Chapter 5: Design Methodology - Plastics Pipe Institute

Chapter 5: Design Methodology - Plastics Pipe Institute

Chapter 5: Design Methodology - Plastics Pipe Institute

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

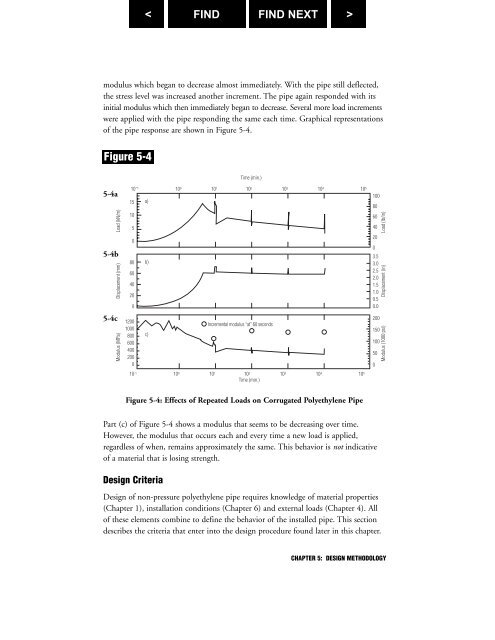

modulus which began to decrease almost immediately. With the pipe still deflected,the stress level was increased another increment. The pipe again responded with itsinitial modulus which then immediately began to decrease. Several more load incrementswere applied with the pipe responding the same each time. Graphical representationsof the pipe response are shown in Figure 5-4.Figure 5-45-4a5-4b5-4cFigure 5-4: Effects of Repeated Loads on Corrugated Polyethylene <strong>Pipe</strong>Part (c) of Figure 5-4 shows a modulus that seems to be decreasing over time.However, the modulus that occurs each and every time a new load is applied,regardless of when, remains approximately the same. This behavior is not indicativeof a material that is losing strength.<strong>Design</strong> Criteria<strong>Design</strong> of non-pressure polyethylene pipe requires knowledge of material properties(<strong>Chapter</strong> 1), installation conditions (<strong>Chapter</strong> 6) and external loads (<strong>Chapter</strong> 4). Allof these elements combine to define the behavior of the installed pipe. This sectiondescribes the criteria that enter into the design procedure found later in this chapter.CHAPTER 5: DESIGN METHODOLOGY