Loctite Products - Sequoia Equipment Company

Loctite Products - Sequoia Equipment Company

Loctite Products - Sequoia Equipment Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

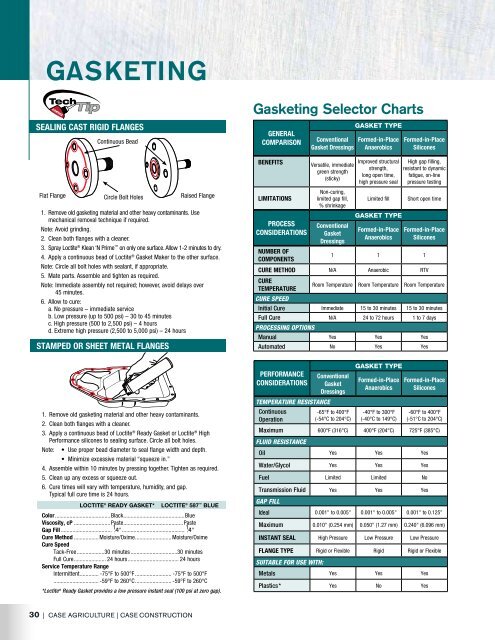

Properties Chart: GasketinggasketingGasketing Selector Charts<strong>Loctite</strong> ®PRODUCTPartNumberContainerColorReady Gasket MC40480 190 ml power can aerosol BlackOilResistanceIncreasedoil resistanceNon-CorrosiveNon-corrosiveTemperatureRange-75° to 500°F(-59° to 260°C)intermittentSealing TimeOperating Strength15 psi - 1 min.AgencyApprovalsGM 998-5990Ford WSE-M4G 323-A6Chrysler GF-44-ASEALING CAST RIGID FLANGESContinuous BeadGeneralcomparisonConventionalGasket DressingsGasket TypeFormed-in-PlaceAnaerobicsFormed-in-PlaceSiliconesRTV Red SiliconeMC37469MC4046580 ml tube190 ml power can aerosolRed • •-75° to 600°F(-59° to 316°C)intermittentTack-free 30 min.—Full Strength 24 hrs.CFIABenefitsVersatile, immediategreen strength(sticky)Improved structuralstrength,long open time,high pressure sealHigh gap filling,resistant to dynamicfatigue, on-linepressure testingRTV 598Black SiliconeMC37467MC40463MC37519MC3751880 ml tube190 ml power can aerosol8.75 oz. can300 ml cartridgeBlackExcellentoil resistanceNon-corrosive-75° to 625°F(-59° to 329°C)intermittentTack-free 30 min.—Full Strength 24 hrs.American Bureauof Shipping,CFIAFlat FlangeCircle Bolt HolesRaised Flange1. Remove old gasketing material and other heavy contaminants. Usemechanical removal technique if required.Note: Avoid grinding.2. Clean both flanges with a cleaner.3. Spray <strong>Loctite</strong> ® Klean ‘N Prime on only one surface. Allow 1-2 minutes to dry.4. Apply a continuous bead of <strong>Loctite</strong> ® Gasket Maker to the other surface.Note: Circle all bolt holes with sealant, if appropriate.5. Mate parts. Assemble and tighten as required.Note: Immediate assembly not required; however, avoid delays over45 minutes.6. Allow to cure:a. No pressure – immediate serviceb. Low pressure (up to 500 psi) – 30 to 45 minutesc. High pressure (500 to 2,500 psi) – 4 hoursd. Extreme high pressure (2,500 to 5,000 psi) – 24 hoursSTAMPED OR SHEET METAL FLANGESLimitationsProcessConsiderationsNon-curing,limited gap fill,% shrinkageConventionalGasketDressingsLimited fillGasket TypeFormed-in-PlaceAnaerobicsShort open timeFormed-in-PlaceSiliconesNumber ofComponents1 1 1Cure Method N/A Anaerobic RTVCureTemperatureRoom Temperature Room Temperature Room TemperatureCure SpeedInitial Cure Immediate 15 to 30 minutes 15 to 30 minutesFull Cure N/A 24 to 72 hours 1 to 7 daysProcessing OptionsManual Yes Yes YesAutomated No Yes YesRTV 587Blue SiliconeRTV 5920Copper SiliconeRTV 5699Grey SiliconeAviationGasket SealantMC37465MC4046280 ml tube190 ml power can aerosolBlueMC37466 80 ml tube CopperMC37464MC40505MC3755880 ml tube190 ml power can aerosol16 oz. brushtop canGreyDarkreddishbrownIncreasedoil resistanceIncreasedoil resistanceIncreasedoil resistanceOil resistantNon-corrosiveNon-corrosiveNon-corrosiveNon-corrosiveGasket Sealant 2 MC37544 3 oz. tube Black Oil resistant Non-corrosiveHi-TackGasket SealantMC37555MC375539 oz. aerosol16 oz. brushtop canRedIncreasedoil resistanceNon-corrosive-75° to 500°F(-59° to 260°C)intermittent-65° to 700°F(-54° to 371°C)intermittent-75° to 625°F(-59° to 329°C)intermittent-65° to 400°F(-54° to 204°C)-65° to 400°F(-54° to 204°C)-65° to 500°F(-54° to 260°C)Aerosol to 600°FTack-free 30 min.—Full Strength 24 hrs.Tack-free 60 min.—Full Strength 24 hrsTack-free 30 min.—Full Strength 24 hrs.Full Strength 12 hrs.Remains tackyAmerican Bureauof Shipping,UL® Classified forU.S., CFIACFIACFIA5 min. to set •••PerformanceConsiderationsTemperature ResistanceConventionalGasketDressingsGasket TypeFormed-in-PlaceAnaerobicsFormed-in-PlaceSiliconesCopperGasket Adhesive510 GasketEliminatorMC37583 9 oz. aerosol Copper Oil resistant Non-corrosiveMC51031 50 ml tube Red Oil resistant Non-corrosive-50° to 500°F(-45° to 260°C)-65° to 300°F(-54° to 149°C)Remains tackyFull Strength 24 hrs.•UL® Classified for U.S.1. Remove old gasketing material and other heavy contaminants.2. Clean both flanges with a cleaner.3. Apply a continuous bead of <strong>Loctite</strong> ® Ready Gasket or <strong>Loctite</strong> ® HighPerformance silicones to sealing surface. Circle all bolt holes.Note: • Use proper bead diameter to seal flange width and depth.• Minimize excessive material “squeeze in.”4. Assemble within 10 minutes by pressing together. Tighten as required.5. Clean up any excess or squeeze out.6. Cure times will vary with temperature, humidity, and gap.Typical full cure time is 24 hours.<strong>Loctite</strong> ® Ready Gasket* <strong>Loctite</strong> ® 587 BlueColor......................................Black..........................................BlueViscosity, cP..........................Paste.........................................PasteGap Fill.................................... 1 ⁄4"............................................ 1 ⁄4"Cure Method.................. Moisture/Oxime......................... Moisture/OximeCure SpeedTack-Free...................30 minutes.................................30 minutesFull Cure...................... 24 hours.................................... 24 hoursService Temperature RangeIntermittent............. -75°F to 500°F.......................... -75°F to 500°F............................... -59°F to 260°C......................... -59°F to 260°C*<strong>Loctite</strong> ® Ready Gasket provides a low pressure instant seal (100 psi at zero gap).ContinuousOperation-65°F to 400°F(-54°C to 204°C)-40°F to 300°F(-40°C to 149°C)-60°F to 400°F(-51°C to 204°C)Maximum 600°F (316°C) 400°F (204°C) 725°F (385°C)fluid ResistanceOil Yes Yes YesWater/Glycol Yes Yes YesFuel Limited Limited NoTransmission Fluid Yes Yes YesGap FillIdeal 0.001" to 0.005" 0.001" to 0.005" 0.001" to 0.125"Maximum 0.010" (0.254 mm) 0.050" (1.27 mm) 0.240" (6.096 mm)Instant seal High Pressure Low Pressure Low PressureFlange Type Rigid or Flexible Rigid Rigid or FlexibleSuitable for Use With:Metals Yes Yes YesPlastics* Yes No YesHigh Flex Form-In-Place GasketProperties Chart: Gasketing<strong>Loctite</strong> ®PRODUCT515518MC38657 50 ml tube BluePartNumberMC38655MC51580MC37394MC37530Container Color Viscosity (cP)50 ml tube300 ml cartridge50 ml tube300 ml cartridgePurpleRedHi-Tack Stick MC39158 19 g stick PurpleExcellentoil resistance275,000/950,000Thixotropic paste800,000/3,750,000Thixotropic pasteVertical applications,repositionableNon-corrosive-65° to 350°F(-54° to 177°C)TemperatureRange-65° to 300°F(-54°C to 149°C)-65° to 300°F(-54°C to 149°C)-65° to 300°F(-54°C to 149°C)* Uncured liquid adhesives may cause stress cracking of certain thermoplastics (e.g., polycarbons, acrylic and polysulfone).Full Strength 24 hrs.Sealing Time15 min-2 hrs. w/primer1-12 hrs. w/o primer30 min-4 hrs. w/primer4-24 hrs. w/o primerAgencyApprovalsUL® Classified for U.S.CFIA5 minutes to set ••30 | Case agriculture | Case construction adhesives & sealants guide | 31