Chemical Compatibility Guide - OEC Fluid Handling, Inc.

Chemical Compatibility Guide - OEC Fluid Handling, Inc.

Chemical Compatibility Guide - OEC Fluid Handling, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

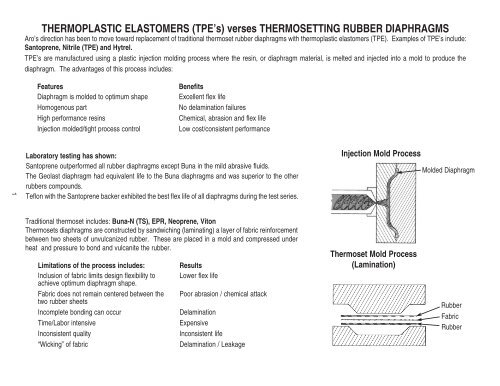

THERMOPLASTIC ELASTOMERS (TPE’s) verses THERMOSETTING RUBBER DIAPHRAGMSAro’s direction has been to move toward replacement of traditional thermoset rubber diaphragms with thermoplastic elastomers (TPE). Examples of TPE’s include:Santoprene, Nitrile (TPE) and Hytrel.TPE’s are manufactured using a plastic injection molding process where the resin, or diaphragm material, is melted and injected into a mold to produce thediaphragm. The advantages of this process includes:FeaturesDiaphragm is molded to optimum shapeHomogenous partHigh performance resinsInjection molded/tight process controlBenefitsExcellent flex lifeNo delamination failures<strong>Chemical</strong>, abrasion and flex lifeLow cost/consistent performance1Laboratory testing has shown:Santoprene outperformed all rubber diaphragms except Buna in the mild abrasive fluids.The Geolast diaphragm had equivalent life to the Buna diaphragms and was superior to the otherrubbers compounds.Teflon with the Santoprene backer exhibited the best flex life of all diaphragms during the test series.Injection Mold ProcessMolded DiaphragmTraditional thermoset includes: Buna-N (TS), EPR, Neoprene, VitonThermosets diaphragms are constructed by sandwiching (laminating) a layer of fabric reinforcementbetween two sheets of unvulcanized rubber. These are placed in a mold and compressed underheat and pressure to bond and vulcanite the rubber.Limitations of the process includes:<strong>Inc</strong>lusion of fabric limits design flexibility toachieve optimum diaphragm shape.Fabric does not remain centered between thetwo rubber sheets<strong>Inc</strong>omplete bonding can occurTime/Labor intensive<strong>Inc</strong>onsistent quality“Wicking” of fabricResultsLower flex lifePoor abrasion / chemical attackDelaminationExpensive<strong>Inc</strong>onsistent lifeDelamination / LeakageThermoset Mold Process(Lamination)RubberFabricRubber