technical data - Lindberg & Lund AS

technical data - Lindberg & Lund AS

technical data - Lindberg & Lund AS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

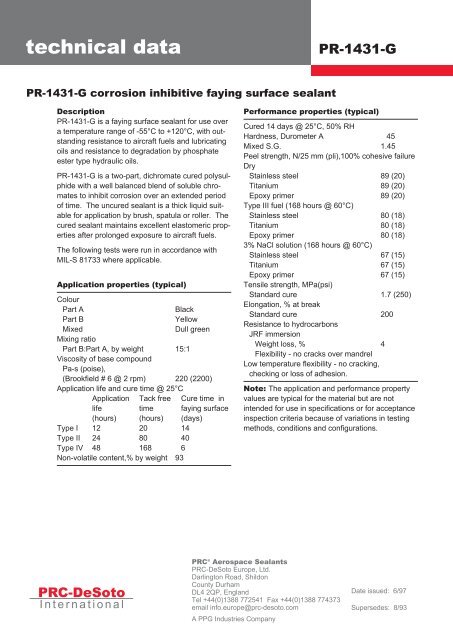

<strong>technical</strong> <strong>data</strong>PR-1431-GPR-1431-G corrosion inhibitive faying surface sealantDescriptionPR-1431-G is a faying surface sealant for use overa temperature range of -55°C to +120°C, with outstandingresistance to aircraft fuels and lubricatingoils and resistance to degradation by phosphateester type hydraulic oils.PR-1431-G is a two-part, dichromate cured polysulphidewith a well balanced blend of soluble chromatesto inhibit corrosion over an extended periodof time. The uncured sealant is a thick liquid suitablefor application by brush, spatula or roller. Thecured sealant maintains excellent elastomeric propertiesafter prolonged exposure to aircraft fuels.The following tests were run in accordance withMIL-S 81733 where applicable.Application properties (typical)ColourPart ABlackPart BYellowMixedDull greenMixing ratioPart B:Part A, by weight 15:1Viscosity of base compoundPa-s (poise),(Brookfield # 6 @ 2 rpm) 220 (2200)Application life and cure time @ 25°CApplication Tack free Cure time inlife time faying surface(hours) (hours) (days)Type I 12 20 14Type II 24 80 40Type IV 48 168 6Non-volatile content,% by weight 93Performance properties (typical)Cured 14 days @ 25°C, 50% RHHardness, Durometer A 45Mixed S.G. 1.45Peel strength, N/25 mm (pli),100% cohesive failureDryStainless steel 89 (20)Titanium 89 (20)Epoxy primer 89 (20)Type III fuel (168 hours @ 60°C)Stainless steel 80 (18)Titanium 80 (18)Epoxy primer 80 (18)3% NaCl solution (168 hours @ 60°C)Stainless steel 67 (15)Titanium 67 (15)Epoxy primer 67 (15)Tensile strength, MPa(psi)Standard cure 1.7 (250)Elongation, % at breakStandard cure 200Resistance to hydrocarbonsJRF immersionWeight loss, % 4Flexibility - no cracks over mandrelLow temperature flexibility - no cracking,checking or loss of adhesion.Note: The application and performance propertyvalues are typical for the material but are notintended for use in specifications or for acceptanceinspection criteria because of variations in testingmethods, conditions and configurations.PRC-DeSotoInternationalPRC ® Aerospace SealantsPRC-DeSoto Europe, Ltd.Darlington Road, ShildonCounty DurhamDL4 2QP, EnglandTel +44(0)1388 772541 Fax +44(0)1388 774373email info.europe@prc-desoto.comA PPG Industries CompanyDate issued: 6/97Supersedes: 8/93

PR-1431-G corrosion inhibitive faying surface sealantSurface preparationImmediately before applying sealant to metallic,chemically treated, or painted substrates, the surfacesshould be cleaned with solvents to removecontamination such as dirt, grease, and/or processinglubricants.A progressive cleaning procedure should beemployed using the appropriate solvents and newlint-free cloth (reclaimed solvents or tissue papershould not be used). Always pour the solvent on tothe cloth to avoid contaminating the solvent supply.Wash one small area at a time. It is important thatthe surface is dried with a second clean cloth priorto the solvent evaporating to prevent the redepositionof contaminants on to the substrate.Substrate composition can vary greatly. This canaffect sealant adhesion. It is recommended thatadhesion characteristics to a specific substrate bedetermined prior to application on production partsor assemblies. For information on specific substratetreatment please refer to the SurfaceTreatment leaflet which is available on request.Storage lifeThe storage life of PR-1431-G is six months whenstored at temperatures between 5°C and 25°C inthe original unopened containers.Health precautionsThese products are safe to use and apply whenrecommended precautions are observed. Beforeusing these products read and understand theMaterial Safety Data Sheets which provide informationon health, physical and environmental hazards,handling precautions and first aid recommendations.An MSDS is available on request. Avoidoverexposure. Obtain medical care in case ofextremeexposure.All recommendations, statements, and <strong>technical</strong> <strong>data</strong> contained herein are based on tests we believe to be reliable and correct, butaccuracy and completeness of said tests are not guaranteed and are not to be construed as a warranty, either expressed or implied.User shall rely on his own information and tests to determine suitability of the product for the intended use and assumes all risks andliability resulting from his use of the product. Seller’s and manufacturer’s sole responsibility shall be to replace that portion of the product ofthis manufacturer which proves to be defective. Neither seller nor manufacturer shall be liable to the buyer or any third person for any injury,loss, or damage directly or indirectly resulting from use of, or inability to use, the product. Recommendations or statements other than thosecontained in a written agreement signed by an officer of the manufacturer shall not be binding upon the manufacturer or seller.

![[pdf] EXXON-TF56-TD - Lindberg & Lund AS](https://img.yumpu.com/52492677/1/190x245/pdf-exxon-tf56-td-lindberg-lund-as.jpg?quality=85)