You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

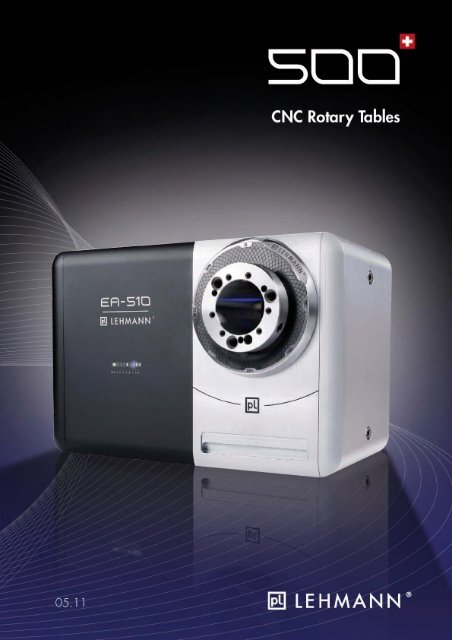

CompanyProven Swiss rotary table technologysince 1974TF-510510 vario on a FANUC robodrill 14i/21iis a medium-sized company whichhas specialised in rotary tables for over 35 years.<strong>The</strong> company is committed to typicalSwiss values:– Swiss product– Swiss quality– Swiss innovation and flexibility– Swiss ethics regarding personnel, production andthe environment2

Table of contents<strong>The</strong> <strong>modular</strong><strong>«500</strong> <strong>series</strong>»Evaluation of machining center and rotary table 8Overview of <strong>«500</strong> <strong>series</strong>» 12Summary+ Technol.EA + M 22EA + MTF 26TFT1 34T1T2 / T3 / T4 42T2...T4rotoFIX / longFLEXTRIAG / zentriX50RFX/LFXTRIAG<strong>The</strong> whole catalogue is subject to technical changes without any prior noticeCabling and angular position measuring systems 54Motors 56CNC control system FANUC PMi 58faceplates, jaw chucks, ISO, HSK, CAPTO 62Centring clamps and force clamps 66Zero point and pallet systems 68Collet systems 76Clamping cylinders and rotary unions 82Tailstocks, counter bearings 84Hydraulic units / gripPACK / buttons 85Company history 90Company 95CAB / WMSMOT / CNCWorkpiececlampingGeneralaccessoriesCompany3

Image gallery and workpiecesEA-510.L on Brother TC-31BSummary+ Technol.12CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +M36EA-510.L Page 22M2-510.L Page 24EA-520.OL Page 2247M3-510.LM4-510.L Page 24 Page 241011 12 13 1415 16 17 1858 9TF-510520.LL fixTF-510520.LL fixXTF-510520.LL varioTF-510520.LL varioX Page 26 Page 28 Page 30 Page 32T1-510520.LL fix T1-510520.LL fixX T1-510520.LL vario T1-510520.LL varioX T1-510520.OLL varioX Page 34 Page 36 Page 38 Page 40 Page 40T2-510520.LL fixT2-510520.LL fixXT2-510520.LL varioT2-510520.LL varioX Page 42 Page 44 Page 46 Page 484

Image gallery and workpiecesEA-520.L with gredoc on DMC1035 V eco1920 21 22EA + MSummary+ Technol.T3-510520.LL fixT3-510520.LL fixXT3-510520.LL varioT3-510520.LL varioXTF Page 42 Page 44 Page 46 Page 48292324T1GLA.5xxT2...T4 Page 85T4-510520.LL fix Page 42T4-510520.LL fixX Page 4430RFX/LFXTRIAG2526RST.L man Page 84CAB / WMSMOT / CNC31EA-520.L rotoFIX centrically Page 50EA-520.L rotoFIX underneath Page 50WorkpiececlampingSPZ.5xx2728 Page 8232GeneralaccessoriesEA-510.L longFLEX RST Page 51EA-510.L longFLEX GLA Page 51DDF.510 Page 83Company5

Evaluation of the machining center5-axis or 5-side machining?T1-520520.LL varioX on BridgeportSummary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MMachine floor space5-axis machining center35–100%100%3-axis machining center(+mountable rotary table)4‘600 kg4‘100 kg7‘700 kg5‘000 kg9‘200 kg5‘600 kg5–9.5m 25–15m 2Procurement costs5-axis machining centerWork table size5-axis machining center35–65%3 axes incl. 4th and 5th axis(pL Lehmann rotary table)approx. 75%3-axis machining centerWeight of typical machining centers5-axis machining center3-axis machining center(+mountable rotary table)50–100% 45–55%Energy consumption is more or less proportional to the moving mass.5-axis machining centerHeavier table = greaterenergy consumption3-axis machining5-axis machining centerTable size is only sufficientfor single clamping500x500 – 620x620 mm 800x400 – 1050x600 mm5-axis machining center:– Deckel MahoTable size 0.25– 0.38 m 2 Table size 0.32– 0.63 m 2 – Hüller Hille– Mazak65–100% 85–165%– MikronEnergy efficiency3-axis machining center(+mountable rotary table)Low energy consumptionbecause the movingmasses are smaller andlighter3-axis machining centerLarge tables enablemultiple clampingMachining centers compared3-axis machining center:– Awea– Brother– Deckel Maho– Famup– Mikron8

Evaluation of the machining centerBear in mind: 3+2 can giveyou more than 5... it also saves electricity andprotects the environment!T3-510520.LL fix on Brother TC-22B-05-side machining5-axis machining center3-axis machining center(+mountable rotary table)Multiple parts with multi-side machining5-axis machining center3-axis machining center(+mountable rotary table)Summary+ Technol.Small partsEA + MTable size is often only sufficient forindividual parts or for a few partsT1Suitable forshort toolsMedium-sized partsMulti-workpiece clamping<strong>The</strong> most varied workpiececlamping systems are availableCAB / WMSMOT / CNCLarge partsSuitable forshort toolsWorkpiececlamping= suitable= possible, but not economicalGeneralaccessories= not possibleCompanyT2...T4TFRFX/LFXTRIAG9

Evaluation of the rotary tableSpace requirements on themachine tableEA-510.L on Wele/Toyoda AA-1365Summary+ Technol.Space requirement for 4 th axisCompetitor710pL rotary table EA-520405CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MWeight = 200 kg100 %Space requirement for 4 th and 5 th axisCompetitor pL rotary table T1-520520Weight = 420 kg100 %pL Lehmann5075105205305751115240435445530...775ø 105 ø 180 ø 200 ø 260 ø 300 ø 320 ø 400 ø 500ø 100 –200ø 160 –240Weight = 70 kg35 %Weight = 166 kg40 %4 sizes from pL compared to 8–10 from the competitorsCompetitorø 200 –350ø 300 –500270142335...46022010

Evaluation of the rotary tableShort positioning time,because time is moneyEA-510.L on Brother S2C-OPositioning time 90° (example)pL LehmannCompetitorSummary+ Technol.Rotating speedmonitored positioning approx.0.4 secRelease spindle clamping 0.1 sec 0.15 secAccelerationLinear rotary movement 0.3 sec 0.5 secDecelerateMachining release... Monitor with pressure sensor ...Clamp spindle (approx. 0.15 sec) – 0.25 sec... machine is already moving ...Positioning time 0.4 sec 0.9 secTime [sec]gain in time of up to 0.5 sec45 %100 %T2...T4 T1 TF EA + MCompetitor: fixed positioning time of approx. 0.9 secRFX/LFXTRIAGCost efficiency calculation (example)Quicker positioning shortens manufacturing time and increasesproductivity.CAB / WMSMOT / CNCA) Increasing the machine's efficiency [hrs / year]Gain in time per positioning = 0.5 sec44 positionings per piece = 44 x 0.5 sec = 22 sec15 pieces per hour x 6000 hrs / year = 550 hrs90°Workpiece example:– 4 tools– 11 positioningsper toolWorkpiececlampingB) Profit increase per year550 hrs x € 60.–/hr (machine cost rate)€ 33‘000.–PressuremonitoringGeneralaccessoriespL spindle clampingwith integrated pressure intensifier(Principle of operation)6 bar air pressure 220 bar oil 507: 150 bar oilCompany11

<strong>The</strong> original:rotary table<strong>The</strong> main facts at a glanceSummary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MFactsCompared to «400 <strong>series</strong>»RPM up to 111 min -1 +50 % ... +120 %Cycle time 90° (incl. clamping) up to 0.35 sec –40 % ... –60 %Clamping time 0.12 sec approx. –40 %Counter bearing clamping torque 300–2'000 Nm ... +400 %Swivelling axis clamping torque up to 6'500 Nm ... +60 %12

<strong>«500</strong> <strong>series</strong>» with «combiFlex ® system»«combiFlex ® »: 4 basic modules can makeover 170 standard versionsInnovation!1From 4 basic modules...– Rotary table sizes 507, 510, 520, 530Suitable for faceplatesø100 – ø500507 510 520 530Summary+ Technol.EA + MTF2 ... 31 basic versions are born thanks to combiFlex ® ...– 4 single units (EA)– 12 multiple rotary tables (M)– 15 swivelling rotary tables (T)EA M TT13... and with 4 motor add-on versions...– left, right, upper left, upper rightleft right upper left upper rightCAB / WMSMOT / CNC4... as well as with 4 divider add-on options...– fix– fixX– vario: adjustable dividing axis, 2 positions– varioX: adjustable dividing axis, 2 positionsWorkpiececlamping5... there are more than170 standard variations!TF-...fix TF-...fixX TF-...vario TF-...varioXGeneralaccessoriesCompanyT2...T4RFX/LFXTRIAGT1-...fix T1-...fixX T1-...vario T1-...varioX13

Adapter plate DTSystem philosophy: «combiFlex ® »Modular system «combiFlex ® »Can be swiftly adapted to meetnew requirementsInnovation!International patent pendingSummary+ Technol.Swiveller(5 th axis)Adapter plate GLAConnection plate bottomCompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MMotor housingDT = rotary table, GLA = counter bearingDivider (4 th axis)Motor housingSpacing plateConnection plate topIntermediate plate DTBase plateImportant advantagesFlexibilitydo-it-yourselfDelivery timeshortCostslowerValue retentionhighCounter bearingalways with clampingBearingpinCounter bearingIntermediate plate GLA14

System philosophy: «combiFlex ® »<strong>The</strong> modules of the 500 <strong>series</strong> can beassembled into various combinations byrepresentatives, machine retailers or customersthemselves.An existing system can therefore bequickly and cheaply adapted to meet newrequirements.EATF varioTF fixTF varioSummary+ Technol.++EA + M==T1TFTF fixT1 fixTF varioTF varioXT2...T4++RFX/LFXTRIAG==CAB / WMSMOT / CNCTF vario T1 varioTF vario T1 varioXWorkpiececlamping=+=+GeneralaccessoriesCompany15

Motor housingNew design with innovativeplug-and-play technology7Summary+ Technol.1CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +M6FactsImperviousnessDesignInstallation positionRust resistance425all rotary tables are fully sealed IP 67 (standard)flat all round (no protrusions)good coolant and chip flowhorizontal and vertical– chromed spindle housing– aluminium motor housing, anodised316

Motor housingExclusive to pLEA-510.L in pool of water (IP68)1 Imperviousness, stainless steel– Motor housing fully sealed in accordance with IP67, option of IP68 andstainless steel– Prevents damages to the motor, cabling, connector, etc. – IP67– Option IP68– Option stainlesssteelSummary+ Technol.EA + M2 Drive motor– One single housing (2 lengths) for all motors: Fanuc, Mavilor (Siemens,Heidenhain), Yaskawa, Sanyo, Meldas, Mitsubishi– Motors can be easily exchanged– Fanuc– Siemens– Heidenhain– Yaskawa– Sanyo– Meldas/Mitsu.TFT13 blackBOX (electronic plate)Innovation!– Measurement of RPM, internal pressure of the motor housing, temperature,moisture and shock– History of important data with real-time clock– Quick error detection and preventative maintenance– Increases availability and reduces maintenance costs– Online error signal and control of the spindle clamping– RPM– Internal pressure– Temperature– Moisture– Shock– ClampingT2...T4RFX/LFXTRIAG4 USB slotInnovation!– Quick and easy data transfer in the case of failure for evaluation on the PC– Licensing option with unlocking code by USB stick (OEM feature)– Fully sealed, placed in a well protected place– quick– well protected– suitable forworkshop useCAB / WMSMOT / CNC5 Cable inlet– Cable inlet can be swivelled up to 150° (in different directions)– Bayonet quick release fastener for quick exchange in case of failure– All cables and hoses are hidden insideInnovation!– Quick releasefastener– Everything ishiddenWorkpiececlamping6 Sealing and service cover– combiFlex ® interface (close the service cover with just two screws)– Service access (configure gear backlash, ventilation)– combiFlexinterface– standardisedadaptationGeneralaccessories7 Transport and ventilation drillingCompany– Screw holes for transport and ventilation (oil bath and spindle clamping)17

Rotary table - insideGear unit with greatly increased impactstrength and speed1Summary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MFactsSpindle clampingSpindle bearingGear unitImperviousness34352very powerful, quick, integrated pressure intensifier(only requires compressed air!)optimal for compact designgreatly improved impact strength,very wear resistantGear unit in oil bath with pressurised oil lubrication(IP67)Material Housing: spheroidal graphite iron, 300 Nm/mm 2Spindle: hardened and polished steel18

Rotary table - inside1 Spindle clamping– Extremely powerful and torsionally rigid– Clamping on large diametersclose to workpiece– Very fast acting– Microprocessor controlled– Integrated pressure sensors for optimalmonitoring– No axial spindle movement upon clampingand releasing– Long lifetime– Consistent clamping strength over the wholelifetime Summary+ Technol.EA + MTF2 SpindleAccessories for...T1– Hardened and polished– Concentricity and axial run-out 6 µm(optional up to 3 µm)– Universal application...manual or automatic HSK/ISO clamping,various collet clamping systems, faceplates andjaw chucks, palletising systems, rotary unionsand clamping cylinders...T2...T43 Spindle bearing– 4 point fitted without backlash, largeprecision anti-friction bearings– Large distance of radial bearings resultsin high spindle rigidity– All bearing points run in oil bath4 Gear unitoptimised!– Good gear efficiency asa result of high surfacequality of the run surfacesoptimised!large distance= high rigidity!RFX/LFXTRIAGCAB / WMSMOT / CNC– Greatly increased impact strength thanks tothe new gear material and thicker teeth– Hardened and polished wheel and worm– Worm 4 point fitted without backlash– Large worm diameter, highly wear resistant =high long-term precision with minimal increasein gear unit backlash– Consistent minimum gear unit backlashover 360°– Quick (46...111min -1 )– Precise (optional to +/– 1“)– High load-bearing capacity– High performance lubrication oil– Running in oil bath in all bearingsWorkpiececlamping5 Imperviousnessoptimised!Generalaccessories– All systems fully sealed IP 67– Spindle housing with pressurised oil lubrication– Motor housing with electronically controlledair overpressure– Additional spindle labyrinthseal (optional) forhigh pressure cooling andaggressive materials suchas glass, graphite, etc.Company19

Machining forces (reference values)Explanatory variables– Supplementary milling machines – Stable clamping– Stable machine – New tool cutting edge– Safety factor 1.5<strong>The</strong> reference values provided are non-binding. <strong>The</strong> rotarytable size can be determined according to the requiredclamping and feed torque.Example: drilling figure 1 with spiral drill ø17mmFeed force F = 3980N, distance A = 120mm,Safety factor S = 1.5, maximum torque = F x A x S= 3985N x 0.12m x 1.5 = 717NmConclusion: EA-510 has a spindle clamping torque of800Nm (see page 21). This machining can be safelycarried out on an EA-510.A1 2 3 4 5FFFFSummary+ Technol.AFAAACompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MF = Force feed, A = Distance [m] rotary table axis to force feed (F) during machining, M = resulting torque (FxA), S = Safety factor 1.5Maximum torque = F x A x S → must not exceed maximum clamping torque [Nm] and/or maximum feed torque [Nm] of the rotary table!Feed forcesType of toolEnd millingcutter VEnd millingcutter VCornermilling cutterWPCornermilling cutterWPFace millingcutter WPSpiral drillVHMSpiral drillVHMTl ø[mm]12204080801017WP drill 38Rotary millingwith cornermilling cutter40Cuttingspeed[m/min]Feedfz x Z[mm]Machiningdepth[mm]Machiningwidth[mm]Material180 0.11 x 4 6 12 CK45 1'100Drills[N]End milling /groove milling[N]Hobbing200 0.11 x 4 12 6 CK45 1'05070 0.07 x 4 6 12 X5CrNi18-10 70077 0.07 x 4 12 6 X5CrNi18-10 700570 0.17 x 4 6 12 AlMg4.5Mn0.7 550627 0.17 x 4 12 6 AlMg4.5Mn0.7 550180 0.095 x 4 10 20 CK45 1'550200 0.15 x 4 20 10 CK45 2'70070 0.08 x 4 10 20 X5CrNi18-10 1'40077 0.08 x 4 20 10 X5CrNi18-10 1'350570 0.017 x 4 10 20 AlMg4.5Mn0.7 950627 0.17 x 4 20 10 AlMg4.5Mn0.7 950160 0.12 x 6 2 40 CK45 1'750160 0.12 x 6 2.5 25 CK45 1'25085 0.12 x 6 2 40 X5CrNi18-10 1'55085 0.12 x 6 2.5 25 X5CrNi18-10 1'150500 0.15 x 6 3 40 AlMg4.5Mn0.7 1'250210 0.15 x 10 3.5 80 CK45 4'900240 0.15 x 10 7 40 CK45 4'900160 0.08 x 10 3.5 80 X5CrNi18-10 3'450176 0.08 x 10 7 40 X5CrNi18-10 3'450450 0.2 x 10 3.5 80 AlMg4.5Mn0.7 3'100495 0.2 x 10 7 40 AlMg4.5Mn0.7 3'100240 0.3 x 7 4 80 CK45 2'800300 0.3 x 7 4 16 CK45 1'700130 0.12 x 7 4 80 X5CrNi18-10 2'500162 0.12 x 7 4 16 X5CrNi18-10 1'000450 0.2 x 7 4 80 AlMg4.5Mn0.7 900550 0.2 x 7 4 16 AlMg4.5Mn0.7 450220 0.27 CK45 1'450120 0.18 X5CrNi18-10 1'900350 0.2 AlMg4.5Mn0.7 650220 0.35 CK45 2'850120 0.25 X5CrNi18-10 3'980350 0.3 AlMg4.5Mn0.7 1'250140 0.09 CK45 4'350100 0.08 X5CrNi18-10 6'550180 0.16 AlMg4.5Mn0.7 2'8001 2 3 4 5130 0.12 x 6 5 1mm / 360° CK45 43585 0.12 x 6 5 1mm / 360° X5CrNi18-10 390500 0.12 x 6 5 1mm / 360° AlMg4.5Mn0.7 193Factory specifications from renowned tool manufacturers[N]RotarymillingV = rough machining, WP = indexable adapters, VHM = solid hard metal[N]20

Product and performance overviewEA-510 M4-510 T1-510520 varioXEA4 th axis, single spindleM4 th multiple axis, with 1...4 spindlesT4 th and 5 th axis, with 1...4 spindlesValue from exampleon page 20EAMOrder no.Center height[mm]T1–510520.LL fix–FAø faceplate[mm]max. spindle load Clamping torque Feed torque[kg][Nm][Nm]Spindle RPM.[min –1 ]MotorFA=Fanuc, MA=Mavilor for Siemens/Heidenhain,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. dividing axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of dividing axis 507, 510, 520 or 530Rotary table modelCycle time [sec] (incl. clamping)90° 180°Swivelling axis(5 th axis)90° 180°without withsupport support max min minM ... -507 150 100 55 75 300* 120 45 0.54 0.87M ... -510 190 160 125 225 800 250 50 0.49 0.79M ... -520 220 200 250 450 2'000 440 40 0.58 0.96M ... -530 280 300 600 1'000 4'500 650 35 0.68 1.41TCenter height[mm]Center height[mm]fixvarioø faceplate[mm]ø faceplate[mm]fix variomax maxmax. spindle load Clamping torque Feed torque[kg]max. spindle load Clamping torque Feed torque[kg]without withsupport support[Nm][Nm]max4 th axis 5 th axis[Nm]max4 th axisSpindle RPM.**[min -1 ]max4 th axis 5 th axisCycle time [sec] (incl. clamping)**90° 180°min4 th axis 5 th axis90° 180°min4 th axis 5 th axisTF-507510 150 200 200 100 55 75 300* 800 120 111 60 0.35 0.57 0.48 0.82TF-510510 200 220 200 – 125 225 800 800 250 90 40 0.41 0.72 0.57 1.10TF-510520 180 230 240 – 125 225 800 2'000 250 90 30 0.41 0.89 0.70 1.49TF-520520 230 260 300 – 250 450 2'000 2'000 440 50 30 0.47 1.02 0.70 1.52TF-530530 270 320 400 – 600 1'000 4'500 4'500 650 46 10 0.58 1.83 0.90 3.33T1-507510 190 240 200 100 55 75 300* 1'100 120 111 60 0.35 0.57 0.48 0.82T1-510520 210 260 240 – 125 225 800 2'600 250 90 30 0.41 0.89 0.70 1.49T1-520520 250 300 300 – 250 450 2'000 4'000 440 50 30 0.47 1.02 0.70 1.52T1-530530 305 350 400 – 600 1'000 4'500 6'500 650 46 10 0.58 1.83 0.90 3.33T2-507510 190 240 200 100 55 75 300* 1'100 120 45 30 0.54 0.72 0.87 0.82T2-510520 210 260 160 – 125 225 800 2'600 250 50 30 0.49 0.89 0.79 1.49T3-507510 190 240 200 100 55 75 300* 1'100 120 30 20 0.70 0.80 1.20 0.82T3-510520 210 260 160 – 125 225 800 2'600 250 45 20 0.51 0.95 0.84 1.55T4-507510 190 240 200 100 55 75 300* 1'100 120 20 15 0.90 1.00 1.65 0.82T4-510520 210 260 160 – 125 225 800 2'600 250 35 15 0.59 1.24 1.02 2.24[Nm]Spindle RPM.[min –1 ]Cycle time [sec] (incl. clamping)90° 180°90° 180°without withsupport support max min minEA-507 110 100 ... 200 55 75 300* 120 111 0.35 0.48EA-510 150 160 ... 240 125 225 800 250 90 0.41 0.57EA-520 180 200 ... 350 250 450 2'000 440 50 0.50 0.80EA-530 220 300 ... 500 600 1'000 4'500 650 46 0.58 0.90* with external hydraulic unit (220 bar) = 400 Nm** reference valuesDivider axis(4 th axis)Summary+ Technol.EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCWorkpiececlampingGeneralaccessoriesCompany21

EA-...Seitentitel rechtsStandardleft modelOptionright modelOptionupper left modelOptionupper right modelOLL/ORR model:Drive data (RPM,acceleration...) isapprox. 40% lowerfor divider axes.Summary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MDimensionsL = gear left (R = gear right, is laterally reversed)Standard spindles507 HSK-A63/ø70 510 HSK-A63/ø80520 HSK-A63/KK5 530 ø90/KK8+0.1526 +0.10X min.80±0.005A min.46.55 +0.0090F+0.040DB0.01/100 B0.04 BX * A* B C D E FEA-507 236 311 165 136 110 23 75EA-510 248 333 215 150 150 23 85EA-520 295 405 270 186 180 44 110EA-530 345 555 380 223 240 43 160160°40°Options20°9 x 40°1R29.5±0.01R29±0.05+0.0056 H5 070 -0.00500M5+0.1026 +0.05B60°AC14°80±0.05E0.0069 x 40°16°46.55 +0.0900.01/100 A0.00660°20.8R32±0.05R30±0.01R29±0.050080 -0.05OLL = gear upper left (ORR = gear upper right, is laterally reversed)+0.0564 0IX min.68 ±0.05F+0.040D020.8B0.01/100 B0.04 BX * B C D E F IEA-510 243 329 187 150 23 85 178EA-520 228 396 296 180 44 110 135EA-530 250 522 350 240 43 160 185Order no. Description DimensionsEA-507 EA-510 EA-520 EA-530 EA-507 EA-510 EA-520 EA-530PrecisionGET.507-GEN GET.510-GEN GET.520-GEN GET.530-GEN Increased gear precision ½ Standard tolerance 4) xGEO.507-GEN GEO.510-GEN GEO.520-GEN GEO.530-GEN Increased geometric precision 1) ½ Standard tolerance 4)) xSpindle models and seal optionsSPI.520-A80 HSK A80 / KK5 xSPI.530-A100 HSK A100 / KK8 Exterior as standard spindle xSPI.507-C4 SPI.510-C4 SPI.520-C6 SPI.530-C6 CAPTO C4 C4 C6 C6 xSPI.520-I50 SPI.530-I50 ISO 50 ø130 KK8 xSPI.507-ix SPI.510-ix SPI.520-ix SPI.530-ix Rust-free spindle xSPI.507-d30 SPI.510-d34 SPI.520-d64 3) SPI.530-d102 3) Increased spindle passage ø64 ø102 xSPI.507-Lab SPI.510-Lab SPI.520-Lab SPI.530-Lab Spindle seal with labyrinth, integrated sealing pressure control 2) xSPI.507-IP68 SPI.510-IP68 SPI.520-IP68 SPI.530-IP68 Bath tight according to IP68 standard (instead of IP67) x1)incl. concentricity and axial run-out precision2)cannot be combined with SPI.xxx-IP6880°6x60°7320°15°6x60°9x40°80°R52.4 ±0.05R55 ±0.01R29±0.0546.55 +0.09 011M10M50130 -0.0510°+0.0590 0B6x60°CA15°CANNOT be retrofittedE30°5°90°30°0.0060.01/100 A0.0066x60°7°7'30"+0.01590 H5 0M1617R85.7±0.1R55.55 ±0.1HSK = hollow shank taper in accordance with DIN 69063-1 (spindle) and DIN 69893 (installation), KK = short taper size ... in accordance with DIN 550263)HSK and ripas clamping not possible4)to order per spindle (example: T3-510520 = 4x)* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.R90±0.0120210 -0.05can be retrofitted22

Seitentitel rechts EA-...ø100 – ø200 EA-507ø160 – ø240 EA-510ø200 – ø350 EA-520ø300 – ø500* EA-530*center increase required (option, see page 62)Alignment tenon block for rotary table see page 84Size / load-bearing capacity / precisionCenterheight[mm]ø faceplate[mm]Weight[kg]Totalratiomax. spindleload[kg]Clampingtorque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Indexing accuracy [arc sec]Position+/-Repet+/-WMS+/-Summary+ Technol.Repet = repetition accuracy, WMS = angular position measurement systemStandard drive dataMotors, cables, accessories from page 50m = 55 kgJ = 0.05 kgm 2m = 125 kgJ = 0.20 kgm 2m = 250 kgJ = 0.80 kgm 2m = 600 kgJ = 2.00 kgm 2Order no.EA–510.L –FA8011314001451600EA-507 EA-510 EA-520 EA-5301752200kg3000without withsupport supportSpindle load (for standard drive data)<strong>The</strong> standard moment of inertia in the table «standard drive data»corresponds to a loading of the tool spindle with the load shown(material: steel).130m = 17 kgJ = 0.05 kgm 2m = 10 kgJ = 0.05 kgm 2EA-507 EA-510 EA-520 EA-530173m = 42 kgJ = 0.20 kgm 240m = 20 kgJ = 0.20 kgm 2Motor MA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasMotor pos. dividing axis L=left, R=right, OR=upper right, OL= upper leftDividing axis size 507, 510, 520 or 530Rotary table modelmax* with external hydraulic unit (220 bar) = 400 Nm200228m = 90 kgJ = 0.80 kgm 24028540273m = 161 kgJ = 2.00 kgm 2Applicable for MAVILOR/MOVINOR standard motors. Dimensionedfor intermittent service S3 ED20% with an operating time of 5 minutes(in accordance with DIN/VDE 0520). Other motors or higher EDrequire adjustment of the drive data (acceleration, jerk limitation, RPM).Reference values: for milling / drilling in intensive mixed operation (positioning/feedmachining) approx. 40% ED, profile and depth grindingapprox. 60% ED or engraving approx 80-100% ED. ED = duty cycle.EA-507 EA-510 EA-520 EA-530m = 40 kgJ = 0.80 kgm 2Stand./increased increasedStand./EA-507 110 100 ... 200 22 90:1 55 75 300* 120 500 20 20/12 3/2 5...1EA-510 150 160 ... 240 30 120:1 125 225 800 250 1'000 25 17/10 3/2 5...1EA-520 180 200 ... 350 57 150:1 250 450 2'000 440 2'500 40 12/8 3/2 5...1EA-530 220 300 ... 500 140 150:1 600 1'000 4'500 650 5'500 60 10/6 3/2 5...1All valuesapply atoperationaltemperature.Moment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. Standard90° 180°4 th axisat Jmax. StandardSpindle RPM.[min –1 ]at Jmax. Standardat Jmax.EA-507 0.05 1 0.35 0.87 0.48 1.37 111 30EA-510 0.2 7 0.41 0.91 0.57 1.34 90 35EA-520 0.8 15 0.50 1.07 0.80 1.57 50 30EA-530 2 30 0.58 1.27 0.90 2.02 46 20400m = 62 kgJ = 2.00 kgm 240500Divider axis(4 th axis)EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCWorkpiececlampingGeneralaccessoriesCompany23

M2 / M3 / M4-...Seitentitel rechtsStandard M2left modelStandard M3left modelStandard M4left modelSummary+ Technol.All valuesapply atoperationaltemperature.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MOption M2right model±0.02X min.BA min.±0.5° ±0.5°G ±0.02M2–510.L –FAFBD+0.040H min.00.01/100 BACE0.006±0.03X * A* B C D E F G Gmin HM2-507 236 471 205 189 150 23 75 160 135 40M2-510 248 513 255 149 190 24 85 180 155 40M2-520 295 635 310 186 220 44 110 230 205 40M2-530 345 885 420 223 280 43 160 330 305 40±0.02X min. G ±0.02 ±0.02 ±0.02BA min.±0.5° ±0.5° ±0.5° ±0.5°0.01/100 BOption M3right modelDimensionsL = gear left (R = gear right, is laterally reversed)L = gear left (R = gear right, is laterally reversed)X * A* B C D E F G Gmin HM4-507 185 805 205 191 150 23 75 160 135 40M4-510 248 895 255 150 190 24 85 180 155 40M4-520 295 1135 310 186 220 44 110 230 205 40M4-530 345 1545 420 223 280 43 160 330 305 40Order no.F0.01/00 BB+0.04D 0H min.00.01/100 BA0.01/100 A0.006CE0.006±0.030.01/100 A0.006Option M4right model±0.02X min.BA min.±0.5° ±0.5° ±0.5°G±0.02 ±0.02F0.01/100 BBD +0.040H min.00.01/100 BX * A* B C D E F G Gmin HM3-507 185 645 205 191 150 23 75 160 135 40M3-510 248 715 255 149 190 23 85 180 155 40M3-520 295 905 310 186 220 44 110 230 205 40M3-530 345 1215 420 223 280 43 160 330 305 40*Standard drive dataMoment ofinertia J[kgm 2 ]JStandard max.Motor MA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasMotor pos. dividing axis L=left, R=right, OR=upper right, OL= upper leftDividing axis size 507, 510, 520 or 530Rotary table modelCycle time (incl. clamping)[sec]StandardImp. informationTwo geometric accuracies areavailable– Standard = see respective dimensionssheet above– high precision: all accuracies½ Standard tolerance GEO.???-GEN(required per spindle e.g. forT2-510520 = 3x)??? = type of rotary table (e.g. 510)90° 180°4 th axisat Jmax.ACEat JStandard max.0.006±0.030.01/100 A0.006* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.SpindleRPM.[min –1 ]at JStandard max.M2...4-507 0.05 1 0.54 0.94 0.87 1.54 45 25M2...4-510 0.2 7 0.49 1.02 0.79 1.62 50 25M2...4-520 0.8 15 0.58 1.27 0.96 1.87 40 25M2...4-530 2 30 0.68 1.11 1.41 2.16 35 20* All values are reference values and apply for M2; for values for M3 and M4 seePDAT at www.lehmann-rotary-tables.com -> Download -> ManualsDivider axis(4 th axis)24

M2 Seitentitel / M3 / M4-... rechtsø100 M...-507ø160 M...-510ø200 M...-520ø300 M...-530Max. use ø, no standard faceplates availableø158 M...-507 ø228 M...-520ø178 M...-510 ø328 M...-530Size / load-bearing capacity / precisionCenterheight[mm]ø faceplate[mm]Weight[kg]Totalratiomax. spindleload[kg]Clampingtorque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Indexing accuracy [arc sec]Position+/-Repet+/-WMS+/-Summary+ Technol.Repet = repetition accuracy, WMS = angular position measurement systemOptions / accessorieskgwithout withsupport supportFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardmaxStand./increased increasedStand./M2-507 150 100 (158) 46 90:1 55 75 300* 120 500 20 20/12 3/2 —M2-510 190 160 (178) 67 120:1 125 225 800 250 1'000 25 17/10 3/2 —M2-520 220 200 (228) 126 150:1 250 450 2'000 440 2'500 40 12/8 3/2 —M2-530 280 300 (328) 264 150:1 600 1'000 4'500 650 5'500 60 10/6 3/2 —M3-507 150 100 (158) 70 90:1 55 75 300* 120 500 20 20/12 3/2 —M3-510 190 160 (178) 102 120:1 125 225 800 250 1'000 25 17/10 3/2 —M3-520 220 200 (228) 191 150:1 250 450 2'000 440 2'500 40 12/8 3/2 —M3-530 280 300 (328) 401 150:1 600 1'000 4'500 650 5'500 60 10/6 3/2 —M4-507 150 100 (158) 93 90:1 55 75 300* 120 500 20 20/12 3/2 —M4-510 190 160 (178) 138 120:1 125 225 800 250 1'000 25 17/10 3/2 —M4-520 220 200 (228) 257 150:1 250 450 2'000 440 2'500 40 12/8 3/2 —M4-530 280 300 (328) 539 150:1 600 1'000 4'500 650 5'500 60 10/6 3/2 —* with external hydraulic unit (220 bar) = 400 NmEA + MTFT1T2...T4RFX/LFXTRIAGSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownM2-507 M2-510m = 12 kgm = 27 kgM2-520 m = 62 kgM2-530J = 0.025 kgm 2J = 0.1 kgm 2J = 0.4 kgm 2m = 106 kgJ = 1.0 kgm 2CAB / WMSMOT / CNC114151M3-507 M3-510 M3-520 M3-530m = 9 kgJ = 0.017 kgm 2m = 21 kgJ = 0.067 kgm 2m = 48 kgJ = 0.267 kgm 2199238m = 82 kgJ = 0.667 kgm 2Workpiececlamping105Status:18.06.2010 rsTransportschema Msst: 1:10Msst: 1:10PETER LEHMANNPETER LEHMANN AG, CH-3552 BÄRAU Würfel 023-0022AG, CH-3552 BÄRAU 0 Würfel Status:023-0025 0Form.: A3Form.: A3M2-520.LStatus:Dokument Nr.:18.06.2010 rsM4-507 M4-510 M4-520 Transportschema M4-530 18.06.2010 rsMsst: 1:10Msst: 1:10m = 8 kgm = 18 kgPETER LEHMANN AG, CH-3552 BÄRAU Würfel 023-0028J = 0.013 kgm 2Form.: A3m = 41 kgForm.: A3J = 0.05 kgm 2J = 0.2 kgm 2100139Status:M2-507.L18.06.2010 rs131Dokument Nr.:M2-510.LAe.-In.:Transportschema183173Dokument Nr.:Ae.-In.:219207Ae.-In.:Transportschemam = 0 70 kg Würfel 023-0031J = 0.5 kgm 2PETER LEHMANN AG, CH-3552 BÄRAUM2-530.LDokument Nr.:Ae.-In.:0GeneralaccessoriesStatus:Status:M3-510.LDokument Nr.:Ae.-In.:M3-530.L18.06.2010 rsDokument Nr.:18.06.2010 rsStatus:TransportschemaStatus:TransportschemaMsst: 1:10M3-507.LDokument Nr.:Ae.-In.:18.06.2010 rsPETER LEHMANN AG, CH-3552 BÄRAU Würfel 023-0026 M3-520.LMsst: 1:100Dokument Nr.:Ae.-In.:18.06.2010 rsPETER LEHMANN AG, CH-3552 BÄRAU Würfel 023-0032Form.: A3Form.: A3TransportschemaTransportschemaMsst: 1:10Msst: 1:10PETER LEHMANN AG, CH-3552 BÄRAU Würfel 023-0023 0PETER LEHMANN AG, CH-3552 BÄRAU Würfel 023-0029 0Form.: A3Form.: A3Applicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensivemixed operation (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.Ae.-In.:0CompanyStatus:18.06.2010 rsMsst: 1:10Form.: A3PETER LEHMANN AG, CH-3552 BÄRAUStatus: M4-507.L18.06.2010Transportschema rsMsst:1:10Dokument Nr.:Würfel 023-0024Form.: A3PETER LEHMANN AG, CH-3552 BÄRAUStatus:Ae.-In.: 18.06.2010 rsM4-510.LDokument Nr.:Msst: 1:10Transportschema 0 Form.: A3PETER LEHMANN AG, CH-3552 BÄRAUWürfel 023-0027M4-520.LTransportschemaAe.-In.:Status:18.06.2010 tmMsst: 1:10Form.: A3PETER LEHMANN AG, CH-3552 BÄRAUDokument Nr.:Würfel 023-00300M4-530.LDokument Nr.:TransportschemaWürfel 023-0033Ae.-In.:025Ae.-In.:0

TF-...fixStandardleft modelOptionright modelSummary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MDimensionsL = gear left (R = gear right, is laterally reversed)0.006X1 min.0.015/100 A0.015/100 A0A min.YFF1BAEB+0.1 D 0H min.0Coaxiality divider axis to swivelling axis = max ±0.02mmX min.C min.180° optional5°0R5°90° StandardX * X1 * Y A* B C* D E F F1 R HTF-507510 248 236 55 466 215 300 150 230 104 230 124 0TF-510510 248 248 65 490 265 422 200 289 116 242 176 50TF-510520 295 248 65 512 270 469 180 267 122 264 177 0TF-520520 295 295 90 591 320 499 230 330 154 296 208 50TF-530530 345 345 140 779 410 635 270 403 204 384 264 30* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Order no.TF–510520.LL fix–FAImportant informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table modelSwivelling axis(5 th axis)Divider axis(4 th axis)26

TF-...fixø100 – ø200 TF-507510 fixø160 – ø200 TF-510510 fixø160 – ø240 TF-510520 fixø200 – ø300 TF-520520 fixø300 – ø400 TF-530530 fixSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.Standard drive data4 th axis 5 th axiswithout withsupport support 4 th axis 5 th axis maxTF-507510 150 100 ... 200 54 90:1 120:1 55 75 300* 800 120 500 20TF-510510 200 160 ... 200 69 120:1 120:1 125 225 800 800 250 1'000 25TF-510520 180 160 ... 240 96 120:1 150:1 125 225 800 2'000 250 1'000 25TF-520520 230 200 ... 300 128 150:1 150:1 250 450 2'000 2'000 440 2'500 40TF-530530 270 300 ... 400 268 150:1 150:1 600 1'000 4'500 4'500 650 5'500 60Moment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. StandardSpindle RPM.[min –1 ]Gear load[Nm]Cycle time (incl. clamping)90° 180° 90° 180°[sec]4 th axis 5 th axis**at Jat Jat J*Mat Mmax. Standard max. Standard max. Standard max. Standard max. StandardSpindle RPM.[min –1 ]at Mmax. StandardTF-507510 0.05 1 0.35 0.87 0.48 1.37 111 30 30 240 0.57 3.5 0.82 6.5 60 5TF-510510 0.2 7 0.41 0.91 0.57 1.34 90 35 75 240 0.72 3.5 1.10 6.5 40 5TF-510520 0.2 7 0.41 0.91 0.57 1.34 90 35 75 420 0.89 3.6 1.49 6.5 30 5TF-520520 0.8 15 0.50 1.07 0.80 1.57 50 30 200 420 1.02 3.6 1.52 6.5 30 5TF-530530 2 30 0.58 1.27 0.90 2.02 46 20 420 600 1.83 3.5 3.33 6.5 10 5* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nmkg* with external hydraulic unit (220 bar) = 400 Nmat Mmax.** reference valuesEA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownTF-507510 TF-510510 TF-510520 TF-520520 TF-530530130m = 17 kgJ = 0.05 kgm 2165m = 35 kgJ = 0.17 kgm 2173m = 42 kgJ = 0.20 kgm 2228m = 90 kgJ = 0.80 kgm 2273m = 161 kgJ = 2.00 kgm 2WorkpiececlampingApplicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensivemixed operation (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.GeneralaccessoriesOptions / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company27

TF-...fixXStandardleft modelOptionright modelSummary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MDimensionsL = gear left (R = gear right, is laterally reversed)X1 min.A min.0.015/100 A0.006 0.0060YFF1AEB+0.1 D 0H min.0Coaxiality divider axis to swivelling axis = max ±0.02mmX min.±0.05C min.180° optionalX * X1 * Y A* B C* D E F F1 R HTF-507510 248 236 102 513 215 358 150 230 151 277 124 0TF-510510 248 248 125 550 265 422 200 289 176 302 176 50TF-510520 295 248 125 572 270 469 180 267 182 324 177 0TF-520520 295 295 177 678 320 499 230 330 241 383 208 50TF-530530 345 345 252 891 420 635 280 396 316 496 264 40* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Order no.TF–510520.LL fixX–FA5°0R90° Standard5°±0.05Important informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table modelSwivelling axis(5 th axis)Divider axis(4 th axis)28

TF-...fixXDivider with spacing plate= larger faceplate diameteris possibleø100 – ø200 TF-507510 fixXø160 – ø240 TF-510510 fixXø160 – ø240 TF-510520 fixXø200 – ø350 TF-520520 fixXø300 – ø500 TF-530530 fixXSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.kg4 th axis 5 th axiswithout withsupport support 4 th axis 5 th axis maxTF-507510 150 100 ... 200 60 90:1 120:1 55 75 300* 800 120 500 20TF-510510 200 160 ... 240 83 120:1 120:1 125 225 800 800 250 1'000 25TF-510520 180 160 ... 240 110 120:1 150:1 125 225 800 2'000 250 1'000 25TF-520520 230 200 ... 350 148 150:1 150:1 250 450 2'000 2'000 440 2'500 40TF-530530 280 300 ... 500 303 150:1 150:1 600 1'000 4'500 4'500 650 5'500 60Standard drive dataMoment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. StandardSpindle RPM.[min –1 ]Gear load[Nm]* with external hydraulic unit (220 bar) = 400 NmCycle time (incl. clamping)90° 180° 90° 180°[sec]4 th axis 5 th axis**at Jat Jat J*Mat Mmax. Standard max. Standard max. Standard max. Standard max. StandardSpindle RPM.[min –1 ]at Mmax. StandardTF-507510 0.05 1 0.35 0.87 0.48 1.37 111 30 30 240 0.57 3.5 0.82 6.5 60 5TF-510510 0.2 7 0.41 0.91 0.57 1.34 90 35 75 240 0.72 3.5 1.10 6.5 40 5TF-510520 0.2 7 0.41 0.91 0.57 1.34 90 35 75 420 0.89 3.6 1.49 6.5 30 5TF-520520 0.8 15 0.50 1.07 0.80 1.57 50 30 200 420 1.02 3.6 1.52 6.5 30 5TF-530530 2 30 0.58 1.27 0.90 2.02 46 20 420 600 1.83 3.5 3.33 6.5 10 5* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nm ** reference valuesat Mmax.EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownTF-507510 TF-510510 TF-510520 TF-520520 TF-530530130m = 17 kgJ = 0.05 kgm 2165m = 35 kgJ = 0.17 kgm 2173m = 42 kgJ = 0.20 kgm 2228m = 90 kgJ = 0.80 kgm 2273m = 161 kgJ = 2.00 kgm 2WorkpiececlampingApplicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensivemixed operation (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.GeneralaccessoriesOptions / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company29

TF-...varioStandardleft modelOptionright modelTF-507510 microleft model,or with spindleModel micro:Drive data (RPM,acceleration...) isapprox. 40% lowerfor divider axes.Summary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MAbmessungenL = gear left (R = gear right, is laterally reversed)X1min.0.006A min.0YFF1A0.015/100 A0.006B+0.1 D 0 EH min.Coaxiality divider axis to swivelling axis = max ±0.02mm0X min.±0.02C min.180° optionalX * X1 * Y A* B C* D E F F1 R HTF-507510 248 236 55 466 265 382 200 200 104 230 197 50TF-510510 248 248 65 490 285 422 220 223 116 242 212 70TF-510520 295 248 65 512 320 469 230 230 122 264 214 50TF-520520 295 295 90 591 350 499 260 260 154 296 251 80TF-530530 345 345 140 779 460 635 320 320 204 384 313 80TF-507510.L microModel left: drive divider through swivelling spindle(R = drive by spindle or right, is laterally reversed)Standard motors for both axes are FANUC b0.5/5000; for details see pages56–57. Drive data is reduced appropriately in comparison to values on page 31.Please contact the factory should you have any questions.755500.00655126.3433Order no.252.3X=3580.015/100 A0.006215TF–510520.LL vario–FAA1500Y min.=190(300 ... 380)Coaxiality divider axis to swivelling axis = max ±0.02mm110655°05°05°5565855°90° StandardR±0.0290° StandardR146* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Important informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table modelSwivelling axis(5 th axis)Divider axis(4 th axis)30

TF-...varioDivider (4 th axis) withadapter plateis height adjustableø100 TF-507510 varioMax. use ø, no standard faceplates availableø108 TF-507510 varioø128 TF-510510 varioø128 TF-510520 varioø178 TF-520520 varioø278 TF-530530 varioSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.kg4 th axis 5 th axiswithout withsupport support 4 th axis 5 th axis maxTF-507510 200 100 (108) 61 90:1 120:1 55 75 300* 800 120 500 20TF-510510 220 (128) 76 120:1 120:1 125 225 800 800 250 1'000 25TF-510520 230 (128) 104 120:1 150:1 125 225 800 2'000 250 1'000 25TF-520520 260 (178) 139 150:1 150:1 250 450 2'000 2'000 440 2'500 40TF-530530 320 (278) 289 150:1 150:1 600 1'000 4'500 4'500 650 5'500 60Standard drive dataMoment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. StandardSpindle RPM.[min –1 ]Gear load[Nm]* with external hydraulic unit (220 bar) = 400 NmCycle time (incl. clamping)90° 180° 90° 180°[sec]4 th axis 5 th axis**at Jat Jat J*Mat Mmax. Standard max. Standard max. Standard max. Standard max. StandardSpindle RPM.[min –1 ]at Mmax. StandardTF-507510 0.05 3 0.35 0.87 0.48 1.37 111 30 30 240 0.57 3.5 0.82 6.5 60 5TF-510510 0.2 7 0.41 0.91 0.57 1.34 90 35 75 240 0.72 3.5 1.10 6.5 40 5TF-510520 0.2 7 0.41 0.91 0.57 1.34 90 35 75 420 0.89 3.6 1.49 6.5 30 5TF-520520 0.8 15 0.50 1.07 0.80 1.57 50 30 200 420 1.02 3.6 1.52 6.5 30 5TF-530530 2 30 0.58 1.27 0.90 2.02 46 20 420 600 1.83 3.5 3.33 6.5 10 5* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nm ** reference valuesat Mmax.EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownTF-507510 TF-510510 TF-510520 TF-520520 TF-530530130m = 17 kgJ = 0.05 kgm 2165m = 35 kgJ = 0.17 kgm 2173m = 42 kgJ = 0.20 kgm 2228m = 90 kgJ = 0.80 kgm 2273m = 161 kgJ = 2.00 kgm 2WorkpiececlampingApplicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensivemixed operation (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.GeneralaccessoriesOptions / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company31

TF-...varioXStandardleft modelOptionright modelSummary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MDimensionsL = gear left (R = gear right, is laterally reversed)X1 min.0.006A min.0YFF1A0.015/100 A0.006B+0.1D 0 EH min.Coaxiality divider axis to swivelling axis = max ±0.02mm0X min.±0.02C min.180° optionalX * X1* Y A* B C* D E F F1 R HTF-507510 248 236 102 513 265 382 200 200 151 277 197 50TF-510510 248 248 125 550 285 422 220 220 176 302 212 70TF-510520 295 248 125 572 320 469 230 230 182 324 214 50TF-520520 295 295 177 678 350 499 260 260 241 383 251 80TF-530530 345 345 252 891 460 635 320 320 316 396 313 80* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Order no.TF–510520.LL varioX–FA5°05°90° StandardR±0.02Important informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table modelSwivelling axis(5 th axis)Divider axis(4 th axis)32

TF-...varioXDivider (4 th axis) withadapter plateis height adjustableDivider with spacing plate= larger faceplate diameteris possibleø100 – ø200 TF-507510 varioXø160 – ø240 TF-510510 varioXø160 – ø240 TF-510520 varioXø200 – ø350 TF-520520 varioXø300 – ø500 TF-530530 varioXSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.kg4 th axis 5 th axiswithout withsupport support 4 th axis 5 th axis maxTF-507510 200 100 ... 200 67 90:1 120:1 55 75 300* 800 120 500 20TF-510510 220 160 ... 240 90 120:1 120:1 125 225 800 800 250 1'000 25TF-510520 230 160 ... 240 118 120:1 150:1 125 225 800 2'000 250 1'000 25TF-520520 260 200 ... 350 159 150:1 150:1 250 450 2'000 2'000 440 2'500 40TF-530530 320 300 ... 500 324 150:1 150:1 600 1'000 4'500 4'500 650 5'500 60Standard drive dataMoment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. StandardSpindle RPM.[min –1 ]Gear load[Nm]* with external hydraulic unit (220 bar) = 400 NmCycle time (incl. clamping)90° 180° 90° 180°[sec]4 th axis 5 th axis**at Jat Jat J*Mat Mmax. Standard max. Standard max. Standard max. Standard max. StandardSpindle RPM.[min –1 ]at Mmax. StandardTF-507510 0.05 1 0.35 0.87 0.48 1.37 111 30 30 240 0.57 3.5 0.82 6.5 60 5TF-510510 0.2 7 0.41 0.91 0.57 1.34 90 35 75 240 0.72 3.5 1.10 6.5 40 5TF-510520 0.2 7 0.41 0.91 0.57 1.34 90 35 75 420 0.89 3.6 1.49 6.5 30 5TF-520520 0.8 15 0.50 1.07 0.80 1.57 50 30 200 420 1.02 3.6 1.52 6.5 30 5TF-530530 2 30 0.58 1.27 0.90 2.02 46 20 420 600 1.83 3.5 3.33 6.5 10 5* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nm ** reference valuesat Mmax.EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownTF-507510 TF-510510 TF-510520 TF-520520 TF-530530130m = 17 kgJ = 0.05 kgm 2165m = 35 kgJ = 0.17 kgm 2173m = 42 kgJ = 0.20 kgm 2228m = 90 kgJ = 0.80 kgm 2273m = 161 kgJ = 2.00 kgm 2WorkpiececlampingApplicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensivemixed operation (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.GeneralaccessoriesOptions / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company33

T1-...fixStandardleft modelOptionright modelSummary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MDimensionsL = gear left (R = gear right, is laterally reversed)0.006A0YFF1A0.015/100 A 90° Standard0.006BED+0.10H min.0Coaxiality divider axis to swivelling axis = max ±0.02mmT1–510520.LL fix–FAX min.C min.180° optionalX * Y A B C* D E F F1 R HT1-507510 248 55 568 255 382 190 269 104 230 136 40T1-510520 295 65 614 310 469 220 307 122 264 177 40T1-520520 295 90 703 340 499 250 350 154 296 208 40T1-530530 345 140 891 455 659 315 448 204 384 270 40* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Order no.5°05°RImportant informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table modelSwivelling axis(5 th axis)Divider axis(4 th axis)34

T1-...fixø100 – ø200 T1-507510 fixø160 – ø240 T1-510520 fixø200 – ø300 T1-520520 fixø300 – ø400 T1-530530 fixSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.Standard drive datakg4 th axis 5 th axiswithout withsupport support 4 th axis 5 th axis maxT1-507510 190 100 ... 200 85 90:1 120:1 55 75 300* 1'100 120 500 20T1-510520 220 160 ... 240 121 120:1 150:1 125 225 800 2'600 250 1'000 25T1-520520 250 200 ... 300 166 150:1 150:1 250 450 2'000 4'000 440 2'500 40T1-530530 305 300 ... 400 328 150:1 150:1 600 1'000 4'500 6'500 650 5'500 60Moment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. StandardSpindle RPM.[min –1 ]Gear load[Nm]* with external hydraulic unit (220 bar) = 400 NmCycle time (incl. clamping)90° 180° 90° 180°[sec]4 th axis 5 th axis**at Jat Jat J*Mat Mmax. Standard max. Standard max. Standard max. Standard max. StandardSpindle RPM.[min –1 ]at Mmax. StandardT1-507510 0.05 1 0.35 0.87 0.48 1.37 111 30 30 240 0.57 3.5 0.82 6.5 60 5T1-510520 0.2 7 0.41 0.91 0.57 1.34 90 35 200 420 0.89 3.6 1.49 6.5 30 5T1-520520 0.8 15 0.50 1.07 0.80 1.57 50 30 200 420 1.02 3.6 1.52 6.5 30 5T1-530530 2 30 0.58 1.27 0.90 2.02 46 20 420 600 1.83 3.5 3.33 6.5 10 5* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nm ** reference valuesat Mmax.EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownT1-507510 T1-510520 T1-520520 T1-530530130m = 17 kgJ = 0.05 kgm 2m = 42 kgm = 90 kgm = 161 kg173 J = 0.20 kgm 2228 J = 0.80 kgm 2273 J = 2.00 kgm 2WorkpiececlampingStatus:12.05.2010 phMsst: 1:7Form.: A4Applicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensiveT1-507510.L fix_sp.Dokument Nr.:Ae.-In.:mixed operation Transportschema (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.Würfel 023-0008 0PETER LEHMANN AG, CH-3552 BÄRAUGeneralaccessoriesOptions / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company35

T1-...fixXStandardleft modelOptionright modelOptionupper left modelOptionupper right modelOLL/ORR model:Drive data (RPM,acceleration...) isapprox. 40% lowerfor divider axes.Summary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MDimensionsL = gear left (R = gear right, is laterally reversed)A0.015/100 A0.006 0.0060YFF1ABED+0.10H min.0Coaxiality divider axis to swivelling axis = max ±0.02mmT1–510520.LL fixX–FAX min.±0.02C min.180° optionalX * Y A B C* D E F F1 R HT1-507510 248 102 615 255 382 190 269 151 277 136 40T1-510520 295 125 674 310 469 220 307 182 324 177 40T1-520520 295 177 790 340 499 250 350 241 383 208 40T1-530530 345 252 1003 455 659 315 448 316 496 270 40* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Order no.5°05°R90° Standard±0.02OLL = gear upper left (ORR = gear upper right, is laterally reversed)0.0060AYFF1A0.015/100 A0.006BED +0.10Coaxiality divider axis to swivelling axis = max ±0.02mmH0X min.±0.02Swivelling axis(5 th axis)C min.180° optional5°R1 RX * Y A B C* D E F F1 R R1 HT1-510520 295 125 551 346 469 220 346 187 328 172 206 40T1-520520 295 177 630 340 499 240 351 241 383 208 272 40T1-530530 345 252 792 455 659 315 431 316 496 270 350 40Important informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table model090° Standard5°±0.05Divider axis(4 th axis)36

T1-...fixXDivider with spacing plate= larger faceplate diameteris possibleø100 – ø200 T1-507510 fixXø160 – ø240 T1-510520 fixXø200 – ø350 T1-520520 fixXø300 – ø500 T1-530530 fixXSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.kgwithout with4 th axis 5 th axis support support 4 th axis 5 th axis maxT1-507510 190 100 ... 200 101 90:1 120:1 55 75 300* 1'100 120 500 10T1-510520 220 160 ... 240 138 120:1 150:1 125 225 800 2'600 250 1'000 25T1-520520 250 200 ... 350 188 150:1 150:1 250 450 2'000 4'000 440 2'500 40T1-530530 315 300 ... 500 366 150:1 150:1 600 1'000 4'500 6'500 650 5'500 60EA + MTFStandard drive dataMoment ofinertia J[kgm 2 ]Cycle time (incl. clamping)[sec]Spindle RPM.[min –1 ]Gear load[Nm]Cycle time (incl. clamping)90° 180° 90° 180°[sec]Spindle RPM.[min –1 ]T1T2...T44 th axis 5 th axis**Jat Jat Jat J*Mat Mat Mat MStandard max. Standard max. Standard max. Standard max. Standard max. Standard max. Standard max. Standard max.T1-507510 0.05 1 0.35 0.87 0.48 1.37 111 30 30 240 0.57 3.5 0.82 6.5 60 5T1-510520 0.2 7 0.41 0.91 0.57 1.34 90 35 200 420 0.89 3.6 1.49 6.5 30 5T1-520520 0.8 15 050 1.07 0.80 1.57 50 30 200 420 1.02 3.6 1.52 6.5 30 5T1-530530 2 30 0.58 1.27 0.90 2.02 46 20 420 600 1.83 3.5 3.33 6.5 10 5* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nm ** reference valuesRFX/LFXTRIAGCAB / WMSMOT / CNCSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownT1-507510 T1-510520 T1-520520 T1-530530130m = 17 kgJ = 0.05 kgm 2m = 42 kgm = 90 kgm = 161 kg173 J = 0.20 kgm 2228 J = 0.80 kgm 2273 J = 2.00 kgm 2WorkpiececlampingStatus:12.05.2010 phMsst: 1:7Form.: A4Applicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensiveT1-507510.L fix_sp.Dokument Nr.:Ae.-In.:mixed operation Transportschema (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.Würfel 023-0008 0PETER LEHMANN AG, CH-3552 BÄRAUGeneralaccessoriesOptions / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company37

T1-...varioStandardleft modelOptionright modelSummary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MDimensionsL = gear left (R = gear right, is laterally reversed)A0.015/100 A0.006 0.006B0YFF1T1–510520.LL vario–FAAD +0.1 E0Coaxiality divider axis to swivelling axis = max ±0.02mmH0X min.±0.02C min.180° optionalX * Y A B C* D E F F1 R HT1-507510 248 55 568 305 382 240 240 104 230 197 40T1-510520 295 65 614 360 469 270 270 122 264 214 40T1-520520 295 90 703 390 499 300 300 154 296 251 40T1-530530 345 140 891 500 659 360 360 204 384 319 40* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Order no.5°05°R90° Standard±0.02Important informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table modelSwivelling axis(5 th axis)Divider axis(4 th axis)38

T1-...varioDivider (4 th axis) withadapter plateis height adjustableø100 T1-507510 varioMax. use ø, no standard faceplates availableø108 T1-507510 varioø128 T1-510510 varioø128 T1-510520 varioø178 T1-520520 varioø278 T1-530530 varioSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.kg4 th axis 5 th axiswithout withsupport support 4 th axis 5 th axis maxT1-507510 190 100 (108) 96 90:1 120:1 55 75 300* 1'100 120 500 20T1-510520 280 (128) 136 120:1 150:1 125 225 800 2'600 250 1'000 25T1-520520 310 (178) 187 150:1 150:1 250 450 2'000 4'000 440 2'500 40T1-530530 360 (278) 363 150:1 150:1 600 1'000 4'500 6'500 650 5'500 60Standard drive dataMoment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. StandardSpindle RPM.[min –1 ]Gear load[Nm]* with external hydraulic unit (220 bar) = 400 NmCycle time (incl. clamping)90° 180° 90° 180°[sec]4 th axis 5 th axis**at Jat Jat J*Mat Mmax. Standard max. Standard max. Standard max. Standard max. StandardSpindle RPM.[min –1 ]at Mmax. StandardT1-507510 0.05 1 0.35 0.87 0.48 1.37 111 30 30 240 0.57 3.5 0.82 6.5 60 5T1-510520 0.2 7 0.41 0.91 0.57 1.34 90 35 200 420 0.89 3.6 1.49 6.5 30 5T1-520520 0.8 15 0.50 1.07 0.80 1.57 50 30 200 420 1.02 3.6 1.52 6.5 30 5T1-530530 2 30 0.58 1.27 0.90 2.02 46 20 420 600 1.83 3.5 3.33 6.5 10 5* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nm ** reference valuesat Mmax.EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownT1-507510 T1-510520 T1-520520 T1-530530130m = 17 kgJ = 0.05 kgm 2m = 42 kgm = 90 kgm = 161 kg173 J = 0.20 kgm 2228 J = 0.80 kgm 2273 J = 2.00 kgm 2WorkpiececlampingStatus:12.05.2010 phMsst: 1:7Form.: A4Applicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensiveT1-507510.L fix_sp.Dokument Nr.:Ae.-In.:mixed operation Transportschema (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.Würfel 023-0008 0PETER LEHMANN AG, CH-3552 BÄRAUGeneralaccessoriesOptions / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company39

T1-...varioXStandardleft modelOptionright modelOptionupper left modelOptionupper right modelOLL/ORR model:Drive data (RPM,acceleration...) isapprox. 40% lowerfor divider axes.Summary+ Technol.CompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MDimensionsL = gear left (R = gear right, is laterally reversed)A0.015/100 A0.006 0.0060YFF1AB+0.1 D 0 ECoaxiality divider axis to swivelling axis = max ±0.02mmT1–510520.LL varioX–FAH0X min.±0.02C min.180° optionalX * Y A B C* D E F F1 R HT1-507510 248 102 615 305 382 240 240 151 277 197 40T1-510520 295 125 674 360 469 270 270 182 324 214 40T1-520520 297 177 790 390 499 300 300 241 383 251 40T1-530530 345 252 1003 490 659 390 390 316 496 319 40* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Order no.5°05°R90° Standard±0.02OLL = gear upper left (ORR = gear upper right, is laterally reversed)A0.015/100 A0.006 0.006BYA0YFF1D +0.1 E 0Coaxiality divider axis to swivelling axis = max ±0.02mmH0R1X min.±0.02C min.180° optionalX * Y A B C* D E F F1 R R1 HT1-510520 295 125 551 350 429 260 260 182 328 220 256 40T1-520520 295 177 630 420 499 330 330 246 387 251 338 40T1-530530 345 252 792 530 659 390 390 316 496 319 431 40Important informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table model0Swivelling axis(5 th axis)5°R90° Standard±0.02Divider axis(4 th axis)40

T1-...varioXDivider (4 th axis) withadapter plateis height adjustableDivider with spacing plate= larger faceplate diameteris possibleø100 – ø200 T1-507510 varioXø160 – ø240 T1-510520 varioXø200 – ø350 T1-520520 varioXø300 – ø500 T1-530530 varioXSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.kg4 th axis 5 th axiswithout withsupport support 4 th axis 5 th axis maxT1-507510 240 100 ... 200 112 90:1 120:1 55 75 300* 1'100 120 500 20T1-510520 270 160 ... 240 152 120:1 150:1 125 225 800 2'600 250 1'000 25T1-520520 300 200 ... 350 207 150:1 150:1 250 450 2'000 4'000 440 2'500 40T1-530530 390 300 ... 500 399 150:1 150:1 600 1'000 4'500 6'500 650 5'500 60Standard drive dataMoment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. StandardSpindle RPM.[min –1 ]Gear load[Nm]* with external hydraulic unit (220 bar) = 400 NmCycle time (incl. clamping)90° 180° 90° 180°[sec]4 th axis 5 th axis**at Jat Jat J*Mat Mmax. Standard max. Standard max. Standard max. Standard max. StandardSpindle RPM.[min –1 ]at Mmax. StandardT1-507510 0.05 1 0.35 0.87 0.48 1.37 111 30 30 240 0.57 3.5 0.82 6.5 60 5T1-510520 0.2 7 0.41 0.91 0.57 1.34 90 35 200 420 0.89 3.6 1.49 6.5 30 5T1-520520 0.8 15 0.50 1.07 0.80 1.57 50 30 200 420 1.02 3.6 1.52 6.5 30 5T1-530530 2 30 0.58 1.27 0.90 2.02 46 20 420 600 1.83 3.5 3.33 6.5 10 5* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nm ** reference valuesat Mmax.EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCSpindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shownT1-507510 T1-510520 T1-520520 T1-530530130m = 17 kgJ = 0.05 kgm 2m = 42 kgm = 90 kgm = 161 kg173 J = 0.20 kgm 2228 J = 0.80 kgm 2273 J = 2.00 kgm 2WorkpiececlampingStatus:12.05.2010 phMsst: 1:7Form.: A4Applicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensiveT1-507510.L fix_sp.Dokument Nr.:Ae.-In.:mixed operation Transportschema (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.Würfel 023-0008 0PETER LEHMANN AG, CH-3552 BÄRAUGeneralaccessoriesOptions / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company41

T2 / T3 / T4-...fixStandard T2left modelStandard T3left modelStandard T4left modelSummary+ Technol.Minimum spindle distanceof the divider axis dimension G:507 = 135mm510 = 155mmCompanyGeneralWorkpiece CAB / WMS RFX/LFXaccessoriesclamping MOT / CNC TRIAG T2...T4 T1 TF EA +MOption T2right model0.006±0.030.006±0.03±0.02GA±0.02A0±0.02 ±0.02 ±0.02GYFF1T2–510520.LL fix–FA0YFOption T3right modelDimensionsL = gear left (R = gear right, is laterally reversed)A0.015/100 A0.006BED +0.10F1H min.0Coaxiality divider axis to swivelling axis = max ±0.05mm0.015/100 A0.006ABED +0.10H min.0X min.±0.05X min.±0.05C min.180° optional5°5°0C min.05°180° optionalOption T4right modelX * Y A B C* D E F F1 R G HT2-507510 248 55 728 255 324 190 269 104 230 136 160 40T2-510520 295 65 794 310 469 220 306 122 264 177 180 40L = gear left (R = gear right, is laterally reversed)Coaxiality divider axis to swivelling axis = max ±0.05mmX * Y A B C* D E F F1 R G HT4-507510 248 55 1048 255 324 190 269 104 230 136 160 40T4-510520 295 65 1154 310 469 220 306 122 264 177 180 40Order no.RR90° Standard5°90° Standard±0.05±0.05L = gear left (R = gear right, is laterally reversed)0.006A±0.02 ±0.02G0YFF1A0.015/100 A0.006BED +0.10H min.0Coaxiality divider axis to swivelling axis = max ±0.05mmX min.±0.05C min.180° optional5°0R5°90° StandardX * Y A B C* D E F F1 R G HT3-507510 248 55 888 255 324 190 269 104 230 136 160 40T3-510520 295 65 974 310 469 220 306 122 264 177 180 40* Dimensions apply for standard motor. Can be up to 50 mm longer for othermotors. For exact dimensions see motor table on pages 56–57.Important informationTwo geometric accuracies are available– Standard = see respective dimensions sheet above– high precision: all accuracies ½ Standard tolerance GEO.???-GEN(required per spindle e.g. for T2-510520 = 3x)??? = type of rotary table (e.g. 510)Error compensationDifferent loads and their forms can result in accuracy differences. We thereforerecommend that you always compensate the reversal slack in both axes or use adirect angular position measuring system. (see page 55)Swivelling range 180°Order no. SWB.???-180 (??? = rotary table type 5th axis, e.g. 510)Center increaseDepending on suitable accessories (clamping cylinder, rotary union, angular positionmeasuring system...), a center increase (dimension D) is required. (See pageswith the respective accessories)MotorMA=Mavilor/Movinor for Siemens/Heidenhain, FA=Fanuc,YA=Yaskawa, SA=Sanyo, MI=Mitsubishi/MeldasDivider add-on version Motor pos. swivelling axis L=left, R=rightMotor pos. divider axis L=left, R=right, OR=upper right, OL= upper leftSize of swivelling axis 510, 520 or 530Size of divider axis 507, 510, 520 or 530Rotary table modelSwivelling axis(5 th axis)±0.05Divider axis(4 th axis)42

T2 / T3 / T4-...fixø100 T...-507510 fixø160 T...-510520 fixMax. use ø, no standard faceplates availableø158 T...-507510 fixø178 T...-510520 fixSize / load-bearing capacityCenterheight[mm]ø faceplate[mm]Weight[kg]Total ratiomax. spindle load[kg]Clamping torque[Nm]Feedtorque[Nm]Pull-outtorque[Nm]Axialforce[kN]Summary+ Technol.kg4 th axis 5 th axiswithout withsupport support 4 th axis 5 th axis max max maxT2-507510 190 100 (158) 99 90:1 120:1 55 75 300* 1'100 120 500 10T3-507510 190 100 (158) 135 90:1 120:1 55 75 300* 1'100 120 500 6.6T4-507510 190 100 (158) 173 90:1 120:1 55 75 300* 1'100 120 500 5T2-510520 220 160 (178) 171 120:1 150:1 125 225 800 2'600 250 1'000 12.5T3-510520 220 160 (178) 222 120:1 150:1 125 225 800 2'600 250 1'000 8.3T4-510520 220 160 (178) 274 120:1 150:1 125 225 800 2'600 250 1'000 6.3Standard drive dataMoment ofinertia J[kgm 2 ]StandardCycle time (incl. clamping)[sec]Jmax. StandardSpindle RPM.[min –1 ]Gear load[Nm]Cycle time (incl. clamping)90° 180° 90° 180°[sec]4 th axis** 5 th axis**at Jat Jat J*Mat Mmax. Standard max. Standard max. Standard max. Standard max. StandardSpindle RPM.[min –1 ]at Mmax. StandardT2-507510 0.05 1 0.54 0.94 0.87 1.54 45 25 35 240 0.72 3.5 0.82 6.5 30 5T3-507510 0.05 1 0.70 1.35 1.20 2.40 30 15 55 240 0.80 3.5 0.82 6.5 20 5T4-507510 0.05 1 0.90 1.80 1.65 3.30 20 10 70 240 1.00 3.5 0.82 6.5 15 5T2-510520 0.2 7 0.49 1.02 0.79 1.62 50 25 95 420 0.89 3.6 1.49 6.5 30 5T3-510520 0.2 7 0.51 1.19 0.84 1.94 45 20 110 420 0.95 3.6 1.49 6.5 20 5T4-510520 0.2 7 0.59 1.19 1.02 2.47 35 15 125 420 1.24 3.6 1.49 6.5 15 5Spindle load (for standard drive data) Material: steel<strong>The</strong> standard moment of inertia in the table «standard drive data» corresponds to a loading of the tool spindle with the load shown* with external hydraulic unit (220 bar) = 400 Nm* total load center to swivel center of 5 th axis [m] x total load [kg] x 9.81 [m/s 2 ] = Nm ** reference valuesat Mmax.EA + MTFT1T2...T4RFX/LFXTRIAGCAB / WMSMOT / CNCWorkpiececlampingT2-507510114m = 12 kgJ = 0.025 kgm 2T2-510520 m = 21 kg T3-507510T3-510520 T4-507510T4-510520J = 0.10 kgm 2140105121100112m = 9 kgJ = 0.017 kgm 2m = 14 kgJ = 0.07 kgm 2m = 8 kgJ = 0.013 kgm 2m = 11 kgJ = 0.05 kgm 2GeneralaccessoriesApplicable for MAVILOR/MOVINOR standard motors. Dimensioned for intermittent service S3 ED20% with an operating time of 5 minutes (in accordance with DIN/VDE 0520). Other motors or higher ED require adjustment of the drive data (acceleration, jerk limitation, RPM). Reference values: for milling / drilling in intensivemixed operation (positioning/feed machining) approx. 40% ED, profile and depth grinding approx. 60% ED or engraving approx 80-100% ED. ED = duty cycle.Options / accessoriesFor spindle options see page 22. Cable, motor and angular position measuring system and pL CNC on page 54 onward. Accessories on page 62 onwardAll valuesapply atoperationaltemperature.Company43