Effideck™ precast concrete deck panels utilize ... - Prolamsa USA

Effideck™ precast concrete deck panels utilize ... - Prolamsa USA

Effideck™ precast concrete deck panels utilize ... - Prolamsa USA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

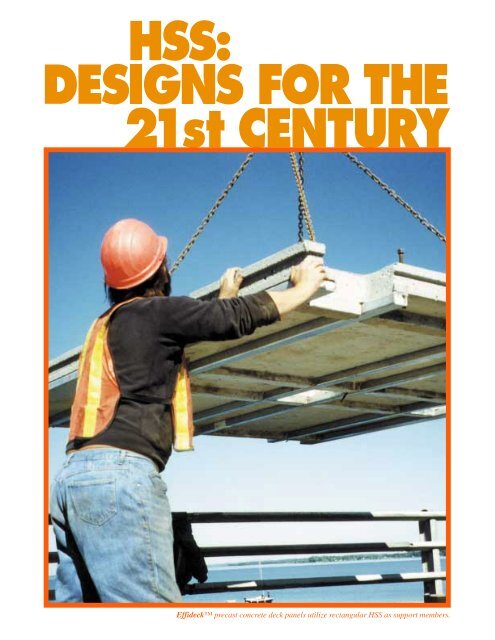

Effi<strong>deck</strong> <strong>precast</strong> <strong>concrete</strong> <strong>deck</strong> <strong>panels</strong> <strong>utilize</strong> rectangular HSS as support members.

NEW BRIDGE PANELS, USING HSS, HELP END A70-MILE DETOUR—IN LESS THAN FIVE DAYS!Effi<strong>deck</strong> Lets RepairsBe Completed Quickly,and at Minimum CostThe closing of Vermont's Missiquoi BayBridge, part of the northernmost U. S.crossing of Lake Champlain, was no minorinconvenience to motorists, since it causeda detour of 70 miles. But thanks to arevolutionary new bridge <strong>deck</strong> replacementsystem, Effi<strong>deck</strong>, that <strong>utilize</strong>s steelHollow Structural Sections (HSS), theheavily-traveled span was closed to trafficfor less than five days.Effi<strong>deck</strong> was developed by The Fort MillerCo., Inc., a <strong>precast</strong> <strong>concrete</strong> companylocated in Schuylerville, New York. Ft.Miller chose HSS for the support membersof the system's <strong>precast</strong> <strong>concrete</strong> <strong>deck</strong><strong>panels</strong> because of its high strength-toweightratio, exceptional size range andready availability.In the Alburg-Swanton Bridge project—one of three in which the new system hasproved its worth—more than 2,000 squarefeet of <strong>deck</strong>ing in two 84-foot spansneeded to be replaced. Ft. Miller cast 16<strong>concrete</strong>-and-steel <strong>panels</strong>, each approximately12' by 10' and weighing four tons.The steel support members were 2" x 3"and 2" x 6" rectangular HSS.

The straight sides of square or horizontalHSS make it easy to assemble <strong>concrete</strong>forms around them, keeping panel fabricationcosts low. And the availability of HSSgives it a big advantage over grid <strong>deck</strong>s thatrequire long lead times to procure andfabricate.Ft. Miller's Effi<strong>deck</strong> system has been<strong>utilize</strong>d in two other New England bridgeprojects—replacement of 23,000 squarefeet of <strong>panels</strong> in a parking <strong>deck</strong> over theNew England Thruway at Larchmont, NewYork, and a 117-foot-long bridge over astream that provides the principal access toan outlet mall in Lee, Massachusetts. Ft.Miller is also marketing Effi<strong>deck</strong> <strong>panels</strong> tosimplify and speed parking <strong>deck</strong> retrofitprojects.Effi<strong>deck</strong> is presently undergoing extensivetesting to meet the standards of the NewYork State Department of Transportation,among the most stringent in the nation.AmericanIron and SteelInstitute2000 Ponce de Leon, Suite 600, Coral Gables, FL 33134 • Tel: (305) 421-6326E-mail: STINA@steeltubeinstitute.org • Website: http://www.steeltubeinstitute.org