer to pages 22-23 for additional detail.7

Reserves and ResourcesAs of 12/31/11, FCX’s consolidated molybdenum reserves approximate 3.4 billion lbs withHenderson and <strong>Climax</strong> comprising about 30% of the consolidated reserves and the balance as byproductat certain of FCX’s copper mining operations. Reserves, net to FCX, total 3.1 billion lbs.RecoverableOre tons Grade Recovery MolyReserves * million mt % Mo % billion lbs<strong>Climax</strong> 187 0.16 89% 0.58Henderson 121 0.17 85% 0.40Subtotal 308 0.16 87% 0.98By-product 2.44FCX consolidated 3.42FCX net interest 3.09ConsolidatedMolybdenum Reserves3.4 billion lbsCerroVerde21%Sierrita36%Bagdad12%Henderson12%<strong>Climax</strong>17%Other2%* based on a $10 long-term molybdenum price.By-productPrimaryAt $12 molybdenum, consolidated resources (mineralized material) approximate 3.5 billionpounds of contained molybdenum with 45% at Henderson and <strong>Climax</strong>.ContainedOre tons Grade MolyResources ** million mt % Mo billion lbs<strong>Climax</strong> 332 0.15 1.08Henderson 158 0.15 0.52Subtotal 490 0.15 1.60By-product 1.93FCX consolidated 3.53FCX net interest 3.40ConsolidatedMolybdenum Resources3.5 billion lbsBy-product55%Henderson15%<strong>Climax</strong>30%** based on a $12 long-term molybdenum price. Geologic resources (e.g. mineralized material, including measuredand indicated) are not included in reserves. The geologic resources will not qualify as reserves until comprehensivestudies establish their legal and economic feasibility. Accordingly, no assurance can be given that the estimatedresources and mineralization will become proven and probable reserves.8

6000 E6000 E8000 E8000 E10000 E10000 E12000 EExplorationConsistent with our view of “greenfield opportunities at our brownfield locations”, we continueto explore near our existing mines with a focus on opportunities to expand reserves that willsupport additional future production capacity. We have significant efforts focused on targets at<strong>Climax</strong>.ExplorationObjectives• Evaluate and drill testexploration targets eitheras extensions to knownmineralization or thepotential for a newsystem at depthResource Potential<strong>Climax</strong> OrebodyPlan View10,880 Bench$15 Cone$10 ConeUGCaveN8000 N7000 N6000 N• Through a drill plan,continue to convertinferred blocks within thereserve pit andmineralized materialcones to a measured orindicated classification (asreported in our publicdisclosures)Exploration DrillingFinal Pit3000 NUnmineralizedSedimentsWest of theMosquito FaultX-Section6000 N13,000 ft12,000 ftUnmineralizedSedimentsWest of theMosquito FaultFinal Pit4000 N5000 NMo Grade0.00% Mo0% to 0.03%0.03% to 0.06%0.06% to 0.12%0.12% to 0.18%0.18% to 0.24%0.24% to 0.30%0.30% to 0.36%> 0.36%OriginalTopography11,000 ft$10 Cone$15 Cone10,000 ftThe <strong>Climax</strong> ore body is a porphyry molybdenum deposit with molybdenite as the primary sulfide mineral.The molybdenum mineralization is associated with the Middle Tertiary age highly differentiated rhyoliteand granite porphyry composite stock that intrudes the Precambrian basement rocks. Host rocks for themineralization include the Precambrian Idaho Springs schist and gneisses intruded by Silver Plume graniteas well as the Tertiary intrusive stocks.The <strong>Climax</strong> stock consists of four nested rhyolite or granite porphyry intrusions which were in turnintruded by late porphyritic dikes. The ore mineralization forms inverted cups or shells draped over thetops of the intrusions and these can be overlapping or stacked. <strong>Climax</strong> is considered the premier exampleof this class of deposit, which as a group has been baptized “<strong>Climax</strong>-type” porphyry molybdenum deposits.9

<strong>Climax</strong> <strong>Mine</strong> Site MapMayflower TailingsStorage FacilityTenmile TailingsStorage FacilityRobinson LakeRobinson TailingsStorage Facility(reclamationsubstantiallycomplete)Mill<strong>Mine</strong>N1 mile10

<strong>Climax</strong> <strong>Mine</strong> Site MapOpen pitConcentratorRobinson TSF (reclamationsubstantially complete)Mayflower TSFTenmile TSFRobinson LakeTSF = Tailings Storage FacilityN3,000 ft11

<strong>Mine</strong>Open Pit <strong>Mine</strong>The open-pit mine operation involvesdrilling, blasting, loading by shovel andtruck haulage of the mined material. Lowgrade,stockpiled ore is expected to beprocessed in the last three years of theproject. Two existing waste rock stockpileswill be built at a 3:1 slope to facilitate thereclamation process that will occurconcurrently with mining activities.The fleet will consist of hydraulic shovels,Caterpillar 789 haul trucks (195-ton haultrucks) and support equipment. Truckswill deliver ore to the existing primarygyratory crusher. The crushed product isconveyed to a covered coarse orestockpile to feed the mill.MosquitoFault12Final PitCaved Material$15 Cone$10 Cone 2,000 ftN

Key <strong>Mine</strong> Statistics• Open pit is approximately 1 to 1.5 miles indiameter• Current pit is 1,900 ft deep; final pit willbe 3,000 ft deep• Mining rates currently average 80,000st/d & are expected to peak at 110,000st/d over the next 10 years• 110 people work in the open pit• Life of mine from January 1, 2012,tonnage mined will total 487 million st• Consume 5 mm gallons of diesel per year• 1.4:1 strip ratio, life-of-mineKey Mining Equipment• Two O&K 340 hydraulic shovels (45 cu. yd)• 7 x Caterpillar 789 haul trucks (195 st load)• 1 x Caterpillar 789 water truck• 4 x Caterpillar D9/D10 dozers &2 x Caterpillar 824 rubber tire dozers• 2 x Caterpillar 988 & 944 loaders• 2 x Caterpillar 16M graders• 2 x Atlas Copco 275 Pit Viper blast holedrills & 1 x Atlas Copco L8 secondary drill• Miscellaneous support pieces ofequipmentMining in the PitLoaderShovelHaul Truck13

MillMillCoarse OreStockpileFlotationPrimaryCrusherCoarse OreStockpileSAG MillFlotationPrimary CrusherPebble CrushersBall MillNew Mill FacilitiesThickenerAt full rates, the mill will operate at 28,000st/d. The ore will be sent to a SAG mill and thento a ball mill for grinding. In the flotationcircuit, water and reagents will be added tocreate a slurry. The reagents will cause theparticles containing molybdenum to float whenthe slurry is mixed with air, and this allowsseparation of the moly from the host rock. Theworthless ground rock (tailings) is sent to thetailings dams.Recoveries are expected to average 89% formolybdenum. Final concentrate will bethickened, pumped to storage tanks, filteredand dried to be stored in day bins. The driedconcentrate will be packed in supersacks andshipped by truck to offsite facilities.14Key Mill Statistics• Full rates of 28,000 st/d (short tons per day)• 115 people work in the mill facility• 89% Mo mill recovery• Ore contains 0.16% Mo (3 lbs Mo/st ore)• Final product packed in supersacks (3,850pounds each)• At full rates, mill will produce 30 millionpounds of molybdenum per year (over80,000 pounds per day)Key Mill Equipment• 34 ft x 17 ft SAG mill• 22 ft x 36 ft Ball mill• 2 x Pebble crushers• Flotation circuit (with Outotecflotation cells)• 3 x M1000 Isa Mills• 2 x Pressure Filters• Thickener

Ore from the Coarse Ore StockpileSAG MillBall MillsCycloneFlotationConcentrate in Supersacks15

70Tailings & Water Treatment PlantTailings from the mill process will be hydraulically70transported to tailings dams. Over its Dillon history,<strong>Climax</strong> has managed 6 tailings storage in differentfacilities. The two active facilities on Dillon site fortailings storage are Tenmile and Mayflower.The plan for tailing and process water is 9based on24a phased approach with the first phase of tailingdeposited in the Tenmile Tailings91Storage Facility(TSF). In the first phase, the mill water reclaimsystem will be from the Tenmile TSF to storage inRobinson Lake. Water <strong>Climax</strong> in Robinson Lake will bepumped to the mill. Excess <strong>Mine</strong>water will be treatedbefore it is discharged from the property. Duringthe second phase, tailings will be deposited inthe Mayflower TSF and a new water treatment N2 milesplant will be constructed. The new water<strong>Leadville</strong>treatment plant replaces the Mayflower TSF forstage 2 metals removal.Water Return Lineto Mill70Influent Pipelineto WaterTreatment PlantMayflower TSF**6Flood ControlSystem*Reservoir1,500 ftNew WaterTreatmentPlant285N1 mileEagle ParkNMayflowerProject Overview<strong>Climax</strong> <strong>Mine</strong>RobinsonLakeFlood ControlSystem(project)TenmileTSFMayflower TSF(project)ConcentratorOpen PitWaterTreatmentPlant (project)• Tailings Storage Facility• New TSF as Tenmile TSF willbe filled in next few years• Tailings area prep, tailingsdelivery line & water returnsystem• New Water Treatment Plant• Mayflower pond currentlyused as water treatmentfacility• With conversion ofMayflower to TSF, watertreatment plant required• Use proven technology• Flood Control System• Flood management & routingof water off Mayflower TSFReplacement Flood Control SystemMainTunnelInletInlet3Inlet2Inlet1*New Water Treatment PlantMayflower* extends out of view beyond tailing damPlant Rendering16

Environmental• <strong>Climax</strong> <strong>Mine</strong> has obtained all needed regulatory permits and approvals for the restart ofoperations• <strong>Climax</strong> <strong>Mine</strong> has an exceptional compliance record and is regulated by a number of state,federal and local environmental agencies, including: US EPA US Army Corps of Engineers Colorado Division of Reclamation, Mining& Safety Colorado Division of Water ResourcesWorkforce Colorado Department of Public Health andEnvironment (Air Pollution Control Division, WaterQuality Control Division, Hazardous Materials &Waste Management Division) Lake, Summit and Eagle County Health andPlanning Departments• <strong>Climax</strong> <strong>Mine</strong> has been actively reclaiming areas no longer needed for mining: Approximately 500 acres fully reclaimed since 1997 Active reclamation occurring on approximately 900 acres <strong>Climax</strong> <strong>Mine</strong> received the Colorado Division of ReclamationMining & Safety’s 2010 “Hardrock Reclamation Award” forChannel Restoration in the Headwaters of the Arkansas River;previous state awards were given out for reclamation of aformer tailing storage facility into the Eagle Park Reservoir(1998) and for the biosolids composting operation to createfuture reclamation cover material (2000), which also won anational EPA award in 2001.Eagle Park Reservoir<strong>Climax</strong> <strong>Mine</strong> currently employs about 350 people.Professional positions include Mining, Mechanical, Electrical,Civil and Environmental Engineering, Global Supply Chain,Human Resources, Health and Safety, as well as a wide varietyof trade positions. Our trade careers include Electricians, ITTechnicians, Equipment Operators, Maintenance Mechanics,Draftsmen, Survey and Warehouse Technicians.Our operations rely heavily on the dedication and expertise ofour employees. We are committed to hiring people withdiverse backgrounds to help build a strong foundation for ourbusiness. We value diversity in the workplace and strive tofind people who share our core values including workingsafely, acting in a manner that is fair and respectful, instillingtrust in each other and the organization and acting honestlyand with integrity throughout our business.We support our employees and community by creating a safework environment, utilizing top technology and offeringcompetitive pay and benefits.17ChaffeeLakeSummitGrand, Clear Creek & Eagle<strong>Climax</strong>OtherEagleLakeGrandClearCreekSummitChaffee

FCXUS Mining**SafetyThe safety & health of all employees, along with ourcommitment to the environment, are of the highestpriority. Our objective is zero work place injuries andoccupational illnesses. While production and costs areimportant, these must never take precedence over safety,employee health or the environment. We believe that allinjuries and occupational illnesses are preventable. Wealso believe that safety and health are integral to, andcompatible with, all other functions in the organization andthat proper safety and health management will enhanceproduction and reduce costs.The safety culture at <strong>Climax</strong> <strong>Mine</strong> is embedded into ouroverall work culture and how we face challenges each day.Key Elements of our Safety Culture• We are each responsible & in control of our safety.• We are responsible for holding each other accountable.• We are each responsible for evaluating the risksinvolved in our assigned tasks, and taking all necessarysteps to manage them.• Our brains are our most important piece of PPE.• We drive for continual improvement.• We are each responsible to come to work “Fit for Duty”.<strong>Climax</strong> <strong>Mine</strong> engages employees, contractors, vendors andvisitors in our health & safety efforts. Our programs aredesigned to make safety an integral part of our lives on andoff the job. These efforts include OHSAS 18001:2007Certification, Comprehensive Risk Management, FatalityPrevention Initiative, Industrial Hygiene Monitoring, Aboveand Beyond Regulatory Compliance, ComprehensiveTraining Programs, Fatigue Management & ContractorSafety Guidelines.Our <strong>Climax</strong> Emergency Response Team is ready to respondto emergency situations that could be encountered. The<strong>Climax</strong> <strong>Mine</strong> Emergency Response Team has an ambulance,wildland fire truck, paramedic, EMTs, and first responders,trained fire brigade, ropes rescue team, surrounding EMS(Emergenecy Medical Services) communications andNIMS/ICS (National Incident Management System/IncidentCommand System) command structure.18HardHatPersonal ProtectiveEquipment (PPE)Our BrainEar ProtectionAnnual Safety TRIR*(including contractors)2.61 2.530.74 0.65 0.612009 2010 2011SafetyGlassesSteel ToeBoots2.29* Total Reportable Incident Rate (TRIR) arenumber of incidents per 200,000 hoursworked** metal mining sector industry average asreported by US <strong>Mine</strong> Safety & HealthAdministration (MSHA)

Community DevelopmentFreeport‐McMoRan Copper & Gold and <strong>Climax</strong> Molybdenum Company strive to create value for ourcommunities, our employees and our businesses, and act as a catalyst for positive development in ouroperating communities through the following initiatives:• Stakeholder Engagement and Partnership. <strong>Climax</strong> Molybdenum established three regionalCommunity Partnership Panels with representatives from Lake, Summit, Chaffee, and Eagle; ClearCreek; and Grand Counties to identify, examine and define regional community issues and priorities.• Strategic Community Investments and Community Investment Funds. The company believes ininvesting in programs that support important community needs and drive sustainability. Thecompany invests funds to address five focus areas that are foundations of sustainable communitiesand are generally aligned with local priorities: education, economic development, safety, health andwellness, the environment, and cultural heritage and preservation. The company also works toinvolve community members in the process of identifying, cultivating and selecting meaningful socialinvestments.• Educational Grants. Through our STEM Innovation grants program, teachers, school administrators,PTA officials and/or parent volunteers can apply to receive up to $5,000 every year to support thedevelopment, improvement or expansion of science, technology, engineering and math (STEM)instructional programs at K‐12 schools or classrooms located near our operations. We also offer minigrantsup to $500 to support a range of other classroom needs.• Matching Gifts Program. This program matches any employee’s charitable financial contributions toqualified organizations such as educational institutions, social service organizations, hospitals,environmental organizations, cultural institutions, and United Way chapters.• Scholarship Programs. Scholarships are available each year to students attending specific collegesand universities as well as occupational and technical training programs to pursue technical,industry‐related degrees such as engineering, geology or electrician certification.• Employee Involvement. <strong>Climax</strong> Molybdenum employees also give of their time to support communityorganizations and programs through the company’s High Grade Helpers employee volunteerprogram.We support sustainable development by investing in locally-identified priorities.• Over $1 million invested in Colorado communities alone during 2011.• In 2011, became a funding partner in 100Kin10, a national effort to prepare, deploy andsupport 100,000 excellent science, technology, engineering and math (STEM) teachers in the USover the next 10 years, pledging $1.5 million over the next three years to support STEMteacher development programs in Colorado, Arizona and New Mexico.• Took a leadership role in supporting the nearly 15,000‐square‐foot <strong>Climax</strong> MolybdenumLeadership Center at Colorado Mountain College’s campus in <strong>Leadville</strong>, pledging a total of $1million over five years (2009‐2013).• Awarded $70,000 in Chaffee County to facilitate the establishment of an open access network,addressing the regional demand for high speed broadband services.• Invested $95,000 in Summit County to support the Ten Mile Canyon Recreation Path Extensionproject.• Awarded $50,000 to Summit Community Care Clinic to support the growth of medical servicesavailable to the community.19

Who is Freeport-McMoRan Copper & Gold?Freeport-McMoRan Copper & Gold is the parent company of <strong>Climax</strong> Molybdenum. Freeport-McMoRan Copper & Gold (NYSE: FCX) is a leading international mining company withheadquarters in Phoenix, Arizona. FCX operates large, long-lived, geographically diverse assetswith significant proven and probable reserves of copper, gold and molybdenum. FCX has adynamic portfolio of operating, expansion and growth projects in the copper industry and is theworld's largest producer of molybdenum. FCX produces molybdenum at its <strong>Climax</strong> and Hendersonmolybdenum mines in Colorado as well as a by-product at several of its copper mines in Northand South America.The company’s portfolio of assets includes the Grasberg minerals district in Indonesia, the world’slargest copper and gold mine in terms of recoverable reserves; significant mining operations inthe Americas, including the large-scale Morenci minerals district in North America and the CerroVerde and El Abra operations in South America; and the Tenke Fungurume minerals district in theDemocratic Republic of Congo.Additional information about FCX is available on FCX's website at www.fcx.com.Morenci, ArizonaSierrita, ArizonaBagdad, ArizonaSafford, ArizonaMiami, ArizonaHenderson, Colorado<strong>Climax</strong>, ColoradoTyrone, New MexicoChino, New MexicoCopper (CU)Gold (Au)Molybdenum (Mo)Cobalt (Co)Cerro Verde, PeruTenke Fungurume,Democratic Republic of CongoGrasberg, IndonesiaEl Abra, ChileCandelaria, ChileOjos del Salado, ChileMorenci, ArizonaCerro Verde, PeruGrasberg, Indonesia20

Jan-02Apr-02Aug-02Nov-02Mar-03Jun-03Sep-03Jan-04Apr-04Aug-04Nov-04Mar-05Jun-05Oct-05Jan-06May-06Aug-06Nov-06Mar-07Jun-07Oct-07Jan-08May-08Aug-08Dec-08Mar-09Jun-09Oct-09Jan-10May-10Aug-10Dec-10Mar-11Jul-11Oct-11Jan-12May-12Molybdenum Fast Facts• What is Molybdenum? Molybdenum obtained its name from theGreek word “molybdos” or “lead-like” because of its greyappearance. Molybdenum does not occur in the metallic form innature. The mineral of commercial significance is molybdenite(MoS 2 ), a natural molybdenum sulphide.• Where is it found? Molybdenum is found all over the world andgenerally mined from two different types of mines:Primary – where the recovery of molybdenite is the sole objective; about 40% of totalmolybdenum production is from primary mines.By-product (at copper mines) – which remove the molybdenite duringcopper recovery (where copper recovery is prime target); about 60% of the world’smolybdenum production is as a by-product.The mined ore is milled to fine particles and is processed through a flotation step toproduce a concentrate containing the molybdenite mineral.• Products• Metallurgical Products. Most of the molybdenum concentrate is roasted to convertthe sulfide to oxide (Tech Oxide). Tech Oxide can be added directly into a steel furnaceto produce alloy steel or it can be used to produce ferromolybdenum (also known asFeMo) and used as a additive to cast irons and steel. Molybdenum additions give alloysteel and iron a combination of strength, toughness and wear resistance not possiblewith unalloyed steels. Approximately 80% of molybdenum production is used in thisapplication.• Chemical Products. The concentrate can also be processed into a variety of chemicalproducts. Molybdenum chemicals are used in a number of diverse applications, such ascatalysts for petroleum refining, production of pure molybdenum metals, and additivesfor water treatment. Molybdenum disulfide is used principally in lubricant and greaseapplications. Pure molybdenum metal powder products are used in a number ofdiverse applications, such as lighting, electronics and specialty steel alloys.• Market. In 2011, the world market approximated537 million pounds of molybdenum.• Prices. Molybdenum demand follows the globalsteel and stainless steel industries. In 2010 &2011, the economy and steel productiongradually improved and moly prices averaged~$15 per pound. Recently, demand hasmoderated with concerns surrounding theEuropean sovereign debt crisis and slower growthin China and the US.$50$45$40$35$30$25$20$15$10$5$0MolybdenumMetals Week Dealer Oxide price ($/lb)2002 2004 2006 2008 2010 201221

<strong>Climax</strong> Molybdenum Company<strong>Climax</strong> Molybdenum, a subsidiary of FCX, is a fully integrated molybdenum producer andchemical processing business with two world-class mines (Henderson and <strong>Climax</strong> in Colorado),two major roasting and chemical processing facilities (Ft. Madison, Iowa and Rotterdam, theNetherlands), a ferromoly production plant (Stowmarket, England) and a <strong>Climax</strong> TechnologyCenter unit with industry-leading customer technical services and product developmentcapabilities.The principal products produced by <strong>Climax</strong> are molybdic oxide, ferromolybdenum, molybdenumchemicals, molybdenum disulfide and pure molybdenum metal powder.We process molybdenum concentrates at our conversion plants in the United States and Europeinto technical-grade molybdic oxide, ferromolybdenum, pure molybdic oxide, ammoniummolybdates, molybdenum metal powders and molybdenum disulfide. We operate roasters atSierrita, Arizona; Fort Madison, Iowa; and Rotterdam, the Netherlands.The Sierrita facility consists of two molybdenum roasters and a leach plant that processmolybdenum concentrates produced at our mines and on a toll basis for third parties. The facilityproduces molybdenum oxide and related products.The Fort Madison facility consists of two molybdenum roasters, a sulphuric acid plant, ametallurgical (technical oxide) packaging facility, and a chemical conversion plant, which includesa wet-chemicals plant and sublimation equipment. In the chemical plant, molybdic oxide isfurther refined into various high-purity molybdenum chemicals for a wide range of uses bychemical and catalyst manufacturers. In addition, the Fort Madison facility produces lubricantgrade molybdenum disulfide.The Rotterdam conversion plant consists of a molybdenum roaster, sulphuric acid plant,metallurgical packaging facility and chemical conversion plant. The plant produces metallurgicalgrade molybdenum oxide products. Ammonium dimolybdate and pure molybdic oxide areproduced in the wet-chemicals plant.We also produce ferromolybdenum at our conversion plant in Stowmarket, United Kingdom.Fort MadisonHenderson and <strong>Climax</strong> minesSierritaStowmarketRotterdam<strong>Climax</strong> MolybdenumWorldwide Operations22

Currently, we produce molybdenum concentrate at some of our copper mines (as a by-product)and at our <strong>Climax</strong> and Henderson primary molybdenum mines. The concentrate is then processedfurther at our downstream facilities into a variety of intermediate and final sales products.By-Product Moly(from Copper <strong>Mine</strong>s)Bagdad, Sierrita, Morenci,Chino and Cerro Verde42 million lbs MoPrimary Moly <strong>Mine</strong>s<strong>Climax</strong>* &Henderson39 million lbs MoSierritaLeach PlantBagdadConcentratePressureLeach PlantPurchases andToll MaterialRoasting FacilitiesSierritaRoasting PlantFort MadisonRoasting PlantRotterdamRoasting PlantStowmarketFeMo PlantFort MadisonChemical PlantChemical PlantsRotterdamChemical PlantSales of ~81 million lbsof molybdenum to customers*** <strong>Climax</strong> is currently ramping up with volumes estimated at 20 million lbs of molybdenum in 2013; dependingon market conditions, <strong>Climax</strong> may increase to 30 million lbs of molybdenum per year.** <strong>Climax</strong> Molybdenum is the world leader in molybdenum chemical sales and has a significant sales position inthe metallurgical market.Note: 2012 estimated volumes, FCX consolidated (excluding purchases and toll material)23

Cautionary StatementThis tour companion contains forward-looking statements in which we discuss factors we believe may affect our future performance in the future.Forward-looking statements are all statements other than statements of historical facts, such as statements regarding projected ore grades andmilling rates, projected production and sales volumes, projected unit net cash costs, projected capital expenditures, exploration efforts and results,mine production and development plans, and the impact of commodity price price changes. We caution readers that forward-looking statementsare not guarantees of future performance and our actual results may differ materially from those anticipated, projected or assumed in theforward-looking statements. Important factors that can cause our actual results to differ from results anticipated in the forward-lookingstatements include commodity prices, mine sequencing, production rates, industry risks, regulatory changes, political risks,, weather- and climaterelatedrisks, labor relations, environmental risks, litigation results, and other factors described in FCX's annual report on Form 10-K for the yearended December 31, 2011, filed with the Securities and Exchange Commission (SEC), as updated by FCX’s subsequent filings with the SEC.We caution readers that many of the assumptions on which our forward-looking statements are based are likely to change after our forwardlookingstatements are made, including for example commodity prices, which we cannot control, and production volumes and costs, some aspectsof which we may or may not be able to control. Further, we may make changes to our business plans that could or will affect our results.In its filings with the SEC, FCX discloses recoverable proven and probable reserves calculated in accordance with Industry Guide 7 as required bythe Securities and Exchange Act of 1934. In this tour companion we refer to potential reserve additions and use phrases such as “mineralizedmaterial.” Potential reserve additions will not qualify as reserves until sufficient mapping, drilling, sampling, and assaying are completed anduntil comprehensive engineering studies establish their economic feasibility. Accordingly, no assurance can be given that any potential reserveadditions will become recoverable proven or probable reserves. We urge you to consider closely the disclosure of recoverable proven and probablereserves in FCX’s Annual Report on Form 10-K for the year ended December 31, 2011, as updated by FCX’s subsequent filings with the SEC.