Westfalia Separator® seaprotectsolutions - ShipServ

Westfalia Separator® seaprotectsolutions - ShipServ

Westfalia Separator® seaprotectsolutions - ShipServ

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

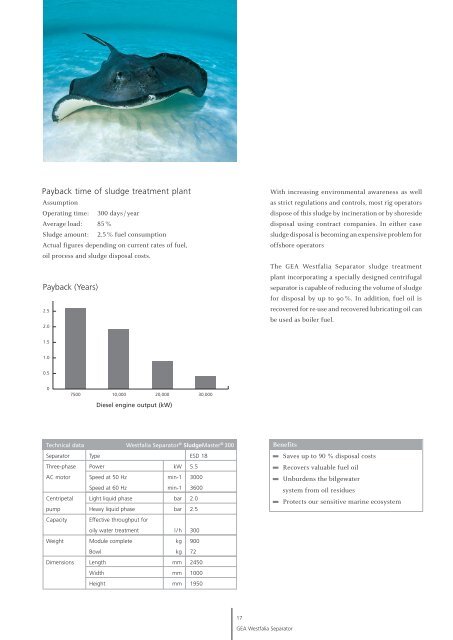

Payback time of sludge treatment plantAssumptionOperating time: 300 days / yearAverage load: 85 %Sludge amount: 2.5 % fuel consumptionActual figures depending on current rates of fuel,oil process and sludge disposal costs.Payback (Years)3.02.52.0With increasing environmental awareness as wellas strict regulations and controls, most rig operatorsdispose of this sludge by incineration or by shoresidedisposal using contract companies. In either casesludge disposal is becoming an expensive problem foroff shore operatorsThe GEA <strong>Westfalia</strong> Separator sludge treatmentplant incorporating a specially designed centrifugalseparator is capable of reducing the volume of sludgefor disposal by up to 90 %. In addition, fuel oil isrecovered for re-use and recovered lubricating oil canbe used as boiler fuel.1.51.00.507500 10,000 20,000 30,000Diesel engine output (kW)Technical data <strong>Westfalia</strong> Separator ® SludgeMaster ® 300Separator Type ESD 18Three-phase Power kW 5.5AC motor Speed at 50 Hz min-1 3000Speed at 60 Hz min-1 3600Centripetal Light liquid phase bar 2.0pump Heavy liquid phase bar 2.5Capacity Effective throughput foroily water treatment l / h 300Weight Module complete kg 900Bowl kg 72Dimensions Length mm 2450Width mm 1000Height mm 1950BenefitsSaves up to 90 % disposal costsRecovers valuable fuel oilUnburdens the bilgewatersystem from oil residuesProtects our sensitive marine ecosystem17GEA <strong>Westfalia</strong> Separator