Arki-Top E45 - Arkichem

Arki-Top E45 - Arkichem

Arki-Top E45 - Arkichem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

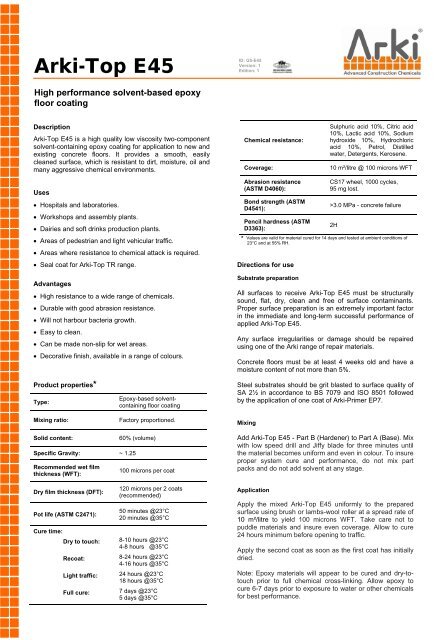

<strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong>ID: G5-<strong>E45</strong>Version: 1Edition: 1High performance solvent-based epoxyfloor coatingDescription<strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong> is a high quality low viscosity two-componentsolvent-containing epoxy coating for application to new andexisting concrete floors. It provides a smooth, easilycleaned surface, which is resistant to dirt, moisture, oil andmany aggressive chemical environments.Uses• Hospitals and laboratories.• Workshops and assembly plants.• Dairies and soft drinks production plants.• Areas of pedestrian and light vehicular traffic.• Areas where resistance to chemical attack is required.• Seal coat for <strong>Arki</strong>-<strong>Top</strong> TR range.Advantages• High resistance to a wide range of chemicals.• Durable with good abrasion resistance.• Will not harbour bacteria growth.• Easy to clean.• Can be made non-slip for wet areas.• Decorative finish, available in a range of colours.Chemical resistance:Coverage:Abrasion resistance(ASTM D4060):Bond strength (ASTMD4541):Sulphuric acid 10%, Citric acid10%, Lactic acid 10%, Sodiumhydroxide 10%, Hydrochloricacid 10%, Petrol, Distilledwater, Detergents, Kerosene.10 m²/litre @ 100 microns WFTCS17 wheel, 1000 cycles,95 mg lost.>3.0 MPa - concrete failurePencil hardness (ASTM2HD3363):* Values are valid for material cured for 14 days and tested at ambient conditions of23°C and at 55% RH.Directions for useSubstrate preparationAll surfaces to receive <strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong> must be structurallysound, flat, dry, clean and free of surface contaminants.Proper surface preparation is an extremely important factorin the immediate and long-term successful performance ofapplied <strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong>.Any surface irregularities or damage should be repairedusing one of the <strong>Arki</strong> range of repair materials.Concrete floors must be at least 4 weeks old and have amoisture content of not more than 5%.Product properties*Type:Mixing ratio:Epoxy-based solventcontainingfloor coatingFactory proportioned.Steel substrates should be grit blasted to surface quality ofSA 2½ in accordance to BS 7079 and ISO 8501 followedby the application of one coat of <strong>Arki</strong>-Primer EP7.MixingSolid content:Specific Gravity: ~ 1.25Recommended wet filmthickness (WFT):60% (volume)100 microns per coatAdd <strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong> - Part B (Hardener) to Part A (Base). Mixwith low speed drill and Jiffy blade for three minutes untilthe material becomes uniform and even in colour. To insureproper system cure and performance, do not mix partpacks and do not add solvent at any stage.Dry film thickness (DFT):Pot life (ASTM C2471):Cure time:Dry to touch:Recoat:Light traffic:Full cure:120 microns per 2 coats(recommended)50 minutes @23°C20 minutes @35°C8-10 hours @23°C4-8 hours @35°C8-24 hours @23°C4-16 hours @35°C24 hours @23°C18 hours @35°C7 days @23°C5 days @35°CApplicationApply the mixed <strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong> uniformly to the preparedsurface using brush or lambs-wool roller at a spread rate of10 m²/litre to yield 100 microns WFT. Take care not topuddle materials and insure even coverage. Allow to cure24 hours minimum before opening to traffic.Apply the second coat as soon as the first coat has initiallydried.Note: Epoxy materials will appear to be cured and dry-totouchprior to full chemical cross-linking. Allow epoxy tocure 6-7 days prior to exposure to water or other chemicalsfor best performance.

<strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong>Packaging4.0 Litre packsCoverage4.0 L pack of <strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong> cover 20 m² in two coats of 100microns each. This is an approximate spread rate given forestimating purposes only.ID: G5-<strong>E45</strong>Version: 1Edition: 1Should accidental eye contamination occur with anyof the above products, wash well with plenty of cleanwater and seek medical advice. If swallowed, seekmedical attention immediately. Do not inducevomiting.For further information, refer to the material safety datasheet.CleaningClean up mixing and application equipment immediatelyafter use. Use <strong>Arki</strong>-Solv 1.Storage and shelf life<strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong> components have a shelf life of 12 monthswhen stored in a dry place and good warehouse conditionsin unopened, undamaged original packaging. If stored athigh temperatures and/or high humidity conditions, theshelf life may be reduced.Safety precautionsThe two components of <strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong> are flammablematerials. Do not expose to naked flames or other sourcesof ignition. Containers should be tightly sealed when not inuse. In the event of fire, extinguish with CO2 or foam.Spillages of component products should be absorbed ontoearth, sand or other inert material and transferred to asuitable vessel. Disposal of such spillages or emptypackaging should be in accordance with local regulations.<strong>Arki</strong>-<strong>Top</strong> <strong>E45</strong> should not come in contact with skin or eyes.Avoid prolonged inhalation of vapours. Some people aresensitive to epoxy resins, hardeners and solvents. Gloves,goggles and barrier cream should therefore be used.Ensure adequate ventilation and if working in enclosedareas, suitable breathing apparatus is recommended.Technical support<strong>Arki</strong> provides assistance to its customers and gives sitesupport, consultations and technical advice on all aspectsrelated to specifications and application methods ofconstruction chemicals and building materials.Additional <strong>Arki</strong> products<strong>Arki</strong> produces high quality products intended for use inconstruction activity, among these products:• Concrete Admixtures• Concrete repair materials.• Mould release agents and curing compounds.• Tile adhesives and coloured grouts.• Waterproofing materials.• Protective coatings.Product QualityAll <strong>Arki</strong> products are manufactured under qualitymanagement system independently certified to conform tothe requirements of the international standards.If mixed resin comes in contact with skin, it must beremoved before it hardens with a resin removing cream orwith soap and water. Do not use solvent. Contamination ofskin with any of the <strong>Arki</strong>p<strong>Top</strong> <strong>E45</strong> components should beremoved immediately with soap and water.P O Box 301100,Riyadh 11372, Saudi ArabiaTele: +966 1 489 1000Fax: +966 1 489 1700e-mail: info@arkichem.comwww.arkichem.comUsers should always refer to the most recent issue of the product technical data-sheet for the productconcerned, copies of which will be supplied on request.<strong>Arki</strong> products are guaranteed against defective materials and manufacture and are sold subject to <strong>Arki</strong>standard terms and conditions of sales.Because the storage, handling and application of these products are beyond our control, we can accept noliability for the results obtained.