english

english

english

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

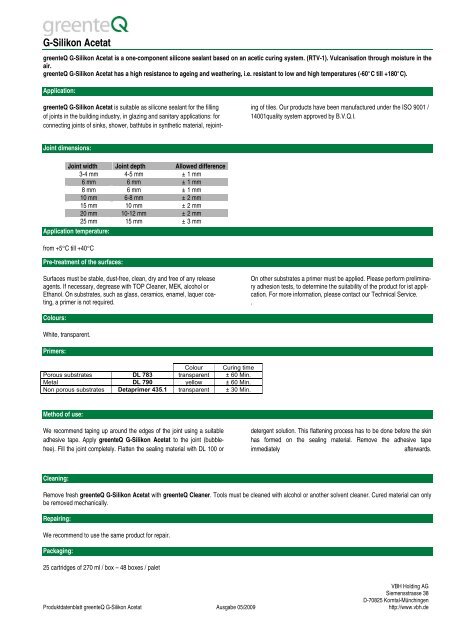

G-Silikon AcetatgreenteQ G-Silikon Acetat is a one-component silicone sealant based on an acetic curing system. (RTV-1). Vulcanisation through moisture in theair.greenteQ G-Silikon Acetat has a high resistance to ageing and weathering, i.e. resistant to low and high temperatures (-60°C till +180°C).Application:greenteQ G-Silikon Acetat is suitable as silicone sealant for the fillingof joints in the building industry, in glazing and sanitary applications: forconnecting joints of sinks, shower, bathtubs in synthetic material, rejointingof tiles. Our products have been manufactured under the ISO 9001 /14001quality system approved by B.V.Q.I.Joint dimensions:Joint width Joint depth Allowed difference3-4 mm 4-5 mm ± 1 mm6 mm 6 mm ± 1 mm8 mm 6 mm ± 1 mm10 mm 6-8 mm ± 2 mm15 mm 10 mm ± 2 mm20 mm 10-12 mm ± 2 mm25 mm 15 mm ± 3 mmApplication temperature:from +5°C till +40°CPre-treatment of the surfaces:Surfaces must be stable, dust-free, clean, dry and free of any releaseagents. If necessary, degrease with TOP Cleaner, MEK, alcohol orEthanol. On substrates, such as glass, ceramics, enamel, laquer coating,a primer is not required.On other substrates a primer must be applied. Please perform preliminaryadhesion tests, to determine the suitability of the product for ist application.For more information, please contact our Technical Service..Colours:White, transparent.Primers:Colour Curing timePorous substrates DL 783 transparent ± 60 Min.Metal DL 790 yellow ± 60 Min.Non porous substrates Detaprimer 435.1 transparent ± 30 Min.Method of use:We recommend taping up around the edges of the joint using a suitableadhesive tape. Apply greenteQ G-Silikon Acetat to the joint (bubblefree).Fill the joint completely. Flatten the sealing material with DL 100 ordetergent solution. This flattening process has to be done before the skinhas formed on the sealing material. Remove the adhesive tapeimmediatelyafterwards.Cleaning:Remove fresh greenteQ G-Silikon Acetat with greenteQ Cleaner. Tools must be cleaned with alcohol or another solvent cleaner. Cured material can onlybe removed mechanically.Repairing:We recommend to use the same product for repair.Packaging:25 cartridges of 270 ml / box – 48 boxes / paletProduktdatenblatt greenteQ G-Silikon Acetat Ausgabe 05/2009VBH Holding AGSiemensstrasse 38D-70825 Korntal-Münchingenhttp://www.vbh.de

G-Silikon AcetatLimitations:- Do not expose to thermal, mechanical or chemical influences before complete vulcanisation.- greenteQ G-Silikon Acetat should not be used in closed areas, since it requires air humidity in order to cure: Good ventilation is important duringapplication and vulcanisation of the product.- greenteQ G-Silikon Acetat is not suitable for bonding of mirrors, for polyacrylate, polycarbonate and natural stone.- greenteQ G-Silikon Acetat cannot be painted.- greenteQ G-Silikon Acetat is not suitable for structural glazing.- Do not use greenteQ G-Silikon Acetat in contact with oxidation-sensitive metals, such as copper, copper, zinc, lead, steel (due to corrosion). In thiscase the use of a primer is required- Do not use greenteQ G-Silikon Acetat on plastics and alkaline surfaces, such as concrete and stone.Shelf-life:Up to 12 months if stored in a cool, dry and frost-free environment in its unopened original packaging (at +23°C and 50% relative air humidity)Apply with:With a manual or air operated applicator. The shape of the joint is important. Avoid thin layers.Safety advice:Keep out oft he reach of children. Avoid contact with the eyes and skin. For more information, please consult our Safety Data Sheet.Technical data:Unvulcanised sealantType of sealantPolysiloxanesVulcanisation systemVulcanisation through moisture in the airSkin forming time (23°C & 50% Lf)17 minVulcanisation rate (23°C & 50% Lf)2,5 à 3 mm / 24 hoursDensity (ISO 1183)1.00 g/mlVulcanised sealantShore A Hardness (ISO 868) 17Elastic recovery capacity (ISO 7389) > 90 %Deformation capability 25%Modulus at 100% Elongation (ISO 8340)0.35 N/ mm²% Elongation at break (ISO 8339) 130%Temperature resistance -60°C / + 180°CThe data on this sheet have been drafted according to the last state of the laboratory data. Technical characteristics can be changed or adapted. We are not responsible incase of incompleteness. Before usage, one needs to ensure that the product is suitable for its application. Therefore, preliminary tests are necessary. Our general conditionsapply.This data sheet replaces all previous versions.Produktdatenblatt greenteQ G-Silikon Acetat Ausgabe 05/2009VBH Holding AGSiemensstrasse 38D-70825 Korntal-Münchingenhttp://www.vbh.de