AMP-Rose '750' Range of Cut & Wrap Machines - TradeKey

AMP-Rose '750' Range of Cut & Wrap Machines - TradeKey

AMP-Rose '750' Range of Cut & Wrap Machines - TradeKey

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

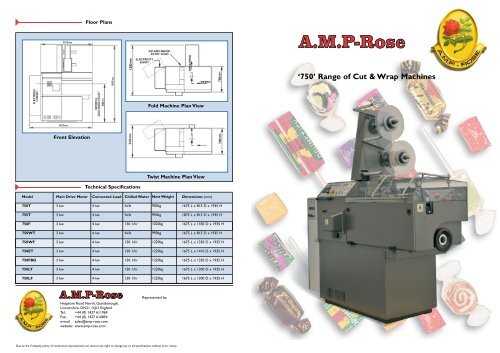

Floor Plans‘750’ <strong>Range</strong> <strong>of</strong> <strong>Cut</strong> & <strong>Wrap</strong> <strong>Machines</strong>Fold Machine Plan ViewFront ElevationTwist Machine Plan ViewTechnical SpecificationsModelMain Drive MotorConnected LoadChilled WaterNett WeightDimensions (mm)750T3 kw4 kwN/A900kg1675 L x 815 D x 1935 H755T3 kw4 kwN/A950kg1875 L x 815 D x 1935 H750F3 kw4 kw150 1/hr1020kg1675 L x 1350 D x 1935 H750WT3 kw4 kwN/A990kg1675 L x 815 D x 1935 H750WF3 kw4 kw150 1/hr1220kg1675 L x 1350 D x 1935 H750ET3 kw4 kw150 1/hr1220kg1675 L x 1410 D x 1935 H750FBG3 kw4 kw150 1/hr1220kg1675 L x 1350 D x 1935 H750LT3 kw4 kw150 1/hr1220kg1675 L x 1300 D x 1935 H750LF3 kw4 kw150 1/hr1220kg1675 L x 1300 D x 1935 HHeapham Road North, Gainsborough,Lincolnshire. DN21 1QU. EnglandTel: +44 (0) 1427 611969Fax: +44 (0) 1427 616854e-mail: sales@amp-rose.comwebsite: www.amp-rose.comRepresented by;Due to the Company policy <strong>of</strong> continuous improvements we reserve the right to change any or all specifications without prior notice

750T/755T - Double Twist750F - Under Fold750WT - Whirl TwistYour partner in the confectionery industryA.M.P-<strong>Rose</strong> ‘750’ <strong>Range</strong> <strong>of</strong> <strong>Cut</strong> & <strong>Wrap</strong> <strong>Machines</strong>The ‘750’ is a versatile cut and wrap machine, which has beendesigned for strength and durability, as well as ease <strong>of</strong> operationand low maintenance. The machine sizes, shapes, cuts to length andwraps t<strong>of</strong>fee, fruit chew, bubble gum, or high boiled sugar fed inrope form from a Batch Roller/Rope Sizer or extruder. Versions<strong>of</strong> the ‘750’ machine can produce square, rectangular, round orcylindrical shaped sweets and lollipops, in various wrapping styles.750LT - Lollipop Twist750LF - Lollipop Fold750FBG* - Bubble Gum End FoldPlease see the sketches below for the complete range <strong>of</strong> productsand wrapping styles that can be produced.<strong>Wrap</strong>ping Styles Model: Maximum output: Size rangeProduct size changing is achieved by adjustment and size parts. <strong>Machines</strong> can be supplied which are interchangeable between some <strong>of</strong> thestyles, i.e Twist and FoldSequence <strong>of</strong> operations:650/minuteLength: 16-50mmWidth: 11-25mmThickness: 5-17mmA rope <strong>of</strong> confectionery product is fed to the infeed section <strong>of</strong> the machine. Two pairs <strong>of</strong> intermittent sizing rollers feed and size the ropeto the desired width and thickness. The presence <strong>of</strong> the rope is detected by a sensor and the PLC signals the paper feed to engage at thecorrect time, thereby avoiding wrapper wastage.Paper feeding rollers provide the correct length <strong>of</strong> paper, which is cut-<strong>of</strong>f by an easily detachable rotary knife. The rope <strong>of</strong> product is cut tothe desired length by a pair <strong>of</strong> nipping knives (rotary knife on 750WT) and then pushed with the cut wrapper into the wrapping wheel. Thewrapping is completed as shown in the diagram, depending upon the desired wrapping style.750T755T750F750WT750WF750FBG750LT750LF750ET650/minute755/minute550/minute650/minute350/minute400/minuteLength: 16-84mm*Width: 11-25mmThickness: 6-17mmDiameter: 9.5 -17mm* max Length for 755T is 38mmDiameters: 16-25mmLength: 16-32mmWidth: 16-25mmThickness: 8-19mmLength: 16-50mmWidth: 11-25mmThickness: 5-17mmLength: 32-70mmWidth: 11-25mmThickness: 6-18mmLength: 84-152mmWidth: 11-25mmDiameter: 9.5-17mm* In the case <strong>of</strong> the ‘750FBG’ (end fold style wrapping), machines can be arranged for running stickers or ‘comic strip’ style wrappers.FeaturesLong, efficient lifeThe machines have been designed to withstand the rigours <strong>of</strong> high-speed confectionery production. Precision machined components arehoused in a solid cast iron frame and are constantly lubricated with oil. External parts are designed for easy removal for cleaning andmaintenance purposes. The machines therefore require little servicing, maintenance or spare parts.Simple yet sophisticated control systemControl <strong>of</strong> the machine is achieved through a PLC system, which has diagnostic features such as warnings <strong>of</strong> wrapper ruffles or guardsincorrectly positioned. All electrical/electronic components are <strong>of</strong> the highest international standards and are housed in a single enclosure witha hinged door for easy access. Operation <strong>of</strong> the machine is via the conveniently located control panel.Health and Safety assuredInterlocked guards are fitted, giving protection to the operator from noise and movement hazards. All machines meet current health andsafety and ‘CE’ standards.Automatic operationThe machines require minimal operator intervention - a sensor detects the presence <strong>of</strong> product in the infeed section <strong>of</strong> the machine,automatically activates the paper feeding mechanism and runs the machine up to the desired operating speed.Reduced cleaning/maintenance timesThe design <strong>of</strong> the guards makes it easy to access all internal and external areas <strong>of</strong> the machine, cutting the time required for routine cleaningand maintenance to a minimum.VersatilityThe ‘750’ machines can handle a wide variety <strong>of</strong> confectionery products, such as hard candy, caramel and t<strong>of</strong>fee, chewy sweets and bubblegum with the minimum <strong>of</strong> adjustments. Change-over parts can also be supplied if a change in product size is required. <strong>Machines</strong> can also besupplied which are interchangeable between some <strong>of</strong> these styles, i.e Twist and Fold.<strong>Wrap</strong>ping Materials:Waxed paper, cellophane, PVC, suitable polypropyleneor paper backed aluminium foil.Reel Sizes:Standard core diameters <strong>of</strong> 57mm and 77mm. Other sizes available on application.Maximum reel diameter 355mm.Optional Extras:Additional sets <strong>of</strong> sizing rollersPhotoelectric cell registration unit (standard on 750FBG)Independently-driven belt discharge unitHeated candy feed for high boiled sugarBuilt-in fold/twist conversion partsSemi-automatic paper reel splicing unitHeapham Road North, Gainsborough, Lincolnshire. DN21 1QU. EnglandTel: (+44) (0) 1427 611969 Fax: (+44) (0) 1427 616854e-mail: sales@amp-rose.com website: www.amp-rose.com