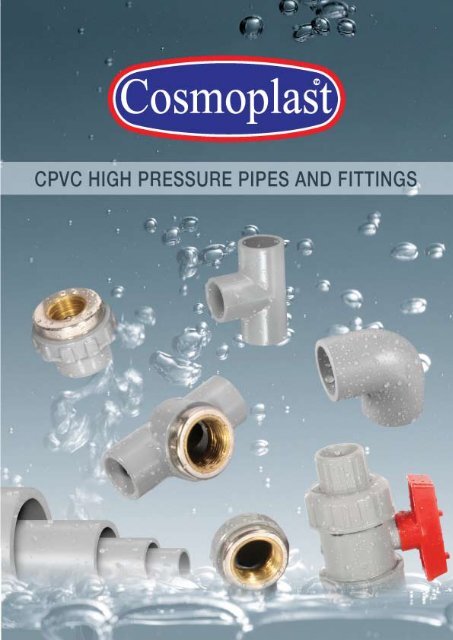

Cosmoplast CPVC PIPES & FITTINGS FOR ... - Harwal.net

Cosmoplast CPVC PIPES & FITTINGS FOR ... - Harwal.net

Cosmoplast CPVC PIPES & FITTINGS FOR ... - Harwal.net

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Resistance to Galvanic or Electrolytic Attack<strong>CPVC</strong> Pressure pipes and fittings are resistant to galvanic and electrolytic attack. They can beused underground, underwater, and can be safely connected to metal parts.Resistance to Ultraviolet ExposureCertain onsite temperatures are higher in the Gulf region, and <strong>Cosmoplast</strong> High Pressure<strong>CPVC</strong> system can easily withstand the ultraviolet exposure commonly experienced during theconstruction phase of the projects, provided the onsite inventories are appropriately stored.Although <strong>CPVC</strong> pipe can be installed in direct sunlight, it will be affected by ultra-violet lightwhich tends to discolor the pipe and can cause a loss of impact strength. No other propertiesare impaired. If the pipe is to be installed in continuous direct sunlight, it is advisable to paint theexterior installations with two coats of white or light color water base latex paint for additionalprotection.Low Thermal Conductivity<strong>CPVC</strong> Pressure pipes and fittings have a lower thermal conductivity compared to metal pipes.This ensures that fluids maintain a more constant temperature and therefore they require lessinsulation than metal pipes. In most cases, pipe insulation is not required.Low Thermal ExpansionLaboratory testing and installation experience have demonstrated that the potential expansionproblems in <strong>CPVC</strong> are much smaller than those which the coefficient of thermal expansion mightsuggest. The stresses developed within the <strong>CPVC</strong> pipes are generally much lower than thosedeveloped in equivalent metal pipe for equal temperature changes due to their elastic nature.Low CondensationDue to the <strong>CPVC</strong>’s polymeric structure, costly condensation and damp concerns are eliminated,in addition to a considerable reduction in most of the long-term problems that would beexperienced with metal installation.3

This special chemical structure of <strong>CPVC</strong> allows it to have a higher temperature resistancecompared to PVC. <strong>CPVC</strong> can withstand temperature in excess of 93°C (for short time loadingup to 100 °C ) while PVC can withstand temperature up to 60°C.The two materials have almost the same chemical resistance.<strong>CPVC</strong> Material Strength<strong>CPVC</strong> enjoys a much higher strength than other common thermoplastic materials used inplumbing systems.Due to this feature, <strong>CPVC</strong> needs fewer hangers and supports than other common materials andeliminates the curvatures in pipe lines experienced in other systems.This feature also makes <strong>CPVC</strong> ideal for vertical installations (risers) and increases its pressurebearing capacity.<strong>CPVC</strong> THERMAL CONDUCTIVITYThe thermal conductivity of <strong>CPVC</strong> material is lower than most of the common thermoplastics usedin plumbing systems. This feature reduces the heat loss / gain of the fluids being transported in<strong>CPVC</strong> pipes.This leads to a higher energy saving and reduces the amount of thermal insulation needed for<strong>CPVC</strong> pipes.5

Fire Resistance<strong>CPVC</strong> material exhibits outstanding fire performance characteristics in terms of limited flamepropagation and low smoke generation. When combined with its excellent mechanical strength,low thermal conductivity, and outstanding corrosion resistance, <strong>CPVC</strong> provides excellent valuein terms of safety and performance in a wide range of applications.<strong>CPVC</strong> material has integral flame retarding property with very high LimitingOxygen Index (LOI) of 60. This feature guarantees that <strong>CPVC</strong> pipes cannotbe the ignition source of fire or support or sustain combustion. It does notincrease fire load, has low smoke generation and low flame spread withoutflaming drips.Ignition Resistance<strong>CPVC</strong> has a flash ignition temperature of 482°Cwhile many other ordinary combustibles, suchas wood, ignite at 260°C or less.The following table shows the ignitiontemperature of some combustible materials:Burning Resistance<strong>CPVC</strong> material will not sustain burningunless it is forced to burn, this is a result ofits very high Limiting Oxygen Index (LOI) of60 ( the percentage of oxygen needed in anatmosphere to support combustion).As Earth>s atmosphere is only 21% oxygen,<strong>CPVC</strong> will not burn unless continuouslysubjected to flame, it will stop burning when theignition source is removed. Other combustiblematerials will support combustion due to theirlow LOI.Material<strong>CPVC</strong>PVCPolyethylenePaperMaterial<strong>CPVC</strong>PVCPVDFABSPolypropylenePolyethyleneIgnition Temperature (°C)482399343232LOI604544181717WORKING CONDITIONS OF <strong>CPVC</strong> PIPiNG SYSTEMSWorking Temperature<strong>Cosmoplast</strong> <strong>CPVC</strong> pipes and fittings are recommended for applications where the operatingtemperature reaches up to 93°C (for short time loading up to 100 °C).There is theoretically no lower temperature limit on <strong>CPVC</strong>. However at very cold temperaturesthe material becomes brittle and the impact strength declines.Working PressureThe working pressure of <strong>CPVC</strong> pipes is directly related to the standard of production andschedule of pipe.The tables on page 14 and 15 show the dimensions and pressure ratings of <strong>CPVC</strong> pipes.6

<strong>CPVC</strong> MATERIAL PropertiesThe <strong>CPVC</strong> typical material properties are listed in the following table. Slight variation could existdepending on the material compounds.7

Recommendations to Achieve an Effective JointMake sure that the end of each pipe is square in its socket and in the same alignment and gradeas the preceding pipes or fittings.Create a 0.5mm chamfer, as a sharp edge on the spigot will wipe off the solvent and reduce theinterface area.Do not attempt to joint pipes at an angle. Curved lines should be jointed without stress, thencurved after the joint is cured.Previously cemented spigots and sockets be re-used. To repair a joint, cut out the defected jointand make a new joint.Do not spill solvent cement onto pipes or fittings. Accidental spillage should be wiped offimmediately.SafetyEnsure good ventilation in the working areas. Forced ventilation should be used in confinedspaces.Do not bring a naked flame close to the solvent cement operations.Spillage of solvent cement on the skin should be washed off immediately with soap and water.Should the solvent cement get in the eyes, wash them with clean water for at least 15 minutesand seek medical advice.THREADED JOINTSCutting of threads on <strong>CPVC</strong> pipes is not an acceptable practice. Instead, moulded threadedadaptors should be used.Recommendations for threaded Joints1 For threaded fittings, use Teflon thread-wrap tape in order to guarantee the water- tightness.2 Grease or solvent cement should never be used on the threads.3 Test the threaded parts before final assembly to ensure thread matching, particularly whenconnecting to other materials or to other manufacturers’ fittings. The amount of Teflontape should be Judged accordingly.4 The threaded joints should be tightened initially by hand, and then a further two moreturns should be sufficient to create a seal.Note. Over tightening will over stress the fitting and could cause cracks and leakage.9

Constant pressure (or very small drop) indicates a satisfactory result, while bigger pressuredrop may indicate a leak.It is recommended that the test pressure should be held for a minimum period of 15 minutes.The test pressure should never exceed 1.5 times the pipe pressure rating.After completing the pressure test, the pipeline should be thoroughly flushed and dosed with asterilizing agent such as chlorine. Local authority requirements should be followed.Handling, storage and Transportation<strong>CPVC</strong> pipes can be damaged by rough handling. Transportation, storage and handling shouldbe done taking into consideration the below directions and precautions.Handling••••Take all reasonable care when handling <strong>CPVC</strong>, particularly in very cold conditions when theimpact strength of the material is reduced.Do not throw or drop pipes, or drag them along hard surfaces.Do not scratch pipes against hard surfaces or drag them along the ground.In case of mechanical handling, use protective slings and padded supports. Metal chainsand hooks should not make direct contact with the pipes.Storage•To avoid deformation over time, pipes should be stacked:» either on a flat base» or on a level ground» or on 75mm x 75mm timber at 1m max. centers.• For long-term storage (longer than 3 months) the maximum free height should not exceed1.5m. The heaviest pipes should be on the bottom.•••••Provide side support with 75mm wide battens at 1m centers.Vertical side supports should also be provided at intervals of 3m along rectangular pipe stacks.Maximum stack height is 1.7 meters regardless the pipe diameter.Store all materials in well-ventilated, shady conditions.Avoid direct exposure to sunlight for long periods.• If stored in the open for long periods or exposed to strong sunlight, cover the stack with heavysheets. Coverings such as black plastic must not be used as these can greatly increase thetemperatures within the stack.••Keep fittings in original packaging until required for use.Store fittings under cover. Do not remove from cartons or packaging until required.12

• Ideally, stacks should contain one diameter pipe size only. Where this is not possible, stacklargest diameter pipes at base of stack. Small pipes may be nested inside larger pipes.••Do not place heavy items on top of the pipes.Protect the pipes from dirt, gravel or mud, as this could damage the ring seals insidethe sockets.• Pipes should be kept clean as much as possible, as this may save cleaning time whilepreparing pipes for welding.TransportationWhile in transit pipes should be well secured and supported. Chains or wire ropes may be usedonly if suitably padded to protect the pipe from damage.Pipes should be arranged safely on trucks avoiding crossing, bending and over stacking. Careshould be taken that the pipes are firmly tied so that the sockets cannot rub together.Pipes may be unloaded from vehicles by rolling them gently down timbers, care being taken toensure that the pipes do not fall onto one another or onto any hard or uneven surface.The pipes should also be fully supported over their total length.13

STANDARDS<strong>Cosmoplast</strong> <strong>CPVC</strong> pipes and fittings are manufactured in accordance with the followingstandards:StandardASTM F 441 Chlorinated Polyvinyl Chloride (<strong>CPVC</strong>) Plastic Pipe, Schedule 40 and 80.ASTM F 439 Chlorinated Polyvinyl Chloride (<strong>CPVC</strong>) Plastic Pipe Fittings, Schedule 80.ASTM F 437ASTM D 2846ASTM D 1784Standard Specification for Threaded Chlorinated Polyvinyl Chloride(<strong>CPVC</strong>) Plastic Pipe Fittings, Schedule 80.Standard Specification for Chlorinated Polyvinyl Chloride (<strong>CPVC</strong>)Plastic Hot- and Cold-Water Distribution Systems.Rigid Poly (Vinyl Chloride) (PVC) Compounds and Chlorinated PolyvinylChloride (<strong>CPVC</strong>) Compounds.ASTM D 2467 Chlorinated Polyvinyl Chloride (<strong>CPVC</strong>) Plastic Pipe Fittings, Schedule 80.EN-ISO 15877:2003DIN 8079DIN 8080topicPlastics Piping Systems for Hot and Cold Water Installations - ChlorinatedPoly Vinyl Chloride (PVC - C).Chlorinated Polyvinyl chloride (PVC-C) Pipes – dimensions.Chlorinated Polyvinyl chloride (PVC-C) Pipes – general qualityand testing.PIPE SPECIFICATIONSASTM F 441 : Sch80 Chlorinated Polyvinyl Chloride (<strong>CPVC</strong>) Plastic PipesNominalSize in Inch¼”½”¾”1”1.251.52”2½”3”4”6”8”Outside DiameterSchedule 80Minimum Wall ThicknessWaterPressure Rating (BAR)Inch mm Inch mm at 83°C at 23°C0.5400.6750.8401.0501.3151.6601.9002.3752.8753.5004.5006.6258.62513.7017.1021.3426.6733.4042.2048.3060.3373.0088.90114.30168.30219.000.1190.1260.1470.1540.1790.1910.2000.2180.2760.3000.3370.4320.5003.023.203.373.914.554.855.085.547.017.628.5610.9712.7019.3015.9014.5011.7010.709.007.906.907.206.205.504.804.1077.9063.4058.6047.6043.4035.9032.4027.6029.0025.5022.1019.3017.20Note: Pressure Rating Applies for Water and for Unthreaded Pipes14

ASTM F 441 : Sch40 Chlorinated Polyvinyl Chloride (<strong>CPVC</strong>) Plastic PipesNominalSize in InchOutside DiameterSchedule 40Minimum Wall ThicknessWaterPressure Rating (BAR)Inch mm Inch mm at 83°C at 23°C¼”0.54013.700.0882.2413.4053.800.67517.100.0912.3110.7042.70½”0.84021.340.1092.7710.3041.40¾”1.05026.670.1132.878.3033.101”1.31533.400.1133.387.6031.001.25”1.66042.200.1403.566.2025.501.5”1.90048.300.1453.685.5022.802”2.37560.330.1543.914.8019.302½”2.87573.300.2035.165.2020.703”3.50088.900.2165.494.5017.904”4.500114.300.2376.023.8015.206”6.625168.300.2807.113.1012.408”8.625219.000.3228.182.8011.00Note: Pressure Rating Applies for Water and for Unthreaded PipesDIN 8079 : Chlorinated Polyvinyl Chloride (<strong>CPVC</strong>) Plastic PipesNominalSize)mm(Pressure Rating at 20˚CPN16 PN20 PN25Wall Thickness (mm) Wall Thickness (mm) Wall Thickness (mm)161.21.51.8201.51.92.3251.92.32.8322.43.03.6403.03.74.5503.74.65.6634.75.87.0755.66.98.4906.78.210.01108.210.012.315

REDUCING BUSH Art No. Item PCS/CTNC-RB-¾.½C-RB-1.¾C-RB-1¼.1C-RB-1½.1¼C-RB-2.1½C-S-2½.2C-RB-3.2½C-RB-4.3¾”x½”1”x¾”1¼”x1”1½”x1¼”2”x1½”2½”x2”3”x2½”4”x3”8505503602701541206020END CAP Art No. Item PCS/CTNC-EC-½C-EC-¾C-EC-1C-EC-1¼C-EC-1½C-EC-2C-EC-2½C-EC-3C-EC-4½”¾”1”1¼”1½”2”2½”3”4”1200570500317240146755228UNION Art No. Item PCS/CTNC-UN-½C-UN-¾C-UN-1C-UN-1¼C-UN-1½C-UN-2½”¾”1”1¼”1½”2”275180120964836FEMALE THREADED ELBOW Art No. Item PCS/CTNC-FE-½C-FE-¾C-FE-1½”¾”1”42025017018

FEMALE THREADED ADAPTER Art No. Item PCS/CTNC-FA-½C-FA-¾C-FA-1C-FA-1¼C-FA-1½C-FA-2C-FA-2½C-FA-3C-FA-4½”¾”1”1¼”1½”2”2½”3”4”70045028019813972453612MALE THREADED ADAPTER Art No. Item PCS/CTNC-MA-½C-MA-¾C-MA-1C-MA-1¼C-MA-1½C-MA-2C-MA-2½C-MA-3C-MA-4½”¾”1”1¼”1½”2”2½”3”4”1000600350150200130604818FEMALE THREADED TEEArt No. Item PCS/CTNC-FT-½C-FT-¾C-FT-1½”¾”1”300180110FEMALE THREADED CAP Art No. Item PCS/CTNC-FC-½C-FC-¾C-FC-1½”¾”1”120075048019

MALE THREADED ELBOW 90˚ Art No. Item PCS/CTNC-ME-½C-ME-¾C-ME-1½”¾”1”420280150MALE ADAPTER WITH BRASS THREAD Art No. Item PCS/CTNC-BMA-½C-BMA-¾C-BMA-1C-BMA-1¼C-BMA-1½C-BMA-2½”¾”1”1¼”1½”2”40022017512010060FEMALE ADAPTER WITH BRASS THREAD Art No. Item PCS/CTNC-BFA-½C-BFA-½.¾C-BFA-¾C-BFA-¾.½C-BFA-1½”x ½”½”x¾”¾”x¾”¾”x½”1”x1”200200200200100FEMALE ELBOW WITH BRASS THREAD Art No. Item PCS/CTNC-BFE-½C-BFE-½.¾C-BFE-¾C-BFE-¾.½½”x ½”½”x¾”¾”x¾”¾”x½”18018014414420

FEMALE TEE WITH BRASS THREAD Art No. Item PCS/CTNC-BFT-½C-BFT-½.¾C-BFT-¾C-BFT-¾.½½”x ½”½”x¾”¾”x¾”¾”x½”1101109090MALE THREADED PLUG Art No. Item PCS/CTNC-MP-½C-MP-¾C-MP-1C-MP-1¼C-MP-1½C-MP-2½”¾”1”1¼”1½”2”1200700375420315168DOUBLE UNION BALL VALVE Art No. Item PCS/CTNC-DUV-½C-DUV-¾C-DUV-1C-DUV-1¼C-DUV-1½C-DUV-2C-DUV-2½C-DUV-3C-DUV-4½”¾”1”1¼”1½”2”2½”3”4”966048423620842SINGLE UNION BALL VALVEArt No. Item PCS/CTNC-SUV-½C-SUV-¾C-SUV-1C-SUV-1¼C-SUV-1½C-SUV-2C-SUV-3C-SUV-4½”¾”1”1¼”1½”2”3”4”12081504220208221

chemical resistance of CpVCThe resistance of <strong>CPVC</strong> material to wide range of chemicals is listed in the below table.The symbols used in the tables are as below:NR : Not Resistant.R : Resistant.C : to be used with Caution, actual testing suggested.NA : Date unavailable, actual testing required.22