IssUe 16 - July 2012 - Trenchless International

IssUe 16 - July 2012 - Trenchless International

IssUe 16 - July 2012 - Trenchless International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Relining Tools<br />

Water<br />

In this issue | Turkey | US | South Korea | Germany | France | China | Brazil | Australia | Colombia<br />

Pipe Jacking and Microtunnelling<br />

The official magazine of the ISTT<br />

Rejuvenating<br />

an old Seoul<br />

<strong>July</strong> <strong>2012</strong><br />

Issue <strong>16</strong>

PRIME<br />

HORIZONTAL<br />

Have an HDD Intersect or CBM project in mind?<br />

Sti ck with the best of class and use Prime Horizontal for planning and guidance of your next HDD<br />

intersect or Coal Bed Methane (CBM) project with proven ParaTrack technology.<br />

Need Drilling Tools for pilot holes and reaming operati ons?<br />

Prime Horizontal is a preferred supplier of drill bits, mud motors, reamers and hole openers,<br />

including all the subs required to make up the bott om hole assembly.<br />

We also maintain a mobile break-out unit for repair and make up of mud motors on site.<br />

Successful partnerships<br />

Prime Horizontal Ltd, a leading guidance company for<br />

Horizontal Directi onal Drilling (HDD) projects, takes<br />

great pride in its partnerships with each of its clients.<br />

We share with our clients the responsibility to<br />

succeed in completi ng our client’s projects on<br />

ti me and on budget. When fi nished, we share in<br />

the pride of a job well done. Our success is due in<br />

large measure to the excellent working relati onship<br />

between us and our drilling company clients.<br />

Prime Horizontal, providing drilling tools, mud motors<br />

and HDD guidance services for CBM projects and<br />

crossings beneath waterways and infrastructure,<br />

was the fi rst company to guide HDD underground<br />

intersects. We have drilled over 50 HDD intersects<br />

around the globe now, 20 of which were over<br />

2,000 m in length.<br />

We look forward to partnering with your company<br />

during your next intersect or CBM project.<br />

Prime Horizontal Group of Companies, Salland 3, 1948 RE Beverwijk, The Netherlands.<br />

Telephone: +31 251 271790, www.primehorizontal.com.

Sam Ariaratnam<br />

Istt Chairman<br />

<strong>International</strong> Society for<br />

<strong>Trenchless</strong> Technology<br />

www.istt.com<br />

info@istt.com<br />

Chairman: Dr Samuel Ariaratnam<br />

Ariaratnam@asu.edu<br />

Vice-Chairman: Derek Choi<br />

derekchoi@balama.com<br />

Executive Director: John Hemphill<br />

hemphill@istt.com<br />

Membership Secretary: Kyoko Kondo<br />

kondo@istt.com<br />

Executive Sub Committee<br />

Jeff Pace: Australasia<br />

Sergio Palazzo: Brazil<br />

Gerda Hald: Denmark<br />

Enrico Boi: Italy<br />

Takehiro Toyoda: Japan<br />

Norman Howell: United Kingdom<br />

Dr Dec Downey (Past Chair): United Kingdom<br />

Executive Director, ISTT<br />

308 S. Lee Street<br />

Alexandria, VA 22314<br />

United States<br />

Tel: +1 (703) 299-8484<br />

Kyoko Kondo (Ms.)<br />

Membership Secretary ISTT<br />

3rd Nishimura Bldg.,<br />

2-11-18, Tomioka, Koto-ku,<br />

Tokyo 135-0047, Japan<br />

Tel: +81 (3) 5639 9970<br />

FAX: +81 (3) 5639 9975<br />

Registered Address:<br />

15 Belgrave Square<br />

LONDON, SW1X 8PS<br />

UK<br />

This pasT quarTer was filled with a<br />

number of activities involving the isTT and<br />

several affiliated societies. in total, there<br />

were six trenchless events – beginning<br />

with No-Dig poland <strong>2012</strong> in april, and<br />

ending with No-Dig Moscow <strong>2012</strong> in<br />

June. it is nice to see so much activity in<br />

various countries.<br />

i had the privilege of attending No-Dig<br />

poland <strong>2012</strong> hosted by the polish Foundation<br />

for <strong>Trenchless</strong> Technology (pFTT) in Kielce<br />

from 17–19 april. The event had over<br />

150 attendees and a dozen exhibitors.<br />

professor andrzej Kuliczkowski was<br />

an excellent host and brought several<br />

top-level administrators from the Kielce<br />

university of Technology to give welcome<br />

addresses during the opening ceremony.<br />

at the Gala Dinner, a number of individuals<br />

received expert statuettes. i was honoured<br />

to receive one of these beautiful statuettes<br />

from the pFTT and will certainly cherish this<br />

award. immediately after the conference,<br />

i had the pleasure of visiting the hobas<br />

plant in Dabrowa Gornicza. it was very<br />

informative as i had the opportunity to see<br />

firsthand the largest CC-Gpr pipe ever<br />

manufactured, which was used on the<br />

project that won the 2011 No-Dig project<br />

of the Year award for New installations.<br />

The <strong>16</strong> th iTTC hosted by the China<br />

society for <strong>Trenchless</strong> Technology (CsTT)<br />

was held in Zhengzhou from 20–22 april.<br />

There were 50 exhibitors and over 1,200<br />

visitors who attended the event, which<br />

had numerous domestic and international<br />

speakers. The CsTT held their reception<br />

Banquet where several awards were<br />

handed out to members. Once again, the<br />

CsTT put on an excellent show!<br />

i attended the No-Dig india <strong>2012</strong> summit<br />

from 14–15 May in Bangalore, india<br />

hosted by the isTT. Dr Dec Downey and i<br />

participated in a very successful masterclass<br />

training seminar attended by 120 people and<br />

10 sponsoring companies who exhibited.<br />

Westrade should be commended for the<br />

excellent job in organising this event for the<br />

isTT. We hope that this event will be the<br />

start of re-establishing an affiliated society<br />

in india. plans are already underway for<br />

another event in 2013.<br />

The Colombian institute for subterranean<br />

infrastructure Technologies and Techniques<br />

(CisTT) held the second Colombian and First<br />

andean and Central american Congress<br />

and exhibition of No-Dig Technologies and<br />

underground infrastructure in Cartagena<br />

from 17–18 May. i had the pleasure of<br />

attending this event and delivering the<br />

opening presentation. There were<br />

250 attendees and over a dozen exhibitors<br />

who participated in a technical program<br />

containing 26 presentations from both<br />

domestic and international presenters. This<br />

was a significant increase in attendance<br />

from the first event held in 2010. it is great<br />

to see so much enthusiasm in the south<br />

american region.<br />

i recently delivered the Keynote address<br />

at the <strong>2012</strong> underground infrastructure<br />

research (uir) international Conference<br />

from 5–6 June, hosted by the Centre for<br />

advancement of <strong>Trenchless</strong> Technology<br />

(CaTT) and Benjamin Media in Niagara<br />

Falls, Ontario Canada. The technical<br />

program consisted of 77 papers with<br />

presenters spread over several countries.<br />

Over 400 attendees and 50 exhibitors were<br />

present. The 14 th international <strong>Trenchless</strong><br />

Technology research Colloquium (iTTrC)<br />

was held prior to the uir Conference<br />

from 3–4 June. Dr Mark Knight from the<br />

university of Waterloo hosted the iTTrC,<br />

which attracted <strong>16</strong> research participants<br />

from europe and North america. The group<br />

worked on developing the framework for<br />

two papers related to research needs in<br />

pressure and gravity pipeline assessment,<br />

rehabilitation and installation.<br />

No-Dig Moscow <strong>2012</strong> was held from<br />

5–8 June in Moscow and was hosted<br />

by the russian society for <strong>Trenchless</strong><br />

Technology (rsTT). in addition to a large<br />

exhibition area, there was a technical<br />

program consisting of papers in three<br />

focus areas: 1) horizontal directional<br />

drilling; 2) rehabilitation and repair; and<br />

3) microtunnelling. Klaus Beyer from<br />

the German society for <strong>Trenchless</strong><br />

Technology (GsTT) delivered the welcome<br />

address on behalf of the isTT.<br />

We are busy getting prepared for<br />

<strong>Trenchless</strong> asia <strong>2012</strong> in singapore from<br />

2–4 <strong>July</strong>. This conference is co-located<br />

with the singapore international Water<br />

Week (siWW) and will be held in the<br />

beautiful Marina Bay sands hotel. siWW<br />

attracts thousands of attendees from<br />

all over the world. This is an excellent<br />

example of collaboration between<br />

the isTT and the international Water<br />

association (iWa).<br />

i hope that you are planning on attending<br />

the 30 th international No-Dig Conference<br />

and exhibition from 12–14 November<br />

in são paolo, Brazil. The associação<br />

Brasileira de Tecnologia não Destrutiva<br />

(aBraTT) has been busy in preparing the<br />

conference, which will feature excellent<br />

exhibits and a strong technical program. i<br />

look forward to another productive quarter<br />

in spreading the message of the benefits<br />

of trenchless technologies!<br />

FROM the ChAIRMAN’s desk<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

1

2<br />

Great Southern Press<br />

Pty Ltd<br />

query@trenchlessinternational.com<br />

www.trenchlessinternational.com<br />

Editor: Kate Pemberton<br />

Associate Editor: Sarah Paul<br />

Assistant Editor: Tori McLennon<br />

Journalist: Isabella Andres<br />

Sales Manager: Tim Thompson<br />

Senior Account Manager: Brett Thompson<br />

Sales Representative: David Entringer<br />

Acting Design Manager: Bianca Botter<br />

Senior Designers: Katrina Rolfe, Susie Monte<br />

Designers: Venysia Kurniawan, Ben Lazaro<br />

Publisher: Zelda Tupicoff<br />

United States<br />

(Sales)<br />

<strong>16</strong>360 Park Ten Place, Suite 109<br />

Houston, TX 77084<br />

Tel: +1 281 492 7272<br />

Fax: +1 713 521 9255<br />

Australia<br />

(Sales and subscriptions)<br />

GPO Box 4967<br />

Melbourne VIC 3001 Australia<br />

Tel: +61 39248 5100<br />

Fax: +61 3 9602 2708<br />

ISSN: 1836-3474<br />

This magazine is an official publication of the<br />

<strong>International</strong> Society for <strong>Trenchless</strong> Technology (ISTT)<br />

and is distributed free to members and other interested<br />

parties worldwide. It is also available on subscription.<br />

The publishers welcome editorial contributions from<br />

interested parties. However, neither the publishers nor<br />

the ISTT accept responsibility for the content of these<br />

contributions and the views contained therein which<br />

will not necessarily be the views of the publishers or<br />

the ISTT. Neither the publishers nor the ISTT accept<br />

responsibility for any claims made by advertisers.<br />

All communications should be directed to the publishers.<br />

Unless explicitly stated otherwise in writing, by providing<br />

editorial material to Great Southern Press (GSP),<br />

including text and images you are providing permission<br />

for that material to be subsequently used by GSP, whole<br />

or in part, edited or unchanged, alone or in combination<br />

with other material in any publication or format in print<br />

or online or howsoever distributed, whether produced<br />

by GSP and its agents and associates or another party to<br />

whom GSP has provided permission.<br />

ReGULARs<br />

From the Chairman’s Desk 1<br />

Executive Director’s Report 6<br />

About ISTT/Membership 62<br />

Contacts and Addresses of Affiliated Societies 62<br />

Upcoming Events 30<br />

Advertisers’ Index 64<br />

Subscription and Editorial Schedule 64<br />

News<br />

World wrap 8<br />

<strong>Trenchless</strong> <strong>International</strong> update 10<br />

Istt News<br />

SASTT visits Zandfontein Depot of Joburg Water 14<br />

ISTT outreach gathers momentum <strong>16</strong><br />

<strong>Trenchless</strong> experts head to Zhengzhou 17<br />

Finnish Society thinks laterally at IFAT 19<br />

wAteR FeAtURe<br />

Tough PE pipe materials ideal for installation 20<br />

CONFeReNCes<br />

Inaugural India No-Dig brings industry together 24<br />

ISTT sets sights on Brazil 25<br />

Fifth Jubilee proves popular in Poland 28<br />

An underground success 29<br />

An eventful year in France 30<br />

Celebrating trenchless in Colombia 31<br />

tURkey<br />

Under Turkey 32<br />

Water utilities in Turkey 34<br />

INspeCtION ANd<br />

CONdItION AssessMeNt<br />

Safety in the shaft 36

4<br />

<strong>IssUe</strong> <strong>16</strong> - <strong>July</strong> <strong>2012</strong><br />

In this issue | Turkey | US | South Korea | Germany | France | China | Brazil | Australia | Colombia<br />

Pipe Jacking and Microtunnelling<br />

Relining Tools<br />

Water<br />

The official magazine of the ISTT<br />

Rejuvenating<br />

an old Seoul<br />

<strong>July</strong> <strong>2012</strong><br />

Issue <strong>16</strong><br />

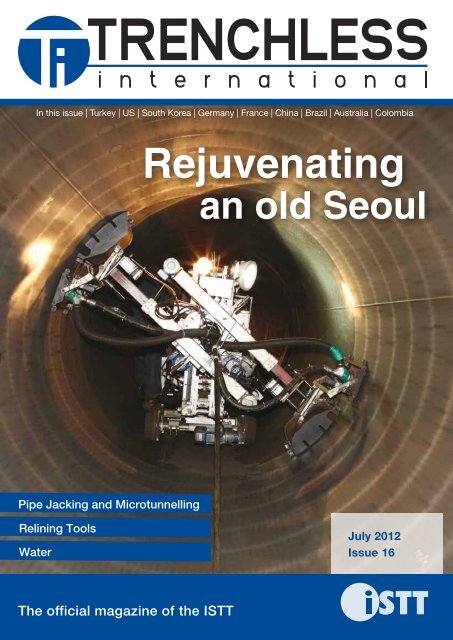

The cover shows blasting equipment removing old paint for<br />

completion of Phase 1 of the Seoul Metropolitan Multi-regional<br />

Water Supply System Rehabilitation Project, in South Korea. For<br />

a full project overview turn to page 54.<br />

MICROtUNNeLLING ANd pIpeJACkING<br />

The in and outs of pipe jacking 38<br />

Microtunnelling mapped for Marmara Sea 40<br />

Tunnelling success Down Under 42<br />

pROdUCts ANd seRvICes<br />

The short and tall of pipe rehabilitation 44<br />

pROJeCts<br />

A burst of inspiration in Germany 46<br />

INspeCtION ANd<br />

CONdItION AssessMeNt<br />

Working through the life cycle 48<br />

COMpANy News<br />

How to capture more customers<br />

with content marketing 50<br />

<strong>Trenchless</strong> online shop launched 52<br />

ReLINING tOOLs<br />

Rejuvenating an old Seoul 54<br />

ResINs<br />

Renovating pressure pipes using the<br />

CIPP process 58<br />

Istt esC pROFILe<br />

5 minutes with Gerda Hald 60<br />

Success story<br />

Russia<br />

Achievement:<br />

German Drilling Specialist DrillTec<br />

relied on mts tunnelling equipment to<br />

implement this complicated project in<br />

the Olympian town of Sochi, Russia.<br />

This impressive work was part of the<br />

effort to complete a section of the Blue<br />

Stream Mega Pipeline Project.<br />

An mts800S4 machine was used to<br />

drill a 2<strong>16</strong> m blind hole at an angle of<br />

13,9° (-24,747%) in complicated soil,<br />

consisting of mudstone, gravel and<br />

boulders. Furthermore DrillTec wished<br />

to recover all machine parts and<br />

equipment once the drilling had been<br />

completed, despite a missing target<br />

shaft.<br />

Client<br />

Project background<br />

Gazprom (Russia)<br />

Job site Sochi (Kudepsta)<br />

Main contractor StroyGasMontazh<br />

Subcontractor Max Streicher (DrillTec GUT GmbH)<br />

mts Perforator GmbH<br />

Am Heisterbusch 18a<br />

19246 Lüttow-Valluhn,<br />

Germany<br />

To achieve this, mts Perforator designed<br />

all parts to be retractable – even<br />

the heavy-duty mixed ground cutting<br />

wheel at the front. Only a steel sleeve<br />

was to remain in the ground, which<br />

helped to stabilise the hole for the HDD<br />

operation, which was to be launched<br />

from this tunnel.<br />

The high degree of professionalism<br />

in both the machine design and<br />

application made this challenging<br />

project to an outright success for<br />

the contractor and enabled a critical<br />

section of the Blue Stream Mega<br />

Pipeline Project to be completed.<br />

Tel.: +49-38851-3270<br />

Fax.: +49-38851-32710<br />

Internet: www.mts-p.de<br />

E-mail: info@mts-p.de<br />

Short facts<br />

Customer Max Streicher<br />

(DrillTec GUT GmbH)<br />

Machine mts800S4<br />

Max. torque 71,000 Nm<br />

Total drive length 2<strong>16</strong>,85 m<br />

Geology mudstone, gravel<br />

and boulders

exeCUtIve dIReCtOR’s RepORt<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

6<br />

John Hemphill<br />

Istt Executive Director<br />

@<br />

Follow us<br />

on Twitter<br />

@<strong>Trenchless</strong>Int<br />

If you juST read the headlines, <strong>2012</strong><br />

might be considered a difficult year,<br />

what with the weakness of the economy<br />

world-wide, political tensions in many<br />

regions of the world, and even a<br />

prophesy of the world coming to an end<br />

according to an ancient Mayan calendar.<br />

however, when it comes to the trenchless<br />

community, <strong>2012</strong> is shaping-up to be a<br />

pretty good year.<br />

at the mid-point of the year, it is<br />

worth assessing what we already have<br />

accomplished as a group and what the<br />

near-term outlook is for isTT and the<br />

member societies. During the first six months<br />

of <strong>2012</strong>, three new societies joined isTT<br />

and several more groups, recognising the<br />

benefits of associating with isTT have shown<br />

an interest in becoming members. For<br />

example, isTT executive sub Committee<br />

member sergio palazzo is taking the lead<br />

in working with the trenchless industry in<br />

argentina towards in the establishment a<br />

new society that would affiliate with isTT.<br />

in May, isTT held a very successful<br />

masterclass training seminar in india, which<br />

attracted approximately 120 attendees,<br />

who gave the masterclass high marks.<br />

Thirty-five of the attendees chose to<br />

become members of isTT. isTT is also a<br />

sponsor of <strong>Trenchless</strong> asia, to be held in<br />

singapore in early <strong>July</strong> in association with<br />

singapore Water Week. We plan to hold at<br />

least one more training seminar in <strong>2012</strong> or<br />

in early 2013.<br />

Throughout the year, many member<br />

societies have held or will be holding<br />

their own education and training programs.<br />

When possible, Chairman Dr sam<br />

ariaratnam, or other members of the isTT<br />

Board, attend and participate in these<br />

events. Thus far, Chairman Dr ariaratnam<br />

has participated in the annual conferences<br />

of North america (NasTT), poland (psTT)<br />

and Colombia (CisTT) and is scheduled to<br />

attend the Turkey society (TsiTT) No-Dig.<br />

in addition, Vice Chairman Derek Choi<br />

attended the China (CsTT) No-Dig and<br />

Board member Klaus Beyer of the German<br />

society represented isTT at the russia<br />

(rsTT) No-Dig. all isTT representatives<br />

have been extremely impressed with the<br />

technical quality of these seminars and<br />

the enthusiasm of those attending. These<br />

events are but a few of the many held by<br />

member societies. a full list of up-coming<br />

member society events is posted on<br />

the isTT website, www.istt.com, and in<br />

<strong>Trenchless</strong> <strong>International</strong> magazine. There<br />

may be an event near you that you would<br />

want to attend.<br />

isTT launched its new website at the<br />

beginning of the year. We have continued<br />

to make upgrades and improvements<br />

to enhance the site’s capacity to add<br />

value to isTT members and the trenchless<br />

community at large. The new website<br />

has many innovative features including a<br />

page that will show videos of trenchless<br />

technologies in action. These videos will<br />

be linked to the website’s <strong>Trenchless</strong><br />

Guidelines allowing viewers to move from<br />

the technical descriptions of a <strong>Trenchless</strong><br />

Technology to a video of the technology.<br />

Not visible to the casual visitor to the<br />

website is a new ‘back-end’, which allows<br />

an affiliated society to easily update its<br />

membership information at any time and<br />

to add information on upcoming society<br />

events. isTT secretary Kyoko Kondo<br />

has done a magnificent job in managing<br />

the development and implementation of<br />

this website membership database and<br />

events system.<br />

The highlight of <strong>2012</strong> will be the 31 st<br />

annual international No-Dig to be held in<br />

são paulo, Brazil on 12–14 November.<br />

isTT will present its annual awards at<br />

the event’s Gala Dinner. if you have an<br />

innovative project or product or are<br />

involved in academic research or a student<br />

of trenchless studies, apply for one of<br />

these awards.<br />

Finally, the isTT Board of Directors at<br />

the <strong>2012</strong> Board meeting to be held in são<br />

paulo will vote to add a new member to the<br />

executive sub Committee (esC). Members<br />

of the esC are nominated by member<br />

societies to serve as their representatives<br />

in the day-to-day oversight of the isTT.<br />

a list of nominees will be circulated to<br />

member societies in early October, with the<br />

election of the new member to be held at<br />

the Board meeting on 11 November <strong>2012</strong>.<br />

so there is reason for optimism. The<br />

trenchless industry continues to grow.<br />

users increasingly are becoming aware of<br />

the environmental and financial benefits of<br />

trenchless methods. <strong>2012</strong> should be a very<br />

good year for <strong>Trenchless</strong> Technology.<br />

FREE <strong>Trenchless</strong> <strong>International</strong> e-newsletter<br />

The latest news, events and job listings emailed weekly<br />

SUBSCRIBE NOW! www.trenchlessinternational.com

News<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

8<br />

world wrap<br />

Aqua-Pipe announce $uS19.58 million contract<br />

sanexen Environmental services was awarded a $Us19.58 million<br />

contract by the City of Montreal for the structural rehabilitation of<br />

approximately 60,000 ft of distribution watermains. Aqua-Pipe crews<br />

will structurally rehabilitate watermains in residential, commercial and<br />

industrial sectors in the city centre and in 15 of its boroughs. More<br />

on page 10.<br />

Record breaking in Mississippi<br />

In east Mississippi a 1,640 ft, 36 inch section<br />

of pipeline has been installed using HDD<br />

– the longest length of 36 inch pipe to be<br />

installed using the trenchless technology<br />

method. the record pull was completed<br />

as part of a 32 mile ductile iron pipeline,<br />

by American Ductile Iron Pipe, that will<br />

carry treated wastewater from Meridian<br />

in Mississippi, to a new industrial facility<br />

northeast of the city.<br />

Collapsed sewer under Reading<br />

A £2 million ($Us3 million) project to repair<br />

a collapsed sewer buried 8 m below a town<br />

centre road has commenced in Reading,<br />

UK. the work will involve building a new<br />

sewer pipe using trenchless technology,<br />

under Blagrave street and Forbury Road.<br />

thames Water is carrying out the project,<br />

which is expected to be complete by<br />

November <strong>2012</strong>.<br />

ISTT heads to Brazil<br />

From 12–14 November <strong>2012</strong>, the 30 th <strong>International</strong> society for trenchless technology (Istt)<br />

No-Dig conference will take place in são Paulo in Brazil. this is the first time the world’s<br />

largest trenchless technology event has been hosted in Brazil, and will be an opportunity<br />

for the latest in trenchless technology equipment and services to be presented to an<br />

international audience. see page 25 for more information.<br />

Istanbul gets microtunnelling<br />

Istanbul’s Metropolitan Water and sewerage Municipality has<br />

commenced three new microtunnelling projects that will provide<br />

turkey’s inland Marmara sea with better environmental protection.<br />

Construction works began in February <strong>2012</strong>, and it is expected<br />

that the projects will be completed in the first half of 2015, with an<br />

estimated cost totalling 43.5 million turkish Liras ($Us24.5 million).<br />

More on page 40.<br />

Rehab finishes on schedule for Cape Town<br />

the City of Cape town, south Africa, appointed three contractors to<br />

perform trenchless pipe rehabilitation in the Durbanville Hills, Welgemoed<br />

and Ridgeworth areas. the contracts commenced 26 March <strong>2012</strong>, and<br />

finished at the end of June <strong>2012</strong>.<br />

Keep up to date with this news and more by subscribing to the <strong>Trenchless</strong> <strong>International</strong> online update. www.trenchlessinternational.com<br />

Damaged pipe gives Bangkok<br />

authorities a sinking sensation<br />

the Bangkok Metropolitan Administration<br />

utilised CCtV and ground penetrating<br />

radar to inspect a sewage pipeline under<br />

the thai-Belgian Friendship Overpass on<br />

Bangkok's Rama IV Road after a 5 m<br />

diameter sinkhole occurred on the<br />

road. the Department of Public Works<br />

employed a ground penetrating radar<br />

(GPR) in combination with a robotic<br />

CCtV camera to check the cavity<br />

beneath the road.<br />

News<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong> 9

News<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

10<br />

CIpp for City of Montreal<br />

sanexen Environmental services was awarded a $Us19.58 million<br />

contract by the City of Montreal for the structural rehabilitation of<br />

approximately 60,000 ft of distribution watermains. Under the contract,<br />

Aqua-Pipe crews will be responsible for the structural rehabilitation<br />

of watermains located on approximately 75 streets in the residential,<br />

commercial and industrial sectors throughout the city centre and 15 of<br />

its 19 boroughs.<br />

In the last four years, the City of Montreal’s Water services<br />

Division has rehabilitated over 150,000 ft of small diameter distribution<br />

watermains with the use of Aqua-Pipe, a structural cured-in-place liner.<br />

Research program to improve sydney water’s<br />

wastewater network<br />

sydney Water is investing $Us22.2 million to fund five years<br />

of research into the best methods, models and tools to minimise<br />

concrete renewals for sydney's wastewater network. the Australian<br />

Research Council Linkage Program is funding $Us4.8 million toward<br />

the initiative, which is the largest Australian Research Council grant<br />

for water industry research.<br />

the project is designed to carry out research in all aspects of the<br />

corrosion process and emissions of odour.<br />

Japan establishes R&d centre in singapore<br />

the toshiba Corporation has established the Aqua Research Centre, the<br />

company’s first water treatment research and development centre located<br />

outside of Japan, at national water agency PUB’s WaterHub in singapore.<br />

Home to several renowned international and local water-related organisations,<br />

such as the singapore society for trenchless technology, Global Water<br />

Intelligence, <strong>International</strong> Water Association, and singapore Water Association.<br />

Uk pipes bursting for a makeover<br />

In Kirk Deighton, UK, more than 1 km of ageing pipe is being replaced by Yorkshire<br />

Water to reduce the risk of future pipe bursts. Engineering company Morrisons Utilities<br />

are replacing the 50-year-old pipe with a new plastic version.<br />

More than 10 km of pipe will be replaced and 6 km relined in Harrogate and<br />

Knaresborough, and in Ripon approximately 9 km will be replaced.<br />

the scheme is part of a wider £4 million program of works to ensure residents of<br />

Ripon, Harrogate and Knaresborough continue to receive quality drinking water.<br />

Can’t wait for the next edition of <strong>Trenchless</strong> <strong>International</strong>?<br />

Get the latest news at www.trenchlessinternational.com/news<br />

LEGACY.<br />

FOUNDER GARY VERMEER WOULD OFTEN FLY HIS PLANE TO<br />

PERSONALLY SERVICE MACHINES AND DELIVER PARTS.<br />

SUPPORT AFTER THE SALE. At Vermeer, earning your confidence is not a pursuit we take lightly. That’s<br />

why you can count on your local Vermeer dealer for experienced service technicians and genuine Vermeer parts<br />

throughout the life of your machine. From periodic maintenance to keep your asset in peak condition, to advice<br />

on tooling and accessories for your next project, Vermeer experts are a call, click or text message away. To learn<br />

more, talk to your local dealer or log on to vermeer.com.<br />

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and/or other countries.<br />

© <strong>2012</strong> Vermeer Corporation. All Rights Reserved.<br />

VERMEER.COM

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong> News<br />

12<br />

hdd under the Colorado River<br />

A proposed Us pipeline project, titled the Kokopelli Phase II<br />

Natural Gas Pipeline and spruce Creek to Beaver Creek Water<br />

Pipelines, plans to utilise horizontal directional drilling and boring<br />

techniques for part of the pipe’s installation.<br />

the proposed new pipelines are needed because existing<br />

pipelines and gathering facilities are approaching maximum capacity<br />

and will be unable to adequately gather and transport the anticipated<br />

volumes of natural gas and water needed to provide continued<br />

support in the project area.<br />

AstM developing CIpp liner standard<br />

New Assistant editor for <strong>Trenchless</strong> <strong>International</strong><br />

<strong>Trenchless</strong> <strong>International</strong> has recently welcomed tori McLennon as Assistant<br />

Editor to the trenchless team, who will be based in Melbourne, Australia.<br />

tori has been with Great southern Press since the start of 2011, working<br />

on publications such as <strong>Trenchless</strong> Australasia, <strong>Trenchless</strong> <strong>International</strong> and<br />

Pipelines Plant and Offshore.<br />

tori is looking forward to meeting the international trenchless community,<br />

and hearing news and views from the industry. tori can be contacted on<br />

tmclennon@gs-press.com.au or +61 3 9248 5100.<br />

Kate Pemberton will continue to edit <strong>Trenchless</strong> <strong>International</strong> and sarah<br />

Paul, based in toronto, Ontario in Canada, remains the Associate Editor.<br />

A proposed American society for testing and Materials standard is<br />

currently being developed for single-sized cured-in-place liners. the<br />

proposed standard will apply to all shapes and types of manholes,<br />

wetwells, catch basins and similar structures.<br />

the practice for installing single-sized cured-in-place liners of varying<br />

sizes for manholes is under the jurisdiction of subcommittee F17.67 on<br />

trenchless plastic pipeline technology.<br />

Once it has been approved, AstM WK36573 will be useful to owners<br />

of buried utility systems such as municipal sewers, telecommunications,<br />

power and similar systems.<br />

First microtunnel sewage collector constructed in Baku<br />

Open joint stock company Azersu, Azerbaijan’s national water operator, has<br />

completed microtunnelling of a sewerage collector in sabail district, Azerbaijan.<br />

the work is part of ongoing development of the sewerage system of Baku, which<br />

will result in better environmental protection of Caspian sea. the 1,270 m tunnel<br />

will provide environmental security to newly constructed areas of Flag square and<br />

National seaside Park. treated water will be used for watering the grounds and<br />

newly planted greenery.<br />

Can’t wait for the next edition of <strong>Trenchless</strong> <strong>International</strong>?<br />

Get the latest news at www.trenchlessinternational.com/news

Istt News<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

14<br />

sAstt visits Zandfontein<br />

depot of Joburg water<br />

As part of the South African Society for <strong>Trenchless</strong> Technology’s 20 th anniversary celebrations, the<br />

Society attended its first site visit in many years. On 28 February <strong>2012</strong>, the Zandfontein Depot of<br />

Johannesburg Water parking lot was crowded with excited society members shaking the hands of<br />

industry friends they had not seen for over a year.<br />

The evenT BeGAn with a brief<br />

presentation about the trenchless<br />

rehabilitation and upsizing of two trunk<br />

sewer lines in Alexandra. the project<br />

posed many challenges due to the extreme<br />

density of residential houses and informal<br />

dwellings in the project area. For example,<br />

inside one informal dwelling, an occupant<br />

was asked if he knew where the sewer<br />

manhole in that area was. the occupant<br />

said that he did and proceeded to move<br />

his bed and pointed to the manhole cover,<br />

which made up part of the floor of his<br />

house. In some instances, parts of informal<br />

dwellings had to be demolished and rebuilt<br />

after the rehabilitation of the sewer had<br />

been completed.<br />

After the presentation, the group boarded<br />

a touring bus for a ride through Alexandra<br />

in order to see the sites in real life. Although<br />

the trenchless rehabilitation posed many<br />

challenges, it was evident when viewing<br />

the project sites how disruptive the use<br />

of open-cut trenching would have been<br />

to those living in the area. the audience<br />

expressed its appreciation for the site visit,<br />

which had been arranged and sponsored<br />

by Insitu-Pipelines Pty Ltd.<br />

Awarding innovation in irrigation<br />

installation<br />

Meanwhile, the south African society<br />

for trenchless technology 2011 Award<br />

of Excellence has been awarded to an<br />

innovative irrigation pipeline project in<br />

the City of Capetown. the City identified<br />

the need for an irrigation supply for the<br />

Rob van Vuuren of Insitu-Pipelines, Tim Pollard of BKS and Zamokuhle Chauke of the City of Cape<br />

Town receiving the Award of Excellence from former SASTT president Andries Lötz.<br />

Green Point Common neighbourhood,<br />

which covers an area of 86 hectares and<br />

incorporates the Cape town stadium. the<br />

natural spring below table Mountain, which<br />

had been used to irrigate the Company<br />

Gardens many years ago, was cited as a<br />

potential supply source.<br />

In order to utilise the spring, a<br />

350 mm pipeline of 5.2 km would need to<br />

be built through the heavily built-up city. the<br />

Although the trenchless rehabilitation posed many challenges,<br />

it was evident when viewing the project sites how disruptive<br />

the use of open-cut trenching would have been to those living<br />

in the area.<br />

3.5 km upper stretch of pipeline was<br />

created by mainly trenchless means in<br />

order to minimise disruption to the very<br />

narrow roadways.<br />

In planning the route, the City located<br />

disused pipes that could be renovated<br />

with pipe cracking and sliplining. In total<br />

2.3 km of old water reticulation pipes<br />

were found and inspected by CCtV<br />

surveys, which were then rehabilitated by<br />

trenchless means.<br />

Directional drilling was used to lay 130 m<br />

of pipe, and 1 km was laid by using open<br />

trench. Care was taken to avoid social<br />

and environmental disruption, this was in<br />

large-part due to the installation taking<br />

place at the time of the 2010 soccer<br />

World Cup. Additionally, the route traversed<br />

numerous heritage sites which crews took<br />

great care to preserve.

Istt News<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

<strong>16</strong><br />

Istt outreach gathers<br />

momentum<br />

The ISTT’s outreach program is continually drawing more international associations together for the<br />

exchange of international knowledge with Argentina working with the ISTT to establish an Affiliated Society.<br />

In The LAST edition of <strong>Trenchless</strong><br />

<strong>International</strong>, the Istt was pleased to<br />

announce the establishment of three new<br />

societies – Romania (Rostt), United<br />

Arab Emirates (UAEstt) and south<br />

Europe (sEstt). the south European<br />

society consists of Bosnia, Herzegovina,<br />

Croatia, Macedonia, Montenegro, serbia<br />

and slovenia. In this edition the Istt is<br />

now pleased to report that Istt Executive<br />

subcommittee member sergio Palazzo<br />

is working with the trenchless industry<br />

in Argentina towards establishing a new<br />

society that would affiliate with Istt.<br />

the Istt’s 2011–2013 Strategic<br />

Operating Plan contains three operational<br />

elements: (1) trenchless Education and<br />

training; (2) trenchless Information; and (3)<br />

trenchless Outreach. the Istt’s Outreach<br />

activities support Affiliated societies,<br />

potential members, and the industry at<br />

large. Once a society becomes affiliated<br />

with the Istt, they then benefit from the<br />

shared knowledge, training, and trenchless<br />

events the Istt co-ordinates to strengthen<br />

the industry.<br />

One of the most important events the<br />

Istt delivers, bringing the industry together,<br />

Representative from the newly established SgSTT and ISTT Chairman Dr Sam Ariaratnam at<br />

Singapore <strong>International</strong> Water Week 2010.<br />

ABRATT Chairman Paulo Dequech and ESC representative and ABRATT member Sergio Palazzo.<br />

is the Annual Istt Awards – a long-standing<br />

program that recognises outstanding<br />

achievements in the trenchless industry.<br />

the Istt also recognises individuals in<br />

the trenchless community for their lifetime<br />

contribution to trenchless. this year’s Istt<br />

awards will be presented at the <strong>2012</strong> Istt<br />

No-Dig, to be held in são Paulo, Brazil. turn<br />

to page 25 for more information.<br />

A strategic component of the education<br />

and training mission of Istt is the sharing<br />

of information. While not everyone has<br />

access to, or can participate in, the training<br />

seminars and courses offered by the<br />

Istt, the <strong>International</strong> society uses other<br />

communication media to inform the public<br />

about the benefits of trenchless technologies.<br />

<strong>Trenchless</strong> <strong>International</strong> magazine –<br />

the official magazine of Istt – reports<br />

on the activities of Affiliated societies<br />

and of Istt. If your society would like<br />

to have their events or achievements<br />

covered in <strong>Trenchless</strong> <strong>International</strong>,<br />

send your articles and photos through to<br />

news@trenchlessinternational.com<br />

the Istt also has a large library of<br />

technical papers covering all aspects of<br />

trenchless technology, which are available<br />

to members and the public at large. the Istt<br />

website allows for an opportunity to extend<br />

its outreach program to individuals who<br />

cannot participate in Istt’s training courses<br />

and seminars. to find out more information<br />

about the Istt’s outreach program, visit<br />

www.istt.com/programs-and-activities<br />

TSITT Chairman Yasin Torun and Dr Dec<br />

Downey; ISTT welcomes TSITT as an Affiliated<br />

Society in 2010.<br />

trenchless experts<br />

head to Zhengzhou<br />

The Chinese Society for <strong>Trenchless</strong> Technology <strong>2012</strong> <strong>International</strong> <strong>Trenchless</strong> Technology Conference<br />

and Exhibition was held in China’s Zhengzhou <strong>International</strong> Convention and Exhibition Centre, from<br />

20–22 April, with great success, bringing over 300 industry representatives from across the globe to the<br />

conference and approximately 1,200 visitors to the exhibition.<br />

MAny DISTInGuISheD GueSTS<br />

attended the Grand Opening ribbon cutting<br />

ceremony, including Chinese society for<br />

trenchless technology (Cstt) Chairman,<br />

and Previous Deputy secretary of China<br />

Geological survey, Professor Wang Da,<br />

Cstt Deputy Chairman Professor Yan<br />

Chunwen, Japan society for trenchless<br />

technology Deputy Chairman Professor<br />

Kusuta tetsuya, and <strong>International</strong> science<br />

and technology Co-operation Department<br />

technology Councillor Liu Yuanwen.<br />

Istt Chairman Dr samuel Ariaratnam<br />

and Istt Vice Chairman Derek Choi sent<br />

congratulatory letters to the conference<br />

in their absence as they could not attend<br />

in person.<br />

Over the course of the threeday<br />

exhibition, more than<br />

80 per cent of the exhibitors<br />

signed purchasing and selling<br />

agreements.<br />

exchanging knowledge globally<br />

the three keynote addresses, presented<br />

by international experts, were of particular<br />

interest to the delegates, and generated<br />

engaged discussions. the three addresses<br />

were ‘Introduction on Global trenchless<br />

Industry 2011’, presented by China<br />

University of Geosciences Professor Wu<br />

Xiaoming; ‘Introduction on trenchless<br />

technology’, presented by Professor<br />

Professor Kusuda presenting his keynote speech at the <strong>International</strong> <strong>Trenchless</strong> Technology<br />

Conference and Exhibition.<br />

Istt News<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong> 17

Istt News<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

18<br />

Chunwen; and ‘Prospects of Japanese<br />

trenchless technology’, presented by<br />

Professor tetsuya.<br />

seminars on trenchless technology use<br />

in metropolitan development instigated<br />

an exchange of ideas between industry<br />

experts. the seminars were themed ‘Henan<br />

Provincial Metro Construction technology’<br />

and ‘Watching sea in the Metropolis –<br />

Municipal Pipelines Reconstruction’.<br />

A seminar was also presented by design<br />

engineers and construction workers<br />

from Zhengzhou Municipal Railway<br />

transportation that looked in-depth at<br />

the techniques and latest products used<br />

in metro construction. After the seminar,<br />

attendees were given the opportunity to<br />

inspect Zhenzhou metro construction sites.<br />

the Institute of Exploration techniques<br />

Professor Zhang Yachun discussed the<br />

issue of urban waterlogging in a report<br />

entitled ‘Rain and sewage Diversion<br />

to Address the Urban Waterlogging in<br />

Langfang’. Ultraliner technology Vice<br />

President and Chief Researcher Dr Zhao<br />

Wei also tackled this issue in his report<br />

‘How to Use trenchless Pipeline Repair<br />

technology to Address Urban Waterlogging<br />

– Analysis and Discussions on Home/<br />

Abroad Experiences’, which attendees<br />

found both useful and informative.<br />

the conference featured three sessions<br />

for technical reports, with a wide array of<br />

technical seminars. A number of renowned<br />

companies presented case studies and<br />

information on their technological strengths,<br />

and products, including Henan Zhong<br />

tuo Petroleum Engineering technology,<br />

Borouge, Xiamen Xin Yong tong trenchless<br />

Engineering technology, Xuzhou Xugong<br />

Foundation Construction Machinery, Beijing<br />

Long Ke Xing trenchless Engineering, and<br />

Jiangsu shi Fang Engineering Equipment.<br />

the topics ranged from pipeline repair,<br />

implementations of novel materials,<br />

construction case-studies of rig products,<br />

and risk control in engineering.<br />

A world-class exhibition<br />

this year’s exhibition drew interest from<br />

80 exhibitors, which was narrowed down<br />

after careful selection to approximately 50<br />

companies. Among these, 13 companies<br />

made their debut at the conference. Over<br />

half of the companies brought along their<br />

products to showcase, with a number<br />

Distinguished guests attending the Opening Ceremony.<br />

performing onsite demonstrations. Domestic<br />

equipment was a great draw-card for<br />

foreign equipment specialists from America,<br />

Japan, Russia, India, and Malaysia. Over<br />

the course of the three-day exhibition, more<br />

than 80 per cent of the exhibitors signed<br />

purchasing and selling agreements.<br />

Recognising the best in the field<br />

the <strong>2012</strong> <strong>International</strong> trenchless<br />

technology Conference (IttC) marked<br />

the <strong>16</strong> th successful year of the conference.<br />

the IttC held a reception banquet,<br />

titled Xugong Night, to honour the<br />

achievements of projects and people<br />

in the trenchless industry. trenchless<br />

Engineering technology Xiamen Xin Yong<br />

tong General Manager Chen Yong was<br />

awarded the Honourable Certificate.<br />

The CSTT’s outstanding efforts in making the technology<br />

conference and exhibition a world-class event were rewarded<br />

with the overall success of the event, and the conference’s<br />

achievements indicates great promise for the future of<br />

<strong>Trenchless</strong> Technology.<br />

the Excellent Product, Engineering<br />

and technology of 2011 Award went<br />

to several recipients, including: Qingdao<br />

WorldCom Construction Engineering;<br />

Henan Zhong tuo Petroleum Engineering<br />

technology; shanghai Hua Qun Industrial<br />

Incorporated; shaoxing Pan Ji Pipe<br />

Engineering; Langfang Municipal Facilities<br />

Management Department; shenzhen<br />

Zuan tong Engineering Machinery;<br />

Xuzhou Xugong Foundation Construction<br />

Machinery; and Beijing Long Ke Xing<br />

trenchless Engineering.<br />

the Annual General Council Meeting<br />

of Cstt was also held at the event.<br />

Committee members listened to the 2011<br />

Debriefing Report, the <strong>2012</strong> Work Plan<br />

Report and the 2011 Financial Report,<br />

which was delivered by Cstt secretary<br />

Zhu Wenjian. Council members also<br />

submitted anonymous votes for several<br />

awards, including Person of the Year 2011.<br />

the Cstt’s outstanding efforts in<br />

making the technology conference and<br />

exhibition a world-class event were<br />

rewarded with the overall success of the<br />

event, and the conference’s achievements<br />

indicates great promise for the future of<br />

trenchless technology.<br />

Finnish society thinks<br />

laterally at IFAt<br />

In May, 22 members of the Finnish Society for <strong>Trenchless</strong> Technology visited the <strong>2012</strong> IFAT Fair in<br />

Munich, Germany. The members, who came from a variety of backgrounds, including employees from<br />

water utilities, trenches consultants and contractors, attended the three-day conference.<br />

The MeMBeRS of the Finnish society for<br />

trenchless technology (Fistt) attended<br />

a series of educational lectures during<br />

the course of the conference. the Fistt<br />

attended four lectures in Finland on the first<br />

day, and on the second day attended three<br />

lectures in Munich. Of particular interest to<br />

the society were the international lectures<br />

on house laterals. According to the Fistt,<br />

house laterals are a difficult subject for<br />

those in the Finnish water industry, and<br />

the legislation surrounding them is often<br />

unclear. Additionally, the society says<br />

proper maintenance and management of<br />

house laterals is often overlooked. From<br />

listening to international speakers at the<br />

conference, the Fistt wanted to learn<br />

how other countries tackle the issues<br />

associated with house laterals, and take<br />

from the lectures learnings and new<br />

ideas on house lateral maintenance.<br />

the Finnish lectures talked about CCtV<br />

inspections on sewers, Finnish legislation on<br />

housepipes, and how water utilities install<br />

and renovate housepipes.<br />

the first international lecturer was Ian<br />

Ramsey from the United Kingdom society<br />

for trenchless technology, who spoke<br />

about house laterals in Great Britain. His<br />

presentation outlined how legislation has<br />

changed in Britain, resulting in water utilities<br />

taking ownership over house laterals.<br />

His presentation outlined how changing<br />

legislation has complicated the situation in<br />

the UK, leading to a predicament where<br />

utilities only have control and ownership<br />

over half of the lateral.<br />

the second international lecturer was<br />

Astrid Hanzen from the German society for<br />

trenchless technology, who spoke about<br />

the maintenance and politics of house laterals<br />

in Germany. Her presentation stated that<br />

legislation on laterals varies between the<br />

different federal states, with only three states<br />

active in maintaining laterals.<br />

Fistt learned that legislation surrounding<br />

house laterals also challenges water<br />

authorities and trenchless workers throughout<br />

Germany and the UK, and the issue is not<br />

unique to Finland. From listening to the<br />

international speakers the society was able to<br />

gather many new ideas on how the situation<br />

could be approached and improved upon in<br />

Finland. It was also a great cultural experience<br />

for the Fistt, who visited the Munich town,<br />

tasted German asparagus and wheat beer,<br />

and went to see the Allianz Arena.<br />

Fistt arranges education annual events<br />

to promote No-Dig. Fistt has 45 member<br />

companies across Finland.<br />

Istt News<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong> 19

wAteR FeAtURe<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

20<br />

PE pipe is attractive from an economic and environmental viewpoint.<br />

tough pe pipe materials<br />

ideal for installation<br />

By Andrew Wedgner and David Walton, Borouge<br />

Polyethylene pipes have long been used to renovate ageing pipeline networks to reduce gas and water<br />

leakage levels and to install new systems. In combination with trenchless installation methods, a new<br />

pipeline can be installed at a low cost without disturbing city flow or damaging the environment. Here<br />

Borouge details three innovative case studies.<br />

WhILe PoLyeThyLene (Pe) pipe<br />

is attractive from an economic and<br />

environmental viewpoint, trenchless<br />

installation methods can be demanding<br />

on the pipe, as gouges and scores to<br />

the outside surface of the pipe during<br />

installation can develop into cracks.<br />

In response, polymer suppliers have<br />

developed high stress crack resistant<br />

(HsCR) PE100 materials that are able<br />

to cope with surface damage without<br />

cracking. the stress crack resistance of<br />

the pipe is at least 20 times the minimum<br />

value specified in international standards,<br />

and gives engineers the confidence to<br />

specify PE pipes in the most difficult<br />

installation circumstances.<br />

hDD in new Zealand<br />

In Auckland, New Zealand, a 1 km<br />

section of a watermain travelling from<br />

Waitakere Water treatment Plant to<br />

tram Valley Road needed to be installed<br />

under a native forest park using horizontal<br />

directional drilling (HDD).<br />

these areas of native forest are protected<br />

by the New Zealand government thus<br />

normal open cut installation was not<br />

The stress crack resistance of the pipe is at least 20 times<br />

the minimum value specified in international standards, and<br />

gives engineers the confidence to specify PE pipes in the most<br />

difficult installation circumstances.<br />

permitted. Engineers from water supply<br />

company Watercare services specified that<br />

HsCR PE100 pipe material should be used,<br />

as they were concerned about the difficult<br />

installation conditions.<br />

For the project, 850 x 70.8 mm PE100<br />

pipe was manufactured by tyco New<br />

Zealand in their Hamilton plant in 6 m lengths<br />

using Borsafe HE3490-Ls-H. the pipe<br />

was butt welded to form two 500 m pipe<br />

strings onsite, and externally de-beaded<br />

before installation.<br />

Drilling contractors Central Drilling were<br />

presented with a number of challenges<br />

by the difficult soil conditions beneath the<br />

forest, however, in late October 2011 all<br />

was ready to pull through the polyethylene<br />

watermain. this final stage went without<br />

a hitch and the new main would soon<br />

provide bulk water for the distribution<br />

companies to supply to their customers in<br />

greater Auckland.

wAteR FeAtURe<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

22<br />

To ensure that the durability of<br />

the system was maintained,<br />

BorSafe HE3490-LS-H PE100<br />

material from Borouge was<br />

used by Jiangyin David Plastics<br />

to manufacture the pipe.<br />

Lining the leaking water mains in<br />

Shanghai<br />

shanghai’s population is growing fast,<br />

and consequently tremendous strain is<br />

put on their water services. While water<br />

companies have worked hard to keep<br />

up with demand by installing many new<br />

watermains, most of the system is still made<br />

up of cast iron and steel pipes, which readily<br />

corrode in shanghai’s acidic water. this<br />

affects the turbidity and the colour of the<br />

water supplied.<br />

Recently, the China Urban Water<br />

Association organised a one day seminar in<br />

shanghai to discuss the different technical<br />

solutions available to renovate and replace<br />

old pipelines. On the following day the<br />

delegates were invited to a project by the<br />

shanghai Fengxian Waterworks Company,<br />

who used swagelining technology to<br />

renovate 270 m of corroded steel watermain<br />

under a wooded area of the city.<br />

A 300 mm diameter PE100 pipe was<br />

pulled through a die that reduced its<br />

diameter, enabling it to enter the old main.<br />

Once in position the load was released and<br />

the pipe expanded to form a close fit with<br />

the ageing host main. to ensure that the<br />

durability of the system was maintained,<br />

Borsafe HE3490-Ls-H PE100 material<br />

from Borouge was used by Jiangyin David<br />

Plastics to manufacture the pipe.<br />

Pipelining in the Middle east<br />

the Daleel Petroleum Company produces<br />

oil in the sultanate of Oman, approximately<br />

300 km west of the city of Muscat. Like<br />

most oil companies, they recycle process<br />

water and then inject it back into the well to<br />

increase oil production.<br />

As the wells increase in age, the level of<br />

hydrogen sulphide and other contaminates<br />

in the process water also increases, which<br />

in turn leads to rapid corrosion of the steel<br />

pipes. One alternative to replacing these<br />

pipes is to use close-fit internal lining made<br />

from PE, which will extend the life of both<br />

old and new pipelines.<br />

For a recent project, 30 km of 8 inch<br />

diameter steel water injection pipe was<br />

lined by United Pipeline Middle East using<br />

the company’s tite Liner technology. to<br />

ensure that the optimum lifetime was<br />

PE pipes can provide high durability solutions.<br />

achieved the PE100 pipes were produced<br />

from Borsafe HE3490-Ls-H high stress<br />

crack resistant material by local pipe<br />

manufacturer Muna Noor Manufacturing in<br />

their Muscat plant.<br />

the individual pipe lengths were welded<br />

into strings that were then drawn through<br />

United’s hydraulically powered roller<br />

reduction box, which temporarily reduced<br />

the diameter of the pipe. the PE pipe was<br />

then easily pulled through the steel pipe,<br />

and once in position the load was released<br />

so the pipe could recover and form a tight<br />

compression fit with the bore of the host<br />

pipe protecting it from any future corrosion.<br />

Confidence with Pe pipes<br />

In response to surface damage that<br />

can come about using modern trenchless<br />

technology, polymer suppliers have<br />

produced a range of HsCR PE100<br />

materials to cope with tough conditions<br />

without cracking. these materials provide<br />

engineers with the confidence to specify PE<br />

pipes in very difficult installation situations<br />

and provide high durability solutions.<br />

Conference and Exhibition<br />

23 – 26 April 2013<br />

Berlin Exhibition Grounds<br />

www.nodigberlin2013.com<br />

Organisers: Supportet by:<br />

Sponsors: Gold: Bronze:<br />

Special Supporter national Societies of ISTT:<br />

Australia<br />

New Zealand<br />

in conjunction with<br />

Messe Berlin GmbH · Messedamm 22 · 14055 Berlin · Germany · www.messe-berlin.de · www.gstt.de<br />

Austria Brazil Bulgaria Hong Kong Colombian China Czech<br />

Republic<br />

Finland France Spain<br />

Portugal<br />

Italy Japan Netherlands USA<br />

Canada<br />

Mexico<br />

Poland<br />

Russian<br />

Federation<br />

South<br />

Africa<br />

Turkey Ukraine United<br />

Kingdom

CONFeReNCes<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

24<br />

Inaugural India No-dig<br />

brings industry together<br />

The ISTT's inaugural No-Dig India Summit <strong>2012</strong>, held in Bangalore from 14–15 May, was attended by<br />

more than 100 delegates from cities across India, including senior government officers, contractors and<br />

consultants.<br />

The MAIn ATTRACTIon of the twoday<br />

summit was the Istt trenchless<br />

Masterclass presented by Istt Chairman<br />

Dr samuel Ariaratnam and Past Chairman<br />

Dr Dec Downey. the international experts<br />

delivered four in-depth, educational modules<br />

that highlighted the main technologies and<br />

techniques used in the industry today.<br />

the program was complemented by<br />

case study presentations from a number<br />

of industry suppliers, who recounted their<br />

experiences using trenchless technologies<br />

in a variety of geological conditions both in<br />

India and across the globe.<br />

the exhibition area, featuring ten key<br />

international organisations, provided a lively<br />

backdrop for delegates to network and<br />

to gather information and knowledge on<br />

some of the key techniques and equipment<br />

utilised in trenchless technology. Delegates<br />

showed a high level of interest in the<br />

products on display, and exhibitors are<br />

confident that business will be forthcoming<br />

as a result of contacts they made.<br />

Delegates in the exhibition area.<br />

At the close of the event, Dr Ariaratnam<br />

commented “Immediate feedback would<br />

suggest that the two-day summit has been<br />

a rewarding experience for attendees.<br />

For Istt’s part, this was an excellent<br />

opportunity to meet local engineers<br />

and to have the opportunity of sharing<br />

information on the technologies available,<br />

Delegates engaging in a presentation.<br />

to discuss the challenges encountered<br />

and also to present some solutions.”<br />

Istt’s educational program will be<br />

featured next in <strong>July</strong> at trenchless Asia in<br />

singapore and at the <strong>International</strong> No-Dig in<br />

Brazil, to be held in November. the No-Dig<br />

India summit is likely to return to India<br />

in 2013.<br />

Istt sets<br />

sights on Brazil<br />

From 12–14 November <strong>2012</strong>, industry professionals from around the world will come together for the<br />

30 th <strong>International</strong> No–Dig conference, to be held in São Paulo, Brazil – a country instigating many major<br />

infrastructure projects.<br />

The <strong>2012</strong> ConfeRenCe and exhibition<br />

will mark the first time the Istt’s annual<br />

event has been hosted in Brazil. With recent<br />

investments in infrastructure that is growing<br />

and transforming the country, it is clear why<br />

the Istt chose Brazil to host the largest<br />

and most prestigious trenchless event of<br />

the year.<br />

In the coming years, funds from the Brazilian<br />

government initiated Growth Acceleration<br />

Program will be used to prepare the country<br />

for hosting both the 2014 soccer World<br />

Cup and the 20<strong>16</strong> Olympic Games. Funds<br />

have been secured for the modernisation<br />

of housing, sanitation, transport, energy,<br />

and the transportation sector.<br />

President of the Brazil Association for<br />

trenchless technology (ABRAtt) Paulo<br />

Dequech says “trenchless technologies are<br />

the only option for building and increasing<br />

the underground networks in the country,<br />

and this event will solidify this technology<br />

here in Brazil.”<br />

Centre of excellence...<br />

www.no-dig.dk e-mail. no-dig@no-dig.dk YouTube channel: ulrich2761<br />

Untitled-1 1 30/05/12 15.26<br />

CONFeReNCes<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong> 25

CONFeReNCes<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

26<br />

A trenchless town<br />

the main theme of the event will be<br />

‘trenchless town’, focusing on ways to<br />

install and renew underground services<br />

without trenching in urban centres.<br />

the event will present the Brazilian<br />

engineering community with the latest<br />

technology in No-Dig equipment and<br />

services available worldwide, as well as<br />

provide exhibitors and utility delegates<br />

the chance to showcase major projects<br />

and issues creating discussion in the<br />

trenchless sector.<br />

Conference papers will be presented on:<br />

• Pipe installation with horizontal directional<br />

drilling (HDD)<br />

• Rehabilitation and replacement networks<br />

• Pipe bursting applications<br />

• Geothecnical analysis<br />

• soil investigations and inspection<br />

• Microtunnelling and pipe jacking<br />

• Asset management<br />

• Leak management<br />

• Cost reduction and environmental impact<br />

• Work safety, law regulations and civil<br />

liability<br />

• New applications of trenchless technologies<br />

• Public investment programs.<br />

A growing trenchless nation<br />

the Brazilian market for No-Dig projects is<br />

currently expanding. the technology arrived<br />

in the country in the early 1990s, mainly due<br />

to the installation of fiber optical networks<br />

under urban centres, highways and railways.<br />

there is significant projected growth in the<br />

trenchless sector in the coming years. Many<br />

companies are currently being established<br />

in the trenchless industry, working in sectors<br />

such as transport, gas, communications,<br />

electrical networks, and sanitation.<br />

Mr Dequech says “Our demand for<br />

infrastructure, due to two world sporting<br />

events – the 2014 World Cup and 20<strong>16</strong><br />

Olympics – is attracting the attention of<br />

foreign companies to Brazil.”<br />

Mr Dequech says many new businesses<br />

are establishing themselves to take on<br />

these projects. While already established<br />

businesses are working to build partnerships<br />

and consolidate the presence they’ve held<br />

since the 1990s.<br />

According to ABRAtt, the trenchless<br />

sector has grown 30 per cent over the<br />

past two years. In <strong>2012</strong>, $Us150 million<br />

has been planned for gas infrastructure,<br />

$Us200 million for sanitation works<br />

Rigs installing critical infrastructure in Brazil.<br />

(state companies, municipal and private),<br />

and $Us50 million for fiber optical<br />

(telecommunications) networks.<br />

this infrastructure overhaul today<br />

generates more than 10,000 direct and<br />

<strong>2012</strong> ISTT AWARDS oPen<br />

The <strong>2012</strong> ISTT No-Dig Awards will be presented at the <strong>International</strong> No-Dig Conference and Exhibition, to be<br />

held in São Paulo, Brazil 12-14 November. Submit your entry now!<br />

The closing date for entries is 31 August <strong>2012</strong>. Entries should be submitted to ISTT at info@istt.com<br />

Award Rules and Application details can be found on the ISTT website at<br />

www.istt.com/award-rules-applications<br />

Awards may be made for work completed during 2011–12 in four categories, as follows:<br />

• Academic research or training aid/course<br />

• <strong>Trenchless</strong> project completed<br />

• New machine, tool, material, system or technique introduced<br />

• Student or young professional paper – members regularly enrolled in college or university, or spending at<br />

least half their time on academic coursework.<br />

All award winners will be:<br />

• Recognised at the conference and presented an award<br />

• Featured in an article in <strong>Trenchless</strong> <strong>International</strong><br />

• Added to the published list of ISTT award winner role of honour posted on the ISTT website<br />

• Authorised to use the ISTT logo on promotional material related to the award activity or recipients.<br />

In addition, the winner may be afforded an opportunity to make a brief presentation on the activity that<br />

received the award at the conference, time and schedule permitting.<br />

The student award winner will receive a small cash award and limited financial travel assistance to attend the<br />

conference.<br />

Affiliated Societies must endorse all awards submitted from their country.<br />

To find out more on the ISTT <strong>2012</strong> No-Dig São Paulo event, visit: www.nodigsaopaulo<strong>2012</strong>.com.br<br />

indirect jobs, is composed of more than<br />

150 companies, and has seen investments<br />

totalling $Us80 million in the last ten years.<br />

no-Dig <strong>International</strong> <strong>2012</strong> São<br />

Paulo<br />

For the past 13 years, ABRAtt’s main<br />

goal has been to make an important<br />

contribution to the Brazilian technical<br />

community by bringing equipment and<br />

technology updates to those working in<br />

new installations or rehabilitation.<br />

For this reason, since 2000, ABRAtt has<br />

hosted five national No-Dig conferences,<br />

and in 2008 and 2010 presented Latin<br />

American international events that were<br />

promoted by Istt.<br />

Mr Dequech says “the significant success<br />

at local events has qualified Brazil for the<br />

first time to host the Istt’s <strong>International</strong><br />

No-Dig.”<br />

For a more in-depth look<br />

at trenchless industry for<br />

Brazil make sure to pick up<br />

the October edition of<br />

<strong>Trenchless</strong> <strong>International</strong>.<br />

The exhIBIToR LIST InCLuDeS:<br />

Ditch Witch<br />

DrillTo<br />

FERNCO<br />

Intech<br />

Mapsolo<br />

MC Elroy<br />

MI Swaco<br />

MND<br />

O-Tek<br />

Pegmatech<br />

Polierg<br />

Romtec<br />

Sanit<br />

Silcon Drilling<br />

Sobratema<br />

Sondeq<br />

System Mud<br />

Vermeer<br />

PETROBRAS<br />

AARSLEFF<br />

AKKERMAN<br />

Herrenknecht<br />

HOBAS<br />

To find out more about the exhibition and floor plan visit www.nodigsaopaulo<strong>2012</strong>.com.br/<br />

IDS<br />

VMRT<br />

CHANNELINE<br />

PURE TECHNOLOGIES<br />

VE GROUP<br />

GSTT pavilion<br />

CSTT pavilion<br />

DOWN 2 EARTH<br />

Hard Metal<br />

Scanprobe<br />

ABRATT/ISTT<br />

<strong>Trenchless</strong> <strong>International</strong> Magazine<br />

Agru Technology<br />

American Auger<br />

HDD Brooker<br />

Aesabesp<br />

Hammer Head<br />

Polidrill<br />

Hammer Head<br />

Perma-Liner<br />

Colli Equipment SRL<br />

AOL<br />

Laney Directional Drilling<br />

CONFeReNCes<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong> 27

CONFeReNCes<br />

<strong>July</strong> <strong>2012</strong> - <strong>Trenchless</strong> <strong>International</strong><br />

28<br />

Fifth Jubilee proves<br />

popular in poland<br />

Poland’s fifth <strong>Trenchless</strong> Technology <strong>International</strong> Jubilee Conference and No-Dig Poland <strong>2012</strong><br />

exhibition, held in Kielce from 17–19 April <strong>2012</strong>, was a great success.<br />

APPRoxIMATeLy 200 DeLeGATeS<br />

from Poland and abroad were present at<br />

the conference, including representatives<br />

from universities, utilities and trenchless<br />

technology companies.<br />

the six-session conference, which<br />

presented 36 papers over the three days,<br />

included topics on:<br />

• Issues in trenchless technology<br />

development in both Poland and abroad<br />

• Problems with installation of underground<br />

utilities<br />

• Exploitation of renovated pipelines<br />

• trenchless technologies that prove to be<br />

optimal when risk is taken into account.<br />

Istt Chairman Dr samuel Ariaratnam<br />

presented an engaging discussion on the<br />

differing global perspectives on trenchless<br />

technology in relation to a country’s<br />

economic position. University of taiwan<br />

Professor Keh-Jian shou’s presentation<br />

looked at a number of taiwanese<br />

construction projects that installed sections<br />

of pipe at a very small radius. Joanna<br />

Jacobs rounded out the internationally<br />

focused program with a presentation on<br />

trenchless technologies currently used by<br />

the Metropolitan Water Reclamation District<br />

of Greater Chicago.<br />

the Gala Dinner and EXPERt <strong>2012</strong><br />