Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

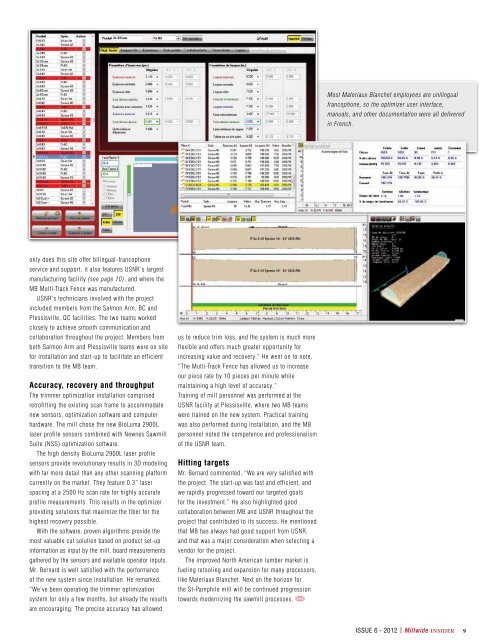

Most Materiaux Blanchet employees are unilingualfrancophone, so the optimizer user interface,manuals, and other documentation were all deliveredin French.only does this site offer bilingual-francophoneservice and support, it also features USNR’s largestmanufacturing facility (see page 10), and where theMB Multi-Track Fence was manufactured.USNR’s technicians involved with the projectincluded members from the Salmon Arm, BC andPlessisville, QC facilities. The two teams workedclosely to achieve smooth communication andcollaboration throughout the project. Members fromboth Salmon Arm and Plessisville teams were on sitefor installation and start-up to facilitate an efficienttransition to the MB team.Accuracy, recovery and throughputThe trimmer optimization installation comprisedretrofitting the existing scan frame to accommodatenew sensors, optimization software and computerhardware. The mill chose the new BioLuma 2900Llaser profile sensors combined with Newnes SawmillSuite (NSS) optimization software.The high density BioLuma 2900L laser profilesensors provide revolutionary results in 3D modelingwith far more detail than any other scanning platformcurrently on the market. They feature 0.3” laserspacing at a 2500 Hz scan rate for highly accurateprofile measurements. This results in the optimizerproviding solutions that maximize the fiber for thehighest recovery possible.With the software, proven algorithms provide themost valuable cut solution based on product set-upinformation as input by the mill, board measurementsgathered by the sensors and available operator inputs.Mr. Bernard is well satisfied with the performanceof the new system since installation. He remarked,“We’ve been operating the trimmer optimizationsystem for only a few months, but already the resultsare encouraging. The precise accuracy has allowedus to reduce trim loss, and the system is much moreflexible and offers much greater opportunity forincreasing value and recovery.” He went on to note,“The Multi-Track Fence has allowed us to increaseour piece rate by 10 pieces per minute whilemaintaining a high level of accuracy.”Training of mill personnel was performed at theUSNR facility at Plessisville, where two MB teamswere trained on the new system. Practical trainingwas also performed during installation, and the MBpersonnel noted the competence and professionalismof the USNR team.Hitting targetsMr. Bernard commented, “We are very satisfied withthe project. The start-up was fast and efficient, andwe rapidly progressed toward our targeted goalsfor the investment.” He also highlighted goodcollaboration between MB and USNR throughout theproject that contributed to its success. He mentionedthat MB has always had good support from USNR,and that was a major consideration when selecting avendor for the project.The improved North American lumber market isfueling retooling and expansion for many processors,like Materiaux Blanchet. Next on the horizon forthe St-Pamphile mill will be continued progressiontowards modernizing the sawmill processes.ISSUE 6 - <strong>2012</strong> | Millwide INSIDER 9