Download - Dapra Corporation

Download - Dapra Corporation

Download - Dapra Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

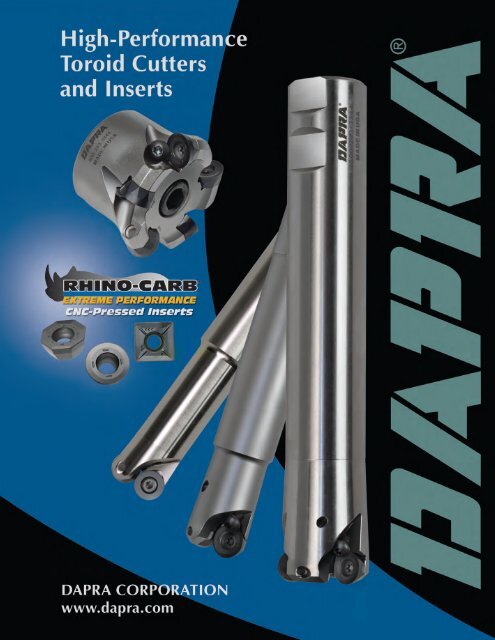

<strong>Dapra</strong>’s RHINO-CARB high-performance insertsare designed for very aggressive metal cuttingand long tool life.Pressed Toroid InsertsStronger cutting edge for heavierchiploads, greater shockabsorption and longer tool lifePositive top rake forreduced cutting forcesand lower torqueThicker inserts for greater strengthand enhancedheat-absorption capabilities“T” inserts have a strong, negative reinforced cuttingedge for steels, irons and hard milling.“D” inserts have a high-positive cutting edge for stainlesssteels, high-temperature alloys and gummy materials.Important! These thickerpressed inserts may causeyour cutter to cut a slightly largerdiameter than with ground inserts.Always measure tool diameter before use.“N” inserts (round and octagonal only) are more positivethan the “T” edge, but stronger than “D.” The “N” shouldbe your go-to geometry for most steels, cast irons and400-series stainless applications.<strong>Dapra</strong>’s Toroid Line includes three high-performance inserts,including our RHINO-CARB line, to maximize the versatilityof our Toroid cutting tools:Match the insert R value to the designation on your cutter body.R3Button Inserts Square Inserts Octagonal InsertsR4R5R6RPMHRDCH & RXCH (ground)R4 ‡SXEH‡Fits 1 1 /4" diameter and above only.R4R5R6OPMHOXCH (ground)2R3: 3/8" IC Cutting Tools & Inserts 4-5R4: 1/2" IC Cutting Tools & Inserts 6-7R5: 5/8" IC Cutting Tools & Inserts 8-9R6: 3/4" IC Cutting Tools & Inserts 10-11Modular Heads and Extensions 12-13Application Information 14Troubleshooting, Optimizationand Reference Information 15-16Metric Cutter Bodies, Inserts,Spare Parts & Tools 17-18Spare Parts 18Insert Grades 19Recommended Cutting Speeds 20

1Button InsertsR3 R4 R5 R6Round inserts have a strong cutting edge, making them an excellent choice formany applications, including:• Mold cavity and core roughing• Roughing of complex part contours• Helical interpolation(larger diameter hole making)• Pocketing• Semifinishing• Face millingSee chart on page 15 for technical help on optimum feeds for button inserts.2Square InsertsR4(1 1 /4" diameter and above only)Your Toroid cutter can now be used for the most common applications involving90˚ milling. Utilize the more economical 4-sided inserts for:• Profiling• Step milling• Face milling• Slotting• Helical interpolation (cored holes only)• Plunge milling3Octagonal InsertsR4*R5 R68-sided geometry is excellent for general face milling.45˚ lead angle provides increased feed capacity for:• Face milling• Profiling• Helical interpolation• ChamferingEach of the 8 usable edges comes with an integralwiper flat for outstanding surface finishes (RHINO-CARB only).See information on page 15 regarding 45˚ lead angle compensation for octagonal inserts.* R4 Octagonal available in RHINO-CARB style only.3

TOROIDR3Ordering InformationR3: 3/8" Insert Cutting Tools1.250" shank dia. cutters and smaller are available in limited supply without Weldon Flats.Add WOF to the end of the part number when ordering.SODLREnd Mills (with thru-tool coolant)ODDiameterHolderREffective LengthLOverall LengthSShank Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia..750".750"1.000"1.000"TREM075-200-R3-2 †TREM075-300-R3-2 †TREM100-250-R3-2 †TREM100-250-R3-3 †2.000"3.000"2.500"2.500"4.030"5.030"4.750"4.750".750".750"1.000"1.000"2223.375".375".375".375"Carbide Core End Mills (solid, no thru-tool coolant)ODDiameterHolderREffective LengthLOverall LengthSShank Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia..750"1.000"1.000"CC-TREM075-300-R3-2 †CC-TREM100-450-R3-2 †CC-TREM100-450-R3-3 †3.000"4.500"4.500"5.030"6.750"6.750".750"1.000"1.000"223.375".375".375"† Does not come with top clamp.4

TOROIDR3Ordering Information“T” inserts have a reinforcedcutting edge for steels, ironsand hard millingR3: 3/8" IC Inserts“N” inserts are for typicalcutting applications where highperformancemilling of steels,irons and 400-series stainless isdesiredStocked standardAvailable upon request“D” inserts have a high-positivecutting edge for stainless steels,high-temperature alloys andgummy materialsButton InsertsICThicknessRadius Uncoated CoatedDMK30DMK25 †DMP25DMK15DMK303DMK253 †DMP253DMK153DMK30-HPDMK25-HP †DMP25-HPDMK15-HPDMK307DMK257 †DMP257DMK157DMK30-GLHDMK25-GLH †DMP25-GLHDMK15-GLHRPMH-33-TRPMH-33-NRPMH-33-D.375".375".375".157".157".157".187".187".187"GroundRDCH-32-T ‡RDCH-32-D*.375".375".125".125".187".187"† DMK25 substrate is available for RHINO-CARB D and N geometries only.‡ Closeout item. Available while supplies last.* RDCH-32-D is available in DMP25 and DMK15 (uncoated and coated) only, while supplies last.DMK30 is not available for this insert.✓See chart on page 15 for technical help on optimum feeds for button inserts.See page 19 for insert grade descriptions.See page 20 for recommended speeds/feeds.5

TOROIDR4Ordering InformationR4: 1/2" Insert Cutting Tools1.250" shank dia. cutters and smaller are available in limited supply without Weldon Flats.Add WOF to the end of the part number when ordering.SEnd Mills (with thru-tool coolant unless noted)ODDiameterHolderREffective LengthLOverall LengthSShank Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.1.000"1.000"1.000"1.250"1.500"TREM100-125-R4-2 ‡TREM100-250-R4-2 ‡TREM100-450-R4-2 ‡TREM125-300-R4-3 *TREM150-350-R4-3 *1.250"2.500"4.500"3.000"3.500"3.530"4.750"6.750"5.280"5.780"1.000"1.000"1.000"1.250"1.250"22233.500".500".500".500".500"LRODDiameterCarbide Core End Mills (solid, no thru-tool coolant)HolderREffective LengthLOverall LengthSShank Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.OD1.000"1.250"1.500"CC-TREM100-450-R4-2 ‡CC-TREM125-500-R4-3CC-TREM150-550-R4-34.500"5.000"5.500"6.750"7.280"7.780"1.000"1.250"1.250"233.500".500".500"* Does not have thru-tool coolant. ‡ Uses RDCH-43 / RPMH-44 / OPMH442 Inserts only.B* All TRSM600 Shell Mills are being transitioned to a 2.000" arbor diameter. Once our current inventory of 1.500" arbors isexhausted, all TRSM600 cutters will come with a 2.000" arbor. Please call for current availability.Shell MillsRODDiameterHolderREffective LengthBArbor Dia.HCounter Bore Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.HOD2.000"2.000"2.500"3.000"3.320"4.000"4.320"5.000"5.320"6.000"6.000"6.320"TRSM200-075-R4-4**TRSM200-075-R4-5**TRSM250-100-R4-6**TRSM300-100-R4-6**TRSM332-100-R4-6TRSM400-150-R4-7TRSM432-150-R4-7TRSM500-150-R4-9TRSM532-150-R4-9TRSM600-200-R4-9TRSM600-150-R4-12*TRSM632-200-R4-91.500"1.500"2.000"2.000"2.000"2.000"2.000"2.000"2.000"2.000"2.000"2.000".750".750"1.000"1.000"1.000"1.500"1.500"1.500"1.500"2.000"1.500"2.000".590".590".790".790".790"2.050"2.050"2.060"2.060"2.875"2.060"2.875"4566677999129.500".500".500".500".500".500".500".500".500".500".500".500"** All Shell Mills 3" diameter and smaller are transitioning to a thru-coolant style.To specify thru-coolant option when ordering, add a "C" to the end of the part number. Stock not guaranteed.✓See chart on page 15 for technical help on optimum feeds for button inserts.See page 19 for insert grade descriptions.See page 20 for recommended speeds/feeds.6

TOROIDR4Ordering InformationR4: 1/2" IC InsertsStocked standardAvailable upon request“T” inserts have a reinforcedcutting edge for steels, ironsand hard millingButton InsertsRPMH-44-TRPMH-44-NRPMH-44-D“N” inserts are for typicalcutting applications where highperformancemilling of steels,irons and 400-series stainless isdesiredIC.500".500".500"Thickness.220".220".220".250".250".250"DMK30DMK25 †DMP25DMK15DMK253 †DMP253DMK153“D” inserts have a high-positivecutting edge for stainless steels,high-temperature alloys andgummy materialsRadius Uncoated CoatedDMK30-HPDMK25-HP †DMP25-HPDMK15-HPDMK307DMK257 †DMP257DMK157DMK30-GLHDMK25-GLH †DMP25-GLHDMK15-GLHGroundRDCH-43-T ‡RDCH-43-D*.500".500".187".187".250".250"† DMK25 substrate is available for RHINO-CARB D and N geometries only.‡ Closeout item. Available while supplies last. DMK30 is out of stock.* RDCH-43-D is available in DMK30 and DMK15 (uncoated and coated) only. DMP25 available while supplies last.Square InsertsSXEH-432-TSXEH-432-DIC Thickness CornerCoatedRadius DMK303 DMK30-HP DMK307DMP253 DMP25-HP DMP257DMK153 DMK15-HP DMK157.500".500".200".200".031".031"DMK30-GLHDMP25-GLHDMK15-GLHSXEH inserts are suitable for 1 1 /4" diameter and above only.Octagonal InsertsICThicknessRadiuscoatedUn-DMK30DMK25 †DMP25DMK15DMK303DMK253 †DMP253DMK153CoatedDMK30-HPDMK25-HP †DMP25-HPDMK15-HPDMK307DMK257 †DMP257DMK157DMK30-GLHDMK25-GLH †DMP25-GLHDMK15-GLHOPMH442-TOPMH442-NOPMH442-D.500".500".500".220".220".220".031".031".031"† DMK25 substrate is available for RHINO-CARB D and N geometries only.‡OPMH442 inserts have a maximum DOC of .135".7

TOROIDR5Ordering InformationR5: 5/8" Insert Cutting Tools1.250" shank dia. cutters and smaller are available in limited supply without Weldon Flats. Add WOF to the end of the part number when ordering.SODLREnd Mills (with thru-tool coolant)ODDiameterHolderREffective LengthLOverall LengthSShank Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.1.250"TREM125-300-R5-23.000"5.250"1.250"2.625"Carbide Core End Mills (solid, no thru-tool coolant)ODDiameterHolderREffective LengthLOverall LengthSShank Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.1.250"CC-TREM125-500-R5-25.000"7.250"1.250"2.625"BRHODShell Mills* All TRSM600 Shell Mills are being transitionedto a 2.000" arbor diameter. Once our currentinventory of 1.500" arbors is exhausted, allTRSM600 cutters will come with a 2.000" arbor.Please call for current availability.ODDiameterHolderREffective LengthBArbor Dia.HCounter Bore Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.2.000"2.500"3.000"3.430"4.000"4.430"5.000"5.430"6.000"6.000"6.430"8.360"TRSM200-075-R5-3**TRSM250-100-R5-4**TRSM300-100-R5-5**TRSM343-100-R5-5TRSM400-150-R5-6TRSM443-150-R5-6TRSM500-150-R5-8TRSM543-150-R5-8TRSM600-150-R5-10*TRSM600-200-R5-10TRSM643-200-R5-10TRSM836-FM-R5-10FLANGE MOUNTED1.500"2.000"2.000"2.000"2.000"2.000"2.000"2.000"2.000"2.000"2.000"2.380".750"1.000"1.000"1.000"1.500"1.500"1.500"1.500"1.500"2.000"2.000"2.500".590".790".790".790"2.060"2.060"2.060"2.060"2.060"2.875"2.875"4.0" B/C3455668810101010.625".625".625".625".625".625".625".625".625".625".625".625"** All Shell Mills 3" diameter and smaller are transitioning to a thru-coolant style.To specify thru-coolant option when ordering, add a "C" to the end of the part number. Stock not guaranteed.8

TOROIDR5Ordering Information“T” inserts have a reinforcedcutting edge for steels, ironsand hard millingR5: 5/8" IC Inserts“N” inserts are for typicalcutting applications where highperformancemilling of steels,irons and 400-series stainless isdesiredStocked standardAvailable upon request“D” inserts have a high-positivecutting edge for stainless steels,high-temperature alloys andgummy materialsButton InsertsICThicknessRadius Uncoated CoatedDMK30DMK25 †DMP25DMK15DMK253 †DMP253DMK153DMK30-HPDMK25-HP †DMP25-HPDMK15-HPDMK307DMK257 †DMP257DMK157DMK30-GLHDMK25-GLH †DMP25-GLHDMK15-GLHRPMH-54-TRPMH-54-NRPMH-54-D.625".625".625".220".220".220".312".312".312"GroundRXCH-53-T ‡RXCH-53-D*.625".625".187".187".312".312"† DMK25 substrate is available for RHINO-CARB D and N geometries only.‡ Closeout item. Available while supplies last.* RXCH-53-D is available in DMK30 and DMK15 (uncoated and coated) only. DMP25 available while supplies last.Octagonal InsertsICThicknessRadiuscoatedUn-DMK30DMK25 †DMP25DMK15DMK303DMK253 †DMP253DMK153CoatedDMK30-HPDMK25-HP †DMP25-HPDMK15-HPDMK307DMK257 †DMP257DMK157DMK30-GLHDMK25-GLH †DMP25-GLHDMK15-GLHOPMH544-TOPMH544-NOPMH544-D.625".625".625".220".220".220".062".062".062"GroundOXCH-534-T ‡OXCH-534-D*.625".625".187".187".062".062"† DMK25 substrate is available for RHINO-CARB D and N geometries only.‡ Closeout item. Available while supplies last.* OXCH-534-D is available in DMK30 and DMK15 (uncoated and coated) only. DMP25 available while supplies last.** OPMH544 inserts have a maximum DOC of .165".✓See chart on page 15 for technical help on optimum feeds for button inserts.See page 19 for insert grade descriptions.See page 20 for recommended speeds/feeds.9

TOROIDR6Ordering InformationR6: 3/4" Insert Cutting ToolsSODLREnd Mills (with thru-tool coolant)ODDiameterHolderREffective LengthLOverall LengthSShank Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.1.500"TREM150-350-R6-23.500"6.190"1.500"2.750"Carbide Core End Mills (solid, no thru-tool coolant)ODDiameterHolderREffective LengthLOverall LengthSShank Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.1.500"CC-TREM150-550-R6-25.500"8.190"1.500"2.750"BRHODShell MillsODDiameterHolderREffective LengthBArbor Dia.HCounter Bore Dia.FlutesInsertMatch color to inserts on opposite pageInsertDia.3.000"3.500"4.000"4.500"6.000"6.500"8.440"TRSM300-100-R6-4**TRSM350-100-R6-4TRSM400-150-R6-6TRSM450-150-R6-6TRSM600-200-R6-8TRSM650-200-R6-8TRSM850-FM-R6-10FLANGE MOUNTED2.000"2.000"2.000"2.000"2.000"2.000"2.380"1.000"1.000"1.500"1.500"2.000"2.000"2.500".790".790"2.060"2.060"2.875"2.875"4.0" B/C44668810.750".750".750".750".750".750".750"** All Shell Mills 3" diameter and smaller are transitioning to a thru-coolant style.To specify thru-coolant option when ordering, add a "C" to the end of the part number. Stock not guaranteed.10

TOROIDR6Ordering Information“T” inserts have a reinforcedcutting edge for steels, ironsand hard millingR6: 3/4" IC Inserts“N” inserts are for typicalcutting applications where highperformancemilling of steels,irons and 400-series stainless isdesiredStocked standardAvailable upon request“D” inserts have a high-positivecutting edge for stainless steels,high-temperature alloys andgummy materialsButton InsertsICThicknessRadius Uncoated CoatedDMK30DMK25 †DMP25DMK15DMK253 †DMP253DMK153DMK30-HPDMK25-HP †DMP25-HPDMK15-HPDMK307DMK257 †DMP257DMK157DMK30-GLHDMK25-GLH †DMP25-GLHDMK15-GLHRPMH-64-TRPMH-64-NRPMH-64-D.750".750".750".220".220".220".375".375".375"GroundRXCH-63-T ‡RXCH-63-D*.750".750".187".187".375".375"†DMK25 substrate is available for RHINO-CARB D and N geometries only.‡Closeout item. Available while supplies last.* RXCH-63-D is available in DMK30 and DMK15 (uncoated and coated) only. DMP25 is not available for this insert.Octagonal InsertsICThicknessRadiuscoatedUn-DMK30DMK25 †DMP25DMK15DMK303DMK253 †DMP253DMK153CoatedDMK30-HPDMK25-HP †DMP25-HPDMK15-HPDMK307DMK257 †DMP257DMK157DMK30-GLHDMK25-GLH †DMP25-GLHDMK15-GLHOPMH644-TOPMH644-NOPMH644-D.750".750".750".220".220".220".062".062".062"GroundOXCH-634-T ‡OXCH-634-D*.750".750".187".187".062".062"†DMK25 substrate is available for RHINO-CARB D and N geometries only.‡Closeout item. Available while supplies last.* OXCH-634-D is available in DMK30 and DMK15 (uncoated and coated) only. DMP25 available while supplies last.** OPMH644 inserts have a maximum DOC of .200".✓See chart on page 15 for technical help on optimum feeds for button inserts.See page 19 for insert grade descriptions.See page 20 for recommended speeds/feeds.11

TOROID Modular Head Ordering InformationCarbide Core Modular Extensions<strong>Dapra</strong>'s Carbide Core Modular ExtensionsAre Ideal for Standard Inch End Mill Holders• Cylindrical inch shanks, providing adaptation for end millholders, milling chucks and heat-shrink holders• 3 sizes to accommodate modular head sizes from3 /4" to 1 1 /2"• Carbide core for enhanced vibration dampening capability;reduced deflection and improved rigidity• Optional add-on extensions for additional 2" reach –screw on to base extensions (for 3 /4" to 1 1 /2" modular heads)• Thru-coolant for delivery of air or coolant right at thecutting edgeCarbide Core Modular ExtensionsFor HeadDia.Extension Part No.ShankDia.EffectiveLengthOALThreadCCA.750"/20mm1.000"/25mm1.250"/1.500"CC-ME-0750-3500CCC-ME-1000-4500CCC-ME-1250-5500C1.000"1.000"1.250"3.7"4.7"5.7"6.0"7.0"8.0"M10M12M167/16" x 4.0"7/16" x 5.0"1/2" x 6.0".660".935"1.175"Extensions feature a cylindrical shank, with no Weldon Flats. Hold with high-performance milling chucksor heat/mechanical shrink holders, or mill Weldon Flats and use a short-length solid end mill holder.2" Add-On ExtensionsFor HeadDia.Extension Part No.EffectiveLengthThread.750"/20mm1.000"/25mm1.250"/1.500"ME-0750-2"C EXTENSION ADAPTERME-1000-2"C EXTENSION ADAPTERME-1250-2"C EXTENSION ADAPTER2.0"2.0"2.0"M10M12M16OALSee next pagefor standardline of ModularHeads andExtensions.EffectiveLengthAEffective LengthCarbide CoreShankThru-CoolantMountingThreadThru-CoolantH6 Tolerance Shank12

TOROID Modular Head Ordering InformationScrew-On Modular HeadsM (MOUNTING THREAD)EScrew-On Heads Fit Industry Standard Cutting Systems• Compatible with ISO standard modular systems• Greater effective reach than solid end mills• Close-tolerance mounting minimizes runout• Standard inch wrench flats – no special metric wrenches neededDIAIC(INSERTDIAMETER)"R"ValueDia.HolderM E IC FlutesToroid Screw-On HeadsWrenchInsertR3.750"TREM075-MOD-R3-2 †M101.50".375"29/16"See pg. 5R4 ‡1.000"TREM100-MOD-R4-2 ‡M121.50".500"211/16"See pg. 7R41.250"TREM125-MOD-R4-3M161.75".500"315/16"See pg. 7R4R61.500"1.500"TREM150-MOD-R4-3TREM150-MOD-R6-2M16M161.75"1.75".500".750"3215/16"15/16"See pg. 7See pg. 11† TREM075-MOD-R3-2 does not come with top clamp. ‡ Uses RDCH-43 / RPMH-44 / OPMH442 Inserts only.Heavy Metal Modular ExtensionsProvide Even More Cutting Options• Made of high-density tungsten, providingextra resistance to vibration and deflection• Machined on both ends; can be cut in halfand used with two different modular heads• Metric shank diameter provides clearancefor each inch size modular headModular ExtensionsModular Head Dia.Part No.OALMShank Dia..750" / 20mm.750" / 20mm1.000" / 25mm1.250"1.500"ME-0750-18MM-900ME-0750-18MM-900C*ME-1000-25MM-1100ME-125/150-25MM-1200ME-125/150-25MM-12009"9"11"12"12"M10M10M12M16M1618mm18mm25mm25mm25mm* Thru-coolant style13

TOROIDApplication InformationRecommendations• Tool is most appropriate for "Z-level" roughing;ramp to Depth of Cut (DOC) and clear entire level.• Plunging is not recommended with Toroidcutters when using RHINO-CARB inserts.Ramping (up to 5˚ max.) is recommended.• Minimum diametric plunging engagement is75% of cutter diameter (RDCH inserts only).• Try to maintain at least 75% of the cutter diameter onthe workpiece whenever possible. Hanging a cutteroff to the side of your work is detrimental to tool lifeand performance.• Width of Cut (WOC) should be 60-75% of cutter diameterwhenever possible, creating a "scalloping" effect (end mills only)between passes, especially with longer-length tools.• Plunging creates a long, continuous chip; use a peck cycle with full withdrawal to break andevacuate this chip when plunging to depths greater than .075" (RDCH inserts only).• Round inserts provide a very strong cutting edge and the ability to machine much closer tofinish size. Utilize high speeds and feeds with light DOC to take advantage of thesebenefits. High metal removal rates will be achieved without high horsepower consumption.• Use the Feed Rate Compensation charts on page 15 to compensate for chip thinning thatoccurs with Toroid inserts. This will provide for optimum metal removal rates and tool life;the lighter the DOC, the more critical feed compensation becomes.Technical Considerations• Always use anti-seize compoundon screws.• Change insert screw every 10 inserts.• Use the shortest-length tool holder (endmill holder) for maximum rigidity; the shankof the cutting tool should be up inside themachine spindle taper whenever possible.• Thoroughly clean pocket and screw ateach insert change.• Use tool holders appropriate for roughingoperations: end mill holders and powerchucks are recommended; collets are notrecommended.SafetyModern metal cutting techniques involve the potential use of very high operating parameters (speeds, feeds,depths of cut, etc.). This creates the potential for flying chips and debris, and can also create tool breakagedue to a variety of causes. As such, any metal cutting operation should be executed in a completely enclosed(shielded) environment to protect against injury from flying objects. <strong>Dapra</strong> does not assume responsibility forany loss, damage or expense incurred in any use or handling of our products after purchase.Grinding produces hazardous dust. To avoid adverse health effects, use adequate ventilation and read materialsafety data sheet first.14

TOROIDTroubleshooting & FormulasTroubleshootingConcernPossible CauseSolutionsConcernPossible CauseSolutionsInsert wearappears high(flank wear)-Not enough chip load-Surface footage ishigh-Incorrect grade orcoating-Verify correct speedand feed-Increase feed rate-Decrease RPM-Increase DOC-Use harder gradeBuilt-up edgeon insert-Low surface footage-Light chip load (feedper tooth)-Incorrect coating-Verify correct speedand feed-Increase cutting speed-Increase feed rate-Select different coating-Use coolantInsertchipping-Surface footage is low-Incorrect grade orcoating-Using dished insertincorrectly-Feed too high-Verify correct speedand feed-Increase spindlespeed-Decrease feed rate-Decrease DOC-Use T-Land insert-Use tougher gradePoor finish/chatterTool shankbreaks-Cutter hung out too far-Excessive runout-Inadequate toolholding-Tool pressure toogreat-Fatigued cutter body-Reduce tool gagelength-Check tool holder wear-Use high-rigidity toolholder-Decrease DOC-Reduce tool gagelength-Decrease feed rateFeed Rate Compensation (Round Inserts)After determining the desired chip thickness (FPT – see chart onback cover), find the insert diameter and Depth of Cut intersectionin the chart at right. Multiply the desired chip thickness by thefactor shown in the chart. This will be the Adjusted Feed per Tooth(AFPT), resulting in a true chip thickness of the desired amount.Example:If using a 1" Toroid end mill with the 1 /2" inserts @ .03" Depth ofCut (DOC), the factor for the chip thickness = 2.1.So, if a chip thickness of .005" is desired, a feed rate of .0105"(.005 x 2.1) needs to be programmed into the machine tool.orAdjusted Feed per Tooth (AFPT) = chip thickness x chip thinning factor(from chart)Depth of Cut (DOC)0.0050.0100.0150.0200.0250.0300.0350.0400.0500.0600.0750.0850.1000.1250.1500.1800.200>0.20Insert Diameter3 /8"4.43.12.62.221.81.71.61.51.41.31.21.11.1NRNRNRNR1 /2"53.62.92.62.32.121.81.71.51.41.31.31.21.1NRNRNR5 /8"5.643.32.82.62.32.221.81.71.51.51.41.31.21.1NRNR3 /4"6.14.43.63.12.82.62.42.221.81.71.61.51.31.31.21.1NRCompensation for 45˚ Lead Angle (Octagonal Inserts)For all Depths of Cut:Multiply desired chip thickness by 1.4 forAdjusted (programmed) Feed per Tooth (AFPT).Example: For .007" chip thickness, feed @ .010"(.007 x 1.4 = .010)15

TOROIDApplication InformationHole Diameter CalculationShell MillPart NumberTRSM200-075-R4-4TRSM200-075-R5-3TRSM250-100-R5-4TRSM300-100-R4-6TRSM300-100-R5-5TRSM400-150-R4-7TRSM400-150-R5-6MinimumHole Dia.3.25"3.06"4.06"5.25"5.06"7.25"7.06"Formulas:Minimum Hole Dia.:(Tool Dia. x 2) - (1.5 x Insert Dia.)Maximum Hole Dia.*:Tool Dia. x 2MaximumHole Dia.*4.00"4.00"5.00"6.00"6.00"8.00"8.00"* Not generally recommended. At this diameter,the center tip is at its maximum. It is suggestedthat you stay slightly under this number.Helical Interpolation for Larger Diameter Hole MakingLarger diameter hole making canbe quick and easy when a ToroidCutter is used in combination withhelical interpolation. Thistechnique resembles thread millingin that all three axes (X, Y and Z)are in motion simultaneously. Itdiffers from thread milling in thatthe tool is introduced into thematerial without a start hole of anykind. The tool simply is positionedat the inside diameter of the holeto begin its helix from there, achieving complete materialremoval from the hole by ramping down to the final depth. Thissmooth operation tends to avoid the high horsepowerconsumption characteristic of large diameter hole making. Andwith the high clearance angles of Toroid cutting tools, rampangles during helical interpolation can be aggressive, withoutconcern for rubbing the bottom of the cutting edge. This quickand easy process offers the added advantage of allowingmany different hole sizes to be generated with the samediameter tool. Hole size variation is all in the programming.For more information on how helical interpolation canimprove your manufacturing efficiency, contact your <strong>Dapra</strong>Applications Specialist.16

TOROIDMetric Ordering InformationSODMetric End Mills (“C” designates a thru-coolant tool)32mm shank dia. cutters and smaller are available in limited supply without Weldon Flats.Add WOF to the end of the part number when ordering.HolderR L S FlutesDiameter Effective Length Overall Length Shank Dia.InsertLR20mm20mm25mm25mm25mm25mm25mm32mm32mmTREM20-50-R5-2 †TREM20-75-R5-2C †TREM25-65-R5-2C †TREM25-65-R5-3 †TREM25-115-R5-3 †TREM25-65-R6-2TREM25-115-R6-2TREM32-75-R6-2TREM32-130-R6-250mm75mm65mm65mm115mm65mm115mm75mm130mm103mm128mm121mm121mm171mm121mm171mm133mm184mm20mm20mm25mm25mm25mm25mm25mm32mm32mm222332222RDCH10RDCH10RDCH10RDCH10RDCH10RDCH12RDCH12RDCH12RDCH12OD† Does not come with top clamps.M (MOUNTING THREAD)Metric Screw-On Modular HeadsDia.HolderMEICFlutesInsertE20mm25mmTREM20-MOD-R5-2C †TREM25-MOD-R5-2C †M10M1238mm38mm10mm10mm22RDCH10RDCH10DIAIC(INSERTDIAMETER)Modular Extensions also available - see page 13 for available sizes.† Does not come with top clamps.BMetric Shell MillsRODDiameterHolderREffective LengthBArbor Dia.HCounter Bore Dia.FlutesMountingScrewInsertHOD50mm63mm80mmTRSM50-22-R6-4TRSM63-27-R6-5TRSM80-27-R6-638mm50mm50mm22mm27mm27mm10.4mm12.4mm12.4mm456M10M12M12RDCH12RDCH12RDCH12“T” inserts have a reinforcedcutting edge for steels, ironsand hard milling“D” inserts have a high-positivecutting edge for stainless steels,high-temperature alloys andgummy materialsMetric InsertsInsert Diameter Uncoated CoatedDMK30DMP25DMK15DMK30-HPDMP25-HPDMK15-HPDMK307DMP257DMK157DMK30-GLHDMP25-GLHDMK15-GLHStocked standardPressedRDCH-10-TRDCH-10-DRDCH-12-TRDCH-12-D10mm10mm12mm12mm17

TOROIDSpare Parts & ToolsTRS-3 TRS-4 TRS-4L TRS-6T-8F T-15T T-20TTRS-4CLTRS-5CLTC-4TC-4-NTC-6TC-6-NSpare Parts & ToolsPart NumberR3R4R5R6Spare Parts & ToolsInsert Screw: TRS-3Top Clamp Screw: N/ATop Clamps: N/AWrench: T-8FTorque: 12-15 in-lbsNew Clamp Screw: TRS-4CLInsert Screw: TRS-4Old Clamp Screw: TRS-4LOld Top Clamps: TC-4, TC-4-NWrench: T-15TTorque: 30-35 in-lbsNew Clamp Screw: TRS-5CLInsert Screw: TRS-6Old Clamp Screw: TRS-6Old Top Clamps: TC-6, TC-6-NWrench: T-20TTorque: 40-50 in-lbsAll listed tools use Anti-Seize Grease ASG-120New cutter bodies may require additional torque to fully seat the inserts. Once the new cutter’spockets are “broken in,” the recommended torque specs in the chart can be followed regularly.TRS-3 TRS-4 TRS-4LT-8FT-15TTRS-4CLTC-4Metric Spare Parts & ToolsPart NumberR5R6Spare Parts & ToolsInsert Screw: TRS-3Top Clamp Screw: N/ATop Clamps: N/AWrench: T-8FTorque: 1.5-1.7 nMNew Clamp Screw: TRS-4CLInsert Screw: TRS-4Old Clamp Screw: TRS-4LOld Top Clamp: TC-4Wrench: T-15TTorque: 3.5-4.0 nMAll listed tools use Anti-Seize Grease ASG-12018

TOROIDInsert Grade SelectionShock & WearResistanceTOUGHESTShockResistanceMEDIUMShockand WearMEDIUMShockand WearHARDESTWearResistanceUncoated(Base Grade)DMK30DMK25 †DMP25DMK15withCoatingDMK303DMK30-HPDMK307DMK30-GLHDMK253DMK25-HPDMK257DMK25-GLHDMP253DMP25-HPDMP257DMP25-GLHDMK153DMK15-HPDMK157DMK15-GLHDescriptionModerate wear resistance/high shock resistance. Recommended forinterrupted or unstable steel, most 300 series stainless steel, hightemperaturealloys and cast iron applications.PVD TiCN coating. Excellent wear resistance for low-to-mediumoperating temperatures.High-performance medium-temperature grade. Optimum performance andwear resistance in most soft steels, soft stainless steels and cast irons.PVD AlTiN coating. For higher-temp. applications including tougherstainless steels, high-temperature alloys and higher-speed machining.Premium high-temperature coating. Best resistance to heat for high-shockapplications. Excellent for tough stainless steels, high-temperature alloysand many tool steels.Micro-grain carbide providing higher wear resistance and good shockresistance for applications in tough stainless steels, high-temperaturealloys, irons and many tool steels.PVD TiCN coating. Excellent wear resistance for low-to-mediumoperating temperatures.High-performance medium-temperature grade. Optimum performance andwear resistance in most soft steels, soft stainless steels and cast irons.PVD AlTiN coating. For higher-temperature applications including highspeedmachining and heat-treated materials < 44 Rc.Premium high-temperature coating. Outstanding performance and wearresistance in high-heat applications involving tough stainless steels, hightemperaturealloys and many tool steels.High wear resistance/moderate shock resistance. Recommendedfor most steel and 400 series stainless steel applications.PVD TiCN coating. Excellent wear resistance for low-to-mediumoperating temperatures.High-performance medium-temperature grade. Optimum performance andwear resistance in most soft steels and cast irons.PVD AlTiN coating. For higher-temperature applications including highspeedmachining and heat-treated materials < 44 Rc.Premium high-temperature grade. Unbeatable performance and wearresistance in high-heat applications such as higher speed machining insteels (< 44 Rc) and ductile irons.Highest wear resistance with reduced shock absorption capabilities.Micro-grain carbide provides excellent edge strength for abrasiveapplications in nonferrous materials. Suitable for castings, aluminum andsmoother cuts in tough stainless steels, high-temperature alloys andhardened steel.PVD TiCN coating. Excellent wear resistance for low-to-medium operatingtemperatures. Good resistance to built-up edge for aluminum machining.High-performance medium-temperature grade. Optimum performance andwear resistance in most soft steels, soft stainless steels and cast irons.PVD AlTiN coating. Appropriate for higher-temperature applicationssuch as high-velocity cast iron machining, tough stainless steels,high-temperature alloys and hardened steel.Premium high-temperature grade. Unbeatable performance andwear resistance in high-heat applications such as harder steels, toughstainless steels and high-temperature alloys.SpecificationsANSI C1-C2ISO K25-K40,M25-M35ANSI C2-C3ISO K15-K30M15-M30ANSI C5-C6ISO P25-P40ANSI C2-C3ISO K15-K25,M15-M25DMK30-HP is a good first choice for most applications.Additional coatings available on request. Contact <strong>Dapra</strong> for details.† DMK25 substrate is available for RHINO-CARB D and N geometries only.19

Recommended Cutting SpeedsSpeeds andFeeds for<strong>Dapra</strong> ToroidCuttersTOUGHESTShock ResistanceMEDIUMShock & WearMEDIUMShock & WearHARDESTWear ResistanceLOWER TEMPSHIGHER TEMPSLOWER TEMPSHIGHER TEMPSLOWER TEMPSHIGHER TEMPSLOWER TEMPSHIGHER TEMPSDMK30DMK303DMK30-HPDMK307DMK30-GLHDMK25DMK253DMK25-HPDMK257DMK25-GLHDMP25DMP253DMP25-HPDMP257DMP25-GLHDMK15DMK153DMK15-HPDMK157DMK15-GLH1018,12L14,1041, 1045LOW-TO-MEDIUMCARBONSTEELS225-340300-525375-600450-675525-750340-600375-640450-750525-900600-1200340-600375-640450-750525-900600-1200450-750525-900600-12004140, 41504340, H13,P20, A2, D2TOOL STEELS,HIGH-ALLOYSTEELS(SOFT)190-300225-450300-525375-600375-675280-525300-600375-675450-750450-900280-525300-600375-675450-750450-900375-675450-750450-9004140, 41504340, H13,P20, A2, D2TOOL STEELS,HIGH-ALLOYSTEELS(HARDENED)145-280145-395145-280145-395145-395170-450303, 304LOW 400SERIESFREEMACHININGSTAINLESS115-225225-450375-600450-675450-825190-300300-525375-675450-800450-900190-300300-525375-675450-800450-900190-300300-525375-675450-800450-900316, 347, PHSTAINLESSTOUGHERSTAINLESSGRAY,MALLEABLE,DUCTILECASTIRONS6061,7075ALUMINUMALLOYSAMPCO,WEARITECOPPERALLOYSINCONEL,WASPALOY,MONELHIGH-TEMP.ALLOYS/TITANIUMPLASTICS,NON-FERROUS1 st CHOICE GEOMETRY N/D N/T T D/N D/N T/N D (Ground) D/N D/N D (Ground)RECOMMENDED IPT .006-.015 .006-.012 .003-.008 .004-.012 .003-.010 .006-.015 .005-.030 .005-.020 .003-.007 .005-.03095-190115-300190-375225-450225-600105-210125-330205-415250-495250-66095-190FINISHING115-300FINISHING190-375FINISHING225-450FINISHING225-600FINISHING300-450500-800600-900600-1200350-550500-765500-935500-1100350-550DUCTILE500-765DUCTILE500-935DUCTILE500-1100DUCTILE350-600GRAY600-765GRAY700-935GRAY800-1100GRAY1000+1000+1000+1000+200-600400-1200200-600400-1200200-600400-800400-900400-120050-150ROUGHING50-150ROUGHING50-200ROUGHING50-250ROUGHING55-16555-16560-20060-25050-150FINISHING50-200FINISHING50-250FINISHING50-150FINISHING50-250FINISHING50-250FINISHING75-250FINISHING75-350FINISHING1000+1000+1000+1000+1000+1000+1000+1000+1000+1000+1000+1000+1000+1000+1000+** Best choice for material shown in bold textThe parameters provided are suggested operating parameters. Actual speeds and feeds will depend on manyvariables, such as rigidity, workpiece hardness, tool extension, machine accuracy, Depth of Cut, etc. Start at themiddle of the SFM range and the low end of the FPT range. Next, increase FPT to optimize productivity and tool life.Higher SFM will provide higher output but may reduce tool life. Try different combinations to find the parameters thatbest suit your needs.• The -3 and -HP coatings are best suited for low to medium operating speeds (temperatures) and softer materials.• The -7 and GLH coatings are best suited for high operating speeds (temperatures) and harder materials.† DMK25 substrate is available for RHINO-CARB D and N geometries only.<strong>Dapra</strong> Toroidproducts aremade in the USA.Bringing Better Ideas to the Cutting Edge 66 Granby Street, Bloomfield, CT 06002800-243-3344 • 860-242-8539 • Fax 860-242-3017Email info@dapra.com • www.dapra.com© Copyright 2012 <strong>Dapra</strong> <strong>Corporation</strong> 04-12-5M