Modern production at HORA: optimized processes through cell ...

Modern production at HORA: optimized processes through cell ...

Modern production at HORA: optimized processes through cell ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRODUCT INNOvATION<br />

Fascin<strong>at</strong>ion and challenge:<br />

Newly developed PT products for emerging markets<br />

Dierk Joachim of the Product Innov<strong>at</strong>ion team with three of more than 60 minimum flow valves th<strong>at</strong><br />

wait in the PT Assembly to be delivered to India.<br />

Power plants in India and China are designed differently<br />

than comparable plants in Europe, and th<strong>at</strong>’s why <strong>HORA</strong><br />

developed special valves for this market. The PT product<br />

portfolio has been expanded to include two new products<br />

– minimum flow control valves and low-pressure turbine<br />

bypass valves – so th<strong>at</strong> <strong>HORA</strong> could take on two orders<br />

from India in 2010 th<strong>at</strong> will be delivered this year. “These<br />

projects have a volume of several million euros,“ says M<strong>at</strong>thias<br />

Dirbach, Director Sales PT. “But since such project packages<br />

can only be commissioned as a whole, we wouldn‘t<br />

have received the order for our existing products without<br />

our new ones.”<br />

The new minimum flow control valves represent an extension<br />

of PT’s product portfolio in the direction of cus-<br />

Construction engineer Horst Seidlitz and welder Ulrich Mickan inspect the<br />

progress of welding on the new low-pressure turbine bypass valve.<br />

tomized high-end solutions: Chinese<br />

and Indian power plants with unit<br />

output in excess of 500 megaw<strong>at</strong>ts<br />

increasingly plan a straight-<strong>through</strong><br />

install<strong>at</strong>ion of these globe valves.<br />

With the new globe valve body, the<br />

modular minimum flow control valve<br />

series is complete, and <strong>HORA</strong> can now<br />

offer its customers a large selection of<br />

tailored combin<strong>at</strong>ions of valve body<br />

designs and inner trims.<br />

Currently, <strong>HORA</strong> is working on a new<br />

series of low-pressure turbine bypass<br />

valves (TBV) for steam temper<strong>at</strong>ures<br />

of over 600°C. These valves are destined<br />

for power gener<strong>at</strong>ion units with<br />

outputs in excess of 600 megaw<strong>at</strong>ts –<br />

a type of large power plant th<strong>at</strong> will<br />

be built especially in Asia in the coming years. And with the<br />

order it received in April 2010 for two units each with two<br />

high-pressure and two low-pressure turbine bypass valves,<br />

<strong>HORA</strong> qualified as a supplier for one of the first supercritical<br />

800 megaw<strong>at</strong>t power plants in India. Because of the<br />

high temper<strong>at</strong>ures, the valve bodies will be manufactured<br />

in forged steel instead of cast steel.<br />

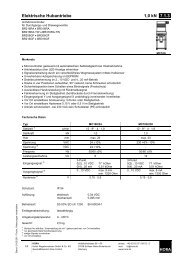

Through the further development of its injection nozzle,<br />

<strong>HORA</strong> can now expand its market share in the low-pressure<br />

turbine bypass valve segment. These new injection nozzles<br />

deliver a significantly finer spray of w<strong>at</strong>er in the partialload<br />

range and thus improve steam desuperhe<strong>at</strong>ing. The<br />

most important goal of this development was the optimiz<strong>at</strong>ion<br />

of droplet size.<br />

velocity dispersion in the new pressure-controlled injection nozzle.<br />

PRODUCT DETAILS<br />

Heavy Duty Control valves now available<br />

The <strong>HORA</strong> Heavy Duty Control Valve is a vers<strong>at</strong>ile, modular<br />

globe valve designed for severe duties. This type of valve<br />

can be utilized to regul<strong>at</strong>e and control the flow of gases,<br />

steams or liquids in all industrial applic<strong>at</strong>ions. “It is particularly<br />

suitable for the w<strong>at</strong>er-steam cycle in high pressure/high<br />

temper<strong>at</strong>ure power plant applic<strong>at</strong>ions,” explains<br />

Franz Hansknecht, Director Product Innov<strong>at</strong>ion PT. “Working<br />

in close cooper<strong>at</strong>ion with end-user facility engineers<br />

and technical staff, we identify common problems. Due to<br />

our long-standing expertise in valve design we are able to<br />

elimin<strong>at</strong>e them.” The result is the <strong>HORA</strong> Heavy Duty Control<br />

Valve, which incorpor<strong>at</strong>es a number of sophistic<strong>at</strong>ed<br />

design improvements:<br />

• For optimum flow, the internal geometry of the valve<br />

body has been designed and valid<strong>at</strong>ed using FEM and<br />

CFD techniques.<br />

• Oper<strong>at</strong>ing and maintenance costs are minimized by the<br />

use of quick-change trims and highly wear-resistant<br />

m<strong>at</strong>erials.<br />

• A modular design with an extensive array of standard<br />

trims as well as tailor-made solutions provides optimum<br />

performance in flow control.<br />

• An exchange of trims is possible so the valve can be<br />

adapted to meet revised process conditions, e.g. plant<br />

upgrades.<br />

• A wide range of actu<strong>at</strong>ors is available: manual, pneum<strong>at</strong>ic,<br />

electric and electro-hydraulic.<br />

• <strong>HORA</strong> maintains a stock of valve bodies and modules,<br />

so product lead times are short, which in turn makes<br />

planning for maintenance and plant outages easier.<br />

Careful m<strong>at</strong>erial selection and proven design elimin<strong>at</strong>e<br />

common issues associ<strong>at</strong>ed with control valves such as erosion,<br />

corrosion, cavit<strong>at</strong>ion, vibr<strong>at</strong>ion, noise and poor controllability.<br />

By combin<strong>at</strong>ion of <strong>optimized</strong> design and costefficiency,<br />

the <strong>HORA</strong> Heavy Duty Control Valve is an ideal<br />

choice for severe service oper<strong>at</strong>ing conditions.<br />

The <strong>HORA</strong> Heavy Duty Control Valves can be combined<br />

with all types of actu<strong>at</strong>ors. Electric or pneum<strong>at</strong>ic actu<strong>at</strong>ors<br />

are used by default, however, other types are available on<br />

request. For applic<strong>at</strong>ions in pressure classes lower than PN<br />

63 or Class 600, please refer to the <strong>HORA</strong> Standard Duty<br />

Control Valves.<br />

The interior geometry of the valve has purposely designed<br />

large spaces to allow easy access with serviceability in<br />

mind. The body can accommod<strong>at</strong>e various trim designs and<br />

exhibits high flow coefficients as well as low turbulence.<br />

Depending on pressure class and valve size, end connections<br />

are available as socket-weld, butt-weld or flanged.<br />

For gas and steam applic<strong>at</strong>ions involving high pressure<br />

drops or high velocities, outlet extensions with integr<strong>at</strong>ed<br />

perfor<strong>at</strong>ed discs can be supplied.<br />

“The temper<strong>at</strong>ure distribution of insul<strong>at</strong>ed valves is analyzed<br />

by extensive CFD simul<strong>at</strong>ions,” says Franz Hansknecht.<br />

“At temper<strong>at</strong>ures above 400°C (752°F), an intermedi<strong>at</strong>e<br />

yoke is utilized to protect the actu<strong>at</strong>or and any optional<br />

accessories from overhe<strong>at</strong>ing and resulting damage.”<br />

The Heavy Duty Control valve is<br />

available now. Please contact<br />

pt@hora.de for more inform<strong>at</strong>ion.<br />

6 7