TECHNICAL

Protein Concentration and Diafiltration by Tangential Flow ... - Bio-Link

Protein Concentration and Diafiltration by Tangential Flow ... - Bio-Link

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

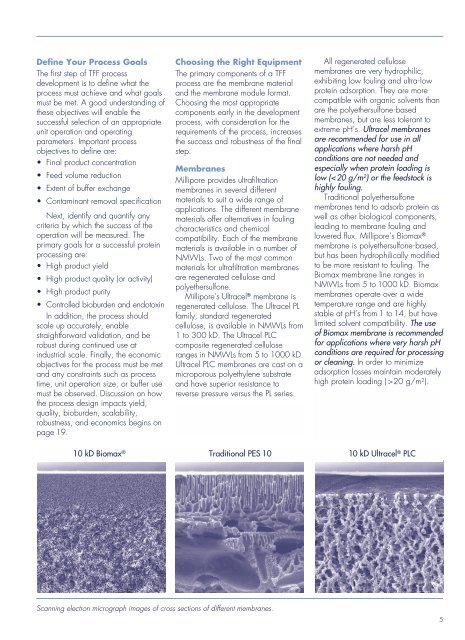

Define Your Process GoalsThe first step of TFF processdevelopment is to define what theprocess must achieve and what goalsmust be met. A good understanding ofthese objectives will enable thesuccessful selection of an appropriateunit operation and operatingparameters. Important processobjectives to define are:• Final product concentration• Feed volume reduction• Extent of buffer exchange• Contaminant removal specificationNext, identify and quantify anycriteria by which the success of theoperation will be measured. Theprimary goals for a successful proteinprocessing are:• High product yield• High product quality (or activity)• High product purity• Controlled bioburden and endotoxinIn addition, the process shouldscale up accurately, enablestraightforward validation, and berobust during continued use atindustrial scale. Finally, the economicobjectives for the process must be metand any constraints such as processtime, unit operation size, or buffer usemust be observed. Discussion on howthe process design impacts yield,quality, bioburden, scalability,robustness, and economics begins onpage 19.Choosing the Right EquipmentThe primary components of a TFFprocess are the membrane materialand the membrane module format.Choosing the most appropriatecomponents early in the developmentprocess, with consideration for therequirements of the process, increasesthe success and robustness of the finalstep.MembranesMillipore provides ultrafiltrationmembranes in several differentmaterials to suit a wide range ofapplications. The different membranematerials offer alternatives in foulingcharacteristics and chemicalcompatibility. Each of the membranematerials is available in a number ofNMWLs. Two of the most commonmaterials for ultrafiltration membranesare regenerated cellulose andpolyethersulfone.Millipore's Ultracel ® membrane isregenerated cellulose. The Ultracel PLfamily, standard regeneratedcellulose, is available in NMWLs from1 to 300 kD. The Ultracel PLCcomposite regenerated celluloseranges in NMWLs from 5 to 1000 kD.Ultracel PLC membranes are cast on amicroporous polyethylene substrateand have superior resistance toreverse pressure versus the PL series.All regenerated cellulosemembranes are very hydrophilic,exhibiting low fouling and ultra-lowprotein adsorption. They are morecompatible with organic solvents thanare the polyethersulfone-basedmembranes, but are less tolerant toextreme pH’s. Ultracel membranesare recommended for use in allapplications where harsh pHconditions are not needed andespecially when protein loading islow (20 g/m 2 ).10 kD Biomax ® Traditional PES 10 10 kD Ultracel ® PLCScanning electron micrograph images of cross sections of different membranes.5