Download - Dapra Corporation

Download - Dapra Corporation

Download - Dapra Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

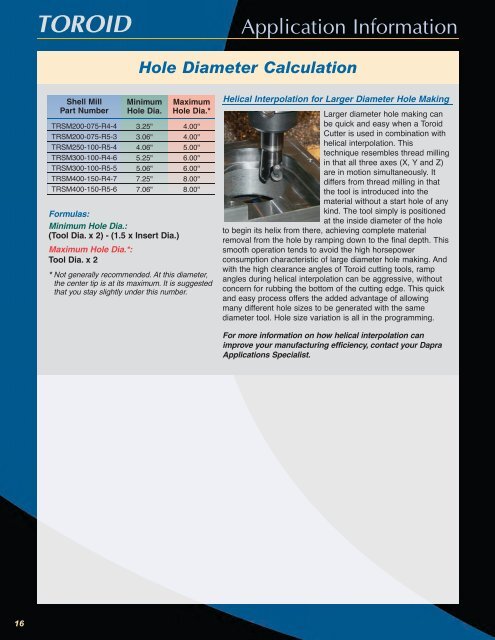

TOROIDApplication InformationHole Diameter CalculationShell MillPart NumberTRSM200-075-R4-4TRSM200-075-R5-3TRSM250-100-R5-4TRSM300-100-R4-6TRSM300-100-R5-5TRSM400-150-R4-7TRSM400-150-R5-6MinimumHole Dia.3.25"3.06"4.06"5.25"5.06"7.25"7.06"Formulas:Minimum Hole Dia.:(Tool Dia. x 2) - (1.5 x Insert Dia.)Maximum Hole Dia.*:Tool Dia. x 2MaximumHole Dia.*4.00"4.00"5.00"6.00"6.00"8.00"8.00"* Not generally recommended. At this diameter,the center tip is at its maximum. It is suggestedthat you stay slightly under this number.Helical Interpolation for Larger Diameter Hole MakingLarger diameter hole making canbe quick and easy when a ToroidCutter is used in combination withhelical interpolation. Thistechnique resembles thread millingin that all three axes (X, Y and Z)are in motion simultaneously. Itdiffers from thread milling in thatthe tool is introduced into thematerial without a start hole of anykind. The tool simply is positionedat the inside diameter of the holeto begin its helix from there, achieving complete materialremoval from the hole by ramping down to the final depth. Thissmooth operation tends to avoid the high horsepowerconsumption characteristic of large diameter hole making. Andwith the high clearance angles of Toroid cutting tools, rampangles during helical interpolation can be aggressive, withoutconcern for rubbing the bottom of the cutting edge. This quickand easy process offers the added advantage of allowingmany different hole sizes to be generated with the samediameter tool. Hole size variation is all in the programming.For more information on how helical interpolation canimprove your manufacturing efficiency, contact your <strong>Dapra</strong>Applications Specialist.16