curriculum vitae Personal data: Summary: Education ... - seacamel

curriculum vitae Personal data: Summary: Education ... - seacamel

curriculum vitae Personal data: Summary: Education ... - seacamel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

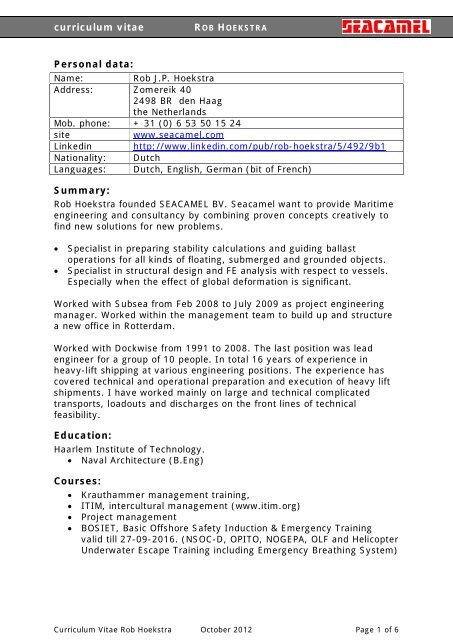

<strong>curriculum</strong> <strong>vitae</strong> ROB HOEKSTRA<br />

<strong>Personal</strong> <strong>data</strong>:<br />

Name: Rob J.P. Hoekstra<br />

Address: Zomereik 40<br />

2498 BR den Haag<br />

the Netherlands<br />

Mob. phone: + 31 (0) 6 53 50 15 24<br />

site www.<strong>seacamel</strong>.com<br />

Linkedin http://www.linkedin.com/pub/rob-hoekstra/5/492/9b1<br />

Nationality: Dutch<br />

Languages: Dutch, English, German (bit of French)<br />

<strong>Summary</strong>:<br />

Rob Hoekstra founded SEACAMEL BV. Seacamel want to provide Maritime<br />

engineering and consultancy by combining proven concepts creatively to<br />

find new solutions for new problems.<br />

� Specialist in preparing stability calculations and guiding ballast<br />

operations for all kinds of floating, submerged and grounded objects.<br />

� Specialist in structural design and FE analysis with respect to vessels.<br />

Especially when the effect of global deformation is significant.<br />

Worked with Subsea from Feb 2008 to July 2009 as project engineering<br />

manager. Worked within the management team to build up and structure<br />

a new office in Rotterdam.<br />

Worked with Dockwise from 1991 to 2008. The last position was lead<br />

engineer for a group of 10 people. In total 16 years of experience in<br />

heavy-lift shipping at various engineering positions. The experience has<br />

covered technical and operational preparation and execution of heavy lift<br />

shipments. I have worked mainly on large and technical complicated<br />

transports, loadouts and discharges on the front lines of technical<br />

feasibility.<br />

<strong>Education</strong>:<br />

Haarlem Institute of Technology.<br />

� Naval Architecture (B.Eng)<br />

Courses:<br />

� Krauthammer management training,<br />

� ITIM, intercultural management (www.itim.org)<br />

� Project management<br />

� BOSIET, Basic Offshore Safety Induction & Emergency Training<br />

valid till 27-09-2016. (NSOC-D, OPITO, NOGEPA, OLF and Helicopter<br />

Underwater Escape Training including Emergency Breathing System)<br />

Curriculum Vitae Rob Hoekstra October 2012 Page 1 of 6

<strong>curriculum</strong> <strong>vitae</strong> ROB HOEKSTRA<br />

Work experience:<br />

Owner of SEACAMEL B.V.<br />

July 2012 – date<br />

� Engineering Manager for “Dockwise” for the loadout, transportation<br />

and discharge of the:<br />

o Lucius Spar,<br />

o Big Dog Spar,<br />

o Asta Hanseen Spar and,<br />

o Heidelberg Spar<br />

Feb 2011 – date<br />

� Support and peer reviews for Mammoet Engineering and Mammoet<br />

Europe.<br />

� GHS (General Hydrostatics) course/training.<br />

October 2011 – date<br />

� Project Engineer for “Heerema Fabrication Group Engineering” HFGE<br />

on the Dagny Jacket FEED. A jacket for Statoil that will be installed<br />

on the Norwegian continental shelf.<br />

November 2010 – July 2012<br />

� Project Engineer for “Heerema Fabrication<br />

Group Engineering” HFGE on the Valemon<br />

Jacket EPC. A jacket for Statoil that will be<br />

installed in about 135m of water some 160km<br />

west of Bergen, Norway.<br />

Responsibility:<br />

o Ensure the engineering progress in<br />

general.<br />

o Engineering for the temporary conditions. Loadout, transport and<br />

Lift-off.<br />

December 2010<br />

� Ballast Engineer for “ALE Heavy Lifting”.<br />

Responsibility:<br />

o Review the ballast and discharge<br />

procedures for the discharge of the “MCR-<br />

A Gravity Base Structure” with Installation<br />

Barge “DAGBASY”<br />

o On site guidance on ballasting and<br />

discharge float-off operation.<br />

Curriculum Vitae Rob Hoekstra October 2012 Page 2 of 6

<strong>curriculum</strong> <strong>vitae</strong> ROB HOEKSTRA<br />

July 2010 – January 2011<br />

� Lead engineer for the transport of the SHELL<br />

Mars-B TLP (South Korea - the US Gulf)<br />

Responsibility:<br />

o Define the project planning.<br />

o Transform concept studies to detailed<br />

engineering and finalize the design so that<br />

construction can proceed.<br />

July 2010 – January 2011<br />

� Lead engineer for the transport of the Goliat<br />

FPSO (South Korea - Hammerfest, Norway)<br />

Responsibility:<br />

o Define the project planning.<br />

o Transform concept studies to detailed<br />

engineering and finalize the design so that<br />

construction can proceed.<br />

August 2009 – July 2010<br />

� Lead engineer for the Vyborg float-over<br />

project. Responsibility was:<br />

o Design of the mooring spread<br />

o FE analyse the interaction between the<br />

vessel, the floating hull and the topside<br />

during the mating process.<br />

o Mating procedures.<br />

o Typhoon procedures<br />

The global deformation of the lower hull of the SSFDR (Semi<br />

Submersible Floating Drilling Rig) during the mating of the topside<br />

on the lower hull and the subsequent impact on a local level was a<br />

very challenging issue.<br />

Project Engineering Manager at Subsea 7<br />

February 2008 – 2009 (1.5 years)<br />

� Responsible for the Project Engineering Group in the Rotterdam<br />

office.<br />

� Proposal engineer for the Kristin K and Q development.<br />

Reeled pipeline with DEH cable, umbilical including riser and<br />

Template installation.<br />

� Lead for the Shell Draugen FLP removal.<br />

The Draugen Floating Loading Platform had to be prepared for<br />

transport to a decommission yard. Responsible for outfitting the FLP<br />

for transport, anchor line recovery and riser disconnection and<br />

subsequent recovery of the risers. Did not participate till the end<br />

due to delays in the project execution.<br />

Lead Engineer at Dockwise Transport NV<br />

2006 – 2008 (2 years)<br />

Curriculum Vitae Rob Hoekstra October 2012 Page 3 of 6

<strong>curriculum</strong> <strong>vitae</strong> ROB HOEKSTRA<br />

� In this role, I executed many business trips with colleagues from the<br />

business acquisition department to discuss contracts and scopes<br />

with clients.<br />

� Responsible for the transport engineering group which consist out of<br />

about 10 people. This group executes all engineering for the<br />

“standard” transports. This is about 90% of all projects.<br />

� Involved in the design of a new generation of heavy lift vessels. My<br />

responsibility was:<br />

o Vessel local deck strength<br />

o Vessel global strength<br />

o Vessel stability in submerged condition<br />

o Pump and ballast line arrangement<br />

o Increase and optimize vessel capabilities/ capacities regarding<br />

side and stern roll-on/roll-off loadout operations.<br />

� Re-assed construction of all Dockwise vessels to increase allowable<br />

bending moments and applied for new class certificates. As a result,<br />

the vessels could carry more cargo and sail with lower drafts<br />

resulting in lower fuel consumption/higher sailing speeds.<br />

� Developed a method and started patent granting procedure to<br />

obtain patent to build a 50.000 mt topside on a quay-side and mate<br />

this topside on a spar buoy.<br />

� Developed a method and started patent granting procedure for a<br />

float-over operation to increase the air gap while avoiding high<br />

grillage on the transport vessel or barge. Method allowed heavier<br />

topsides to be mated for a given distance between the legs of the<br />

jacket.<br />

� Made a study and defended methodology towards DNV to calculate<br />

GM in an alternative manner to get more accurate results for<br />

asymmetric floating objects. This action opened the way for GHS<br />

(www.ghsport.com) to obtain class approval for their software on<br />

this subject.<br />

2007 Lead Project engineer Chevron CVX Tahiti<br />

Spar. The Tahiti spar is the heaviest spar<br />

transported in one piece.<br />

2007 Lead Project engineer and assistant<br />

superintendent Murphy Kikeh Spar.<br />

Senior Engineer at Dockwise Shipping B.V., Breda, the<br />

Netherlands<br />

2001 – 2006 (5 years)<br />

� Responsible for maintenance and support of FE software. Developed<br />

a method to make quick assessments to calculated local deck stress<br />

variations as a result of variations in global vessel deformation due<br />

to waves.<br />

Curriculum Vitae Rob Hoekstra October 2012 Page 4 of 6

<strong>curriculum</strong> <strong>vitae</strong> ROB HOEKSTRA<br />

2006 Lead Project engineer for the Kerr-McGee Constitution Spar<br />

transport.<br />

2006 Lead Project engineer for 3 Russian nuclear<br />

powered submarines that had to be<br />

transported to a dismantling yard. Developed<br />

a new way to support and seafasten<br />

submarines which reduced seafastening costs<br />

by 60% and seafastening time by 3 days.<br />

2004 Lead Project engineer for the BP Mad Dog Spar transport.<br />

Developed and introduced a new method to skid spars from the<br />

quay onto a vessel. The loadout time was reduced by about 20h and<br />

ensured better load spreading and hence allowed for heavier cargoloads.<br />

2003 Lead Project engineer for the BP Holstein Spar<br />

transport.<br />

2003 Lead Project engineer and load out<br />

superintendent for the Dominion Devils Tower<br />

Spar transport.<br />

2002 Lead Project engineer and load out superintendent for the Dominion<br />

Medusa Spar transport.<br />

2003 Lead Project engineer for the Kerr-McGee Gunnison Spar transport.<br />

2002 Lead Project engineer for the BP Horn Mountain Spar transport.<br />

Senior Engineer at Dockwise N.V., Meer, Belgium<br />

1994 – 2001 (7 years)<br />

� Support commercial department with contract negotiations.<br />

� Involved in training of new personnel.<br />

� Working on the more complex type of projects from an engineering<br />

viewpoint.<br />

� Responsible for the implementation of the stability software GHS.<br />

� Involved in the implementation of Finite Element software and<br />

responsible for standardization of Finite Element Analysis.<br />

2001 Lead Project engineer and loadout superintendent for the Conoco<br />

Hang Tuah Self-Installing platform. Developed and introduced a<br />

method to calculate and evaluate initial and dynamic stability for<br />

units that float on air bubbles under their skirts. This discharge<br />

method was adopted by Arup Energy when they designed the “MCR-<br />

A Gravity Base Structure” for PETRONAS.<br />

Curriculum Vitae Rob Hoekstra October 2012 Page 5 of 6

<strong>curriculum</strong> <strong>vitae</strong> ROB HOEKSTRA<br />

2001 Lead Project engineer for the Kerr-McGee Nansen Spar transport.<br />

Developed and introduced a method to calculate and evaluate initial<br />

and dynamic stability for asymmetric floating objects.<br />

2001 Lead Project engineer for the Kerr-McGee Boomvang Spar transport.<br />

1999 Lead Project engineer for the Exxon Diana Spar transport.<br />

1998 Lead Project engineer for the Chevron Genesis Spar transport.<br />

Project Engineer at Wijsmuller Transport B.V.<br />

1991 – 1993 (2 years)<br />

� Working on transports of jack-up rigs and the jacket launch<br />

performed by the Mighty Servant 2, the only launch executed from a<br />

heavy lift vessel so far.<br />

Curriculum Vitae Rob Hoekstra October 2012 Page 6 of 6