download Gradall Telehandlers Product Brochure - Gold Coast Hi-Lift

download Gradall Telehandlers Product Brochure - Gold Coast Hi-Lift

download Gradall Telehandlers Product Brochure - Gold Coast Hi-Lift

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

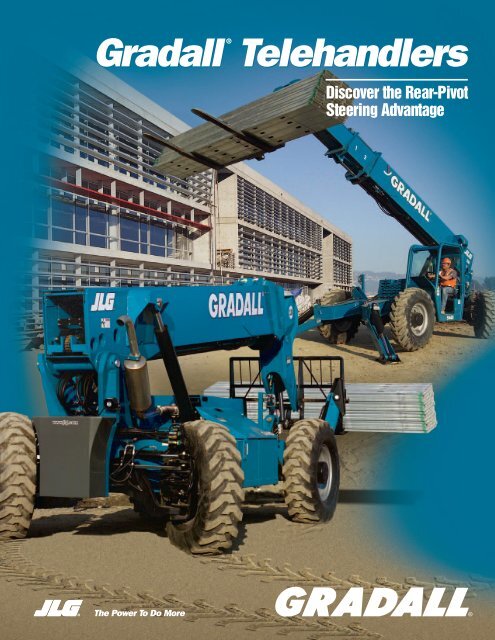

<strong>Gradall</strong>® <strong>Telehandlers</strong>Discover the Rear-PivotSteering Advantage

90˚ REAR-PIVOT STEERING▼<strong>Gradall</strong> ®telehandlers can maneuverand turn sharply on an axis allowingthe operator to move, square andplace loads with precision.Nothing Maneuvers<strong>Gradall</strong> ®AdvantagesManeuverability & Precision Handling■ 90˚ rear-pivot steering fornegotiating narrow aislesor crowded job sites.■ Mid-mounted engine providesbalanced weight distribution,allowing operation in mud,rocks or sand.■ Long wheelbase forlow center of gravity andstability on rough terrain.■ No-shift hydrostatic drive train providesthe precision handling operatorsneed to inch the machine into exactpositions for critical load placements.Versatility & Efficiency■ Quick-Switch attachments turnyour base machine into a versatileproductivity tool for dozens of jobsite challenges.■ Spacious and comfortableoperator cab provides protectionand a clear view.■ Convenient single joystick controlfor boom lift and crowd.Strength & Reliability■ <strong>Hi</strong>gher capacities throughout lift range.■ Rugged design and proven durabilityfor lower cost of operation.

Like a <strong>Gradall</strong>®TelehandlerWhat Can You Do witha <strong>Gradall</strong> Telehandler?<strong>Gradall</strong> telehandlers are widely recognized for theirstrength, reliability and low cost of ownership. Butit’s their exclusive 90˚ rear-pivot steering thatsets them apart. And gives you outstandingmaneuverability even in the tightest work areas.Operators can take them where other telehandlerscan’t go. They can turn sharp corners, move downnarrow aisles and square-up lumber and block incrowded landing areas with greater speed andaccuracy. All with a clear view of the job site fromthe comfort of a spacious machine cab. Plus, <strong>Gradall</strong>telehandlers can be equipped with a full range ofattachments to handle a wide variety of jobs. Forthe high level performance you need, there’salmost nothing a <strong>Gradall</strong> Telehandler can’t do.Makes sharp turns aroundcorners and obstacles. Turnswithin its outside radius fornarrow or enclosed areas.

<strong>Gradall</strong> <strong>Telehandlers</strong>Backed by the Power of JLG<strong>Gradall</strong> telehandlers are backed by thestrength and technology of JLG, withthe most powerful service, parts,support and distribution in the world.You’ll have everything you need to keepyour machine on the job, whenever andwherever you need it.Attachments to help youget the job doneChoose from a wide variety of Quick-Switch attachments and turn your<strong>Gradall</strong> telehandler into a versatileproductivity tool capable of handlingdozens of job site challenges. Ourexclusive boom-end designs allow asingle operator to change from oneattachment to another in seconds.ModelRatedCapacityMaximum<strong>Lift</strong> HeightCapacity@ Max.<strong>Lift</strong> HeightMaximumReachCapacity@ Max. ReachEngine<strong>Gradall</strong> 6,600 lb 42 ft 6,000 lb 29 ft 1,300 lb John DeereG6-42P (2,994 kg) (12.8 m) (2,722 kg) (8.84 m) (590 kg) 4045DF150<strong>Gradall</strong> 9,000 lb 45 ft 7,000 lb 31 ft 6 in. 1,600 lb John Deere534D9-45 (4,082 kg) (13.7 m) (3,175 kg) (9.6 m) (726 kg) 4045TF275<strong>Gradall</strong> 10,000 lb 45 ft 7,000 lb 31 ft 6 in. 4,500 lb* John Deere534D10-45 (4,536 kg) (13.7 m) (3,175 kg) (9.6 m) (2,041 kg) 4045TF275<strong>Gradall</strong> 10,000 lb 55 ft 5,000 lb* 42 ft 3,000 lb* John Deere544D10-55 (4,536 kg) (16.76 m) (2,268 kg) (12.8 m) (1,361 kg) 4045HF275PLEASE NOTE: These limited specifications are for reference only. Please refer to appropriate specification sheet for complete information.*Stabilizers are required to acheive stated capacity.Quick-Switch AttachmentsTruss BoomPlace roof trusses withprecision and lowermaterials into tight spots.Light MaterialHandling BucketClean up the job site orspread gravel or rip-rap witha range of buckets.Personnel Work PlatformPlace people and materialswhere they’re needed foroptimum productivity.Side-Tilt CarriageMaintain a level loadeven on hillsides andrough terrain.WinchDeliver loads behindwalls or from behind tallobstructions with an instanthook that is securely andpermanently fixed to theboom end.Swing MastThe swing mast increaseslift height by six feet andthen swings 50 degreeseither right or left.Swing CarriageExtend the boom andswing the carriage right orleft by 50 or 90 degrees.Drywall CarriageAvoid drywall damageand speed up unloadingand placement throughdoors and windows.Pallet ForksChoose from a widerange of forks of varyingthicknesses, widthsand lengths.Cubing ForksLoad, unload andplace cubes of brickand block with ease.Clear PathMaterial BucketThe 102-inch (259 cm) widebucket cleans aisles andaccess paths with one pass.Broom SweeperIdeal for brushing debrisfrom job site pathways,brushing away snow orhandling light cleanup.JLG Industries, Inc.1 JLG Drive, McConnellsburg, PA 17233-9533Telephone 717-485-5161Toll-free in US 877-JLG-LIFTFax 717-485-6417www.jlg.comForm No.: B-GRAD-0205-15MPart No.: 3132215Printed in USA