Modern production at HORA: optimized processes through cell ...

Modern production at HORA: optimized processes through cell ...

Modern production at HORA: optimized processes through cell ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

horapower 2nd Edition | August 2011<br />

Your Power Technology Upd<strong>at</strong>e<br />

A Fresh Look<br />

A new logo and a completely<br />

revamped website<br />

Page 9 – New Corpor<strong>at</strong>e Design<br />

Clearly structured <strong>production</strong> hall: A light, well-arranged work st<strong>at</strong>ion is a definite asset. <strong>HORA</strong> employees enjoy a comfortable work area.<br />

<strong>Modern</strong> <strong>production</strong> <strong>at</strong> <strong>HORA</strong>:<br />

<strong>optimized</strong> <strong>processes</strong> <strong>through</strong><br />

<strong>cell</strong> manufacturing<br />

Order management center and new factory layout cre<strong>at</strong>e<br />

the perfect framework<br />

Recap<br />

Looking back to the Sales<br />

Meeting in November 2010<br />

Page 11 – Coming Together<br />

<strong>HORA</strong> had already been manufacturing valves for 40 years<br />

when, in 2007, the implement<strong>at</strong>ion of a new <strong>production</strong><br />

system was considered in the Power Technology business<br />

unit. Up to th<strong>at</strong> point, valves had been produced using a<br />

workshop orient<strong>at</strong>ion, which involves classifying <strong>production</strong><br />

steps according to the manufacturing technology: bo-<br />

Award<br />

TOP Innov<strong>at</strong>ion Prize<br />

goes to <strong>HORA</strong><br />

Page 11 – Outstanding Processes<br />

ring, milling or l<strong>at</strong>hing. However, internal studies revealed<br />

th<strong>at</strong> <strong>production</strong> in line with component segment<strong>at</strong>ion,<br />

also known as <strong>cell</strong> manufacturing, would offer <strong>HORA</strong> a<br />

number of advantages. Its efficiency, punctuality, and costeffectiveness<br />

would all mean gre<strong>at</strong>er reliability in the interests<br />

of customer s<strong>at</strong>isfaction. Yet the gre<strong>at</strong>est value of<br />

<strong>cell</strong> manufacturing lies in the specializ<strong>at</strong>ion of employees<br />

in one particular component group, resulting in enormous<br />

improvements to product quality. Cell manufacturing also<br />

results in gre<strong>at</strong>er personal initi<strong>at</strong>ive and responsibility in<br />

employees’ daily work, because the basic idea of the <strong>cell</strong><br />

concept is very simple: wh<strong>at</strong> used to be controlled centrally<br />

is now shifted to the <strong>cell</strong>s and managed decentrally.

COvER STORY PROGRESS<br />

Organiz<strong>at</strong>ional Structure<br />

“Group work“ is the official terminology for <strong>cell</strong> manufacturing<br />

in a work organiz<strong>at</strong>ion. Within a defined task area,<br />

a group of employees independently manages the division<br />

of tasks in a particular <strong>production</strong> process. After all, employees<br />

directly involved in <strong>production</strong> are in a better position<br />

to evalu<strong>at</strong>e and carry out work steps in their own <strong>cell</strong>s. An<br />

autonomous manufacturing <strong>cell</strong> can manage itself. And it<br />

functions on the basis of a customer-supplier rel<strong>at</strong>ionship:<br />

every <strong>cell</strong> has the st<strong>at</strong>us of a supplier th<strong>at</strong> delivers parts to<br />

an internal customer – for example, the <strong>cell</strong> th<strong>at</strong> carries out<br />

the next step in <strong>production</strong>. On-time delivery plays an important<br />

role here, too, because <strong>at</strong> the end of the process,<br />

power plant customers expect the products they ordered<br />

to be shipped on time.<br />

Roland Liedtke joined <strong>HORA</strong> in 2009 as Director of Manufacturing<br />

right in the middle of the ‘hot phase’ of this<br />

transform<strong>at</strong>ion, and the <strong>cell</strong> concept was implemented<br />

under his leadership. “At the beginning, some of the employees<br />

were n<strong>at</strong>urally resistant to the new approach and<br />

uncertain about it,” says Liedtke. “But we were convinced<br />

th<strong>at</strong> a more structured work method would optimize our<br />

<strong>production</strong> <strong>processes</strong>. We actively involved the employees<br />

in the project phases, because their experiences were extremely<br />

important for layout planning and the design of<br />

the work st<strong>at</strong>ions.“<br />

PT’s new approach to <strong>production</strong> also led to a new factory<br />

layout and the <strong>HORA</strong> order management center, so th<strong>at</strong><br />

the project would have a framework th<strong>at</strong> enables its success.<br />

The order management center synthesizes the organiz<strong>at</strong>ional<br />

output of all <strong>HORA</strong>‘s departments as efficiently as<br />

possible, and controls order planning with view to quality,<br />

cost and time. A daily cross-departmental order management<br />

meeting <strong>at</strong> 1:00 p.m. makes sure th<strong>at</strong> all the necessary<br />

decisions can be made together on the spot.<br />

The assembly and pressure testing <strong>cell</strong>s have moved to a<br />

new loc<strong>at</strong>ion. “The new hall has a much higher ceiling,“<br />

says Reinhard Kruse who oper<strong>at</strong>es the pressure test facility.<br />

“It’s much easier to use the crane to mount large valve<br />

bodies in the test bay.” Moreover, the four test st<strong>at</strong>ions<br />

allow tasks to be divided up much more sensibly. The result:<br />

“Pressure testing is now simpler, faster, and physically<br />

less demanding,“ explains Kruse, “and th<strong>at</strong> means we can<br />

gener<strong>at</strong>e higher unit numbers.“<br />

In spite of an investment of approxim<strong>at</strong>ely three million<br />

Euros, Director of Manufacturing Roland Liedtke still isn‘t<br />

quite s<strong>at</strong>isfied; instead, he’s committed himself to ongoing<br />

further developments and improvements with the goal<br />

of increasing productivity. Internal workshops are taking<br />

place in 2011 in order to identify and maximize potential in<br />

the <strong>cell</strong>s. We plan to order submerged arc welding equipment,<br />

for example. With its expertly trained employees,<br />

modern equipment and professional methods, <strong>HORA</strong> is<br />

able to master the complexities of high-end valve <strong>production</strong><br />

and ensure the cost-effective, lean execution of even<br />

the largest projects.<br />

The introduction of the 5S method was an important element in restructuring<br />

<strong>production</strong>. The principle “order and cleanliness” is based on the Japanese<br />

<strong>production</strong> philosophy: seiri (sort), seiton (place in an orderly fashion),<br />

seiso (clean), seiketsu (standardize) and shitsuke (practice self-discipline).<br />

The result is visible everywhere in the <strong>production</strong> areas. Manfred Krypczyk<br />

opens a drawer <strong>at</strong> his work st<strong>at</strong>ion. The blue background space indic<strong>at</strong>es<br />

th<strong>at</strong> a tool is not <strong>at</strong> its place.<br />

Upcoming projects revolve around efficiency<br />

Efficiency is a major topic for the <strong>production</strong><br />

team <strong>at</strong> <strong>HORA</strong>. Harald Wick,<br />

Director Oper<strong>at</strong>ions, explains: “Efficiency<br />

is all about doing things right.<br />

We are always looking for ways to<br />

optimize time and efforts used for the<br />

intended task or purpose.“ The <strong>production</strong><br />

team is currently working on<br />

a few projects to improve efficiency:<br />

1. Advance actu<strong>at</strong>or assembly to save<br />

time<br />

2. Design for <strong>optimized</strong> <strong>production</strong> to<br />

lower manufacturing costs<br />

3. “Cell-hopping“: better alloc<strong>at</strong>ion<br />

of the components to the <strong>cell</strong>s<br />

4. Work queue per <strong>cell</strong>: hedging the<br />

3-day horizon<br />

During the first quarter of 2011, students<br />

from a local college in Bielefeld<br />

spent eight weeks <strong>at</strong> <strong>HORA</strong> working<br />

on their technical theses. They improved<br />

the planning and control of the<br />

annealing process after welding in<br />

order to achieve gre<strong>at</strong>er process efficiency.<br />

Harald Wick looks into ways<br />

to continue this transfer process with<br />

universities over the course of the<br />

year. An additional project is to increase<br />

the machine availability. Total<br />

productive maintenance (TPM) is a standardized method<br />

to increase machine availability and to reduce unplanned<br />

idleness during <strong>production</strong> <strong>processes</strong> to a minimum.<br />

A new device called “EnergySave” now shifts four Gildemeister<br />

l<strong>at</strong>hes autom<strong>at</strong>ically into power-saving mode during<br />

unproductive hours. The yearly energy savings from<br />

EDITORIAL<br />

M<strong>at</strong>thias Dirbach and Harald Wick<br />

Dear Partners and Customers,<br />

Last November we met with many<br />

of you <strong>at</strong> the <strong>HORA</strong> Sales Meeting in<br />

Schloss Holte. Your feedback was very<br />

positive. We were impressed by the<br />

in-depth technical convers<strong>at</strong>ions and<br />

The portable 3D measuring arm is an example for investments in gre<strong>at</strong>er reliability enabling gre<strong>at</strong><br />

measuring accuracy and improved quality. Tobias Ottensmeier, industrial engineer in PT Production,<br />

with the new measuring machine, which has a range of 2.5 meters. The portable 3D measuring arm<br />

enables a high degree of accuracy in the manufacturing process, even in spots th<strong>at</strong> are difficult to<br />

reach.<br />

the ideas and experiences you shared.<br />

It makes such a difference when we<br />

“come together to grow together” –<br />

th<strong>at</strong> was our slogan for the event and<br />

it proved to be true!<br />

<strong>HORA</strong> Power Technology needs your<br />

input to continue to develop reliable<br />

and innov<strong>at</strong>ive high-end products.<br />

Our goal is to improve our <strong>processes</strong><br />

to better serve your needs. Exciting<br />

things happen <strong>at</strong> <strong>HORA</strong>: here you’ll<br />

read more about our improved <strong>production</strong>,<br />

our new logo and web site,<br />

and new products.<br />

We’ve had an exceptional year in<br />

2010 and are going strong in 2011 as<br />

this step amount to around 45,000 kWh. A new clamp used<br />

with the EX-CELL-O machining centre helps reduce machining<br />

costs for angle valve bodies by around 50%. “There<br />

is a special aspect of this project,” stressed Wick. “Our<br />

trainees from the engineering and manufacturing departments<br />

were involved in its implement<strong>at</strong>ion. Improving efficiency<br />

is a cross-departmental effort.”<br />

well. We are proud to present to you<br />

the second edition of our newsletter<br />

<strong>HORA</strong>power. Don’t hesit<strong>at</strong>e to contact<br />

us with any feedback or questions<br />

you may have! We look forward<br />

to continue our partnership.<br />

2 3<br />

Best regards,<br />

M<strong>at</strong>thias Dirbach<br />

Director Sales<br />

Power Technology<br />

Harald Wick<br />

Director Oper<strong>at</strong>ions<br />

Power Technology

PHOTO STORY<br />

The route <strong>through</strong> the PT Production process<br />

There’s no standard route <strong>through</strong> <strong>production</strong> for valves<br />

from <strong>HORA</strong>’s PT business unit, since they’re made to order<br />

for each project. Even so, <strong>at</strong> the component level there<br />

are several st<strong>at</strong>ions within the <strong>production</strong> process th<strong>at</strong> all<br />

valves must pass.<br />

1. Supply (incoming goods / raw m<strong>at</strong>erial stock)<br />

The photo shows outdoor bar m<strong>at</strong>erial storage. An<br />

intelligent and flexible disposition system controls all<br />

supply <strong>processes</strong>.<br />

3. Machining (l<strong>at</strong>hing, boring, milling)<br />

Component machining takes place in the <strong>production</strong> <strong>cell</strong>s,<br />

which are divided according to product groups and managed<br />

independently. In the photo, you see a Gildemeister<br />

Gamma 2000 turning-milling center <strong>at</strong> the bonnet <strong>cell</strong>.<br />

2. Sawing<br />

The employees <strong>at</strong> the logistics <strong>cell</strong> manage m<strong>at</strong>erial<br />

supply for the <strong>production</strong> <strong>cell</strong>s. The photo shows one of<br />

three band saws for bar m<strong>at</strong>erial.<br />

4. Welding technology (welding, he<strong>at</strong> tre<strong>at</strong>ment,<br />

m<strong>at</strong>erial inspection)<br />

Welding technology, including he<strong>at</strong> tre<strong>at</strong>ment, is integr<strong>at</strong>ed<br />

in the valve body <strong>cell</strong> in order to enable the complete<br />

manufacture of complex valve bodies <strong>at</strong> one st<strong>at</strong>ion. The<br />

photo shows the welding process for a forged-steel body.<br />

5. Commissioning<br />

At <strong>HORA</strong>, commissioning is loc<strong>at</strong>ed <strong>at</strong> the logistics <strong>cell</strong> to<br />

ensure m<strong>at</strong>erial supply to the assembly <strong>cell</strong>. In the photo,<br />

you can see the p<strong>at</strong>ernoster storage in the assembly hall.<br />

7. Pressure testing<br />

Following final assembly, pressure tightness testing of the<br />

valves takes place in <strong>HORA</strong>‘s own testing department. The<br />

maximum test pressure used is up to 280 bar when the<br />

test medium is air, and 1600 bar with w<strong>at</strong>er. Here you see<br />

a cast steel valve mounted in the test bay.<br />

6. Final assembly<br />

Final assembly of <strong>HORA</strong> valves takes place in close cooper<strong>at</strong>ion<br />

with the quality assurance department. After the<br />

individual components have been released, the valves are<br />

assembled. The photo shows completely assembled valves<br />

th<strong>at</strong> are ready for pressure tightness testing.<br />

8. After painting, valves are shipped.<br />

After the valves have passed tightness testing and been<br />

painted, they are packed for shipping and turned over to<br />

the freight hauler. A large valve is being loaded.<br />

4 5

PRODUCT INNOvATION<br />

Fascin<strong>at</strong>ion and challenge:<br />

Newly developed PT products for emerging markets<br />

Dierk Joachim of the Product Innov<strong>at</strong>ion team with three of more than 60 minimum flow valves th<strong>at</strong><br />

wait in the PT Assembly to be delivered to India.<br />

Power plants in India and China are designed differently<br />

than comparable plants in Europe, and th<strong>at</strong>’s why <strong>HORA</strong><br />

developed special valves for this market. The PT product<br />

portfolio has been expanded to include two new products<br />

– minimum flow control valves and low-pressure turbine<br />

bypass valves – so th<strong>at</strong> <strong>HORA</strong> could take on two orders<br />

from India in 2010 th<strong>at</strong> will be delivered this year. “These<br />

projects have a volume of several million euros,“ says M<strong>at</strong>thias<br />

Dirbach, Director Sales PT. “But since such project packages<br />

can only be commissioned as a whole, we wouldn‘t<br />

have received the order for our existing products without<br />

our new ones.”<br />

The new minimum flow control valves represent an extension<br />

of PT’s product portfolio in the direction of cus-<br />

Construction engineer Horst Seidlitz and welder Ulrich Mickan inspect the<br />

progress of welding on the new low-pressure turbine bypass valve.<br />

tomized high-end solutions: Chinese<br />

and Indian power plants with unit<br />

output in excess of 500 megaw<strong>at</strong>ts<br />

increasingly plan a straight-<strong>through</strong><br />

install<strong>at</strong>ion of these globe valves.<br />

With the new globe valve body, the<br />

modular minimum flow control valve<br />

series is complete, and <strong>HORA</strong> can now<br />

offer its customers a large selection of<br />

tailored combin<strong>at</strong>ions of valve body<br />

designs and inner trims.<br />

Currently, <strong>HORA</strong> is working on a new<br />

series of low-pressure turbine bypass<br />

valves (TBV) for steam temper<strong>at</strong>ures<br />

of over 600°C. These valves are destined<br />

for power gener<strong>at</strong>ion units with<br />

outputs in excess of 600 megaw<strong>at</strong>ts –<br />

a type of large power plant th<strong>at</strong> will<br />

be built especially in Asia in the coming years. And with the<br />

order it received in April 2010 for two units each with two<br />

high-pressure and two low-pressure turbine bypass valves,<br />

<strong>HORA</strong> qualified as a supplier for one of the first supercritical<br />

800 megaw<strong>at</strong>t power plants in India. Because of the<br />

high temper<strong>at</strong>ures, the valve bodies will be manufactured<br />

in forged steel instead of cast steel.<br />

Through the further development of its injection nozzle,<br />

<strong>HORA</strong> can now expand its market share in the low-pressure<br />

turbine bypass valve segment. These new injection nozzles<br />

deliver a significantly finer spray of w<strong>at</strong>er in the partialload<br />

range and thus improve steam desuperhe<strong>at</strong>ing. The<br />

most important goal of this development was the optimiz<strong>at</strong>ion<br />

of droplet size.<br />

velocity dispersion in the new pressure-controlled injection nozzle.<br />

PRODUCT DETAILS<br />

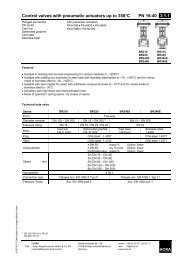

Heavy Duty Control valves now available<br />

The <strong>HORA</strong> Heavy Duty Control Valve is a vers<strong>at</strong>ile, modular<br />

globe valve designed for severe duties. This type of valve<br />

can be utilized to regul<strong>at</strong>e and control the flow of gases,<br />

steams or liquids in all industrial applic<strong>at</strong>ions. “It is particularly<br />

suitable for the w<strong>at</strong>er-steam cycle in high pressure/high<br />

temper<strong>at</strong>ure power plant applic<strong>at</strong>ions,” explains<br />

Franz Hansknecht, Director Product Innov<strong>at</strong>ion PT. “Working<br />

in close cooper<strong>at</strong>ion with end-user facility engineers<br />

and technical staff, we identify common problems. Due to<br />

our long-standing expertise in valve design we are able to<br />

elimin<strong>at</strong>e them.” The result is the <strong>HORA</strong> Heavy Duty Control<br />

Valve, which incorpor<strong>at</strong>es a number of sophistic<strong>at</strong>ed<br />

design improvements:<br />

• For optimum flow, the internal geometry of the valve<br />

body has been designed and valid<strong>at</strong>ed using FEM and<br />

CFD techniques.<br />

• Oper<strong>at</strong>ing and maintenance costs are minimized by the<br />

use of quick-change trims and highly wear-resistant<br />

m<strong>at</strong>erials.<br />

• A modular design with an extensive array of standard<br />

trims as well as tailor-made solutions provides optimum<br />

performance in flow control.<br />

• An exchange of trims is possible so the valve can be<br />

adapted to meet revised process conditions, e.g. plant<br />

upgrades.<br />

• A wide range of actu<strong>at</strong>ors is available: manual, pneum<strong>at</strong>ic,<br />

electric and electro-hydraulic.<br />

• <strong>HORA</strong> maintains a stock of valve bodies and modules,<br />

so product lead times are short, which in turn makes<br />

planning for maintenance and plant outages easier.<br />

Careful m<strong>at</strong>erial selection and proven design elimin<strong>at</strong>e<br />

common issues associ<strong>at</strong>ed with control valves such as erosion,<br />

corrosion, cavit<strong>at</strong>ion, vibr<strong>at</strong>ion, noise and poor controllability.<br />

By combin<strong>at</strong>ion of <strong>optimized</strong> design and costefficiency,<br />

the <strong>HORA</strong> Heavy Duty Control Valve is an ideal<br />

choice for severe service oper<strong>at</strong>ing conditions.<br />

The <strong>HORA</strong> Heavy Duty Control Valves can be combined<br />

with all types of actu<strong>at</strong>ors. Electric or pneum<strong>at</strong>ic actu<strong>at</strong>ors<br />

are used by default, however, other types are available on<br />

request. For applic<strong>at</strong>ions in pressure classes lower than PN<br />

63 or Class 600, please refer to the <strong>HORA</strong> Standard Duty<br />

Control Valves.<br />

The interior geometry of the valve has purposely designed<br />

large spaces to allow easy access with serviceability in<br />

mind. The body can accommod<strong>at</strong>e various trim designs and<br />

exhibits high flow coefficients as well as low turbulence.<br />

Depending on pressure class and valve size, end connections<br />

are available as socket-weld, butt-weld or flanged.<br />

For gas and steam applic<strong>at</strong>ions involving high pressure<br />

drops or high velocities, outlet extensions with integr<strong>at</strong>ed<br />

perfor<strong>at</strong>ed discs can be supplied.<br />

“The temper<strong>at</strong>ure distribution of insul<strong>at</strong>ed valves is analyzed<br />

by extensive CFD simul<strong>at</strong>ions,” says Franz Hansknecht.<br />

“At temper<strong>at</strong>ures above 400°C (752°F), an intermedi<strong>at</strong>e<br />

yoke is utilized to protect the actu<strong>at</strong>or and any optional<br />

accessories from overhe<strong>at</strong>ing and resulting damage.”<br />

The Heavy Duty Control valve is<br />

available now. Please contact<br />

pt@hora.de for more inform<strong>at</strong>ion.<br />

6 7

WORK PLAN<br />

PT’s logistics hall is now more clearly structured<br />

PT’s logistics hall contains the incoming goods, incoming<br />

goods inspection and shipping departments. In recent<br />

weeks, noticeable changes have been made: the arrangement<br />

of these areas is now significantly clearer.<br />

Stefan Fritze, project engineer in the Process Innov<strong>at</strong>ion<br />

team, describes the project: “First, shelving was moved or<br />

dismantled to cre<strong>at</strong>e space precisely where it was needed.<br />

We then moved the existing groups of tables, and we improved<br />

the work systems so th<strong>at</strong> we can do without some<br />

of the workbenches in the future. Finally, we moved the incoming<br />

goods, inspection and shipping departments. The<br />

different areas are now separ<strong>at</strong>ed and signed, floor spaces<br />

INNOvATION PEOPLE<br />

<strong>HORA</strong> now developed its own iPhone app called valveM<strong>at</strong>e,<br />

the ultim<strong>at</strong>e tool for sizing control valves for w<strong>at</strong>er and<br />

steam. Initi<strong>at</strong>or Dr. Klaus Mehnert works in the PT Product<br />

Innov<strong>at</strong>ion team: “For everyone interested in m<strong>at</strong>ters concerning<br />

controls for w<strong>at</strong>er-steam-cycles, <strong>HORA</strong> now offers<br />

an easy-to-use calcul<strong>at</strong>ion tool. This applic<strong>at</strong>ion for modern<br />

smart phones is basically a new version of the sliderule,<br />

just with a lot more functionality.”<br />

For one, the sales personnel, developers and engineers<br />

<strong>at</strong> <strong>HORA</strong> can use the app, but on the other hand, <strong>HORA</strong><br />

also targets customers, resellers, engineers <strong>at</strong> power plants<br />

along with students from relevant fields of studies with<br />

this app available for download <strong>at</strong> www.hora.de/en.<br />

The necessary thermodynamic properties of the fluid are<br />

calcul<strong>at</strong>ed using the formul<strong>at</strong>ions of the Intern<strong>at</strong>ional Associ<strong>at</strong>ion<br />

for the Properties of W<strong>at</strong>er and Steam. Based<br />

upon the input d<strong>at</strong>a, valveM<strong>at</strong>e autom<strong>at</strong>ically detects the<br />

aggreg<strong>at</strong>e st<strong>at</strong>e of the fluid and applies the respective formulae.<br />

valveM<strong>at</strong>e‘s intuitive user interface with the simple<br />

input-output approach lets users get straight to the results.<br />

All calcul<strong>at</strong>ions are done in real-time, no extra calcul<strong>at</strong>ion<br />

button is needed.<br />

are marked and we’ve cre<strong>at</strong>ed space for supply.”<br />

The reorganiz<strong>at</strong>ion has shortened p<strong>at</strong>hs and reduced both<br />

the work needed to find things and possible sources of error<br />

– and all this makes the work process here more effective<br />

as a whole.<br />

The next step will be a detailed look <strong>at</strong> each department to<br />

discover its individual optimiz<strong>at</strong>ion potential. At Ostwestfalen-Lippe’s<br />

University of Applied Sciences in Lemgo, the<br />

Ergonomics group in the Logistics department has scheduled<br />

a project on the detailed examin<strong>at</strong>ion of the workst<strong>at</strong>ions<br />

in the PT logistics hall for l<strong>at</strong>er in this year.<br />

MARKETING<br />

A fresh look: New logo and a completely revamped<br />

website for <strong>HORA</strong><br />

In the second quarter of 2011 <strong>HORA</strong><br />

introduced a new logo in a more intense<br />

shade of blue and a new shape.<br />

The new look is fresher and more<br />

modern and signals a new chapter in<br />

the company’s development: <strong>HORA</strong><br />

adapts its external present<strong>at</strong>ion to reflect<br />

its increased importance on the<br />

market and its global orient<strong>at</strong>ion. As<br />

part of the new corpor<strong>at</strong>e design, the<br />

Power Technology business unit received<br />

its own logo. The final touch will<br />

continue to be the slogan “Ex<strong>cell</strong>ence<br />

is our standard” as an expression of<br />

<strong>HORA</strong>’s general commitment to highest<br />

quality and expertise.<br />

As part of the new appearance, the<br />

<strong>HORA</strong> website was completely revamped.<br />

Enlightening pictures tell the<br />

story of a successful family-owned<br />

engineering business. We invite you<br />

to take a closer look <strong>at</strong> the PT business<br />

unit on the new website and discover<br />

more about <strong>HORA</strong>’s service and<br />

its products:<br />

www.hora.de/en<br />

Discover the new <strong>HORA</strong> iPhone App valveM<strong>at</strong>e Dr. Dieter Dresselhaus<br />

receives honorary professorship<br />

iPhone App valveM<strong>at</strong>e: Within the first<br />

weeks of valveM<strong>at</strong>e‘s publishing in the<br />

Apple AppStore the app got downloaded<br />

several hundred times, half of it<br />

from outside Germany.<br />

Engineer Dr. Klaus Mehnert’s primary<br />

job is to develop the product configur<strong>at</strong>or.<br />

As a side product of his daily work,<br />

he now came up with valveM<strong>at</strong>e.<br />

Processes in the logistics hall are now much<br />

more effective: The clearer arrangement of<br />

work areas means shorter p<strong>at</strong>hs.<br />

Wareneingangsprüfung = Incoming goods<br />

inspection<br />

Wareneingang = Incoming goods<br />

Warenausgang = Shipping<br />

A journey into the history of our logo<br />

A look <strong>at</strong> the predecessor version<br />

of our logo is a journey into our<br />

company’s past, which began in 1967,<br />

when the first company logo was<br />

cre<strong>at</strong>ed with the founding of Holter<br />

Regelarm<strong>at</strong>uren GmbH & Co KG.<br />

Since then, our logo has changed<br />

along with the times: the 1967 logo<br />

was replaced after just five years, and<br />

since then we’ve upd<strong>at</strong>ed it every ten<br />

to fifteen years. The slogan “Ex<strong>cell</strong>ence<br />

is our standard” was added <strong>at</strong><br />

the end of the 1990s to represent the<br />

start of a new phase in company development.<br />

Prof. Dieter Dresselhaus and Prof. Wilfried Jungkind of the University of Applied Sciences have been<br />

working on joint projects for more than ten years.<br />

In October 2010, Dr. Dieter Dresselhaus<br />

was named an honorary professor<br />

of Ostwestfalen-Lippe’s University<br />

of Applied Sciences. With this step,<br />

the university expressed its appreci<strong>at</strong>ion<br />

for Dresselhaus’ long years<br />

of work as a lecturer: “Mr. Dresselhaus<br />

understands how to win students‘<br />

interest and enthusiasm even<br />

for complex and demanding topics.“<br />

Since last winter semester, he has<br />

also taught courses on str<strong>at</strong>egic management<br />

for the Master of Business<br />

Administr<strong>at</strong>ion (MBA) program. Dieter<br />

Dresselhaus notes: “This honor<br />

recognizes a cooper<strong>at</strong>ion of more<br />

than ten years between the university<br />

and <strong>HORA</strong>, and it‘s one with gre<strong>at</strong><br />

benefits for <strong>HORA</strong> in particular. We<br />

focus on method transfer <strong>through</strong><br />

the implement<strong>at</strong>ion of ideas from<br />

Bachelor’s theses, and especially on<br />

early contact to the university‘s gradu<strong>at</strong>es.<br />

Students discover <strong>HORA</strong> very<br />

early on, and th<strong>at</strong> stimul<strong>at</strong>es an exchange<br />

of knowledge.” It’s a volunteer<br />

commitment th<strong>at</strong> pays off for<br />

both sides!<br />

8 9<br />

1967<br />

1972<br />

During the 1980s<br />

As of 1998<br />

As of 2011

DEvELOPMENT<br />

A special kind of employee qualific<strong>at</strong>ion<br />

The <strong>HORA</strong> participants in front of the Kraftwerksschule, which calls itself the “PowerTech Training Center”.<br />

<strong>HORA</strong> offers 20 of its employees a tailor-made power plant<br />

ex<strong>cell</strong>ence study course <strong>at</strong> the renowned Kraftwerksschule<br />

(Power Plant College) in Essen, the only company in this<br />

sector to do so. <strong>HORA</strong> covers the entire costs. Furthermore,<br />

two-thirds of the time invested by the participants is working<br />

time. The lecture series started in mid-May and will<br />

continue until September 2012. It teaches an interdisciplinary<br />

understanding for fossil fuel-fired power plants. The<br />

interdepartmental participants come from the areas of PT<br />

Sales, Service, Design and Product Innov<strong>at</strong>ion. The group includes<br />

more experienced colleagues in addition to younger<br />

employees. Two participants even come from the Dutch PT<br />

represent<strong>at</strong>ive Advanced Valve Solutions (AVS). The goal is<br />

to deepen the knowledge individually and across departments,<br />

so th<strong>at</strong> <strong>HORA</strong> experts develop even more marketoriented<br />

products. The course incorpor<strong>at</strong>es the following<br />

modules: Design and oper<strong>at</strong>ion of power plants, power<br />

plant instrument<strong>at</strong>ion and control, steam gener<strong>at</strong>ion with<br />

fossil fuels as well as steam and gas turbines. It requires<br />

three <strong>at</strong>tendance weeks in Essen spread over 18 months as<br />

well as 17 weekends <strong>at</strong> <strong>HORA</strong>.<br />

We asked two participants why they are taking part in the<br />

training, and wh<strong>at</strong> they expect.<br />

Heike Böckhaus (44) is responsible for sales in Germany in<br />

the Power Technology division. “My goal is to find <strong>optimized</strong><br />

solutions for our customers. It helps to understand<br />

the overall situ<strong>at</strong>ion and the demands placed on the individual<br />

power plant components.”<br />

Ulrich Brentrup (40) works as a supervisor in the forged<br />

steel group. The focus of his work is in the strength calcul<strong>at</strong>ion<br />

of valves. “I would like to know wh<strong>at</strong> happens with<br />

our valves; wh<strong>at</strong> are the effects of the start-ups, start-up<br />

frequency as well as the other influences on the valves. The<br />

knowledge is intended to help me when assessing problems<br />

and to help my understanding of the causes of the<br />

problem. I hope to gain an insight into the <strong>processes</strong> of the<br />

entire power plant and particularly into the function of the<br />

valves in the power plant. I hope to discover some additional<br />

insights for optimizing our final control elements.”<br />

The Kraftwerksschule Essen and the KWX<br />

The Kraftwerksschule in Essen has being training oper<strong>at</strong>ing<br />

personnel for German power st<strong>at</strong>ions for more<br />

than 50 years and has for a number of years offered a<br />

university semester in power plant engineering in cooper<strong>at</strong>ion<br />

with the University of Applied Sciences Aachen<br />

(Fachhochschule Aachen). Employees <strong>at</strong> <strong>HORA</strong><br />

now have an exceptional opportunity to gain university<br />

level power plant academic knowledge in the course of<br />

an occup<strong>at</strong>ional qualific<strong>at</strong>ion measure.<br />

The lectures are generally held on Fridays and S<strong>at</strong>urdays.<br />

The participants <strong>at</strong> several seminars in Essen are<br />

offered labor<strong>at</strong>ory experiments and training on modern<br />

power plant simul<strong>at</strong>ors. It is the management‘s intention<br />

to secure their long-term position in the sector by the<br />

high-value qualific<strong>at</strong>ion of the employees.<br />

Kerstin Kofink<br />

PowerTech Training Center Essen<br />

<strong>HORA</strong> “students” have a control room for simul<strong>at</strong>ing a complete power<br />

st<strong>at</strong>ion all to themselves.<br />

AWARD<br />

TOP Innov<strong>at</strong>ion Prize 2010 goes to <strong>HORA</strong><br />

Best company in TOP Innov<strong>at</strong>ion Network<br />

At the TOP Entrepreneurs’ Meeting in Berlin <strong>at</strong> the Federal<br />

Ministry of Economics and Technology, St<strong>at</strong>e Secretary<br />

Jochen Homann presented <strong>HORA</strong> with the TOP Innov<strong>at</strong>ion<br />

Prize for 2010. More than 120 represent<strong>at</strong>ives of the<br />

companies th<strong>at</strong> host TOP, a technology-oriented visit<strong>at</strong>ion<br />

and innov<strong>at</strong>ion program, took part in this event. The prize<br />

has been awarded yearly since 1993 to the company within<br />

TOP’s network of over 100 enterprises th<strong>at</strong> best demonstr<strong>at</strong>es<br />

its innov<strong>at</strong>ive power.<br />

<strong>HORA</strong> was honored for its continual efforts to transl<strong>at</strong>e<br />

innov<strong>at</strong>ions into solutions. Both Product Innov<strong>at</strong>ion and<br />

especially Process Innov<strong>at</strong>ion have contributed to the ongoing<br />

success of the company. Prof. Dresselhaus commented:<br />

“I see the TOP Innov<strong>at</strong>ion Prize as recognition of all of<br />

<strong>HORA</strong>’s employees. It rewards the enthusiasm of our staff<br />

and is a gre<strong>at</strong> incentive to us to continue on this p<strong>at</strong>h.”<br />

“<strong>HORA</strong> has served the TOP program as a host since 2006.<br />

When we hold meetings <strong>at</strong> <strong>HORA</strong> on the topic of implementing<br />

the balanced scorecard or lean management in<br />

made-to-order <strong>production</strong>, we always receive above-ave-<br />

SALES MEETING<br />

24 Sales Partners from Australia to Finland visit <strong>HORA</strong><br />

The second PT Sales Meeting in the<br />

company’s history took place from<br />

November 24 to 26, 2010 and was a<br />

complete success. Two dozen sales<br />

partners from Spain, Finland, Greece,<br />

Denmark, Ireland, Netherlands,<br />

Gre<strong>at</strong> Britain, Austria, Portugal, Russia,<br />

Sweden, China, India, Australia,<br />

the USA and Canada were our guests.<br />

The slogan of the event, “Growing<br />

together means getting together”,<br />

was borne out by discussions on networking<br />

the company’s worldwide<br />

business and <strong>HORA</strong>’s compliance policies,<br />

among other things. In addition,<br />

we used the occasion to present<br />

our partners the brand new product<br />

brochure from the new heavy duty<br />

series, hot off the presses. Our partners<br />

also received the PT newsletter<br />

<strong>HORA</strong>power for the first time, with<br />

its reports on current developments,<br />

projects and successes. A pleasant<br />

An interested look <strong>at</strong> the new PT Production<br />

rage positive feedback from participants,” says P<strong>at</strong>rick<br />

Merke, Deputy Program Director <strong>at</strong> TOP.<br />

Best company in TOP Innov<strong>at</strong>ion Network 2010 (from left): St<strong>at</strong>e Secretary<br />

Jochen Homann, Prof. Dr. Dieter Dresselhaus, Ralf Schulz, Georg Bode and<br />

Harald Wick in Berlin <strong>at</strong> the award ceremony.<br />

change from the meetings was a visit<br />

to Wiedenbruck’s Christmas market.<br />

The next sales meeting will take place<br />

in conjunction with the Achema congress<br />

in Frankfurt in June 2012.<br />

Prof. Dresselhaus with Wilhelm and Christian Friedrich, Austria M<strong>at</strong>thias Dirbach explains the significance of flow simul<strong>at</strong>ion<br />

10 11

SALES MEETING<br />

Our foreign sales partners with their <strong>HORA</strong> contacts <strong>at</strong> the conference hotel in Marienfeld<br />

Prof. Dresselhaus responds to questions<br />

Henning Brock explains a <strong>HORA</strong> work plan<br />

The 5S reference workst<strong>at</strong>ion in the CNC department<br />

Intern<strong>at</strong>ional interest in a <strong>HORA</strong> valve<br />

Reinhard Kruse proudly presents the new test area<br />

Arousing curiosity: the COMTES 700 prototype Partners from three continents<br />

“It was my first experience to be a part of <strong>HORA</strong> Conference.<br />

I gained understanding on many aspects of ‘new<br />

<strong>HORA</strong>’, which is evolving from 2008 onwards. I have a lot<br />

of ideas / points to share.”<br />

Vikash Agrawal, Hi-Tech Systems & Services,<br />

Kalkutta, Indien<br />

“There is a Chinese saying: Seeing is a hundred<br />

times better than hearing. The sales meeting<br />

was a very good opportunity for us employees<br />

to speak directly to many partners and to find<br />

out more about the needs of the global valve<br />

market. It is important for us to know which<br />

new technical and commercial requirements<br />

our worldwide customers have. This helps us to<br />

individualize our sales and product str<strong>at</strong>egies.‹<br />

Yang Cao, PT Sales, Schloss Holte, Germany<br />

“It was interesting to see so many other reps from<br />

around the world. We found the present<strong>at</strong>ions by<br />

the reps showed different approaches to business<br />

th<strong>at</strong> illustr<strong>at</strong>e the good qualities of a successful<br />

global business… Thank you all for being good<br />

hosts.”<br />

Ian Braff, Armour Valve Ltd., Toronto, Canada<br />

“Besides the fact th<strong>at</strong> this was a well-organized<br />

meeting, the <strong>HORA</strong> sales meeting provided additional<br />

value on the background of other partners<br />

and distributors. It was interesting to find<br />

out wh<strong>at</strong> products they focus on. I had open and<br />

transparent discussions with other guests about<br />

different markets and pricing structures. In Finland<br />

for example we have a lot of OEM customers.<br />

At the meeting I also got an idea in which<br />

way the company will face the future. I‘ve got a<br />

positive impression.”<br />

Johan Bäckström, Kokko Control Oy,<br />

Espoo, Finland<br />

12 13

SALES MEETING<br />

Mr. Sun with Yang Cao<br />

Jose Figueiredo from Portugal and Roland<br />

Liedtke<br />

Our foreign sales partners with the new PT brochure<br />

vikash Agrawal from India during his<br />

present<strong>at</strong>ion<br />

Exchange of business cards between India and Ireland<br />

Johan Bäckström from Finland<br />

AROUND THE WORLD<br />

<strong>HORA</strong> exhibited<br />

for the first time <strong>at</strong><br />

valve World Expo<br />

The <strong>HORA</strong> booth drew crowds of visitors.<br />

The intern<strong>at</strong>ional industry event Valve<br />

World Expo took place in Düsseldorf<br />

<strong>at</strong> the end of 2010. For three<br />

days, 536 intern<strong>at</strong>ional companies<br />

from 37 different countries exhibited<br />

the l<strong>at</strong>est technologies, components<br />

and systems from the vast field of industrial<br />

valves. <strong>HORA</strong> displayed new<br />

products from the two business units<br />

Power Technology and Flow Control<br />

(formerly Building+Autom<strong>at</strong>ion) <strong>at</strong> its<br />

booth. Hans-Jürgen Bracke, PT Area<br />

Sales Manager Germany, Austria and<br />

Switzerland, commented: “Our business<br />

unit presented the new 89 series<br />

for the first time. We also call them<br />

Heavy Duty Control Valves. Its advantage<br />

is the high-pressure clamp construction.<br />

We also displayed the PRDS<br />

(pressure-reducing and desuperhe<strong>at</strong>ing)<br />

valve with integr<strong>at</strong>ed steam assisted<br />

desuperhe<strong>at</strong>er, which is very <strong>at</strong>tractive<br />

for our customers because it<br />

safely injects the w<strong>at</strong>er downstream<br />

the valve.“<br />

Russia Power:<br />

<strong>HORA</strong> <strong>at</strong> the most important industry conference<br />

in Russia<br />

Russia Power <strong>at</strong> the end of March 2011 in Moscow: Sven Podlech and Prof. Dieter<br />

Dresselhaus present Ivan Shumeyko from <strong>HORA</strong>’s partner in Russia, the East<br />

Energo Group, with all the product models used <strong>at</strong> the event, so th<strong>at</strong> they can<br />

be kept in Russia.<br />

<strong>HORA</strong> <strong>at</strong> Russia Power: more than 5800 visitors from 50 countries <strong>at</strong>tended this industry conference.<br />

Partner Schubert & Salzer Iberica (BvALvE)<br />

named Best Technology Supplier 2010<br />

The 600 participants <strong>at</strong> the 4th Intern<strong>at</strong>ional Concentr<strong>at</strong>ed Solar Thermal Power<br />

Summit, which took place in November 2010 in Seville, named our Spanish partner<br />

Schubert & Salzer Iberica “Best Technology Supplier” for 2010. The company<br />

prevailed over both Foster Wheeler/Schott Solar and Siemens in this c<strong>at</strong>egory.<br />

Sven Podlech (front) <strong>at</strong> the booth of our Spanish sales partner Schubert & Salzer Iberica in Sevilla<br />

with (l. to r.) Michael Mostolski (<strong>HORA</strong>) and Angel S. Tavira, Jose Luis Soriano, Carlos Pont and Francisco<br />

Bort (all Schubert & Salzer Iberica)<br />

14 15

16<br />

PEOPLE<br />

Industrial Engineer Tobias Ottensmeier optimizes internal<br />

PT Production <strong>processes</strong><br />

Tobias Ottensmeier started working as an Industrial Engineer <strong>at</strong> <strong>HORA</strong> in August<br />

2010. He studied mechanical engineering focusing on <strong>production</strong> engineering.<br />

The 37-year-old takes care of the planning and optimiz<strong>at</strong>ion of internal<br />

<strong>processes</strong> in the PT Production. Purchasing new manufacturing tools or new<br />

machines belong to his tasks. Objective is clear: optimize the PT Production and<br />

increase efficiency. Tobias Ottensmeier keeps in mind th<strong>at</strong> <strong>at</strong> the end the employee<br />

has to work with his ideas on a daily basis, so communic<strong>at</strong>ing with his<br />

colleagues on the <strong>production</strong> floor plays an important role.<br />

Sergej Kunz new CAM-Manager<br />

In March 2011 Sergej Kunz became CAM-Manager (CAM=Computer Aided Manufacturing)<br />

<strong>at</strong> <strong>HORA</strong>. The 31-year-old trained toolmaker used to work <strong>at</strong> a<br />

different company as <strong>production</strong> supervisor gaining experience with CAM systems.<br />

At <strong>HORA</strong> Kunz started to establish a central CAM programming. Right<br />

from the start he’s spoken with colleagues from many different departments:<br />

“They were all very friendly and cooper<strong>at</strong>ive,” said Kunz. He was also impressed<br />

by the tidiness of the <strong>production</strong> area: “I have never seen such clean<br />

<strong>production</strong> floors in other companies before.”<br />

Nico Hillebrand becomes an engineer after his coop-studies<br />

<strong>at</strong> <strong>HORA</strong><br />

Nico Hillebrand (30) gradu<strong>at</strong>ed with a B.A. degree in mechanical engineering<br />

with the best grade possible: 1,0. He wrote his thesis about the “Optimiz<strong>at</strong>ion<br />

of fixing perfor<strong>at</strong>ed discs in steam transforming valves“, for which he won an<br />

award given by the regional business associ<strong>at</strong>ion. During his studies, Nico Hillebrand<br />

also worked as a trainee <strong>at</strong> <strong>HORA</strong>. He belonged to the group of so called<br />

coop-students combining an apprenticeship with a university program.<br />

Today, Nico Hillebrand works as an engineer in the PT Design and Product Innov<strong>at</strong>ion,<br />

where he focuses on the design of steam valves.<br />

Dr. Gabor Bihercz development engineer<br />

Dr. Gabor Bihercz joined <strong>HORA</strong> in early 2011 as a development engineer in<br />

the Product Innov<strong>at</strong>ion department. The 33-year-old, who studied mechanical<br />

engineering, had already been working in this position in several companies<br />

for five years. One of his motiv<strong>at</strong>ions to come to <strong>HORA</strong> was the prosperous<br />

image of the company. “<strong>HORA</strong> is a company where everyone can bring on own<br />

ideas. Working here is a gre<strong>at</strong> challenge for me,” says Dr. Bihercz. After just a<br />

few weeks <strong>at</strong> his new job, he was impressed by how many highly qualified and<br />

trained experts are working <strong>at</strong> <strong>HORA</strong>. One of his first projects was the development<br />

of an internal norm for a specific m<strong>at</strong>erial th<strong>at</strong> is used in the <strong>production</strong><br />

process.<br />

<strong>HORA</strong> | Holter Regelarm<strong>at</strong>uren GmbH & Co. KG | Helleforthstraße 58-60 | 33758 Schloß Holte-Stukenbrock | Germany<br />

Telephone +49 (0) 52 07-89 03-0 | Telefax +49 (0) 52 07-8 80 37 | e-mail: mail@hora.de | www.hora.de