P385 Asphalt Paver Features - Weiler Products

P385 Asphalt Paver Features - Weiler Products

P385 Asphalt Paver Features - Weiler Products

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

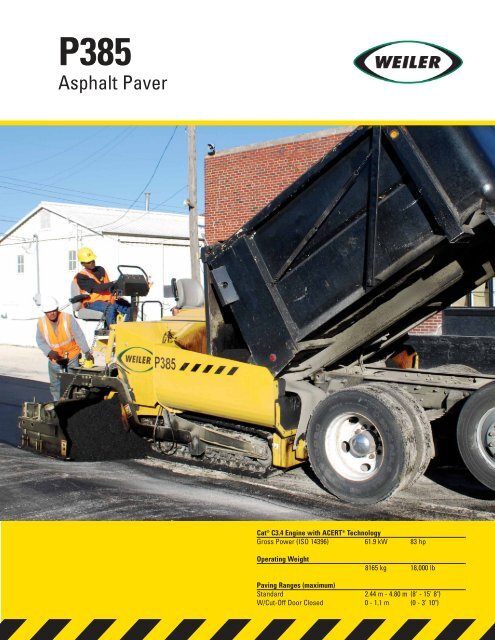

<strong>P385</strong> <strong>Asphalt</strong> <strong>Paver</strong> <strong>Features</strong>Balanced design delivers versatility and durability.UNMATCHED PRODUCTIVITY• Compact balanced weight of 8165 kg (18,000 lb) allows for easytransport with other job site equipment• Independent control of the left and right side of the feedersystem enables variable width paving• Pause mode maintains settings for easy restarts• 6-position adjustable push-roller, easily adapts to trucking fleets• 9 ton hopper capacity, best in classSCREED VERSATILITY• Hydraulically extendable paving range of 2.44 m - 4.80 m (8' - 15' 8")• Cutoff doors provide a paving range of 0 - 1.1 m (0 - 3' 10")• Rigid electric screed, excellent stability• Optional remote for tow-point, extender width, and feeder system override• Foldable rear walkway with optional sliding extensions optimize visibility• Grade and Slope Control option for automatic height control• Extender height adjusters, match main screed height• Angle of attack adjusters on main screed and extensions2

EXCEPTIONAL VISIBILITY AND CONTROL• Three different operating positions, top, mid-level, and screed,optimize visibility and crew requirements• Individual cut-off doors prevent spillage and limit cleanup, theycan be set to automatically close when reversing direction• Electronic controller keeps operator informed of machineoperating conditionsDURABLE UNDERCARRIAGE• Track length of 2.3 m (90"), best in class• 89 m/min (294 fpm) travel speed for quickmobility around the job site• 6 track rollers per side ensure smooth operation• 355 mm (14") track pads deliver traction, stabilityand long life performance• Automatic track tensioning ensures performancewhile maximizing component life• “Best in Class” chain pitch of 140 mm (5.5")delivers maximum track lifeEXCELLENT SERVICEABILITY• Cat ® Dealer sales, service and support• Electronic controller provides diagnostic capability• Replaceable hopper floor plates, maximize paver life• Manual overrides on hydraulics, ensure jobs are completed• Visual indicators for routine service checks• Large access doors simplify maintenance3

Powerful Cat ® C3.4 EngineHaul trucks and inclines are no match.QUIET POWER, LOWER EMISSIONSThe Cat C3.4 engine with ACERT Technology is a turbo-charged,four-cylinder, diesel engine that provides a gross power of 61.9 kW(83 hp) and meets U.S. EPA Tier 3 and E.U. Stage IIIA engineemission standards. Quiet power and lower emissions ensureminimal job site disturbance when working in residential areas andbusiness developments.The 12-volt alternator and main valve body can beaccessed through the front engine access panelCAT C3.4 ENGINE HIGHLIGHTS– Single side service to engine oil filter and air cleaner– Electronic shut off solenoid– Belt-driven coolant pump– 17% torque back-up ensures performance in tough conditions– Efficient air cleaner with visual indicator keeps operatorinformed of condition4

Durable Track UndercarriageLarge footprint delivers optimal traction.“Best in Class” TrackLength 2.29 m (90”)UNDERCARRIAGE FEATURESQuick mobility around the job site combined with low speedprecision near obstacles maximizes performance for efficientoperation. The large ground contact area optimizes tractionwhen pushing trucks and working on inclines.THREE SPEED HYDROSTATIC DRIVE– Three speed hydrostatic drive delivers a travel speed of89 m/min (294 fpm) for quick transport to the next startingposition– Automatic track tensioning ensures performance whilemaximizing component life– Propel override switches for the hydraulic system ensurepaver mobilitySTEEL TRACK UNDERCARRIAGE– “Best in Class” 2.29 m (90”) track length with 1.72 m (68”) ofground contact provides smooth ride and excellent flotationon all types of base materials– The large 356 mm (14”) enhanced performance track padsensure long-term performance and easy replacement– Six track roller per side deliver smooth operation andminimize wear– Track chains are designed with a 140 mm (5.51") pitch inorder to optimize ride5

Operating EnvironmentMultiple operating positions to suit your crew.OPTIMAL VISIBILITY AND COMFORTGood visibility and comfort enable effective communicationthat leads to smooth truck exchanges and steady materialflow throughout the day. The standard operating environmentincludes two consoles and a single seat. The consoles canbe positioned in three different locations around the tractor andscreed.FRIENDLY WORKING ENVIRONMENT– Electric screed heat eliminates propane fumes and promotescleaner working conditions for the crew– Low profile exhaust promotes good forward visibility andlowers sound levels– Large capacity cooling system directs air away from theoperatorCHOICE OF OPERATING POSITIONS– Three different operating positions maximize crewrequirements– Top position provides good visibility into the hopper andoptimizes communication with the truck driver– The mid-level position enables clear views to the augerchamber and screed– The screed level position allows a single operator to controlpaver and screed functions from the screed walkway orground level– Tools are not required to move stations6

Complete ControlQuick setup enables the crew to optimize performance.INTUITIVE CONTROLS– The dual operating stations offer grouped controls for mix deliveryand speed control, maximizing operator efficiency– The consoles maintain a similar layout that allows the operator toquickly move from side to side when working in close proximity tocurbs, pillars and other obstacles– Controls are automated, well labeled, and grouped by functionmaking operation more efficient– LCD display keeps operator informed of machine conditions anddelivers diagnostic information for service personnel– Unique “pause mode”, interrupts mix delivery and enables returnto the same settings when resuming operation– Dual joystick operation enables precise control when working nextto obstaclesElectronic controller provides instant feedback onsystem hydraulic pressures, ground speed, enginemonitoring as well as system calibrations andtrouble-shooting7

Smooth DeliveryHigh capacity delivery system optimizes material flow.RETURN ON INVESTMENT– “Best in Class” hopper capacity of 3.8 m 3 (135 ft 3 ) promotesefficient operation– Replaceable floor plates with bolt-on design maximize paverlife and lower lifetime operating costs– Heavy-duty chains and flight bars provide long-term reliability– Narrow chain guards minimize drag for smooth mix flow– Rounded hopper design simplifies clean-out– Large Ni-hard augers with diameter of 355 mm (14") providesmooth mix delivery and best in class performancetr1. Replaceable Floor Plates2. Narrow Chain Guards3. Heavy-duty Flight Bars and Chains4. Rounded Hopper Design5. Front Engine Access6. Adjustable Push RollerqweThe push roller with center pivotoffers five different positions thatcan be tailored to match yourtrucking fleet.yHigh ground clearance for workingover manholes and curbs.254 mm (10")8

Precise ControlAutomated systems optimize efficiency.MINIMIZE CLEANUP AND MAXIMIZE PAVING CAPABILITY– Independent control of each side of the delivery system enables variable width paving– Cut-off doors enable a narrow paving range of 0 - 1.1 m (0 - 3' 10")– Cut-off doors limit spillage and automatically close when reversing travel direction– Independent hopper control for paving close to buildings and obstaclesui7. Independent Mix Delivery8. Independent Cut-off Doors9. Auger Bearing Lubricationo9

Vibratory Screed <strong>Features</strong>Multiple adjustments and wide paving range maximize performance.ELECTRIC SCREED HEAT– Electrically heated screed plates powered by atractor-mounted 9 kW generator produce even heat– Four heating elements ensure consistent temperaturethroughout the screed plates, two on main screed, one oneach extender– 8 mm (3/8") thick screed plates deliver long life andreduce lifetime operating costsREMOTE PENDENT CONTROLS– Remote pendent with magnetic mount includes tow pointheight adjustment, extender width, and auger overrideadjustments for complete control from the screed orground levelOPERATOR FRIENDLY FEATURES– Grade and slope controls optimize mat quality– Folding rear walkway enables close positioning to curbs,buildings and other obstacles in order to minimize handwork– Optional walkway extensions easily slide out for improvedviews around the extenders– Sonic feed sensors deliver a consistent head of materialleading to quality mats– Oversized height adjustment screws optimize performanceand minimize operator fatigue– Washdown system includes 30 L (8 gal) tank and twohoses/spray nozzles, one for each side of the machine1. Sonic Feed Sensors (standard)2. Angle of Attack (Extender)3. Angle of Attack (Main Screed)4. Extender Height Adjustment5. Crown Adjustment (manual)qerwt10

PAVING RANGE– Standard paving range, 2.44 m - 4.80 m (8' - 15' 8")– With cut-off doors closed 0 - 1.1 m (0 - 3' 10")APPLICATIONS– City streets, parking lots, cart paths, walkingpaths, trenches, patch work, etc.0 - 1.1 m (0 - 3' 10")Paving range withcutoff door closedyRemote Pendantui6. Integrated Sonic Sensor7. Adjustable End Gates8. Replaceable Wear Plates11

Fast ServiceLarge compartments and easy access simplify service requirements.LOCAL SALES, SERVICE, AND SUPPORT– <strong>Weiler</strong> products are sold and serviced exclusively throughCat ® dealers around the globe– Large service access doors, dealer inventoried replacementparts, remote grease lines, manual overrides on pumps andvalves are just a few of the features designed for easyservice– Customer input has always been the standard for design andengineering which leads to enhanced performance andsatisfied end-usersRELIABLE ELECTRICAL SYSTEM– Electrical system utilizes braided harnesses and sealedconnections for optimal reliability– Color-coded electrical wires with number identifiers makestrouble-shooting easier– 12-volt electrical system with automotive-type fusessimplifies service requirements12

qweuiyrtoLeft Side Service AccessRight side service access to the hydraulic system includingtank, valves, pumps and filter1. Power Disconnect Switch2. Automotive-Type Fuses3. 30 L (8 gal) Washdown Tank4. Dual-Side Wands with Single 7.6 m (25 ft)Retractable Hose Reel5. Fuel Tank Capacity of 83 L (22 gal)6. 12-Volt Electrical System7. Radiator Access8. Hydraulic Tank9. Hydraulic Filter10. Remote Grease Fittings11. Lockable Vandal CoveraRemote grease fittings for the conveyor bearingssimplifies daily serviceDURABLE COMPONENTS, EASY ACCESS– Replaceable floor plates in hopper; maximize life of the paver– Remote grease fittings are grouped for the front and rearconveyor bearings– Replaceable bushings in the tow-arms and extender tubesenable easy replacement for optimal screed performance– Electronic controller provides machine diagnostics for easycomponent calibration– Large access doors simplify maintenancesLockable vandal covers and engine access doors provideprotection13

Specifications<strong>P385</strong> <strong>Asphalt</strong> <strong>Paver</strong>Operating WeightTractor with Screed 8165 kg 18,000 lbScreed 1361 kg 3,000 lbMachine DimensionsLength 4000 mm (13' 2")Height 1778 mm (70")Transport Width 2591 mm (102")Hopper Width (inside) 2997 mm (118")Track Length 2286 mm (90")Standard Equipment• Adjustable Push Roller• Dual Operating Consoles with Single Seat• Electric Screed Heat• Foldable Screed Walkway• Hydrostatic Transmission (Three-Speed)• Individual Cut-Off Doors• Replaceable Hopper Floor Plates• Electronic Controller• Sonic Feed Sensors• Washdown System with Dual Spray Nozzles• 9 kW GeneratorCapacitiesFuel 83 L (22 gal)Washdown Tank 30 L (8 gal)Hopper 8 Metric Tons (9 Tons)Paving RangeMaximum Range 2.44 m - 4.78 m 8' - 15' 8"With Cut-off Doors Closed 0 -1.1 m 0 - 3' 10"Optional Equipment• Grade and Slope Automation• Lighting Group (working)• Remote Screed Pendant• Screed Walkway Extensions• Seat (additional)• Truck Hitch• Warning Beacon14

<strong>Weiler</strong> Paving SolutionsRemixing Transfer Vehicles E1250A E2850Engine Cat C7 Cat C9Power 186.4 kW (250 hp) 223.7 kW (300 hp)Weight 23 133 kg (51,000 lb) 33 792 kg (74,500 lb)Height 3.51 m (11' 6") 3.54 m (11' 4")Length (shipping) 13.7 m (45') 16.8 m (55' 3")Windrow ElevatorsE550AE650AEngine Cat C4.4 Cat C4.4Power 85 kW (114 hp) 85 kW (114 hp)Weight 6849 kg (15,100 lb) 7985 kg (17,600 lb)Height 2946 mm (116") 2946 mm (116")Length 5283 mm (208") 5283 mm (208")Road WidenerW330 W430 W530 W730Engine Cat C2.2 Cat C3.4 Cat C4.4 Cat C6.6Power 36 kW (49 hp) 62 kW (83 hp) 85 kW (114 hp) 130 kW (174 hp)Weight 5545 kg 8391 kg 8845 kg 15 195 kg(12,200 lb) (18,500 lb) (19,500 lb) (33,500 lb)Max. Spread Width 1.8 m (6') 2.4 m (8') 3.0 m (10') 4.3 m (14')SpeedWorking 0-46 mpm 198 mpm 222 mpm 106 mpm0-150 fpm 0-650 fpm 0-730 fpm 0-350 fpmTransport 12.8 km/hr 17.7 km/hr 25.7 km/hr 22.5 km/hr8 mph 11 mph 16 mph 14 mph15

W<strong>P385</strong>SP-00 (3/11)© 2011 <strong>Weiler</strong>Materials and specifications are subject to change without notice. Featured machines and photos may include optional equipment.See your Cat Dealer for available options.SIMPLE. PROVEN. POWERFUL.