V-Flow DF dry-fix GRP valley gutter system - Filon Products

V-Flow DF dry-fix GRP valley gutter system - Filon Products

V-Flow DF dry-fix GRP valley gutter system - Filon Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

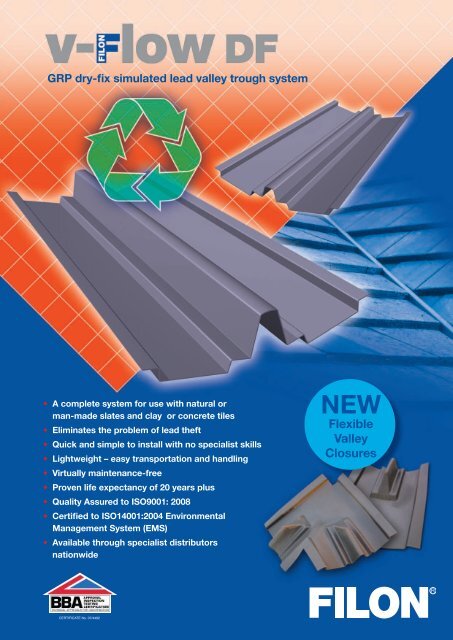

<strong>GRP</strong> <strong>dry</strong>-<strong>fix</strong> simulated lead <strong>valley</strong> trough <strong>system</strong>• A complete <strong>system</strong> for use with natural orman-made slates and clay or concrete tiles• Eliminates the problem of lead theft• Quick and simple to install with no specialist skills• Lightweight – easy transportation and handling• Virtually maintenance-free• Proven life expectancy of 20 years plus• Quality Assured to ISO9001: 2008• Certified to ISO14001:2004 EnvironmentalManagement System (EMS)• Available through specialist distributorsnationwideNEWFlexibleValleyClosuresCERTIFICATE No. 07/4492

V-<strong>Flow</strong> <strong>DF</strong> <strong>GRP</strong> <strong>dry</strong>-<strong>fix</strong> <strong>valley</strong> troughsFILON has been producing <strong>GRP</strong> (Glass Reinforced Polyester)products for over 50 years and produced the first <strong>GRP</strong> <strong>valley</strong><strong>gutter</strong>s for the UK market in the 1980’s.FILON <strong>valley</strong> troughs are produced for a number of UK andEuropean companies and are sold via selected distributors.The V-<strong>Flow</strong> <strong>DF</strong> <strong>valley</strong> trough range caters for tiles and slate roofmaterials and allows for even the deepest tile profile to be used,with the G<strong>DF</strong>VT110 <strong>valley</strong> trough. This <strong>dry</strong>-<strong>fix</strong> <strong>system</strong> has beenbeen developed to eliminate the problems associated with theuse of cement mortar and is finished in grey to simulate theappearance of lead. The flexible closures are finished inmatt black.<strong>Filon</strong> V-<strong>Flow</strong> <strong>DF</strong> <strong>valley</strong> troughs have a minimum life expectancyof 20 years. Many FILON <strong>GRP</strong> products, which use the sametechnology as the V-<strong>Flow</strong> range, achieve working lifespans inexcess of 30 years or more.FILON’s V-<strong>Flow</strong> <strong>DF</strong> <strong>valley</strong> troughs and accessories are fullyrecyclable at end of life.Installation instructions1. V-<strong>Flow</strong> <strong>valley</strong> troughs are suitable for roof pitches up to 60º.FILON strongly recommends that where possible, plywood orother suitable <strong>valley</strong> boards should be used.2. The underlay material and battens should be <strong>fix</strong>ed inaccordance with standard roofing best practice with a battenrunning the length of the <strong>valley</strong> on each side to accommodatethe V-<strong>Flow</strong> <strong>DF</strong> external raised water bar section.3. When using the FILON eaves closure, the 150mm long <strong>GRP</strong>pre-cut <strong>valley</strong> section support should be positioned close to theeaves. (See photo A, opposite).4. The eaves closure piece should be overlaid onto the <strong>GRP</strong> precut<strong>valley</strong> section (ensuring 150mm overlap), ensuring that theside winged sections are located over the longitudinal battens(See photo B, opposite). The bottom of the eaves closurepiece should overhang the eaves. At the highest point of theeaves closure section a large headed galvanised or aluminiumnail should be <strong>fix</strong>ed through the section into the longitudinalbatten. Note: A length of flexible packing is supplied with theeaves closure, to use if required to form the continuation of theside support timber battens (when the angle of the <strong>valley</strong> doesnot allow the battens to extend to the rear of the fascia board).5. V-<strong>Flow</strong> <strong>DF</strong> <strong>valley</strong> troughs are fitted onto the <strong>valley</strong> boards andshould be firmly <strong>fix</strong>ed from the eaves closure section upwards,using suitable large headed roofing nails on either side of thetrough and through the top flat section of the water bar, at aminimum of 500mm centres (See photo C, opposite).All overlaps of troughs and eaves closure piece should beat least 150mm. Care should be taken to ensure that thecentral raised section is not distorted in any way and that it ispositioned central to the <strong>valley</strong>.6. If the <strong>valley</strong> trough finishes at a ridge section with acorresponding <strong>valley</strong>, the top closure pieces 90 or 75 canbe used. These closure sections overlap the <strong>valley</strong> troughsand underlap the slates / tiles that form over this point. Thelongitudinal battens of each <strong>valley</strong> should meet and be mitredso that the top of the top closure can be <strong>fix</strong>ed with a suitableroofing nail to stop any movement. The top closure thenoverlaps both <strong>valley</strong> troughs by 150mm and forms a neat, tidy,waterproof seal. (See photo E, opposite).7. Tiles or slates being laid into and over the troughs should belaid in accordance with the manufacturer’s recommendations.When cutting tiles or slates it is important that neither shouldbe forced to fit. The central raised section of the V-<strong>Flow</strong> <strong>valley</strong>trough should not be distorted.8. Where possible the roof tiling should be planned to avoid smallcut sections. However, in some instances small cuts will berequired. Self adhesive packers are supplied with the <strong>valley</strong> tosupport these small cuts if required (See fig 2, below).9. When the slating or tiling has being completed, the eavesclosure section should be cut with a sharp knife or scissors toallow water discharge into the rain water <strong>gutter</strong>.10. It is important to ensure that the <strong>valley</strong> troughs are cleared ofany debris on completion, so water flow is not impeded.Fig 1. G<strong>DF</strong>VT70 V-<strong>Flow</strong> <strong>valley</strong> troughSlate or shallow tile applicationBATTENFELT OVERLAYFIXINGPOINTFELTLAID UPVALLEYLONGITUDINALBATTENV-FLOW VALLEYTROUGHFIXING POINTSLATEFig 2. G<strong>DF</strong>VT110 V-<strong>Flow</strong> <strong>valley</strong> troughConcrete tile applicationBATTENCONCRETETILEROOFINGUNDERLAYV-FLOW VALLEYTROUGHCONCRETE TILELONGITUDINALBATTENRAFTERRAFTERNOTE: Packer may not be required

ABA. 150mm long pre-cut <strong>GRP</strong> <strong>valley</strong> section support is placedon the battens so that it will locate under the raised ridge of the flexibleeaves closure piece which will be placed on top of the support. Thismust be positioned to allow the closure piece to be later cut to length todischarge into the <strong>gutter</strong>.CB. The eaves closure piece is placed over the support – a flexiblepacking piece is used to support the sides of the closure if thebattens do not extend to the fascia.DC. The V-<strong>Flow</strong> <strong>DF</strong> <strong>valley</strong> trough is <strong>fix</strong>ed in position over the eavesclosure piece at 500 mm centres, with large headed galvanised oraluminium nails.ED. The eaves closure piece is cut to allow water dischargeinto the <strong>gutter</strong>.FE. The top closure 90 or 75 should be <strong>fix</strong>ed in positionover the two joining FILON V-<strong>Flow</strong> <strong>DF</strong> <strong>valley</strong> troughs.F. The completed installation: neat, tidy and effective –with minimal on-site time.

V-<strong>Flow</strong> <strong>DF</strong> Technical informationHandling and StorageAppropriate care must be taken at all times when handling, storingand installing <strong>GRP</strong> roofing <strong>system</strong> components. Care must betaken to avoid damage to edges of sheets and trims. All <strong>GRP</strong>components should be stored under cover in <strong>dry</strong> conditions wherepossible. When stored in open conditions, components should bekept clear of the ground on timber battens or pallets and protectedby opaque, waterproof covers.Specification and Application<strong>GRP</strong> components can be specified for warm or cold roofconstructions in new build or refurbishment projects. They aresuitable for use with most types of roof construction. The relevantcomponents have been tested in accordance with BS 2782 andBS 4154 for <strong>GRP</strong>.SealantsLow modulus sealants can be used with <strong>GRP</strong> products.If in doubt, always seek advice as to the correct sealant.BiologicalResistant to attack by micro-organisms, fungi, larvae, insects andmildew. Wash with mild detergents to remove deposits.Thermal Properties‘U’ value is dependent upon roof construction.Coefficient of linear expansion: 22 x 10 -6 m/m per ºC.Effects of SunlightAll polyester resins used in production of FILON <strong>GRP</strong>, as well asthose used for laminating, are UV stabilised. FILON <strong>valley</strong> <strong>gutter</strong>shave a UV protective coating on the weather face.CompatibilityNo chemical reaction with other established construction materialswhen fully cured.FireTested to: BS476 - Part 3 – SAB. BS476 - Part 7 – Class 3.Effects of ChemicalsSuitable for exposed, harsh environments. Certain acids, alkalisand solutions of water soluble gases may attack <strong>GRP</strong> sheets and<strong>fix</strong>ings. Where such conditions occur please contact you supplier.LiquidsWater absorption: 50mg after 7days (BS2782: Part 4, Method430A: 1983).Eaves closure piece90º / 70º top closurepieceG<strong>DF</strong>VT70 Valley TroughG<strong>DF</strong>VT110 Valley Troughfor use with natural orman-made slates400mmfor use with concrete/claytiles or slate roofing400mm3000mm3000mm70mm highcentreupstand110mm highcentreupstand<strong>Filon</strong> <strong>Products</strong> LimitedUnit 3, Ring Road, Zone 2, Burntwood Business ParkBurntwood, Staffordshire WS7 3JQ, EnglandTel: +44 (0)1543 687300 Fax: +44 (0)1543 687303Email: sales@filon.co.ukFILON is a trademark of <strong>Filon</strong> <strong>Products</strong> Ltd.Information and recommendations contained in this publication are given ingood faith without warranty or guarantee. We are constantly seeking to improveour products and therefore reserve the right to alter specifications at any time.No liability can be accepted for any claims, losses or demands arising fromcontents of this publication. This statement does not affect statutory rightswhich cannot be excluded by agreement.www.filon.co.ukM.VFLOW<strong>DF</strong>.10.12