DEPENDABLE

135ZV Brochure 5-04 - Kawasaki Construction Machinery Corp. of ...

135ZV Brochure 5-04 - Kawasaki Construction Machinery Corp. of ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

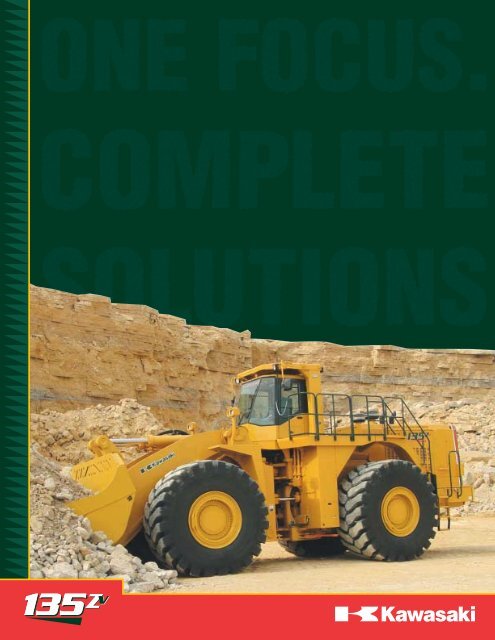

RUGGED AND<strong>DEPENDABLE</strong>A COMPLETE SOLUTION• Emissions-compliant 720 HP Cumminsdiesel engine• 12.8 cu. yard heavy-duty rock bucketavailable• Increased width of cab by 20% foroperator comfort• Automatic transmission, reduces operatoreffort, extends component life• Traction control eliminates tire spin and wear• Dual Z-linkage distributes load evenly• High breakout force with PowerBoost fortough materials• Customized operating modes matchtorque requirements for normal, heavy-dutyand load & carry• Kawasaki variable piston pumps, efficient,responsive hydraulics• Engine PreLub ® feature, standardTHE POWER TO PERFORM!The x was designed for increased production anddecreased operational costs resulting in the most productivemachine in its class.OPERATOR PRODUCTIVITYThe x has several standard features to maximizeoperator efficiency and overall productivity. The cab offersexcellent visibility and the openness of the dual Z-linkage.K-Lever+ steering gives the operator good control with littleeffort. The standard single-lever hydraulic control coupledwith the K-Lever+ steering give the operator total commandfrom the armchair. The automatic transmission furtherreduces operator fatigue. The push of a button allows theoperator to change the torque curve of the engine with theCummins mode selection feature. The operator can selectfrom Normal, Heavy-Duty and Load & Carry modes tomatch the torque requirements to the job at hand.

Kawasaki and their dealerorganization offer comprehensivesupport and serviceprograms designed to keepyou on the job.THE x IN THE QUARRYThe x is available with a 12.8 cubic yard rock bucket.Team that with the high breakout force of the x, thedual Z linkage, the excellent traction, and you have themost productive machine in its size class. Features suchas the PowerBoost Button for additional breakout force,automatic transmission and traction control keep thiswell-balanced machine working in the most demandingenvironments.ECONOMICALThe Cummins QST30 provides outstanding fuel economyas well as overall efficiency. Equipped with a grid heater,the QST30 does not require ether starting aids. Thevariable piston pumps and Kawasaki lock-up clutch help toconserve fuel.Kawasaki standard features such as the PreLub ® starter,oversize planetary automatic transmission with Shift ControlUnit, oversize sealed universal joints, high capacity drivelines, outboard mounted planetaries, Kawasaki pistonpumps, and heavy support structures are designed forlong life and minimal maintenance.UNMATCHED SUPPORTKawasaki maintains a large inventory of new components toensure outstanding parts availability and minimal downtime.In addition, a predictive oil analysis program helps eliminateunnecessary maintenance and helps find problems beforethey occur. Kawasaki also stocks an array of cost-effectiverebuilt components.BUILT TO STAY ON THE JOBKawasaki loaders are designed with the durability toprovide years of service. Backed by a dealer network ofheavy equipment experts and a dedicated support staffin the Kawasaki parts and service organization, yourinvestment in a Kawasaki loader is an excellent choicethat will pay dividends for years to come.

POWER AND PERFORMANCEPROVIDE UNMATCHEDPRODUCTIVITYThe Kawasaki x means business. It incorporates the best in design andtechnology, giving your operators the tool they need to get the job done.Because Kawasaki specializes in the design and manufacture of articulated wheelloaders, you get a machine with a 40-year heritage of successful innovations.The power and productivity that the x brings to the job is a result ofthat experience.WORLD CLASS ENGINESThe Cummins Full AuthorityElectronic engines provideincreased torque and horsepowerwhile decreasing fuel consumption.• 720 HP Cummins QST30 dieselengine• 30 liter, V12 capable of 1050HP• Heater grid—electronic cold startfeature eliminates need for etherstarting aids, standard• Supported by Cummins extensivedistribution system and a generouswarranty programENGINE MODESEngine Mode Switch:• Normal—the most fuel-efficient setting• Heavy Duty—10% increase in rim pull force overnormal mode• Load & Carry—significant increase in acceleration insecond and third gear. Ground speed is improved.PreLub ® starter, standard, prevents dry starts.

SteeringControlValveSurplus FlowPUMPPUMPHIGH EFFICIENCYHYDRAULIC SYSTEMKawasaki is the oldest, most sophisticatedmanufacturer of hydraulic piston pumpsin the world.• Kawasaki dual, variable piston pumps inmain & steering• Energy efficient system designed byKawasaki, steering supplements mainfor maximum performance• Excellent filtration system filtershydraulic fluid down to 10 micron• Supplemental hydraulic fluid reservoirsupplies continuous oil supply to pumpsto prevent dry start.TRANSMISSIONKawasaki engineered and manufacturedtransmission and torque converter• Oversized planetary clutches• Automatic three speed with powershift• Lock-up feature converts to direct driveat higher speeds• Helical gears provide a quiet operation• Autobrake feature protects transmissionfrom overspeeding and directionalshift shock• Number of clutches is double industrystandard• Switch activates transmission declutchAXLES/BRAKES• Traction control eliminates wheel spin• Large, sealed universal joints forreduced maintenance costs• High capacity drivelines• Outboard mounted planetaries• Separate front and rear brake systemsfor safety• Conventional differentials—massive size• Full floating axle, front & rear• Replaceable wear surfaces on rearaxle trunion• 45/65-R39 Bridgestone VSDL (L5)standard tires• Wet disc parking brake mounted ontransmission meets MSHA standardsInside transmission withplanetary gears

HEAVY IRONLIFT ARMS/BUCKETS• Proven dual Z-Linkage for evendistribution of load and added strength• S-shaped lift arms increaseclearance and reach• High breakout force with PowerBoost• 12.8 cu. yd. spade nose or straight-edgerock bucket—heavy duty and normalservice• Boom Soft-Landing safety feature• High lift arms availableSTRUCTURE• Massive center pin structure• Full box frame rear chassis• Excellent stability without the needfor massive counterweight• High-strength loader tower

THE COMFORT ZONEOPERATOR COMFORTKawasaki loaders are engineeredand manufactured with operator productivityin mind. With attention todetail, this cab is designed to providethe operator with the ideal working environment.Armchair controls offer fingertipcontrol and easy access to gauges forquick, easy monitoring.• Viscous isolation mounted cab to reducevibration and sound levels• Flat glass windows for easy replacement• K-Lever+ steering replaces steeringwheel offering precision hydraulicmodulation• Unique, single lever, pilot-assistedhydraulic controls, standard• Climate controlled air conditioning andheater, standard• Side windows roll down for ventilation• Front and rear wipers and washers• Deluxe air ride seat with adjustableheadrest and armrests, standard• AM/FM cassette radio, standard• One rear, two side mirrors• Easy access with left rear staircaseand right ladder• Dual Z-linkage increases visibilityfor straight-on loadingKawasaki engineers its cabswith operator productivity inmind. With attention to eventhe smallest details, thiscab is designed to providethe operator with the idealworking environment.OPERATOR EFFICIENCY• PowerBoost button allows fingertipcontrol increasing hydraulic pressurefor work in tough materials• All analog gauges are convenientlygrouped for monitoring at a glance• Operating mode selection allows operatorto match torque with the application• Switch activates transmission declutch• Boom soft landing control allowsoperator to concentrate on maneuveringrather than attempting to control theboom speed while lowering bucket• Single-lever hydraulic and K-Lever+ sticksteer controls for ease of operation,reduced operator fatigue• Air-ride seat, standard• Ride control system, optionalK-LEVER+• Hydraulically modulated for smooth and responsive steering• Up/Down shift control• Increases productivity and reduces fatigue• Forward, neutral, reverse and downshift buttons (electric)for one-hand transmission control• Positive, well modulated hydraulic steering• Fully adjustable wrist rests for maximumoperator comfort

SERVICEEASY ACCESS SIMPLIFIESSERVICING• Access panels provide easy access toall major components• Donaldson and Fleetguard filterssimplify service• Sealed universal joints (only requiregreasing at 2000 hour intervals)• Left side rear stair access, right sideladder access• Ladder light switch activated fromoperator compartment• Cummins INSITE diagnostics programsimplifies engine troubleshooting• Trunion wear surfaces are replaceablefor easier servicing• Hydraulic reservoir services both steeringand main system to simplify servicing• Grease fittings are grouped at groundlevel for faster service• Transmission diagnostic program recordsand stores transmission data• Battery disconnect safety switch cutspower to machine for ease of maintenance• Autolube system, optional• Fast engine oil drain system, optional• Ground-level fueling system, optional

OPTIONSRIDE CONTROL• Stable load handling• Reduces operator fatigue• Cuts vibration and equipment wear• Improves safety and productivity• Less spillage• Faster travel speedWithout Ride ControlWith Ride ControlIllustration representativeof similar models—x not shown.AUTOMATIC LUBE SYSTEM• Ease of maintenance• Lubricates while machine is in operation,ensuring proper distribution of greaseover the bearings’ surface• Measured distribution assuresexact levels ofgrease required,more economical• Reducesdowntime• Reduces manuallaborEMERGENCY STEERING• Maintain control if power loss occurs• Operator and job site safety featureGROUND LEVEL FUELING• Improves safety and productivityHINGED BELLY GUARD• Protects Powertrain• Less down-timeLOAD SCALES• Improves accuracy• Less product waste• Increases profits through product wastesavings• Provides accurate load recordsK-LINK• On Demand reports providemachine location, hours, operatingstatus• Alarm notification by phone orpager will indicate equipment failure,low-fuel, geo-fence break• Worldwide satellite coverage• Customize reports and alerts• Internet access to all reportsand alertsQUICK-CHANGE OILSYSTEM• Ease of maintenance• Less down-time• Supported by Cummins extensivedistribution system

BUCKET DATAHEAVY-DUTY ROCKSTRAIGHT EDGE BUCKETAND HEAVY-DUTY ROCKV-EDGE BUCKET• 12.8 cu. yd. capacity• Bucket rock guard, welded, standard• Heel plates, welded, standard• Bucket leveler, standard• Boom kickout, standard• Bucket side guards, optional• Snap-lock (easy lock) segments,optional• V51 snap-lock teeth, optional, nobolting required, installs in minutes• Payload scale system, optionalAll pins of the loading systemare fully sealed with grease toprovide dependable service withminimum maintenance.TRUCK DESIGNATION35 Ton 40 Ton 50 Ton 65 Ton 85 Ton 100 TonHeight: 10' 4" Height: 11' 2" Height: 12' 5" Height: 13' 1" Height: 13' 8" Height: 14' 1"Width: 11' 11" Width: 11' 11" Width: 16' 8" Width: 16' 8" Width: 17' 11" Width: 19' 10"Kawasaki 135ZV (18 T)12.8 cu. yd.Spade Nose Rock Bucket 2 Pass 2–3 Pass 3 Pass 3–4 Pass 5 Pass N/ADump: 13' 5"Reach: 7' 1 /4"Kawasaki 135ZV (16.8 T)Hi-Lift 11.5 cu. yd.Spade Nose Rock Bucket 2–3 Pass 3 Pass 3–4 Pass 4 Pass N/A 5–6 PassDump: 15' 5"Reach: 7' 11 /16"

BUCKET DATAStandard BoomRock-V-Edge Rock-Straight-Edge General PurposeWith Teeth & Segments Without Teeth With Teeth & Segments With Bolt-on Cutting EdgeHeaped yd 3 12.8 12.0 12.8 13.5Capacity(m 3 ) (9.7) (9.2) (9.7) (10.3)Struck yd 3 10.5 9.8 10.5 11.5(m 3 ) (8.0) (7.5) (8.0) (8.8)Maximum dumping ft-in 13'5 1 /16" 14'6 5 /8" 14' 11 /16" 14'7 1 /16"clearance (mm) (4,090) (4,435) (4,283) (4,445)Dumping reach (to front ft-in 7' 1 /4" 6'3 5 /8" 6'4 11 /16" 6' 1 /4"of bucket edge or tooth) (mm) (2,140) (1,920) (1,947) (1,837)Bucket hinge pin height ft-in 19'9 7 /8" 19'9 7 /8" 19'9 7 /8" 19'9 7 /8"(mm) (6,040) (6,040) (6,040) (6,040)Digging depth ft-in 6 11 /16" 2 15 /16" 6 11 /16" 2"(mm) (169) (75) (169) (50)Breakout force lb 140,400 140,400 164,380 156,526(kg) (63,680) (63,680) (74,560) (71,000)Bucket tilt- at ground level 41.0° 41.0° 41.0° 41.0°back angle at carry position 49.2° 49.2° 49.2° 49.2°Length ft-in 42'4 1 /16" 41'1 7 /8" 41'5 7 /16" 40'8 3 /4"(mm) (12,900) (12,540) (12,630) (12,410)Height ft-in 16'2 3 /4" 16'2 3 /4" 16'2 3 /4" 16'2 3 /4"Overall(mm) (4,945) (4,945) (4,945) (4,945)Width ft-in 13'7 13 /16" 13'7 13 /16" 13'7 13 /16" 13'7 13 /16"(outside tire) (mm) (4,160) (4,160) (4,160) (4,160)Width ft-in 14'10" 14'10" 14'6 1 /16" 14'6 1 /16"(outside bucket) (mm) (4,520) (4,520) (4,420) (4,420)Wheel base ft-in 15'9" 15'9" 15'9" 15'9"(mm) (4,800) (4,800) (4,800) (4,800)Minimumturning radiusat outside ft-in 31'11 9 /16" 31'6 1 /16" 31'11 9 /16" 31'9 1 /4"bucket (mm) (9,740) (9,600) (9,740) (9,680)at center of ft-in 26'7 13 /16" 26'7 13 /16" 26'7 13 /16" 26'7 13 /16"outside tire (mm) (8,120) (8,120) (8,120) (8,120)Minimum ground ft-in 1'11 1 /4" 1'11 1 /4" 1'11 1 /4" 1'11 1 /4"clearance (mm) (590) (590) (590) (590)Full articulation angle degree 40° 40° 40° 40°Operating weight lb 176,200 175,100 175,500 176,100(with ROPS Canopy and Cabin) (kg) (79,900) (79,390) (79,590) (79,850)Static TippingLoad (withROPS Canopyand Cabin)Straight lb 113,300 114,400 114,200 113,000(kg) (51,400) (51,870) (51,800) (51,250)Full turn lb 99,710 100,640 100,490 99,400(kg) (45,230) (45,650) (45,580) (45,700)Specifications based on counterweight, open ROPS and enclosed cab, 45/65-39 L5 tires, full fuel tank, and operator.Materials and specifications are subject to change without notice and without obligation on the part of the manufacturer. The specifications supplied, whilebelieved to be completely reliable, are not to be taken as warranty for which we assume legal responsibility.

BUCKET DATARock-V-EdgeWith TeethHigh-Lift BoomRock-Straight-EdgeWith TeethHeaped yd 3 11.5 11.5Capacity(m 3 ) (8.6) (8.6)Struck yd 3 10.2 10.2(m 3 ) (7.6) (7.6)Maximum dumping ft-in 15'5 1 /8" 17'clearance (mm) (4700) (4900)Dumping reach (to front ft-in 7' 11 /16" 6'4 13 /16"of bucket edge or tooth) (mm) (2150) (1950)Bucket hinge pin height ft-in 21'8 5 /16" 21'8 5 /16"(mm) (6610) (6610)Digging depth ft-in 6 1 /2" 6 1 /2"(mm) (165) (165)Breakout force lb 145,725 171,740(kg) (66,100) (77,900)Bucket tilt- at ground level 42° 42°back angle at carry position 49° 49°Length ft-in 43'9 15 /16" 42'10 3 /4"(mm) (133,551) (130,701)Height ft-in 16'2 3 /4" 16'2 3 /4"Overall(mm) (4945) (4945)Width ft-in 13'7 13 /16" 13'7 13 /16"(outside tire) (mm) (4160) (4160)Width ft-in 14'6 1 /16" 14'6 1 /16"(outside bucket) (mm) (4420) (4420)Wheel base ft-in 15'9" 15'9"(mm) (4800) (4800)Minimumturning radiusat outside ft-in 32'8 1 /4" 32'8 1 /4"bucket (mm) (9960) (9960)at center of ft-in 26'7 13 /16" 26'7 13 /16"outside tire (mm) (8120) (8120)Minimum ground ft-in 1'11 1 /4" 1'11 1 /4"clearance (mm) (590) (590)Full articulation angle degree 40° 40°Operating weight lb 178,700 178,000(with ROPS Canopy and Cabin) (kg) (81,050) (80,740)Static TippingLoad (withROPS Canopyand Cabin)Straight lb 98,000 101,300(kg) (44,450) (45,960)Full turn lb 85,240 86,040(kg) (38,660) (39,020)

OPERATING SPECIFICATIONSBUCKET SELECTION CHARTSBucket Sizeyd 3 (m 3)12.0 (9.2)12.8 (9.7)13.5 (10.3)Bucket Sizeyd 3 (m 3)11.5 (8.6)Standard Arm2300 2400 2500 2600 2700 2800 2900 3000 3100 3200 3300 3400 3500 3600 3700 3800Material Density lbs/yd 3High Lift Arm 115% 100% 95%Bucket Fill2300 2400 2500 2600 2700 2800 2900 3000 3100 3200 3300 3400 3500 3600 3700 3800WEIGHTS AND DIMENSIONS (SUPPLEMENTAL DATA)Operating Tipping Load Overall Width Tread Vertical OverallWeight Straight Full Turn (Outside Tire) Dimensions LengthTires: 41.25/70-39 PR34 lb -880 -650 -575 in 1 7 /8"(kg) (-400) (-295) (-260) (mm) (-48)Tread . . . . . . . . . . . . . . . . . .10' 1 /8" (3050mm)Width (outside tire) . . . . . . . .13'7 13 /16" (4160mm)Width (outside bucket) . . . . .14'6 1 /16" (4420mm)Equipped with Rock-V-Edge bucket with teeth,45/65 R39 (L-5) Tire and ROPS Canopy and Cab19'9 7/8"7' 1/4"4513'51/16"5016'2 3/4"431'111/4"15'9"6 11/16"42'6 3/8"

OPERATING SPECIFICATIONSENGINEMake/Model/Fuel TypeCummins QST30Type4-cycle, watercooled, inline, direct injection typewith turbocharger and aftercooledNet flywheel horsepower 720HP/2100 RPMMaximum torque2400 ft/lb @ 1300 RPMNumber of cylinders 12Bore and stroke5.25" x 6.25" (190mm x 165mm)Total displacement 1861 in 3 (30,500 cm 3 )AlternatorAC24V–1800W (75 amp)Starting motor24V–8.9kw (12HP)Battery12V–160AH, 4 unitsGovernorAll-speed, electrical typeTORQUE CONVERTER AND TRANSMISSIONTorque converter3 elements, single stage with lock-upTorque stall ratio 2.53:1Main clutchesWet hydraulic, multi-disc typeCooling methodForced circulation typeTransmissionFull powershift, 4 forward, 3 reverse withautomatic mode (2nd–3rd) with downshiftswitch for 2nd–1st downshifting. Autobrakeprotects transmission from overspeedingSpeeds Forward 1st: 4.3 MPH (6.9 km/hr)2nd: 8.0 MPH (12.8 km/hr)3rd: 15.2 MPH (24.4 km/hr)Lock-up: 18.6 MPH (30.0 km/hr)Speeds Reverse 1st: 4.8 MPH (7.7 km/hr)2nd: 8.9 MPH (14.3 km/hr)3rd: 17.0 MPH (27.3 km/hr)SERVICE REFILL CAPACITYLOCATION Gallons LitersEngine (coolant) 71.3 270Fuel tank (diesel fuel) 277.4 1050Engine (oil pan) 35.1 133Front axle (gear oil) 83.7 317Rear axle (gear oil) 83.7 317Torque converter and 52.8 200transmission (engine oil)Hydraulic system including 190.2 720tank (hydraulic oil)HYDRAULIC AND STEERING SYSTEMSteering typeSteering mechanismLift (boom) cylinderTilt (bucket) cylinderSteering cylinderSteering oil pump(double section)Main oil pumpPilot/Brake oil pumpK-Lever + hydraulic over hydraulicHydraulic power steering unit, pilotoperated typeTwo (2) double-acting piston type:9.43" x 50" (240mm x 1270mm)Two (2) double-acting piston type:7.31" x 35.37" (185mm x 898mm)Two (2) double-acting piston type:5 1 /8" x 26 1 /3" (130mm x 671mm)Piston type: 120.5 GPM @ 2000 RPM(456 LPM @ 2000 RPM)Piston type: 86.1 GPM @ 2000 RPM(321 LPM @ 2000 RPM)Gear type: 25.9 GPM @ 2000 RPM(97 LPM @ 2000 RPM)Relief Loading 4550 psi (320 kg/cm 2 )set pressure Steering 4550 psi (320 kg/cm 2 )HYDRAULIC CYCLE TIME*Lifting time (at full load) 9.8 sec.Lowering time (empty) 4.3 sec.Bucket dumping time 1.4 sec.TOTAL15.5 sec.* Measured in accordance with SAE J732CAXLE SYSTEMDrive system4-wheel driveFront and rear axle Full floating banjo typeTires Standard 45/65-39 (L-5) RadialOptional 45/65-39 (L-4) and 41/25-70-39PR34Reduction & differential gear Spiral bevel gear, 1 stage reductionFinal reduction gear Outboard mounted, internal planetary gearOscillation angle ±11° (total 22°)BRAKE SYSTEMService brakesParking/Emergency brake4-wheel adjustment-free, wet disc brake.Controlled by full hydraulic system, dual-circuit.Transmission transfer gear-mounted, multi-disc,spring applied, hydraulically released

EQUIPMENT DATASTANDARD EQUIPMENTAir Cleaner (2)(Dual ElementPrecleaner)Air Conditioner(R134 Refrigerant)Alarms (Audible):Auto BrakeBrake PressureEngine Oil PressureAlarms (Visual):Air FilterAuto BrakeBattery DischargeBrake PressureBrake Disc WearBrake Oil Temp.Converter Oil TemperatureEngine Oil PressureEngine Coolant TemperatureParking BrakeTransmission ControlTransmission Oil FilterAlternator (75 amp)AM/FM Cassette StereoAuto BrakeBatteries: 12V–140AH (4 units)Belly Guard for EngineBrake Line ProtectionBrake (Parking)Spring applied;Oil released, Multi-DiscBrakes (Service)Axle BrakeOil/Oil ActuationEnclosed Wet DiscDual SystemBucket Control Lever(Single, Pilot Assisted)Bucket LevelerBoom KickoutBoom, Soft-LandingCoat HookCold Start Aid (Air Heater)CounterweightCup HolderDownshift ButtonDrawbarElectrical System (24 volt)Engine Stop SwitchFan (Blower)Fenders (Front and Rear)Gauges:Converter Oil TemperatureEngine Coolant TemperatureFuel LevelHour MeterHydraulic Oil LevelTachometerHeater/Pressurizer(40,000 BTU)Horn (Electric)Hydraulic PowerBoost Indicators:High BeamParking BrakeTransmission DeclutchTransmission ShiftWorking LightK-Lever + SteeringLinkage (Dual Z-type, Sealed)Lights:2 Headlights (Halogen)2 Backup Lights2 Step Lights2 Rear Working LightsMuffler (2)Neutral Safety StartOpen ROPS & Enclosed Cab:Enclosed cab with soundsuppression, front lights,front and rear wipers andwashers, one rear view andtwo side mirrors, tinted glassand roll-up side windowsOperator’s Manual BoxOperating Mode Selection(Normal, Heavy Duty,Load & Carry)PreLub ® StarterRadiator: Heavy DutyPlate Fin TypeRadiator GrilleReverse AlarmSafety Articulation Locking BarSeat, Air RideSeat Belt, RetractableShift Control Unit forAutomatic ShiftSingle Lever HydraulicControlsTires, 45/65-R39 (L-5)Traction ControlTransmission Lock-UpWrist Rest, AdjustableOPTIONAL EQUIPMENT41.25/70-39 PR34Converter, 12vEmergency SteeringGround-Level Fueling SystemHigh Lift ArmsHinged Belly GuardK-LINKPayload Scale SystemQuick-change Oil SystemRide ControlSnap-On Cutting EdgeSegments

KAWASAKI LOADERSMore Than A Machine, A Complete SolutionKawasaki Construction MachineryCorp. of America, a division ofKawasaki Heavy Industries, is aleading supplier of a full range ofhigh quality wheel loaders. In fact,Kawasaki is the oldest on-goingmanufacturer of articulated, rubbertiredwheel loaders in the world.Since 1962, Kawasaki wheel loadershave continuously evolved to bringyou the best in equipment and supportservices, backed by a carefullyselected dealer network.Kawasaki articulated wheelloaders incorporate innovativedesign features coupled withextensive knowledge and experiencegained from real-worldapplications. Kawasaki pioneeredZ-Link design to provide unmatchedutility, high breakout force andefficiency in its machines. Poweredby proven emissions-compliantCummins diesel engines, durabilityand serviceability are designed intoevery Kawasaki loader.Kawasaki loaders are assembled atthe company’s modern facilities inNewnan, GA. Service and supportoperations are headquartered inKennesaw, GA.A state-of-the-art parts distributionsystem links dealers with the mainparts warehouse, allowing themto order parts directly. Qualifiedcraftsmen rebuild components forall Kawasaki models at our fullyequippedrebuild center, makingcomponent exchange easier andfaster. An independent oil analysisprogram allows monitoring of criticalsystems to reduce unscheduleddowntime.The independent dealers that representand support Kawasaki loaders areexperts in their markets and arededicated to providing you with thebest service available. Together, we arecommitted to making your investmentin a Kawasaki loader a sound businessdecision that will pay dividends foryears to come.2140 Barrett Park Drive • Suite 101Kennesaw, Georgia 30144Tel: 770-499-7000 • Fax: 770-421-6842www.kawasakiloaders.comPart #135ZV Broch05-04