INVENT HyperClassic⢠Mixer Aerator Brochure - Treatment ...

INVENT HyperClassic⢠Mixer Aerator Brochure - Treatment ...

INVENT HyperClassic⢠Mixer Aerator Brochure - Treatment ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

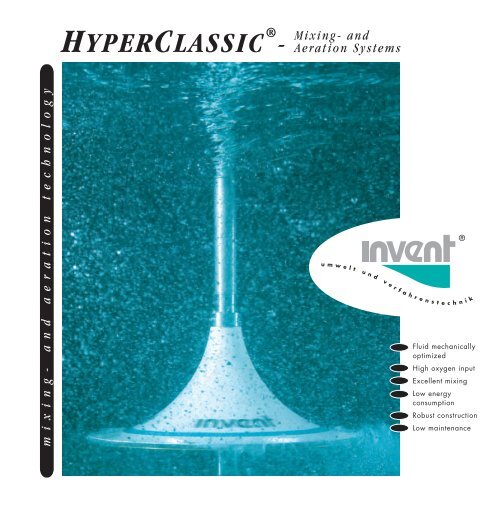

H Y P E RC L A S S I C ®An OverviewEfficient and reliableAn intensive mixing is highly importantfor the optimal and safeoperation of an activated sludgeplant. The influence of mixing on thepurification capacity of a plant isquite often underestimated. However,it is easily understandable that e.g.sedimentation on the tank’s bottom,not only diminishes the availablereactor volume, but also representsoxygen depression and a source fortoxins due to the mostly anaerobicputrefaction. Beside reduced performancethis leads to poor sedimentationqualities of the sludge flocs inthe secondary sedimentation tank.All in all one wishes for a systemwhich fulfils the above demandswith regard to optimal bubble sizesand homogenous mixing and isfurthermore flexibly applicable, isof sturdy construction and resistantto wear and tear.Poor mixing, however, also leads tooxygen gradients in the activatedsludge tank. This on the other handreduces the oxygen supply performance,as the driving concentrationgradient diminishes. Furthermore,such non-homogenous occurrencesreduce the customary single pointoxygen measurements to absurdityand only a limited percentage of theexisting reactor volume is used.Figure 1: Oxygen distribution with insufficient mixing- poor purification performanceFigure 2: Oxygen distribution with good mixing &homogenization - excellent purification performance

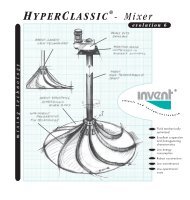

H Y P E RC L A S S I C ®The SolutionHighest efficiencythrough optimal designThe SolutionThe <strong>INVENT</strong> HYPERCLASSIC ® -Mixingand Aeration System is a fluidmechanically optimized mechanicalaeration system with a hyperboloidshapedmixer-body which is installedclose to the bottom and a drivemounted on top of the tank in dryposition. In contrast to other productsit was developed not only for thepurpose of oxygen input, but alsofor the task of mixing and is tailormadeespecially for carrying out thisdouble task.The way the hyperboloid mixer/aeratorfunctions can be seen in theillustration below. The hyperboloidmixer/aerator is pictured with its threemain components, the drive, the shaftand the hyperboloid mixer-body in atypical activated sludge tank, which,depending on the type of treatmentplant, can be rectangular or circular.Naturally, other shapes of tank arealso possible, e. g. carousel tanks oraerated lagoons can be equippedwith the HYPERCLASSIC ® -Mixing andAeration System.The hyperboloid mixer/aeratorrotates close to the bottom and its8 integrated and specially optimizedmotion fins thus produce a bottomflow which is directed radiallyoutwards. Particularly at the bottom,this flow is highly turbulent and thuseffectively whirls up any depositions.Along the walls the flow risesupwards and transports all particlesuntil they are just below the watersurface. Due to the overall flowwhich forms in the activated sludgetank an intensive mixing of theactivated sludge is achieved.driveshaftair pipeSchematicalrepresentation of theHYPERCLASSIC ®Mixing & AerationSystemmicro-vorticesmotion finsring spargerhyperboloidmixer-bodyshear fins

H Y P E RC L A S S I C ®The Cage-Solutiondrivemounting baserubber buffersair tubingstealcageshafthyperboloidmixer-bodyspargerbearingshaftbottombearingThe Cage-SolutionCombine the HYPERCLASSIC ® -Mixingand Aeration system with the cagesolution specially designed for thissystem. Then you can install andcommission the complete system evenin filled tanks and without removingthe water so there is no need tointerrupt the operation. The samealso applies of course for the dismantlingor the relocation of thesystem. The cage-solution HYPERCAGEthereby guarantees the greatestflexibility and security.The HYPERCLASSIC ® /HYPERCAGEcombination can be completely premountedbefore delivery to the plantif requested by the customer.This reduces the installation andcommissioning time to a minimum.The HYPERCAGE cage consists of aheavy base construction with asteel cage mounted upon it. The baseconstruction is always made from asolid steel construction coated withepoxy-resin. This gives the HYPER-CAGE weight, which guarantees, thatit always remains in the positionassigned to it.Furthermore, the base, through itsshape, also supports the developmentof a flow beneath the hyperboloidmixer-body which is favourableto the aeration and mixing. Thebottom bearing is integrated into thebase construction and is easy to install.5 HYPER-CLASSIC ® Mixing & Aeration Systems in anindustrial wwtp in Brazil (Chemical Industry)The cage construction can be madeeither from a steel constructioncoated with epoxy-resin like the base,or from stainless steel. In the lattercase, the air supply can be carriedout through the 4 main pipes (cf.accompanying blow-up diagram).Otherwise the cage is equipped witha separate air pipe. Above the watersurface, the air is introduced througha flexible pipe.baseEasy, problem-freeand quick

Low operational costsdue to low energy consumptionH Y P E RC L A S S I C ®Installation and OperationThe InstallationThe HYPERCLASSIC ® -Mixing andAeration System is constructed insuch a way that it can be easily andquickly installed. It is normally deliveredto the construction site in adisassembled state. There the shaftis first of all connected to the driveunit by pulling the top end of theshaft into the hollow shaft of thedrive. Next both drive and shaft areplaced on top of the prepared stainless-steelthread bolts or adhesionanchors on the bridge or the mountingbracket. The drive is alignedand is ready for operation after theelectrical connection and checkingof the oil level. The last step consistsof screwing the hyperboloid stirrerto the lower shaft flange. Just a shortdry run and the mixer/aerator isready for operation.The installation is even quicker ifthe pre-mounted HYPERCLASSIC ® /HYPERCAGE combination is selected.The system can be delivered to theplant in a completely pre-mountedstate and unloaded there.Just a short dry run, some safetychecks, and the system can beinstalled and commissioned with afilled tank and without interruptionof the operation.The OperationAfter a short dry run and a check ofthe direction of rotation the hyperboloidmixer/aerator can startoperating without any further work.It is designed for permanent operationand does not require anymaintenance work, except anoccasional inspection of the oil level.4 HYPER-CLASSIC ® Mixing & Aeration Systems inan industrial wwtp in Belgium (Food Industry)Depending on the type of oil, an oilchange is carried out once every 1or 2 years. Due to the location andthe excellent accessibility of the drivethis is effortless. There are nowork-intensive and unpleasantpulling and cleaning jobs, which forexample, is generally the case withsubmerged drives. Expensivemaintenance work, such as theregular exchange of mechanicalseals, are superfluous, because noexpensive parts which are subjectto wear are installed below waterlevel.Low maintenance costswith HYPER-CLASSIC ® Mixing & Aeration System

H Y P E RC L A S S I C ®Lay-out and DesignCompetent and experiencedLay-out and DesignThe lay-out and design of an optimummixing and aeration system is a verycomplex task. It requires a largeamount of competence, know-howand experience. Above all, it isimportant to consider the entiresystem and to understand the completeprocess in addition to thestandard parameters, to incorporatethis information and to integrate theaeration system optimally into thecomplete process. In the case ofindustrial plants e. g. in the paperand the petrochemical industry, inaddition to this, it can be importantto understand the production processto a certain degree, because thissignificantly influences the wastewatercomposition .<strong>INVENT</strong>’s approach is to focus onthe customer and to always try andoffer objectively the best solution.When strictly put into practise thismeans not just offering one singlesystem but instead initially selectingthe most suitable one for the applicationat hand from a range ofmixing and aeration systems, membraneand further aeration systems.The selection of the suitable systemis the first and most important stepin the planning and designing of aplant. If the wrong system is chosen,it inevitably leads to a solution whichis only partially suitable and therebyto a restricted performance of theplant and to increased costs. Thisdisadvantage cannot even be compensatedfor through optimistic layouts.Through many years of intensiveresearch and development work inthe field of mixing and aerationtechnology <strong>INVENT</strong> has been able todevelop a range of products, whichalmost optimally cover every application.Therefore you can alwaysrely on getting the best solution from<strong>INVENT</strong> and not just the only oneavailable.Typical characteristics of a HYPERCLASSIC ® Mixing& Aeration SystemTypical gassed power characteristics

H Y P E RC LL ASSSSII C ® ®<strong>INVENT</strong> Products worldwideSuccessful worldwide<strong>INVENT</strong> Team meeting<strong>INVENT</strong> ® , HYPERCLASSIC ® and DoubleFin Technology ® are registeredtrademarks of <strong>INVENT</strong> Umwelt- undVerfahrenstechnik AG.Chosen referencesIndustrial:Dow Chemicals,Chemical IndustryDSM, Chemical IndustryQ8 Raffinerie,Petrolchemical IndustryAlpro Milk,Food IndustryArla Foods,Food IndustrySAPPI, Pulp- andPaper IndustryJass Papier, Pulp- andPaper IndustryZucchi & Basetti, Textile IndustryMascioni, Textile IndustryDortmunder Union Brauerei,Beverage IndustryMunicipal:Presidente Prudente, BrazilSao José Dos Campos, BrazilCaleta Olivia, ArgentinaYokohama, JapanARA Feldkirch Meiningen,AustriaKA Riedlingen, GermanyKA Isny, GermanyBiomüllvergärung Mühlheiman der Ruhr, GermanyThe ServiceHow can we support you with theplanning, optimization, modernizationof your plant, or justgenerally with the realization ofyour ideas? Please ask us aboutit!In close co-operation with you,the <strong>INVENT</strong> team will draw up afirst draft and will, if necessary,develop it further together withyou via numerous iteration steps,until all requirements are met.After the order has been placedan experienced team of engineerswill see to it that your project iscarried out on schedule.In accordance with the agreementwe will deliver and install the plantfor you and will also carry out thecommissioning. Our service teamwill reliably take care of allnecessary maintenance work.

H Y P E RC L A S S I C ®Further <strong>INVENT</strong> ProductsProfessional and innovativeBeyond the delivery of componentsand plants we also offer you generaladvisory and engineering servicesin the field of stirring technology.This can be, for example, the layoutor optimisation of a stirrer, or theexperimental examination of astirring tank on a laboratory-scaleor through numeric simulation.Furthermore, we carry out large-scaleacceptance tests, whereby usuallythe velocity field, the solid matterconcentration distribution and thedetention distribution are examined.Other Productsand Services<strong>INVENT</strong> is the market leader formixers, mixing and aeration systemsand membrane aeration systems forthe water and wastewater treatment.Please do not hesitate to ask forinformation about our additionalproduct lines. We would also behappy to offer you complete systemsolutions for your plants, such as acarefully laid-out and adaptedequipment package. We simulateand optimize your plant with thehelp of appropriate softwarepackages, or else we optimize yourplant or building with regard to fluidmechanics.We are your competent partnerfor all questions on water andwastewater treatment.engineering &consultingaerationtechnologysoftwareproductssystemsolutionsresearch &development

l o c a t i o n sYou can reach us at:<strong>INVENT</strong> UmweltundVerfahrenstechnik AGHeadquarters:Am Weichselgarten 3691058 ErlangenGermanyFon: +49 (0) 9131 690 98-0Fax: +49 (0) 9131 690 98-99E-mail: info@invent-uv.dePlant 1:Burgstallerweg 1491074 HerzogenaurachGermanyFon: +49 (0) 9132 74 13 70Fax: +49 (0) 9132 74 13 72Berlin Office:Platanenweg 612437 BerlinGermanyFon: +49 (0) 30 5 34 10 63Fax: +49 (0) 30 5 34 10 63E-mail: jwelzel@invent-uv.deWest Office:Am Steinberg 2352353 DürenGermanyFon: +49 (0) 24 21 88 83 07Fax: +49 (0) 24 21 8 47 86E-mail: plaskaris@invent-uv.deBenelux Office:Kapitein De Rijkstraat 422583 BK The HagueThe NetherlandsFon: +31 (0) 70 30619 98Fax: +31 (0) 70 30619 97E-mail: mhuijboom@invent-uv.deUS Office:<strong>INVENT</strong> Environmental Technologies LLC122 Oakwell Farms ParkwaySan Antonio, TX 78218USAFon: +1 210 832 0100Fax: +1 210 568 6136E-mail: info@invent-et.comworldwideA list of our sales partnersabroad is available by requestor on the internet:www.invent-uv.deHCMA 2.000 04.05-1 Eprinted on chlorine-free bleached paper