Gas pressure and temperature measuring system GTM Method of ...

Gas pressure and temperature measuring system GTM Method of ...

Gas pressure and temperature measuring system GTM Method of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

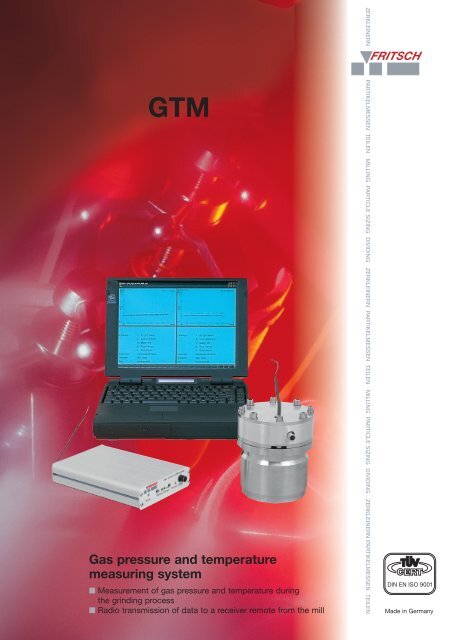

<strong>GTM</strong><br />

<strong>Gas</strong> <strong>pressure</strong> <strong>and</strong> <strong>temperature</strong><br />

<strong>measuring</strong> <strong>system</strong><br />

■ Measurement <strong>of</strong> gas <strong>pressure</strong> <strong>and</strong> <strong>temperature</strong> during<br />

the grinding process<br />

■ Radio transmission <strong>of</strong> data to a receiver remote from the mill<br />

ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN MILLING PARTICLE SIZING DIVIDING ZERKLEINERN PARTIKELMESSEN TEILEN<br />

Made in Germany

<strong>Gas</strong> <strong>pressure</strong> <strong>and</strong> <strong>temperature</strong><br />

<strong>measuring</strong> <strong>system</strong> <strong>GTM</strong><br />

Field <strong>of</strong> application<br />

The <strong>system</strong> can be used wherever batch quantities need to be<br />

ground in a totally enclosed container. It is available as st<strong>and</strong>ard<br />

for the „pulverisette 4“, „pulverisette 5“ <strong>and</strong> „pulverisette 6“. It<br />

transmits directly from the grinding bowl lid without the mill<br />

having to be adapted.<br />

The <strong>GTM</strong> <strong>system</strong> is suitable for investigations in the area <strong>of</strong><br />

mechanical alloying for the preparation <strong>of</strong> new amorphous <strong>and</strong><br />

nano-crystalline materials. Furthermore it allows grinding<br />

processes for industrial use to be monitored <strong>and</strong> optimised.<br />

By <strong>measuring</strong> the grinding container <strong>temperature</strong>, an „integral“<br />

figure for the process value <strong>of</strong> <strong>temperature</strong> is possible, reflecting<br />

the effects <strong>of</strong> friction, impact <strong>and</strong> conversion processes. Abrupt<br />

<strong>and</strong> minute changes in reaction are recorded by the continual <strong>and</strong><br />

highly sensitive measurement <strong>of</strong> the gas <strong>pressure</strong> within the grinding<br />

container.<br />

The measured gas <strong>pressure</strong> describes amongst other things the<br />

interaction <strong>of</strong> the gas with the surfaces created during the<br />

grinding process (absorption <strong>and</strong> desorption <strong>of</strong> gases). Extremely<br />

rapid phase formation can, for the first time, be observed<br />

„IN SITU“ as an adiabatic process (no heat exchange with the<br />

<strong>system</strong>).<br />

The influence <strong>of</strong> the grinding parameters - revolutions,<br />

ball-grinding/material ratio <strong>and</strong> grinding duration - can, for the<br />

first time, be carried out without time-consuming <strong>and</strong> costly<br />

„abortive attempts“. As a result <strong>of</strong> the exact <strong>measuring</strong> <strong>and</strong><br />

recording <strong>of</strong> reaction times, for example, specific addition <strong>of</strong><br />

reaction materials can be used to prepare new materials or<br />

combinations <strong>of</strong> materials to produce powder mixtures with<br />

particular mechano-chemical properties.<br />

<strong>Method</strong> <strong>of</strong> operation<br />

The gas <strong>pressure</strong> <strong>and</strong> <strong>temperature</strong> <strong>measuring</strong> <strong>system</strong> (<strong>GTM</strong>),<br />

was developed in co-operation with the Fraunh<strong>of</strong>er Institute<br />

for Applied Material Research in Dresden, <strong>and</strong> enables process<br />

values to be measured during the grinding process. A<br />

radio transmitter located in the lid <strong>of</strong> the grinding bowl sends<br />

data from the grinding bowl to a receiver, which is connected to<br />

a computer. The corresponding WINDOWS programme presents<br />

the results in the form <strong>of</strong> tables <strong>and</strong> graphics.<br />

Technical data<br />

System requirements St<strong>and</strong>ard WINDOWS PC<br />

with at least 8 Mbyte RAM<br />

Right to modify technical<br />

specifications reserved<br />

Design Characteristics<br />

■ UHF-radio transmitter, 10 mW, free <strong>of</strong> admission <strong>and</strong> charge<br />

■ Up to four transmitter componentries can operate simultaneous<br />

in the mill<br />

■ Measuring range for single <strong>and</strong> dual transmission operation<br />

with up to 200 measurements<br />

■ Pressure measurement range: 0...700 kPa<br />

■ Temperature <strong>measuring</strong> range: 0-70°C<br />

■ Resolution <strong>pressure</strong> signal: 0.175 kPa<br />

■ Resolution <strong>temperature</strong> signal: 0.025 K<br />

■ Permissible transient (-2 s) heat <strong>of</strong> reaction 30 kJ<br />

■ Measurement value recording-resolution 1ms<br />

■ Receiver componentry is also charging station for rechargeable<br />

batteries <strong>of</strong> the transmitter componentry<br />

■ RS232 connection to computer<br />

■ Bowl 250 ml or 500 ml stainless steel<br />

Advantages<br />

■ Can be used with „pulverisette 4“, „pulverisette 5“ or<br />

„pulverisette 6“ without modification<br />

■ Evaluation <strong>of</strong> data by WINDOWS programme<br />

■ Indoor range <strong>of</strong> up to 30 metres<br />

■ Operating time with fully charged battery approx. 50 hours<br />

■ Alignment <strong>of</strong> the <strong>measuring</strong> rate to the signal dynamic for<br />

enhanced battery life: Sleep-mode <strong>of</strong> the transmitter componentry<br />

when <strong>measuring</strong> signals remain the same<br />

Ordering data<br />

Planetary Mill<br />

“pulverisette 5 ” with <strong>GTM</strong>-System<br />

Order no. Description For rapid<br />

fax-quotation<br />

tick here!<br />

<strong>Gas</strong> <strong>pressure</strong> <strong>and</strong> <strong>temperature</strong><br />

<strong>measuring</strong> <strong>system</strong> (<strong>GTM</strong>)<br />

50.2510.00 incl. 250 ml grinding bowl made <strong>of</strong> stainless<br />

steel with special lid, transmitter <strong>and</strong><br />

separate receiver<br />

50.2540.00 incl. 500 ml grinding bowl made <strong>of</strong> stainless<br />

steel with special lid, transmitter <strong>and</strong><br />

separate receiver<br />

If further grinding bowls <strong>and</strong> transmitters are needed, please ask for the<br />

respective order numbers.<br />

See separate brochures for ordering information on Vario-Planetary Mill<br />

“pulverisette 4”, Planetary Mill “pulverisette 5” <strong>and</strong> Planetary Mono Mill<br />

“pulverisette 6”.<br />

FRITSCH GmbH · Industriestrasse 8 · D-55743 Idar-Oberstein<br />

Phone: (0)67 84/70-0 · Telefax: (0)67 84/70-11 · E-Mail: info@ fritsch.de ·Internet: http://www.fritsch.de<br />

gtme-04-01-5/P