You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

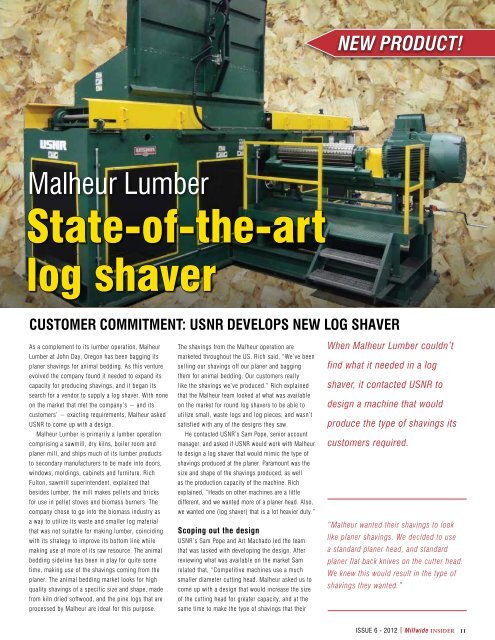

NEW PRODUCT!Malheur LumberState-of-the-artlog shaverCUSTOMER COMMITMENT: USNR develops new log shaverAs a complement to its lumber operation, MalheurLumber at John Day, Oregon has been bagging itsplaner shavings for animal bedding. As this ventureevolved the company found it needed to expand itscapacity for producing shavings, and it began itssearch for a vendor to supply a log shaver. With noneon the market that met the company’s − and itscustomers’ − exacting requirements, Malheur askedUSNR to come up with a design.Malheur Lumber is primarily a lumber operationcomprising a sawmill, dry kilns, boiler room andplaner mill, and ships much of its lumber productsto secondary manufacturers to be made into doors,windows, moldings, cabinets and furniture. RichFulton, sawmill superintendent, explained thatbesides lumber, the mill makes pellets and bricksfor use in pellet stoves and biomass burners. Thecompany chose to go into the biomass industry asa way to utilize its waste and smaller log materialthat was not suitable for making lumber, coincidingwith its strategy to improve its bottom line whilemaking use of more of its raw resource. The animalbedding sideline has been in play for quite sometime, making use of the shavings coming from theplaner. The animal bedding market looks for highquality shavings of a specific size and shape, madefrom kiln dried softwood, and the pine logs that areprocessed by Malheur are ideal for this purpose.The shavings from the Malheur operation aremarketed throughout the US. Rich said, “We’ve beenselling our shavings off our planer and baggingthem for animal bedding. Our customers reallylike the shavings we’ve produced.” Rich explainedthat the Malheur team looked at what was availableon the market for round log shavers to be able toutilize small, waste logs and log pieces, and wasn’tsatisfied with any of the designs they saw.He contacted USNR’s Sam Pope, senior accountmanager, and asked if USNR would work with Malheurto design a log shaver that would mimic the type ofshavings produced at the planer. Paramount was thesize and shape of the shavings produced, as wellas the production capacity of the machine. Richexplained, “Heads on other machines are a littledifferent, and we wanted more of a planer head. Also,we wanted one (log shaver) that is a lot heavier duty.”Scoping out the designUSNR’s Sam Pope and Art Machado led the teamthat was tasked with developing the design. Afterreviewing what was available on the market Samrelated that, “<strong>Co</strong>mpetitive machines use a muchsmaller diameter cutting head. Malheur asked us tocome up with a design that would increase the sizeof the cutting head for greater capacity, and at thesame time to make the type of shavings that theirWhen Malheur Lumber couldn’tfind what it needed in a logshaver, it contacted USNR todesign a machine that wouldproduce the type of shavings itscustomers required.“Malheur wanted their shavings to looklike planer shavings. We decided to usea standard planer head, and standardplaner flat back knives on the cutter head.We knew this would result in the type ofshavings they wanted.”ISSUE 6 - <strong>2012</strong> | Millwide INSIDER 11