TECHNICAL

Protein Concentration and Diafiltration by Tangential Flow ... - Bio-Link

Protein Concentration and Diafiltration by Tangential Flow ... - Bio-Link

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

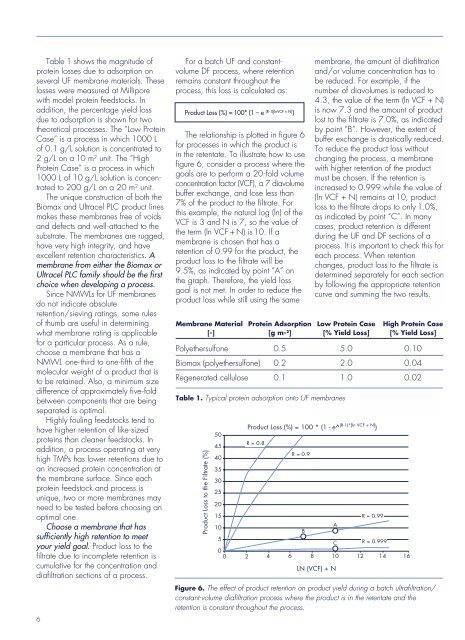

Table 1 shows the magnitude ofprotein losses due to adsorption onseveral UF membrane materials. Theselosses were measured at Milliporewith model protein feedstocks. Inaddition, the percentage yield lossdue to adsorption is shown for twotheoretical processes. The “Low ProteinCase” is a process in which 1000 Lof 0.1 g/L solution is concentrated to2 g/L on a 10 m 2 unit. The “HighProtein Case” is a process in which1000 L of 10 g/L solution is concentratedto 200 g/L on a 20 m 2 unit.The unique construction of both theBiomax and Ultracel PLC product linesmakes these membranes free of voidsand defects and well-attached to thesubstrate. The membranes are rugged,have very high integrity, and haveexcellent retention characteristics. Amembrane from either the Biomax orUltracel PLC family should be the firstchoice when developing a process.Since NMWLs for UF membranesdo not indicate absoluteretention/sieving ratings, some rulesof thumb are useful in determiningwhat membrane rating is applicablefor a particular process. As a rule,choose a membrane that has aNMWL one-third to one-fifth of themolecular weight of a product that isto be retained. Also, a minimum sizedifference of approximately five-foldbetween components that are beingseparated is optimal.Highly fouling feedstocks tend tohave higher retention of like-sizedproteins than cleaner feedstocks. Inaddition, a process operating at veryhigh TMPs has lower retentions due toan increased protein concentration atthe membrane surface. Since eachprotein feedstock and process isunique, two or more membranes mayneed to be tested before choosing anoptimal one.Choose a membrane that hassufficiently high retention to meetyour yield goal. Product loss to thefiltrate due to incomplete retention iscumulative for the concentration anddiafiltration sections of a process.6For a batch UF and constantvolumeDF process, where retentionremains constant throughout theprocess, this loss is calculated as:Product Loss (%) = 100* (1 – e (R-1)[lnVCF + N] )The relationship is plotted in figure 6for processes in which the product isin the retentate. To illustrate how to usefigure 6, consider a process where thegoals are to perform a 20-fold volumeconcentration factor (VCF), a 7 diavolumebuffer exchange, and lose less than7% of the product to the filtrate. Forthis example, the natural log (ln) of theVCF is 3 and N is 7, so the value ofthe term (ln VCF + N) is 10. If amembrane is chosen that has aretention of 0.99 for the product, theproduct loss to the filtrate will be9.5%, as indicated by point “A” onthe graph. Therefore, the yield lossgoal is not met. In order to reduce theproduct loss while still using the sameTable 1. Typical protein adsorption onto UF membranesmembrane, the amount of diafiltrationand/or volume concentration has tobe reduced. For example, if thenumber of diavolumes is reduced to4.3, the value of the term (ln VCF + N)is now 7.3 and the amount of productlost to the filtrate is 7.0%, as indicatedby point “B”. However, the extent ofbuffer exchange is drastically reduced.To reduce the product loss withoutchanging the process, a membranewith higher retention of the productmust be chosen. If the retention isincreased to 0.999 while the value of(ln VCF + N) remains at 10, productloss to the filtrate drops to only 1.0%,as indicated by point “C”. In manycases, product retention is differentduring the UF and DF sections of aprocess. It is important to check this foreach process. When retentionchanges, product loss to the filtrate isdetermined separately for each sectionby following the appropriate retentioncurve and summing the two results.Membrane Material Protein Adsorption Low Protein Case High Protein Case[-] [g m- 2 ] [% Yield Loss] [% Yield Loss]Polyethersulfone 0.5 5.0 0.10Biomax (polyethersulfone) 0.2 2.0 0.04Regenerated cellulose 0.1 1.0 0.02Product Loss to the Filtrate (%)504540353025201510500Product Loss (%) = 100 * (1 - e^(R-1)*[In VCF + N] )R = 0.8R = 0.9B2 4 6 8 10 12 14LN (VCF) + NFigure 6. The effect of product retention on product yield during a batch ultrafiltration/constant-volume diafiltration process where the product is in the retentate and theretention is constant throughout the process.ACR = 0.99R = 0.99916