PI617 - C201 Winter Equipment Options - Johnston Sweepers

PI617 - C201 Winter Equipment Options - Johnston Sweepers

PI617 - C201 Winter Equipment Options - Johnston Sweepers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

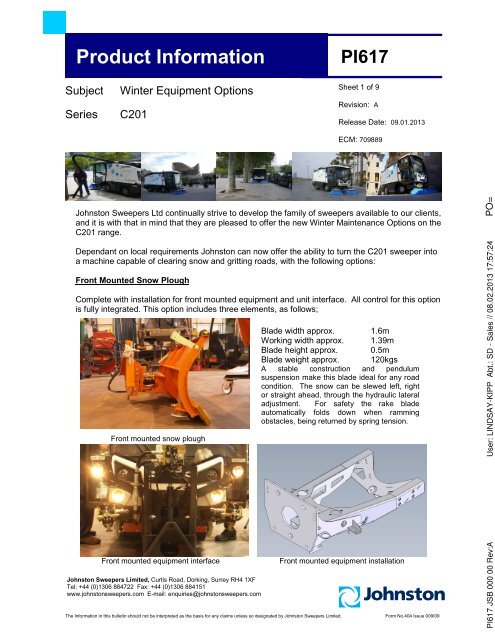

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 1 of 9Revision: ARelease Date: 09.01.2013ECM: 709889<strong>Johnston</strong> <strong>Sweepers</strong> Ltd continually strive to develop the family of sweepers available to our clients,and it is with that in mind that they are pleased to offer the new <strong>Winter</strong> Maintenance <strong>Options</strong> on the<strong>C201</strong> range.Dependant on local requirements <strong>Johnston</strong> can now offer the ability to turn the <strong>C201</strong> sweeper intoa machine capable of clearing snow and gritting roads, with the following options:Front Mounted Snow PloughComplete with installation for front mounted equipment and unit interface. All control for this optionis fully integrated. This option includes three elements, as follows;Front mounted snow ploughBlade width approx. 1.6mWorking width approx. 1.39mBlade height approx. 0.5mBlade weight approx. 120kgsA stable construction and pendulumsuspension make this blade ideal for any roadcondition. The snow can be slewed left, rightor straight ahead, through the hydraulic lateraladjustment. For safety the rake bladeautomatically folds down when rammingobstacles, being returned by spring tension.Front mounted equipment interfaceFront mounted equipment installation<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 2 of 9Revision: ARelease Date: 09.01.2013ECM: 709889Front Mounted Snow BroomComplete with Installation for front mounted equipment and unit interface. All control for this optionis fully integrated. This option includes three elements as follows;Front mounted snow broomBroom width approx. 1.5mWorking width approx. 1.35mWeight approx.130kgsBroom diameter420mThe pendulum mounted broom is ideally suited toclearing snow, using a spiral broom, driventhrough the centre drive unit. The broom can beslewed hydraulically in both directions to allow forclearing of the full road width, whilst also beingeasy to replace, with no need to demount theunit. With the mechanical drive unit there aretwo different sweeping speeds.Front Mounted Snow Plough and Snow Broom.Front mounted equipment interfaceFront mounted equipment installationComplete with installation for front mountedequipment and one unit interface. This optionconsists of four elements, including the frontmounted snow plough, the front mountedsnow broom, the front mounted equipmentinterface and the front mounted equipmentinstallation as pictured aboveFront mounted snow plough and snow broom<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 3 of 9Revision: ARelease Date: 09.01.2013ECM: 709889Front <strong>Equipment</strong> Installation OnlyOnly suitable for winter equipment (plough/broom), left/right hand drive installation. (Includes highlevel worklights). This option does not include the new auxiliary equipment pump for the thirdbrush option.This option has two elements, for either left or right hand drive, which is the equipment installation,and the high level work lights as below;This option cannot be used in conjunction with the third brush.Install height approx.315mmInstall length approx.820mmInstall width approx.410mmHydraulic Pressure required 150barHydraulic Flow required25l/minWeight difference between standardand winter equipment installation 17kgMade of powder coated mild steelDue to the normal work lights being obstructed bythe front equipment, high level worklights areincluded in this option. These are LED, combineddirectional indicator and front marker work lampsdesigned to replace the standard work lights on thismodel.For more detail of the installation please see the parts book for the <strong>C201</strong>.<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 4 of 9Revision: ARelease Date: 09.01.2013ECM: 709889Front <strong>Equipment</strong> Install OnlySuitable for third brush on its own or together with winter equipment (plough/broom), left/right handdrive Installation. (Includes high level worklights). This option includes two elements, the frontequipment installation, as pictured above, and a new auxiliary equipment pump used to run thethird brush.This option should be chosen if the operator wishes to have third brush capability, with or withoutthe winter equipment options.The pump change can be seen below;Original gear type, 6.4cc/rev displacement pumpNew auxiliary equipment pump<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 5 of 9Revision: ARelease Date: 09.01.2013ECM: 709889Interface OnlyFor front mounted winter equipment. Suitable for plough or broom. This option consists of only oneelement, the front mounted interface, as pictured below;Interface width approx.Interface height approx.Interface depth approx.Interface weight approx.Hydraulic Pressure requiredHydraulic Flow requiredMade of powder coated mild steel.1200mm1150mm300mm60kg180bar25l/minThe front mounted equipment interface includes acategory zero hitch. This means that otherequipment can be used on this interface if itconforms to category zero.For more information please see parts book for the <strong>C201</strong>.GritterRear mounted drop type unit, complete with interface equipment, hitch and electrics. This optionconsists of two elements, the gritter unit and the interface equipment including the tow hitch andelectrics for rear lights, as below;Rear mounted drop type gritterContainer volume approx. 200lBox height approx. 0.75mBox width approx. 1.28mBox depth approx. 0.75mSpread width approx. 1.2mEmpty weight approx.350kgsThis gritter reliably and evenly spreads all freeflowingmaterials such as sand, salt and grit.Volume control, via a mechanically adjustablefeeding slide, allows control of flow through thespreader. The feeding slide and gritting bottom aremade of special steel and inside the container adosing shaft ensures an even spread. The parkingdevice stops flow when parked to ensure safety ofother vehicles and members of the public.<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 6 of 9Revision: ARelease Date: 09.01.2013ECM: 709889Rear mounted equipment interfaceInterface swung to show hingingRear tow hitch for electrical connection to lightsIn cab switch for gritter controlIn transit mode pressing the gritter switch will set the gritter mode to off. In work mode pressing theswitch will advance the gritter through the following cycle:• Start; the gritter is switched off.• First press; the gritter is in standby and will activate when work mode is engaged and thevehicle is moving.• Second press; the gritter is in run state and will activate whenever work mode is engaged.In addition to this, if the front winter equipment is not installed, then the normal sweeping functionsand the gritting functions become exclusive of each other.<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 7 of 9Revision: ARelease Date: 09.01.2013ECM: 709889Interface OnlyFor rear mounted winter equipment. Suitable for gritter (includes rear tow hitch and electrics).This option has just one element, the unit interface including the rear tow hitch and the electricalconnections, all as above.The interface only option includes threepoint attachment for other units, but doesnot automatically include the three pointattachment bracket for the Wiedenmanngritter unit. All hydraulic feed and returnconnections are included in this option.Rear mounted equipment interfaceCover for Standard Gritter UnitCover for the gritter to ensure the elements stay out while you are gritting and while the gritter isstored.Cover for standard gritter unit<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 8 of 9Revision: ARelease Date: 09.01.2013ECM: 709889Spinning DiscAddition to standard gritter unit. Hydraulic drive, mechanical swivel. This option is an add on for astandard gritter unit, it has only one element as below;Spread width approx. 1-6mThe gritting plate made of special steel is anoptional extra to upgrade the drop typegritter. It can be swivelled mechanically toensure asymmetric spreading over a muchlarger area then the box alone offers. Thisoption allows for easy switching between boxspreading method, for gritting pavements andspinning disc method for gritting roads or carparks.Electronic Metering UnitOperated from cab.This optional extra allows control of the volume of gritbeing spread electronically from the cab instead of viathe mechanical arm at the rear of the sweeper,allowing the user to remain in cab if the environmentrequires. This control is also used to swap betweendrop type gritting and spinning disc gritting.<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09

Product Information<strong>PI617</strong>SubjectSeries<strong>Winter</strong> <strong>Equipment</strong> <strong>Options</strong><strong>C201</strong>Sheet 9 of 9Revision: ARelease Date: 09.01.2013ECM: 709889Stand for Standard Gritter UnitFor when not in operation. This option has only one element, the stand, as below;This stand is excellent as an aid toinstallation and removal of the gritterunit. With castor wheels andadjustable height, this stand eliminatesthe need for heavy lifting equipmentduring fitment of the gritter unit to thesweeper. The stand is also an idealstorage solution for when the gritter isnot in use.Due to continuous development, <strong>Johnston</strong> <strong>Sweepers</strong> Ltd reserves the right to alter specifications withoutprior notice.<strong>Johnston</strong> <strong>Sweepers</strong> Limited, Curtis Road, Dorking, Surrey RH4 1XFTel: +44 (0)1306 884722 Fax: +44 (0)1306 884151www.johnstonsweepers.com E-mail: enquiries@johnstonsweepers.comThe Information in this bulletin should not be interpreted as the basis for any claims unless so designated by <strong>Johnston</strong> <strong>Sweepers</strong> Limited. Form No.404 Issue 009/09