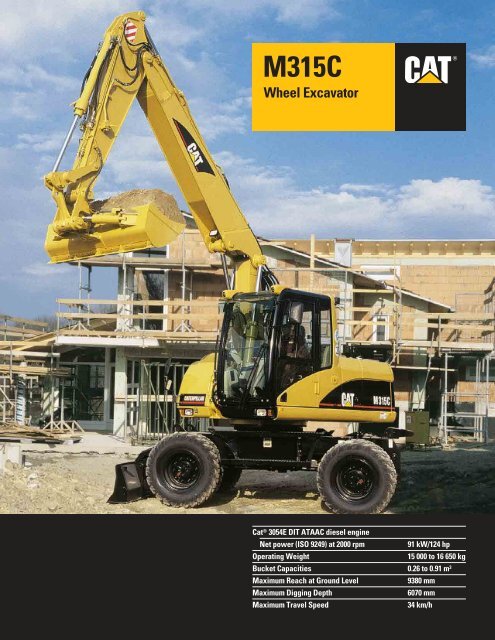

M315C Wheel Excavator - Unimaq

M315C Wheel Excavator - Unimaq

M315C Wheel Excavator - Unimaq

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Cat 3054E DIT ATAAC EngineThe four-cylinder, turbocharged, air-to-air aftercooled and electronically controlled engineis built for power, reliability, low maintenance, excellent fuel economy and low emissions.Powerful Performance. The 3054EDIT ATAAC engine delivers a netpower of 91 kW (124 hp) at the ratedspeed of 2000 rpm, and meets allcurrent worldwide emission standards.Turbocharged and Air-to-AirAftercooled. The turbocharger packsmore dense air into the cylinders formore complete combustion and loweremission improving performanceand engine efficiency. These benefitsare especially useful at high altitudes.The air-to-air aftercooler reducessmoke and emissions by providinga cooler inlet air for more efficientcombustion. This also extends the lifeof the piston rings and engine bore.Cooling System. Features an electronicallycontrolled variable speed on-demand fan.A hydraulic motor drives the fan and itsspeed is determined by engine coolant andhydraulic oil. Cooler operating conditionsallow lower average fan speeds resulting inreduced fuel consumption and lower noiselevels. The electronic engine controlcontinuously compensates for this varyingfan load, providing consistent nethorsepower, regardless of operatingconditions. The fan and air conditionercondenser are both hinged for easiercleaning of the cores.Engine Oil. Caterpillar engine oil isformulated to optimize engine life andperformance and is strongly recommendedfor use in Cat diesel engines.The engine oil change interval is increasedto 500 hours.Low Sound, Low Vibration.The 3054E design improves operatorcomfort by reducing sound and vibration.The <strong>M315C</strong> has been awarded the GermanBlue Angel for low operator and spectatorsound levels. Operator sound level, L PA , 71 dB(A) Spectator sound level, L WA 101 dB(A)Factory Remanufactured Parts. A largechoice of factory remanufactured partsand dealer proposed repair options increasemachine availability and reduce totalrepair costs.Fuel Injection Pump. The new injectionpump is electronically controlled and helpsto reduce fuel consumption.Service. The engine is longitudinallymounted on the right side to make it easierto access the oil filter, oil filler, oil drainvalve, fuel filter, V-belt tightener,and the oil dipstick. All are accessiblefrom ground level.4

HydraulicsFast cycle times, increased lift capacity and high bucket and stick forces combine to maximizeyour productivity in any job.Automatic Engine Control. AutomaticEngine Control (AEC) reduces engine rpmif no operation is performed, maximizingfuel efficiency and reducing sound levels.Dedicated Swing Pump. A separatededicated variable displacement pistonpump and fixed displacement piston motorpower the swing mechanism. This closedhydraulic circuit helps to provide maximumswing performance without reducing powerto the main hydraulic functions.Caterpillar’s XT-6 ES Hoses. To meet thecritical flexibility and strength demandsof wheel excavator applications, XT-6 EShoses are installed in the high pressurehydraulic system. XT-6 ES hoses are madeof four overlapping insulated wire spiralwraps bonded together for high abrasionresistance, excellent flexibility and easyinstallation. Hose routings are designed toprotect from damage in this way reducinghose failure downtime. O-ring face sealcouplings provide positive sealing forreliable and leak-free connections.Auxiliary Hydraulic Valves. The versatilityof the hydraulic system can be expandedwith multiple valve options.Multifunction Valve. The multifunction valveis the core of the innovative Tool Controlsystem. This valve can be electronicallyprogrammed for flow direction (one or twoways), pressure and flow rate. The valvealso features priority flow to maximizecontrol of the work tool. This on-boardelectro-hydraulic functionality eliminatesthe need for manual readjustments to theauxiliary hydraulics each time a differenttool is used.Hammer. The dedicated hammer valveis the best option for machines which willonly require a hammer tool and do notneed the flexibility provided by the multifunctionvalve.Hydraulic Cylinder Snubbers.The hydraulic cylinder snubbers atthe rod end of boom cylinders, both endsof stick cylinders and bucket cylinderrod end cushion shocks, reduce soundand increase cylinder life, keeping themachine working longer.Caterpillar ® Hydraulic Oil.Maximum protection against mechanicaland corrosive wear in all hydraulic systems.Its high zinc content reduces wear andextends pump life. Provided certainrequirements are met (e.g. S•O•S analysisevery 500 hours), the hydraulic oil changeinterval is extended from 2000 hours to4000 hours.Controllability. The hydraulic systemoffers precise control of the <strong>M315C</strong>,reducing operator fatigue and improvingeffectiveness.Stick Regeneration Circuit. Stick regenerationcircuits increase efficiency andhelp increase controllability for higherproductivity and lower operating costs.Adjustable Hydraulic Sensitivity.It allows the operator to adjustthe aggressiveness of the machineaccording to needs. For precisionwork, one of four different levels ofaggressiveness can be pre-selectedon the soft-switch panel. Increasedsensitivity can then be quicklyactivated and deactivated during thework cycle by using the joysticks.Proportional Medium Pressure.The unique Cat proportional slidingswitches provide modulation to themedium pressure circuit and bettercontrol for attachments and work tools.They are ideal for tilting buckets androtating tools. They enable the operatorto select exactly how much movementis required and subsequentlyvary this throughout the operation.5

Environmentally Responsible DesignCaterpillar machines not only help you build a better world, they help maintain and preservethe fragile environment.More Performance. The <strong>M315C</strong> isdesigned for outstanding performancewith high fuel efficiency. This meansmore work done in a day, less fuelconsumed and minimal impact on ourenvironment.Low Exhaust Emissions. The Cat 3054Eused in the <strong>M315C</strong> is a low emissionengine designed to meet EU Stage IIOff-Highway and US EPA Tier IIemission regulations.Quiet Operation. The noise level insidethe cab and as well the outside spectatorsound are extremely low. As a result ofthe new variable speed fan and remotecooling system all machines meet theGerman Blue Angel award for lowsound operation.Ozone Protection. To help protectthe earth’s ozone layer, the <strong>M315C</strong>’sair conditioning unit uses only R-134arefrigerant which does not containharmful chlorofluorocarbons (CFC’s).Biodegradable Hydraulic Oil.Available as an option, CaterpillarBiodegradable Hydraulic Oil (HEES TM )is formulated from a fully saturatedHydraulic Environmental with EsterSynthetic base stock and selectedadditives. It has excellent high-pressureand high-temperature characteristics andis fully compatible with our hydrauliccomponents and allows operation overa broad temperature range. Cat’s HEESis fully decomposed by soil or watermicroorganisms, providing a moreenvironmentally-sound alternative tomineral-based oils. This is availableas an attachment.Fewer Leaks and Spills. Lubricantfillers and drains are designed tominimize spills. Cat O-Ring Face Seals,XT Hose and hydraulic cylinders are alldesigned to help prevent fluid leaks thatcan reduce the machine performanceand cause harm to the environment.Longer Service Intervals. 500-hourengine service intervals and CatExtended Life Coolant/Antifreezemean that fluid renewal and disposalare less frequent.6

Ease of Operation and Enhanced ProductivityDesigned for simple, easy operation, the <strong>M315C</strong> allows the operator to focuson production.WEX Multipro. New, compact Multiproenhances viewing while displayinga variety of easy-to-read andunderstandable information invarious languages.Pre-start WEX Multipro System.The Pre-start Multipro system alertsthe operator of low coolant or hydraulicoil levels, before starting the engine.When the engine key remains in the“ON” position for more than 2 seconds,a warning indicator and message aredisplayed if actual fluid levels are lowerthan required.Filter and Oil Change Warnings.The filter and oil change warningsare displayed when the number of hoursused reaches the maintenance interval.Languages. 23 different languages areavailable on the <strong>M315C</strong>.Power Modes. There are three powermode settings. The operator can choosethe best power setting for both engineand hydraulic power versus fuelefficiency.Economy Mode. The economy modeis often used for lifting, pipe setting,grading, slope finishing and precisework. This mode helps ensure minimumfuel consumption.Power Mode. This mode is used fornormal truck loading and diggingapplications, trenching or hammer use.Travel Mode. The travel mode is automaticallyset when the travel pedal isactuated. It provides maximum speedand drawbar pull.Integrated Tool Control System.The integrated Tool Control systemallows the operator to quickly selecta tool out of five pre-set combinations,eliminating the need to reset thesehydraulic parameters each time a toolis changed. Specific flow and pressurecan be programmed easily as well asone-way/two-way hydraulic functions.Each of the five programmed toolscan even be given a specific name.Joystick Steering. It allows the operatorto reposition the machine in the firstgear and work simultaneously withthe implements, keeping both hands onthe joysticks. The operator is able to domore precise work in a shorter amountof time. This provides increased safetyfor all people working around themachine by removing the need forthe operator to move their hands backto the steering wheel for maneuvering.7

All-day operator comfortThe <strong>M315C</strong> interior layout maximizes operator space, provides exceptional comfortand reduces operator fatigue.8

Interior Operator Station. The <strong>M315C</strong>operator work station is quiet, controls havebeen placed conveniently for easy adjustmentand ease of operation. The seat design isergonomic and ventilation is highly effective.Seat. The wheel excavator seat with two-tonecolor design offers adjustable back rest,lumbar support, cushion length and cushionangle. Independently adjustable armrests andpilot controls allow tailored ergonomics tosuit operator preference. Optional Comfortseat provides air suspension, seat heating,horizontal suspension and automatic adjustmentfor the operator’s weight to helpmaximize comfort.Consoles. Designed for simplicity andfunctionality, the left side console is tiltablefor excellent access to the cab.Dozer blade and/or outrigger controlsas well as the radio-off switch are locatedon the left console.Automatic Climate Control. Fully automaticclimate control adjusts temperature andair flow.Greater Control Convenience. Each controlis placed within easy reach of the operator.Joysticks control all attachments and swingfunctions and can also be used to steerthe machine and to activate the adjustablehydraulic sensitivity. By means of the softswitch panel, which is placed to be easilyreached, the operator controls the oscillatingaxle, power modes, parking brake, automaticengine speed control and other hydraulicfunctions.Cab Mounts. The cab shell is attached tothe frame with resilient mounts, reducingvibration and sound.Foot Pedals. Two-way pedals for the traveland auxiliary circuits give more floor spaceand reduce the need to change positions.The foot pedal for the auxiliary high-pressurecircuit can now be locked in the off positionto be used as a footrest for greater operatorcomfort.Skylight. A unique large polycarbonateskylight provides excellent upwardvisibility.Viewing Area. There is excellent viewingarea through wide windows. The lowerof the two-piece window can be openedseparately for better air ventilation orbe slid into the upper window to completelyopen the front bay. An optional one-piecewindow is available.Wipers. Designed to maximize visibilityin poor weather conditions. The parallelwiper system covers almost the completefront window without leaving unwipedareas in the immediate line of sight ofthe operator.Large Storage Compartment. Locatedbehind the seat, provides sufficient room.An optional cover is available to close offthe storage space if preferred.Easy Access. Conveniently located grabirons and large steps mounted to theundercarriage, together with the tiltablesteering column and the tiltable left sideconsole, provide easy access to the cab.9

Undercarriage and Drive LineUndercarriage and axle design provides maximum strength, flexibility and mobilityon wheels.Strong Undercarriage. The welded frame provides excellentrigidity and long life. Efficient hydraulic lines routing,transmission protection and heavy-duty axles makethe undercarriage perfect for wheel excavator applications.Both outriggers and dozer blade are pin-on for maximumflexibility.New Drive Line Concept. The new travel motor andtransmission control in the drive line provide morecomfortable travel due to increased smoothness,improved hydraulic braking and improved gear shifting.Travel Motor. The advanced travel motor gives higherhydraulic braking forces particularly in downhill roading bycontinuously using the optimal displacement of the travelmotor for braking. Braking characteristics can be adjusted tothe operator’s preferred level of aggressiveness in three steps.Transmission Control. The intelligent implementation of theengine torque curves in an optimized gear shifting processreduces uphill travel time, particularly in hilly areas.Heavy Duty Axles. The front axle offers great oscillating andsteering angles. The transmission is mounted directly on therear axle for protection and optimum ground clearance.Advanced Disc Brake System. The new disc brake system actsdirectly on the hub instead of the drive shaft to avoid planetarygear backlash. This technical solution eliminates the rockingeffect associated with working free on wheels. The new axleis designed for low maintenance and lifetime costs. Oil changeintervals are increased from 1000 up to 2000 working hoursin order to further reduce owner and operator costs.Outriggers. Recommended for maximum operating stabilitywhen digging and lifting, the outriggers can be individuallycontrolled to level the machine on slopes. Featuring pin-ondesign, heavy-duty cylinder guards, and optimized kinematics,the outriggers can be mounted on the front, rear or on bothends of the machine.Dozer Blade. A useful addition for leveling and clean-up work,it can also be used to stabilize the machine during diggingapplications. The large dozer floor and the parallel designprovide minimal ground pressure reducing impact to the worksurface. Featuring a pin-on design, heavy-duty cylinderguards, and optimized kinematics, the dozer blade can bemounted either on the front or the rear end.Tool Box. A large sealed and lockable toolbox is mounted onthe undercarriage between the steps on the machine’s left side.A second optional toolbox is available for the right side.10

Booms and SticksImproved strength and kinematics help to bring higher production and efficiencyto all jobs.Booms and Sticks. Built for performanceand long service life, Caterpillar boomsand sticks are large, welded, box-sectionstructures with thick, multi-plate fabricationsin high-stress areas.Flexibility. The choice of three booms andfour different sticks means that the <strong>M315C</strong>offers the right combination of reach anddigging forces for all applications.Hydraulically Adjustable Boom (VA).The VA boom (5200 mm) offers improvedvisibility and machine roading balance.When working in tight quarters or liftingheavy loads, the VA boom offers the bestflexibility.One-piece Boom. The one-piece boom(5050 mm) fits best for all standardapplications such as truck loading anddigging. A unique straight section inthe curve of the side plate reduces stressflow and helps increase boom life.Offset Boom. The offset boom (5200 mm)adds a major advantage and a high levelof versatility to the machine, as the largeoffset dimensions (left/right 2460/2760 mm)allow you to dig along walls, over obstacles,to grade while driving, and to dig underlaid tubes without damaging them.The combination with a tiltable ditchcleaning bucket lets you operate a highlyversatile system.Sticks. Four different stick lengths are offeredto match different applications. Short stick (2100 mm) for maximumbreakout force and lifting capability Medium stick (2400 mm) as standardfor most applications Long stick (2600 mm) to match reachand depth requirements Industrial stick (3100 mm) for usewith free swinging grapples in materialhandling and industrial applications11

Buckets and TeethA wide variety of buckets help optimize machine performance. Purpose designed and built toCaterpillar’s high durability standards.Caterpillar K Seriesvertical tip retention1 2 3456Caterpillar K Series TM Tooth System10 11 12 1314 1516 17181 Excavation Bucket. Digs and loads softto medium materials such as clay and earth.Features weld on tip adapters, hardenedcutting edge and side bars.2 Extreme Excavation Bucket. Digs and loadscompact/abrasive materials like earth/rock,sand/clay, sand/gravel, coal, chalk and lowabrasion ores. Features abrasion resistantsteel for all wear parts.3 Skeleton Bucket. For soft and moist soilsand for applications where separationof materials, e.g., branches, peat moss,is required and for breaking up asphalt.Heavy Duty Skeleton Bucket. As standardskeleton bucket, but for more demandingapplications such as sorting rock from sandor gravel on demolition sites.4 Ditch Cleaning Bucket. Wide, lightbucket used mainly with long reachconfigurations to clean waterbedsand banks.5 Tiltable Ditch Cleaning Bucket.Wide, light hydraulically tiltable bucketfor ditch cleaning and slope finishingapplications.6 Trapezoidal Bucket. To prepareand maintain small irrigation ditches.Features angled sides to shape ditchbanks in one operation. Optionallyavailable with mechanically adjustableside angles.Pin-on version and Quick Couplers.All Cat buckets are available in bothquick coupler and pin-on version.Tip Selection. The newCaterpillar K Series ToothSystem holds tighter, changeseasier and stays sharper.10 General Duty11 Extra Duty12 Penetration13 Penetration Plus14 Heavy Penetration15 Heavy Abrasion16 Wide17 Spike18 Double Spike12

Tool Control System, Quick Couplers and Work ToolsUser-friendly, integrated electro-hydraulics make changing tools easy and quick andallow the operator to focus on efficient work.Tool Control. Five hydraulic pump flow and pressure settingscan be preset on the Multipro, eliminating the need to adjustthe hydraulics each time a tool is changed. Selecting the propersetting from the Multipro’s menu instantly provides the operatorwith the correct amount of flow and pressure for the tool.The unique Cat proportional sliding switches providemodulation to the tool and make precision work easy.Quick Couplers. Caterpillar Quick Couplers enable the operatorto simply release one work tool and pick up another. Yourhydraulic excavator becomes highly versatile. To suit yourbusiness and application needs, Caterpillar offers two differenttypes of Quick Couplers.CW-Series Dedicated Quick Coupler. The dedicated CW-Seriesquick coupler enables a quick tool exchange while maintainingtop machine performance. It is available ina hydraulic and spindle version. The hydraulic version is available ina standard and a narrow version andmakes it very easy for the operator toswitch tools without having to leavethe cab. The spindle version is a user-friendlymechanical version that can later be easily converted intothe hydraulic version if required. The spindle version is alsoavailable in the narrow and standard version.A lifting hook is added to the dedicated quick coupler formaximum lift capacity.A quick coupler hydraulic circuit for this CW-Series coupleris available factory installed.Pin Grabber Plus Quick Coupler. This hydraulically controlledPin Grabber Plus quick coupler makes changing buckets andother popular work tools simple and fast. The Pin Grabber Pluscoupler mounts to the end of the stick and allows buckets,clamshells and other work tools to be used with little or nomodification. Each model fully adjusts to different pin spreads of varioustools regardless of manufacturer – it is the only coupler thataccommodates a wide range of work tool makes and models. Pin-on assembly makes coupler installation and removal fastand easy. Coupler retains the same bucket opening and closing angles. Buckets can be reversed for greater flexibility when workingaround and under obstructions. Integrated lift eye.Pin Grabber Plus quick coupler hydraulic circuit for wheeledexcavators is available as a retrofit kit dedicated to this coupler.Ask your Cat dealer for more specific information.Multi-Processor. The Caterpillar Multi-Processors can beequipped with different jaw types depending on your need. CC-jaws combi cutter. CR-jaws concrete crusher. PP-jaws primary pulverizer. PS-jaws secondary pulverizer. S-jaws steel.Multi-Grapple. The Multi-Grapple with unlimited left and rightrotation is the ideal tool for stripping, sorting, handling and loading.Orange Peel Grapple. Specifically designed for handling scrap androck in recycling and transfer applications.Clamshell. For some trenching applications or jobs beingperformed on inner city roads, a clamshell provides an idealsolution. The free-swinging tool makes it possible to digsmall sized holes easily.Hammer. With their wide variety of tools, Cat hammers provide theperfect match for maximum life, efficiency and productivity.13

Maximum Uptime – Service and MaintenanceExtended service intervals and easy access reduce operating costs.Extended Service Intervals. <strong>M315C</strong>service and maintenance intervals havebeen extended to reduce machine servicetime, increase machine availability andreduce operating costs. Using S•O•Shydraulic oil change intervals can beextended from 2000 hours to 4000 hours.Engine coolant change intervals areup to 12 000 hours with using CatExtended Life Coolant/Anti-Freeze.Easy, Wide Open Access. Gull-wingdoors with pneumatically assisted liftcylinders lift up effortlessly forexcellent access to the engine and to allservice points. An additional toolboxlocated under the step leading to theupper platform offers clean, dry spacefor the operator.Storage Box. The upperstructure accessincorporates a sealed and lockablestorage box for personal belongingsof the operator.Easy to Clean Coolers. Flat fins onall coolers reduce clogging and makeit easier to remove debris.Ground Level Service. The design andlayout of the <strong>M315C</strong> was made withthe service technician in mind. The fuelwater separator, engine oil filter,battery, radiator fluid level, fuel filter,engine oil gauge, hydraulic oil level,air cleaner and pilot system filter areall easily accessible at ground levelallowing critical maintenance to bedone quickly and efficiently.Front Compartment. The front servicecompartment provides ground levelaccess to the batteries, ATAAC,AC condenser and the air filter.Swing-Up AC Condenser. Without usingtools, the AC condenser swings upvertically to allow cleaning on bothsides as well as clear access to theATAAC.Fuel Tank Drain. Located at the bottomof the upper frame, the fuel tank drainwith a hose connection allows simple,spill free fluid draining.Air Filter. Caterpillar Radial Seal air filtersdo not require tools to service them, thusreducing maintenance time. The air filterfeatures a double-element construction andbuilt-in precleaner for superior cleaningefficiency. When the air cleaner plugs,a warning is displayed on the monitor screeninside the cab.Capsule Filter. The hydraulic return filter,a capsule filter, is situated inside the hydraulictank. This filter prevents contaminants fromentering the system when hydraulic oil ischanged and keeps the operation clean.Engine Inspection. The engine can be accessedfrom both ground level and from the upperstructure. The longitudinal layout ensures thatall daily inspection items can be accessedfrom ground level. The engine and pumpcompartment are separated by a steel wall.Water Separator. The water separatorremoves water from fuel even when underpressure and is located in the enginecompartment.14

Remote Greasing Block. A greasing blockis located in the engine compartment onthe upper carriage, with two grease pointsfor the swing bearing and one for the frontend attachment. This delivers grease tohard-to-reach locations. For the lowerundercarriage, two remote blocks give easyaccess for greasing to the oscillating axleand, as an option, the dozer blade.Hydraulic Tank Drain. The hydraulictank drain enables simple, spill-freefluid changes.Handrails and Steps. Well-sizedhandrails and steps assist the operator inclimbing on and off of the machine.Diagnostics and Monitoring.The <strong>M315C</strong> is equipped with S•O•Ssampling ports for the hydraulic systemand engine oil. A connection forthe Electronic Technician (ET) isconveniently located in the cab.Anti-Skid “Punched-Star” Plate.An anti-skid punched-star plate coversthe top of the steps and the upperstructure to prevent slipping duringmaintenance.Electronic Technician (ET).The electronic engine and machinecontrollers provide detailed diagnosticpossibility for service technicians.The ability to store both active andintermittent indicators simplifiesproblem diagnosis and reduces totalrepair time, resulting in improvedmachine availability and loweroperating cost. ET can be used to... access data stored in the engineand transmission controls via the CatData Link System display the status of parameters suchas engine speed, gear engaged,control switch position, etc. view active and non-active diagnosticcodes and clear them after repair perform diagnostic tests andcalibrations of electro-hydrauliccomponents view current configuration andchange parameter settingsflash new Caterpillar software intothe Electronic Control ModulesA customer version of ET is alsoavailable for your fleet of Caterpillarequipment. Contact your Caterpillardealer.Scheduled Oil Sampling (S•O•S)Analysis. Caterpillar has speciallydeveloped S•O•S to help ensure betterperformance, longer life and increasedcustomer satisfaction. It is a thoroughand reliable early warning system whichdetects traces of metals, dirt and othercontaminants in your engine, axle andhydraulic oil. It can predict potentialtrouble early, thus avoiding costlyfailures. Your Caterpillar dealer cangive you results and specific recommendationsshortly after receiving yoursample. Each S•O•S test can providespecific types of diagnosis: Oil condition analysis identifies lossof lubricating properties byquantifying combustion productssuch as soot, sulfur, oxidation andnitrates. Wear analysis monitors componentwear by detecting, identifying andassessing the amount and type ofmetal wear elements found in the oil. Chemical and physical test detect thephysical presence of unwanted fluids(water, fuel, antifreeze).15

Lower Operating CostsImprovements in operating costs provide a long-term investment.Fuel Consumption. The new EU Stage IIand US EPA Tier II, electronicallycontrolled engine, new fuel injectionsystem and new ATAAC combine toprovide outstanding fuel consumptionduring both production and traveling.The Automatic Engine Speed Controlreduces idle speed when the implementsare not active to further improve fuelconsumption.Filter Change Intervals. 2000 hourshydraulic oil and 500 hours engine oilfilter change intervals save time andmoney.Hydraulic Oil Change Intervals.With the aid of S•O•S samplinghydraulic oil change intervals canbe extended from 2000 hours toan average of 4000 hours.Rebuildable Components.Many of the major components usedin the <strong>M315C</strong> are designed for remanufacturing.This means you havehigh-quality, certified rebuilt replacementparts available at a fraction ofthe cost of new parts. There is lessscrap for disposal.Your Caterpillar dealer can provide you with detailed calculations and simulationsof how our low operating costs can benefit your particular application.Maximum uptime – ReliabilityCaterpillar standard features help to increase machine uptime.Caterpillar Braided Harnesses.Designed and manufactured to resistthe most severe conditions. Harnessesare made of large section, colored andnumber-coded wires with the completeharness being protected by an abrasionresistant braiding. Harnesses areproperly routed and securely clampedto ensure their reliability and life.XT-6 ES Hoses. Premium quality rubber,precision 4-ply wire reinforcementand exclusive reusable couplings areall unique features of Cat hoses whichdeliver top performance and long life.O-Ring face seals provide positivesealing for reliable and leak-freeconnections.Caterpillar Batteries. Caterpillarmaintenance-free, high output batteriesare designed for high cranking powerand maximum protection againstvibration.Fuel Filters. Cat high efficiency fuelfilters with a Stay-Clean Valve TMfeature cellulose/synthetic blend mediathat remove more than 98 percent ofparticles that are two microns or larger,increasing fuel injector life.16

Complete Customer SupportCat dealer services help you operating longer with lower costs.Services. Customer Service is criticaltoday in every business. That’s why somany people buy Cat equipment.They know they are getting qualityreliability and performance backed-upwith the best Customer Service.Your Caterpillar dealer offers a widerange of services that can be set upunder a Customer Support Agreement.The dealer will help you choose a planthat can cover the whole machineincluding work tools, to help yougetting the best out of your investment.Product Support. You will find asolution for your parts requirementsat your dealer. Cat dealers utilize aworldwide network to find in-stockparts to minimize downtime.In addition your dealer can offeralternative solutions like Reman,Classic Parts and quality used parts tosave money on original Caterpillarcomponents.Service Capability. Whether in thedealer’s fully equipped shop or inthe field, you will get highly trainedservice technicians using the latesttechnology and tools.Maintenance. More and more equipmentbuyers are planning for effectivemaintenance before buying equipment.Choose from your dealer’s wide rangeof maintenance services at the timeyou purchase your machine. Repairoption programs guarantee the cost ofrepairs up front. Diagnostic programssuch as S•O•S Fluid Analysis andTechnical Analysis help you avoidunscheduled repairs.Selection. Make detailed comparisonsof the machines you are consideringbefore you buy. How long docomponents last? What is the costof preventive maintenance? Your Catdealer can give you precise answersto these questions to make sure youoperate your machines at the lowest cost.Purchase. Consider the financingoptions available as well as day-to-dayoperating costs. This is also the timeto look at dealer services that can beincluded in the cost of the machineto yield lower equipment and owningand operating costs over the long run.Operation. Improving operatingtechniques can boost your profits.Your Cat dealer has training material andideas to help you increase productivity.Replacement. Repair, rebuild or replace?Your Cat dealer can helpyou evaluate the cost involved soyou can make the right choice.17

EngineCat 3054E DIT ATAAC diesel engineRatings2000 rpmNet powerISO 924991 kW/124 hpEEC 80/1269 91 kW/124 hpBore105 mmStroke127 mmDisplacement4.4 litersCylinders 4Maximum torque at 1400 rpm 500 NmAll engine horsepower (hp) are metricincluding front page.The 3054E engine meetsEU directive 97/68/EC Stage IIemission requirements.Net power advertised is the poweravailable at the flywheel when theengine is equipped with fan, aircleaner, muffler, and alternator.No engine derating is required below3000 m altitude.Swing MechanismSwing speedSwing torqueMaximum flowMaximum pressureTiresStandard 10.00-20 (dual pneumatic)Optional 11.00-20 (dual pneumatic) 18 R 19.5 XF (single pneumatic) 600/40-22.5 (single pneumatic) 10.00-20 (dual solid rubber)10.5 rpm40.1 kNm80 l/min370 barHydraulic SystemTank capacitySystemMaximum pressureImplementsTravelMaximum flowPilot systemMaximum pressureTransmission133 liters230 liters350 bar350 bar220 and 80 l/min31 bar1st gear,forward/reverse8 km/h2nd gear,forward/reverse 20/25/30/34 km/hCreeper speed(first gear)3 km/hCreeper speed(second gear)13 km/hDrawbar pull97 kNMaximum Gradeability 80%UndercarriageMaximum steering angle 32°Oscillation axle angle ± 9°Minimum turning radius(outside of tire)6400 mmMinimum turning radius(end of VA boom)7200 mmMinimum turning radius(end of Mono boom) 8600 mmGround clearance370 mmService Refill CapacitiesLiterFuel tank capacity 235Cooling 39Engine crankcase 9Rear axle housing (differential) 14Front steering axle (differential) 10.5Final drive 2.5Powershift transmission 2.5CabFOGS meets ISO 10262.SoundLow sound, low vibration. The 3054Edesign improves operator comfort byreducing sound and vibration. The<strong>M315C</strong> was awarded the German BlueAngel for low spectator sound levels.Operator Sound The operator sound level measuredaccording to the procedures specifiedin ISO 6396:1992 is L PA 71 dB(A),for cab offered by Caterpillar, whenproperly installed and maintained andtested with the doors and windowsclosed. Hearing protection may be neededwhen operating with an open cabfor extended periods or in a noisyenvironment.Exterior Sound The labeled spectator sound powerlevel measured according to the testprocedures and conditions specified in2000/14/EC is L WA 101 dB(A).WeightsAverage operating weights includea general purpose bucket,100% fuel and an operator.VA boomkgrear dozer only 15 500rear dozer, front outriggers 16 400front and rear outriggers 16 650One-piece boomrear dozer only 15 000rear dozer, front outriggers 15 900front and rear outriggers 16 150Dozer blade 645Outriggers 890CounterweightsStandard 3500Optional 390018<strong>M315C</strong> <strong>Wheel</strong> <strong>Excavator</strong> specifications

DimensionsAll dimensions are approximate – measured in mmBDAFECVA boom One-piece boommmmmA Shipping height(cab height) 3150 3150B Shipping length2100 mm stick 8480 83202400 mm stick 8480 83302600 mm stick 8470 8330C Support Point2100 mm stick 3910 35602400 mm stick 3660 32802600 mm stick 3560 3160D Tail swing radius 2197 2197E Counterweight clearance 1262 1262F Cab height 3150 3150with 1200 mm fixed cab riser 4350 4350Overall machine widthStandard gauge axle 2550 2550Wide gauge axle 2750 275039802540370*1202550 36653210* Max outrigger lifting above groundRoading positionwith 2100 mm stickUndercarriage with dozer onlyUndercarriage with 2 setsof outriggersUndercarriage with 1 setof outriggers and dozer250041601110500325107511004925800 1100 1110107525004960500

Work Tools Matching GuideWhen choosing between various work tool models that can be installed onto the same machine configuration,consider work tool application, productivity requirements, and durability. Refer to work tool specifications forapplication recommendations and productivity information.Without quick couplerHammersMultiprocessorsCrushers and Pulverizers360° rotatable Shears(boom mounted)Multi-GrapplesCompactorsDigging Clamshell BucketsTransfer Clamshell BucketsOrange Peel GrapplesStick length (mm) 2100 2400 2600 2100 2400 2600 2100 2400 2600 2100 2400 2600 2100 2400 2600 2100 2400 2600H100, H115 sH120C sMP15 CC, CR, PS, SPPVHC-30VHP-30S320S325G310B DRG315B D, RCVP75GGS-25GGS-35GOS-25 460520/580750/900980/1140GOS-35 620700/780105012601460/1670GSM-25 4005 tines 500/600/800GSM-35 5005 tines 6008001000GSH15B 400/500/6005 tines 800GSH15B 4004 tines 500/600800× × × × × × × × × × ×× × ×× × ×× × × × × × × ×× × × × × ×× × ×× × ×× × × × × ×× × × × × ××Dozerlowered×Variable adjustable boom5200 mm×2 setsof stabilizerloweredDozerand stabilizerloweredDozerlowered× ××× × × × × ×× × ×× × ×× × × × × ×× × × × × ×× × × × × ×× × × × × × × × × ×× × × × × × × × × × × × × × × ×× × ×× ×× × × × × ×× × × × × ×× × × × × ×× × × × × ×× × × × × × × × × × × × × ×× × × × × ×× × ×× × ×× × × × ×× × ×× × ×× × × × × ××One-piece boom5050 mm2 setsof stabilizerlowered×××Dozerand stabilizerlowered×××With quick couplerQuick CouplersMultiprocessorsCrushers and PulverizersMulti-GrapplesCompactorsCW-20, 20SMP15VHC-30VHP-30G310BG315BCVP75CC, CR, SPP, PSDRDR× × × × × × × × × × × × × ×× × × × × × × × × × × × × × × ×× × × × × × × × × × × × × ×× × × × × × × × × × × ×× × ××× × ×× ×× × × × × ×× × × × × × × × × ×360° Working RangeMaximum Material density 3000 kg/m 3Over the front only Maximum Material density 1800 kg/m 3AvailableMaximum Material density 1200 kg/m 3× Not Compatible<strong>M315C</strong> <strong>Wheel</strong> <strong>Excavator</strong> specifications21

Lift capacitieswith 5200 mm Variable adjustable boom, Quick Coupler CW and 3900 kg counterweight. All weights are in kg.Stick2100 mm6.0 m4.5 m3.0 m1.5 m0 m-1.5 m-3.0 mUndercarriageconfigurationRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab down3.0 m 4.5 m 6.0 m 7.5 m*4900 4300 4100 2600*4900 4800 *4400 3000*4900 *4900 *4400 3600*4900 *4900 *4400 *4400*4900 *4900 *4400 4400*6200 *6200 *5600 4200 4100 2700*6200 *6200 *5600 4700 *4600 3100*6200 *6200 *5600 *5600 *4600 3600*6200 *6200 *5600 *5600 *4600 *4600*6200 *6200 *5600 *5600 *4600 4300*7400 7300 6100 4100 4000 2700 2700 1700 *2400 1500*7400 *7400 *6500 *4600 *4900 3000 *4000 1900 *2400 1700*7400 *7400 *6500 5400 *4900 *3600 3900 2400 *2400 2100*7400 *7400 *6500 *6500 *4900 *4900 *4000 3500 *2400 *2400*7400 *7400 *6500 *6500 *4900 4300 *4000 2900 *2400 *2400*9200 *7000 *6000 4000 4100 2600 2700 1600 2300 1400*9200 8200 *7200 4500 *5200 3000 *4000 1900 *2500 1700*9200 *9200 *7200 5400 *5200 3500 3900 2300 *2500 2000*9200 *9200 *7200 *7200 *5200 4900 *4000 3500 *2500 *2500*9200 *9200 *7200 6400 *5200 *4300 *4000 2900 *2500 *2500*10900 6900 6100 3900 3900 2400 2600 1600 2400 1500*10900 8200 *7200 4500 *5200 2800 *3700 1800 *2600 1700*10900 10000 *7200 5400 *5200 3400 *3700 2300 *2600 2100*10900 *10900 *7200 *7200 *5200 5000 *3700 3400 *2600 *2600*10900 *10900 *7200 6500 *5200 4200 *3700 2800 *2600 260011800 6700 6100 3700 3800 2300 2700 1600*11900 8000 *7400 4300 *5200 2700 *3000 1900*11900 10100 *7400 5300 *5200 3300 *3000 2300*11900 *11900 *7400 *7400 *5200 4900 *3000 *3000*11900 *11900 *7400 6600 *5200 4100 *3000 2900*12100 6800 5900 3500*12100 8000 *6900 4100*12100 10100 *6900 5100*12100 *12100 *6900 *6900*12100 *12100 *6900 6400m8.118.217.997.42Stick2400 mmUndercarriageconfiguration3.0 m 4.5 m 6.0 m 7.5 mm6.0 m4.5 m3.0 m1.5 m0 m-1.5 m-3.0 mRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab down*4400 4300 4100 2700*4400 *4400 *4200 3000*4400 *4400 *4200 3600*4400 *4400 *4200 *4200*4400 *4400 *4200 *4200*4600 *4600 *5100 4200 4100 2700 *2700 1700*4600 *4600 *5100 4700 *4400 3100 *2700 2000*4600 *4600 *5100 *5100 *4400 3600 *2700 2400*4600 *4600 *5100 *5100 *4400 *4400 *2700 *2700*4600 *4600 *5100 *5100 *4400 4400 *2700 *2700*7900 *7200 6100 4100 4000 2700 2800 1700 *2100 1400*7900 *7900 *6300 4600 *4800 3100 *3900 2000 *2100 1600*7900 *7900 *6300 5400 *4800 *3600 3900 2400 *2100 2000*7900 *7900 *6300 *6300 *4800 *4800 *3900 3500 *2100 *2100*7900 *7900 *6300 *6300 *4800 4300 *3900 3000 *2100 *2100*9100 7000 6000 3900 4000 2600 2700 1700 *2200 1300*9100 8100 *7100 4500 *5100 3000 *4000 1900 *2200 1600*9100 *9100 *7100 5300 *5100 3600 3900 2400 *2200 1900*9100 *9100 *7100 *7100 *5100 4900 *4000 3500 *2200 *2200*9100 *9100 *7100 6400 *5100 4300 *4000 2900 *2200 *2200*10600 7000 6100 3900 3900 2500 2600 1600 2300 1400*10600 8300 *7200 4500 *5200 2900 *3900 1900 *2300 1600*10600 10000 *7200 5400 *5200 3400 3800 2300 *2300 2000*10600 *10600 *7200 *7200 *5200 *5000 *3900 3400 *2300 *2300*10600 *10600 *7200 6400 *5200 4200 *3900 2800 *2300 *230011700 6700 6100 3700 3800 2300 2500 1500*11700 8000 *7300 4300 *5300 2700 *2700 1800*11700 10100 *7300 5200 *5300 3300 *2700 2200*11700 *11700 *7300 *7300 *5300 4900 *2700 *2700*11700 *11700 *7300 6600 *5300 4100 *2700 *270012100 6700 5900 3500 3700 2200*12100 8000 *7200 4100 *3800 2600*12100 10100 *7200 5000 *3800 3200*12100 *12100 *7200 *7200 *3800 *3800*12100 *12100 *7200 6400 *3800 *38008.388.488.277.7322<strong>M315C</strong> <strong>Wheel</strong> <strong>Excavator</strong> specifications

Stick3.0 m 4.5 m 6.0 m 7.5 mUndercarriage2600 mm configurationm6.0 m4.5 m3.0 m1.5 m0 m-1.5 m-3.0 m-4.5 mRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downFor machines with offset boom deduct approx. 3% from the above loads.*4000 *4000 *4100 2700*4000 *4000 *4100 3100*4000 *4000 *4100 3700*4000 *4000 *4100 *4100*4000 *4000 *4100 *4100*4600 4200 4100 2700 2800 1700*4600 *4600 *4300 *3100 *3300 2000*4600 *4600 *4300 3600 *3300 2400*4600 *4600 *4300 *4300 *3300 *3300*4600 *4600 *4300 *4300 *3300 3000*7400 7300 *6100 4100 4000 2700 2800 1700 *1900 1300*7400 *7400 *6100 4600 *4700 *3100 *3900 2000 *1900 1600*7400 *7400 *6100 5400 *4700 3600 *3900 2400 *1900 1900*7400 *7400 *6100 *6100 *4700 *4700 *3900 3600 *1900 *1900*7400 *7400 *6100 *6100 *4700 4300 *3900 3000 *1900 *1900*9200 7100 6000 4000 4000 2700 2700 1700 *2000 1300*9200 8100 *7000 4500 *5100 3000 *4000 2000 *2000 1500*9200 *9200 *7000 5300 *5100 3600 3900 2400 *2000 1900*9200 *9200 *7000 *7000 *5100 4900 *4000 3500 *2000 *2000*9200 *9200 *7000 6400 *5100 4200 *4000 3000 *2000 *2000*10300 7000 6000 3900 4000 2500 2700 1600 *2200 1300*10300 8200 *7200 4500 *5200 2900 *4000 1900 *2200 1500*10300 9900 *7200 5300 *5200 3500 3800 2300 *2200 1900*10300 *10300 *7200 *7200 *5200 *4900 *4000 3400 *2200 *2200*10300 *10300 *7200 6400 *5200 4300 *4000 2900 *2200 *2200*11600 6700 6100 3700 3800 2300 2600 1500 2400 1400*11700 8000 *7300 4300 *5300 2700 *3200 1800 *2400 1700*11700 10100 *7300 5300 *5300 3300 *3200 2200 *2400 2100*11700 *11700 *7300 *7300 *5300 4900 *3200 *3200 *2400 *2400*11700 *11700 *7300 6600 *5300 4100 *3200 2800 *2400 *240012100 6700 5900 3500 3700 2200 *2500 1800*12100 7900 *7400 4100 *4300 2600 *2500 2100*12100 10000 *7400 5100 *4300 3200 *2500 *2500*12100 *12100 *7400 *7400 *4300 *4300 *2500 *2500*12100 *12100 *7400 6400 *4300 4000 *2500 *2500*8400 6600*8400 7800*8400 *8400*8400 *8400*8400 *84008.578.678.477.947.02Load Point Height Load Radius Over Front Load Radius Over RearLoad Radius Over Side Load at Maximum Reach* Limited by hydraulic rather than tipping load.The above loads are in compliance with hydraulic excavator lift capacity ratings standard ISO 10567, they do not exceed 87% of hydraulic lifting capacityor 75% of tipping capacity. Weight of all tools and lifting accessories must be deducted from the above lifting capacities.<strong>M315C</strong> <strong>Wheel</strong> <strong>Excavator</strong> specifications23

Lift capacitieswith 5050 mm One-piece boom, Quick Coupler CW and 3900 kg counterweight. All weights are in kg.Stick3.0 m 4.5 m 6.0 m 7.5 mUndercarriage2100 mm configurationm6.0 m4.5 m3.0 m1.5 m0 m-1.5 m-3.0 mRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab down4000 2600*4100 3000*4100 3500*4100 *4100*4100 *4100*5300 4100 4000 2600*5300 4600 *4500 2900*5300 *5300 *4500 3500*5300 *5300 *4500 *4500*5300 *5300 *4500 43006100 3800 3900 2500 *2400 1600*6300 4300 *4900 2800 *2400 1900*6300 5300 *4900 3400 *2400 2200*6300 *6300 *4900 *4900 *2400 *2400*6300 *6300 *4900 4200 *2400 *24005800 3500 3800 2300 2700 1700 2500 1500*7200 4100 *5200 2700 *3700 1900 *2500 1800*7200 5000 *5200 3300 *3700 2300 *2500 2100*7200 *7200 *5200 4900 *3700 3500 *2500 *2500*7200 6200 *5200 4100 *3700 2900 *2500 *25005600 3300 3700 2200 2500 1600*7300 3900 *5300 2600 *2700 1800*7300 4800 *5300 3200 *2700 2200*7300 *7300 *5300 4800 *2700 *2700*7300 6100 *5300 4000 *2700 *2700*7400 6100 5600 3300 3600 2200 2800 1800*7400 7300 *6700 3900 *4800 2600 *3100 2000*7400 *7400 *6700 4800 *4800 3200 *3100 2500*7400 *7400 *6700 *6700 *4800 4800 *3100 *3100*7400 *7400 *6700 6000 *4800 3900 *3100 3100*6900 6200 *5200 3400 *3000 2200*6900 *6900 *5200 3900 *3000 2600*6900 *6900 *5200 4900 *3000 *3000*6900 *6900 *5200 *5200 *3000 *3000*6900 *6900 *5200 *5200 *3000 *30007.908.017.797.216.15Stick2400 mmUndercarriageconfiguration3.0 m 4.5 m 6.0 m 7.5 mm6.0 m4.5 m3.0 m1.5 m0 m-1.5 m-3.0 mRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab down*4000 2600*4000 3000*4000 3600*4000 *4000*4000 *40004000 2600*4300 3000*4300 3500*4300 *4300*4300 *4300*6100 3800 3900 2500 2700 1700 *2100 1500*6100 4400 *4700 2800 *3700 2000 *2100 1700*6100 5300 *4700 3400 *3700 2400 *2100 *2100*6100 *6100 *4700 *4700 *3700 3500 *2100 *2100*6100 *6100 *4700 4200 *3700 3000 *2100 *21005800 3500 3800 2300 2700 1600 *2200 1400*7000 4100 *5100 2700 *4100 1900 *2200 1700*7000 5000 *5100 3300 3800 2300 *2200 2000*7000 *7000 *5100 4900 *4100 3500 *2200 *2200*7000 6300 *5100 4100 *4100 2900 *2200 *2200*3700 *3700 5600 3300 3600 2200 2600 1600 2400 1500*3700 *3700 *7300 3900 *5300 2600 *3900 1900 *2400 1700*3700 *3700 *7300 4800 *5300 3200 3800 2300 *2400 2100*3700 *3700 *7300 *7300 *5300 4800 *3900 3400 *2400 *2400*3700 *3700 *7300 6100 *5300 3900 *3900 2900 *2400 *2400*7200 6000 5500 3300 3600 2200 2700 1600*7200 7200 *6800 3800 *4900 2600 *2800 1900*7200 *7200 *6800 4700 *4900 3100 *2800 2300*7200 *7200 *6800 *6800 *4900 4700 *2800 *2800*7200 *7200 *6800 6000 *4900 3900 *2800 *2800*7600 6100 *5500 3300 *3600 2200 *3100 2000*7600 7300 *5500 3900 *3600 2600 *3100 2400*7600 *7600 *5500 4800 *3600 3200 *3100 2900*7600 *7600 *5500 *5500 *3600 *3600 *3100 *3100*7600 *7600 *5500 *5500 *3600 *3600 *3100 *31008.168.278.057.506.4924<strong>M315C</strong> <strong>Wheel</strong> <strong>Excavator</strong> specifications

Stick3.0 m 4.5 m 6.0 m 7.5 mUndercarriage2600 mm configurationm6.0 m4.5 m3.0 m1.5 m0 m-1.5 m-3.0 mRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab downRear dozer upRear dozer downRear stab down2 sets stab downDozer and stab down*3900 2700*3900 3000*3900 3600*3900 *3900*3900 *39004100 2600 *2300 1700*4200 3000 *2300 2000*4200 3600 *2300 *2300*4200 *4200 *2300 *2300*4200 *4200 *2300 *2300*5900 3800 3900 2500 2700 1700 *1900 1400*5900 4400 *4600 2900 *3900 2000 *1900 1700*5900 5400 *4600 3400 *3900 2400 *1900 *1900*5900 *5900 *4600 *4600 *3900 3500 *1900 *1900*5900 *5900 *4600 4200 *3900 3000 *1900 *19005800 3500 3800 2300 2700 1700 *2000 1400*6900 4100 *5100 2700 *4100 1900 *2000 1600*6900 5000 *5100 3300 3800 2300 *2000 2000*6900 *6900 *5100 4900 *4100 3500 *2000 *2000*6900 6300 *5100 4100 *4100 2900 *2000 *2000*3900 *3900 5600 3300 3700 2200 2600 1600 *2200 1400*3900 *3900 *7300 3900 *5300 2600 *4000 1900 *2200 1600*3900 *3900 *7300 4800 *5300 3200 3800 2300 *2200 2000*3900 *3900 *7300 *7300 *5300 4800 *4000 3400 *2200 *2200*3900 *3900 *7300 6100 *5300 4000 *4000 2800 *2200 *2200*7000 6000 5500 3300 3600 2200 2500 1600*7000 *7000 *7000 3800 *5000 2500 *2600 1800*7000 *7000 *7000 4700 *5000 3100 *2600 2200*7000 *7000 *7000 *7000 *5000 4700 *2600 *2600*7000 *7000 *7000 6000 *5000 3900 *2600 *2600*8100 6100 5600 3300 3600 2200 *3100 1900*8100 7300 *5800 3900 *3900 2600 *3100 2200*8100 *8100 *5800 4800 *3900 3200 *3100 2700*8100 *8100 *5800 *5800 *3900 *3900 *3100 *3100*8100 *8100 *5800 *5800 *3900 3900 *3100 *31008.368.468.257.716.74Load Point Height Load Radius Over Front Load Radius Over RearLoad Radius Over Side Load at Maximum Reach* Limited by hydraulic rather than tipping load.The above loads are in compliance with hydraulic excavator lift capacity ratings standard ISO 10567, they do not exceed 87% of hydraulic lifting capacityor 75% of tipping capacity. Weight of all tools and lifting accessories must be deducted from the above lifting capacities.<strong>M315C</strong> <strong>Wheel</strong> <strong>Excavator</strong> specifications25

VA Boom Working Ranges5200 mm Variable adjustable boom, quick coupler and bucket.Stick LengthA MaximumDigging HeightB MaximumDump HeightC MaximumDigging DepthD Maximum VerticalWall Digging DepthE Maximum Depth 2500 mmStraight Clean-upF Maximum ReachG Maximum Reachat Ground LevelTip RadiusBucket Forces (ISO 6015)Stick Forces (ISO 6015)mm 2100 2400 2600mm 10 040 10 230 10 380mm 6950 7140 7300mm 5590 5890 6090mm 3720 3920 4090mm 5369 5687 5897mm 9100 9360 9560mm 8910 9190 9380mm 1552 1552 1552kN 93 93 93kN 75 69 66One-piece Boom Working Ranges5050 mm One-piece boom, quick coupler and bucket.Stick LengthA MaximumDigging HeightB MaximumDump HeightC MaximumDigging DepthD Maximum VerticalWall Digging DepthE Maximum Depth 2500 mmStraight Clean-upF Maximum ReachG Maximum Reachat Ground LevelTip RadiusBucket Forces (ISO 6015)Stick Forces (ISO 6015)mm 2100 2400 2600mm 8980 9070 9190mm 6000 6110 6230mm 5390 5690 5890mm 3510 3650 3820mm 5169 5487 5697mm 8900 9160 9350mm 8710 8970 9170mm 1552 1552 1552kN 93 93 93kN 75 69 6626<strong>M315C</strong> <strong>Wheel</strong> <strong>Excavator</strong> specifications

Standard EquipmentStandard equipment may vary. Consult your Caterpillar dealer for specifics.Operator StationAshtray with cigarette lighterAir conditioner with automatic climatecontrolBolt-on FOGS capabilityBottom mounted parallel wiperand washerCoat hookDrink holderFiltered ventilationFloormat, washableFully adjustable suspension seatHeater and defrosterJoysticks, adjustableLH console, tiltableLight, interiorLiterature holderLow fuel indicator lightOpenable two-piece front windscreenParking brakePre-wired radio mountingPolycarbonate skylightPower supply 12V – 7ARetractable seat beltSteering column, tiltableStorage compartment suitable fora lunch boxSunscreenLanguage display WEX MultiproClock with 10-day backup batteryFilter / fluid change informationGauges for fuel level, engine coolanttemperature and hydraulic oiltemperatureHeadlights indicatorIndicator for engine dial settingPre-start level check for hydraulic oil andengine coolantTurn signal indicatorWarning messagesWorking hour informationEngineAutomatic engine speed controlAutomatic starting aidCat 3054E DIT ATAAC Stage II engine,turbocharged with air-to-air aftercoolerMufflerUndercarriage10.00-20 16 PR tiresHD-axles, with advanced disc brakesystem and advanced travel motor withadjustable braking forceOscillating front axle with remotegreasingPin-on design preparation for dozer bladeand outriggersToolbox in undercarriageTwo-piece drive shaftUpper carriage storage boxHydraulicsCat XT-6 ES hosesLoad-sensing plus hydraulic systemManual work modes (economy,power, travel)Oil coolerOverload warning deviceSeparate swing pumpStick regeneration circuitElectricalAlternator, 75ABoom working lightHeavy-duty maintenance-free batteriesHornMain shut-off switchRoading lightsOther equipmentAutomatic swing brakeDoor locks and caps locks withCaterpillar one-key security systemLockable Tool Box in upper frameMirrors, frame and cabOptional EquipmentOptional equipment may vary. Consult your Caterpillar dealer for specifics.Operator StationFalling objects guardFixed cab riser (1200 mm)Fixed one-piece front windscreenHeadrestLid for storage compartmentTravel speed lockVandalism guardVisor, rain protection, polycarbonateWEX comfort seat with seat heating andair suspensionElectricalBack-up alarmRefueling pumpRotating beaconWorking lights, cab mounted(front and rear)Booms and SticksHydraulically adjustable boom(5200 mm)Offset boom (5200 mm)One-piece-boom (5050 mm)Sticks:2100 mm, 2400 mm, 2600 mmIndustrial: 3100 mmUndercarriageDozer blade, front or rear mountedOptional tiresOutriggers, front or rear mountedRemote dozer blade greasingSecond storage box for undercarriageWide dozer blade, front or rear mountedWide gauge axles (2750 mm)HydraulicsControl group for quick couplerHammer valveHydraulic lines for quick coupler – boomand stickLowering control devices for boomand stickMultifunction valve, provides up to5 programmed tools and tool selectionfrom the cab (including hammerfunction)Proportional medium pressure functionSynthetic ester based biodegradablehydraulic oilOther equipmentAdjustable hydraulic sensitivityCat Machine Security System (MSS)Counterweight (3900 kg)Custom paintJoystick steering27

<strong>M315C</strong> <strong>Wheel</strong> <strong>Excavator</strong>HEHH2873-2 (01/2005) hrMaterials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.See your Caterpillar dealer for available options.www.CAT.com© 2005 CaterpillarAll rights reserved®