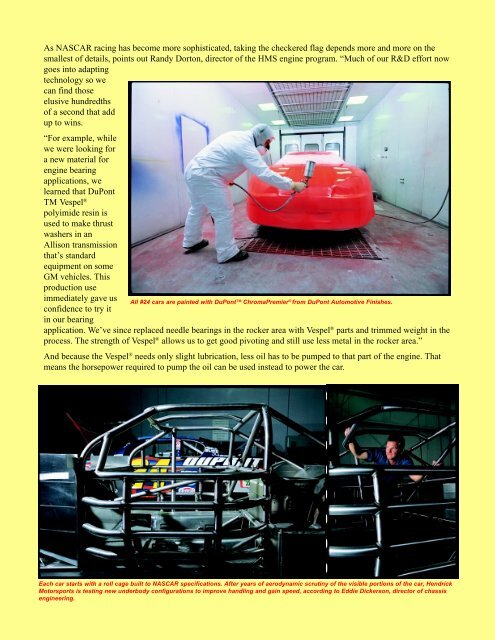

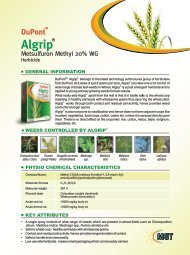

As NASCAR racing has become more sophisticated, taking the checkered flag depends more and more on thesmallest of details, points out Randy Dorton, director of the HMS engine program. “Much of our R&D effort nowgoes into adaptingtechnology so wecan find thoseelusive hundredthsof a second that addup to wins.“For example, whilewe were looking fora new material forengine bearingapplications, welearned that <strong>DuPont</strong>TM Vespel ®polyimide resin isused to make thrustwashers in anAllison transmissionthat’s standardequipment on someGM vehicles. Thisproduction useimmediately gave usAll #24 cars are painted with <strong>DuPont</strong> ChromaPremier ® from <strong>DuPont</strong> Automotive Finishes.confidence to try itin our bearingapplication. We’ve since replaced needle bearings in the rocker area with Vespel ® parts and trimmed weight in theprocess. The strength of Vespel ® allows us to get good pivoting and still use less metal in the rocker area.”And because the Vespel ® needs only slight lubrication, less oil has to be pumped to that part of the engine. Thatmeans the horsepower required to pump the oil can be used instead to power the car.Each car starts with a roll cage built to NASCAR specifications. After years of aerodynamic scrutiny of the visible portions of the car, HendrickMotorsports is testing new underbody configurations to improve handling and gain speed, according to Eddie Dickerson, director of chassisengineering.

“We’re always trying to make #24 the slickest caron the track,” says crew chief Robbie Loomis.“Having <strong>DuPont</strong> as sponsor of the #24 Monte Carlo puts us in adifferent relationship with our sponsor than most other teams,” saysDickerson. “Sponsors’ candy and burgers and such certainly are goodproducts, but they won’t make a car run faster. <strong>DuPont</strong>, on the otherhand, brings us materials and technology. We didn’t need to developVespel ® ; it was already there for us. We just needed to learn to applyit.”Similarly, HMS mechanicslearned to use <strong>DuPont</strong> TMKrytox ® performancelubricant to prevent therubber/silicone boot onspark plug wires fromadhering to the plug’sceramic insulator becauseof the intense heat generatedunder the hood. “Whena mechanic tried to removethe wire,” Dickersonexplains, “the wiringassembly pulled apart. Wediscovered that by applyinga small dab of Krytox ®inside the boot, we eliminated the problem because the Krytox ® easilystands up to the heat. Now Krytox ® is used on General Motors productioncars to solve this same problem.”Each Winston Cup team will use 60 to 80 tiresMoving fluids around the #24 are lots of hoses and tubing of <strong>DuPont</strong> TMTeflon ® per race, including practice sessions.PTFE. HMS engineers have found that the strong, lightweightmaterial is ideal for the very tight bends necessary to fit all the fluidlines into cramped spaces. The hoses are extruded in a convoluted configuration – rather than a smooth bore – toprevent collapsing in sharp-radius bends.Developing engine components is no small part of the HMS operation. Each year, the HMS engine departmentbuilds more than 700 engines for its own teams and for lease to a number other NASCAR competitors. As important,the engine department is an extensionof the GM Motorsports technicalprogram. Most recently, HMS played akey role in the development and testingof the new SB2 engine that powers allGM cars in NASCAR Winston Cupcompetition.<strong>DuPont</strong> Motorsports Network sponsors of #24 include Corian ® , Tyvek ® ,Stainmaster ® , Nomex ®, and Sontara ® .“We’ve brought together a lot of talent –electrical, mechanical, and chemicalengineers, as well as specialists inmetallurgy and combustion – to buildengines that are not only powerful, butdurable, too,” says Jim Wall, engineeringgroup manager for Hendrick Engines.“There’s a careful balance betweenpower and durability, which is why we’realways seeking new materials that willlast without sacrificing horsepower.”