Machine Design Optimization Based on Finite Element ... - TWiki

Machine Design Optimization Based on Finite Element ... - TWiki

Machine Design Optimization Based on Finite Element ... - TWiki

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

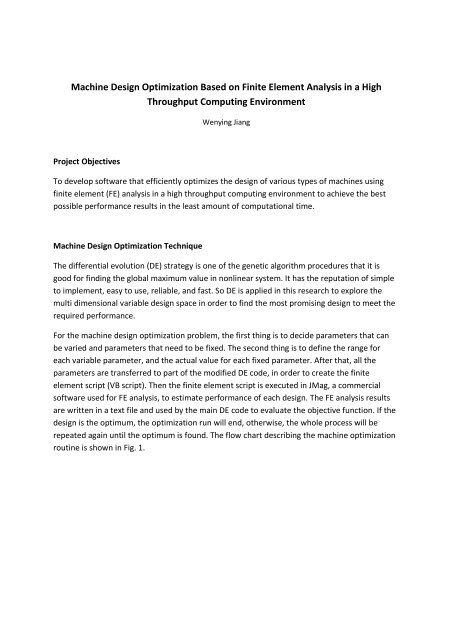

<str<strong>on</strong>g>Machine</str<strong>on</strong>g> <str<strong>on</strong>g>Design</str<strong>on</strong>g> <str<strong>on</strong>g>Optimizati<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Based</str<strong>on</strong>g> <strong>on</strong> <strong>Finite</strong> <strong>Element</strong> Analysis in a HighThroughput Computing Envir<strong>on</strong>mentWenying JiangProject ObjectivesTo develop software that efficiently optimizes the design of various types of machines usingfinite element (FE) analysis in a high throughput computing envir<strong>on</strong>ment to achieve the bestpossible performance results in the least amount of computati<strong>on</strong>al time.<str<strong>on</strong>g>Machine</str<strong>on</strong>g> <str<strong>on</strong>g>Design</str<strong>on</strong>g> <str<strong>on</strong>g>Optimizati<strong>on</strong></str<strong>on</strong>g> TechniqueThe differential evoluti<strong>on</strong> (DE) strategy is <strong>on</strong>e of the genetic algorithm procedures that it isgood for finding the global maximum value in n<strong>on</strong>linear system. It has the reputati<strong>on</strong> of simpleto implement, easy to use, reliable, and fast. So DE is applied in this research to explore themulti dimensi<strong>on</strong>al variable design space in order to find the most promising design to meet therequired performance.For the machine design optimizati<strong>on</strong> problem, the first thing is to decide parameters that canbe varied and parameters that need to be fixed. The sec<strong>on</strong>d thing is to define the range foreach variable parameter, and the actual value for each fixed parameter. After that, all theparameters are transferred to part of the modified DE code, in order to create the finiteelement script (VB script). Then the finite element script is executed in JMag, a commercialsoftware used for FE analysis, to estimate performance of each design. The FE analysis resultsare written in a text file and used by the main DE code to evaluate the objective functi<strong>on</strong>. If thedesign is the optimum, the optimizati<strong>on</strong> run will end, otherwise, the whole process will berepeated again until the optimum is found. The flow chart describing the machine optimizati<strong>on</strong>routine is shown in Fig. 1.

Fig. 1: <str<strong>on</strong>g>Machine</str<strong>on</strong>g> <str<strong>on</strong>g>Optimizati<strong>on</strong></str<strong>on</strong>g> RoutineFE <str<strong>on</strong>g>Based</str<strong>on</strong>g> <str<strong>on</strong>g>Optimizati<strong>on</strong></str<strong>on</strong>g>The FE analysis is a numerical technique for finding approximate soluti<strong>on</strong>s of partial differentialequati<strong>on</strong>s as well as integral equati<strong>on</strong>s. Its final result is from adding calculati<strong>on</strong> results <strong>on</strong>every finite element. So FE analysis is more accurate than magnetic circuit analysis. Because ofits high accuracy, FE analysis was chosen to evaluate the performance for each machine designin this research. However, the price paid for high accuracy is large computing time. For a singledesign, the executi<strong>on</strong> time difference between FE analysis and magnetic circuit analysis couldbe more than 50 : 1. As a result, in order to find the optimum design in a reas<strong>on</strong>able period oftime, this FE based optimizati<strong>on</strong> has to be realized in a high throughput computing envir<strong>on</strong>ment.<str<strong>on</strong>g>Optimizati<strong>on</strong></str<strong>on</strong>g> in C<strong>on</strong>dor – High Throughput Computing Envir<strong>on</strong>mentFortunately, C<strong>on</strong>dor, a high throughput computing envir<strong>on</strong>ment, which harnesses the parallelprocessing capability of more than a thousand workstati<strong>on</strong> computers, is available in UW-Madis<strong>on</strong>. Moreover, JSOL Corp. has generously d<strong>on</strong>ated 100 JMag licenses, making it possible

to analyze up to 100 candidate machines at the same time. The flow chart for future C<strong>on</strong>dorbased optimizati<strong>on</strong> is shown in Fig. 2. It has similar routine shown in Fig.1. The difference is thatinstead of evaluating designs in each generati<strong>on</strong> <strong>on</strong>e by <strong>on</strong>e <strong>on</strong> a single computer, all theperformances of all the design can be calculated simultaneously in C<strong>on</strong>dor.Fig. 2: Future <str<strong>on</strong>g>Optimizati<strong>on</strong></str<strong>on</strong>g> in CONDORSoluti<strong>on</strong>: Process and Required ResourceStep 1: Run the main DE code (written in Matlab) <strong>on</strong> a single computer, which acts as a “master”machine to c<strong>on</strong>trol the whole optimizati<strong>on</strong> process.Operating system: Either Windows or Linux, having Matlab installed.

Output: 100 finite element script (VB script) files for each generati<strong>on</strong>. Each VB script is around10 kBInput: 100 text files showing the results from FE analysis. Each text file is around 10 kBEstimated time: 30 min for each generati<strong>on</strong>, around 20 generati<strong>on</strong>s to c<strong>on</strong>verge. Total time =30 min*20 = 10 hr.Step 2: Transform VB scripts into “.jcf” files <strong>on</strong> “slave” machines, processors in C<strong>on</strong>dor pool.One hundred “slave” machines run at the same timeOperating system: Windows, having JMag installed.Output: “.jcf” file. Each “.jcf” file is around 10 kBInput: VB script. Each VB scrip is around 10 kBStep 3: Evaluate the “.jcf”model file and get FE analysis result <strong>on</strong> each “slave” machine.Operating system: Windows, having JMag installed.Output: “.plot” file. The maximum size for each “.plot” file is around 500 MBInput: “. Jcf” file. Each “.jcf” file is around 10 kBStep 4: Extract result from “.plot” file <strong>on</strong> each “slave” machine.Operating system: Windows, having JMag installed.Output: text file, c<strong>on</strong>taining result informati<strong>on</strong>, should be fed back to the master machine tolaunch another generati<strong>on</strong> (Start Step 1 again). Each text file is around 10 kB.Input: “.plot” file. The maximum size for each “.plot” file is around 500 MB.Status and Future PlansMembers from UW-Madis<strong>on</strong> C<strong>on</strong>dor team, engineer from JSOL, and our research team areworking together to write and install optimizati<strong>on</strong> program in C<strong>on</strong>dor computers. The surfaceand interior PM machines are selected as initial targets for optimizati<strong>on</strong>. Later <strong>on</strong>, thisoptimizati<strong>on</strong> technique will be extended to other types of machines. In l<strong>on</strong>ger term, theprogram will be expanded to include structural and thermal analysis, in order to realize asystem level optimizati<strong>on</strong>.

AcknowledgementThis project is sp<strong>on</strong>sored by Vestas Wind Systems and JSOL Corp. And efforts are being made byour research team. My team partners are Patel Reddy, Li Zhu, Prof. T.M. Jahns, and Prof. T.A.Lipo, Yusaku Suzuki, and Bill Taylor.