FIRE PRE-PLANS

FIRE PRE-PLANS - Marsh

FIRE PRE-PLANS - Marsh

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

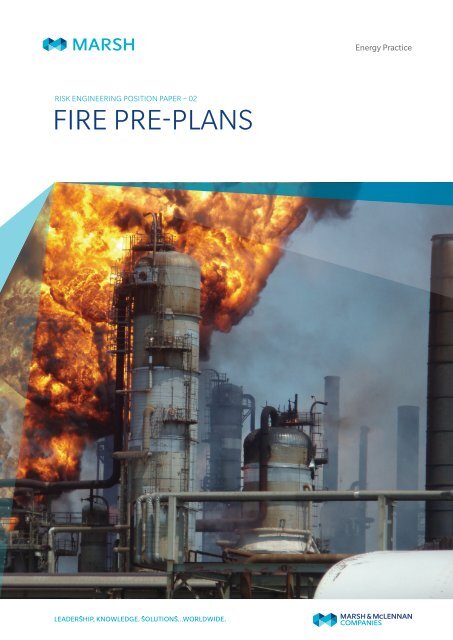

RISK ENGINEERING POSITION PAPER – 02<strong>FIRE</strong> <strong>PRE</strong>-<strong>PLANS</strong>Energy Practice

March 2011ii • Fire Pre-plans

RISK ENGINEERING POSITION PAPERCONTENTSSectionTitle.............................................................................................................................. Page1. Background...................................................................................................................................... 12. Objective.......................................................................................................................................... 13. Scope................................................................................................................................................ 14. General Principles............................................................................................................................. 15. Specific Requirements...................................................................................................................... 25.1 Policy and Procedure........................................................................................................................ 25.2 Ownership and Development........................................................................................................... 25.3 Fire Pre-plan Portfolio....................................................................................................................... 25.4 Format and Content.......................................................................................................................... 35.5 Drills................................................................................................................................................. 45.6 Distribution....................................................................................................................................... 46. Reference to Industry Losses............................................................................................................. 57. Reference to Industry Standards....................................................................................................... 58. Appendices....................................................................................................................................... 6REV 0.0. Published: March 2011Marsh • iii

March 20111. BACKGROUNDThe potential for major fires in any installation that handles large quantities of hydrocarbonproducts is self-evident. There have been numerous large damaging fires over the years andthese include tank fires which involve massive product losses and process unit fires which causemajor plant damage and process interruption.2. OBJECTIVEThe objective of this position paper is to define the standards that would be expected of a verygood level of Fire Pre-plans in the oil, gas and petrochemical industry. These standards are alsoreflected in the Marsh Energy Risk Ranking criteria. They can be used to support and define riskimprovement recommendations and also to provide detailed advice to clients seeking toimprove their fire protection and emergency response systems.3. SCOPEThe scope of this position paper includes the description and purpose, the ownership anddevelopment, and the format and content of Fire Pre-plans. It is applicable to any facilityhandling hydrocarbons and toxic materials.4. GENERAL PRINCIPLESPlants are normally designed, built and operated to avoid fires by controlling the basic causes –loss of containment and ignition. They are also provided with detection and alarm systems topromote early response and intervention. Finally, there are passive and active fire protectionfacilities ‐ and emergency response systems and resources, to be used as a final barrier toprevent or minimise the consequences.A Fire Pre-plan is a scenario based plan, specific to a particular process area or equipment item.All Fire Pre-plans should be referenced in the Site Emergency Response Plan. They shoulddescribe how the fire protection and emergency response systems are to be used in specific firecase scenarios. Fire Pre-plans should take into account the nature and likely effects of the firescenario, the materials involved (process materials and plant construction materials), thesurrounding environment, including plant layout, any special hazards pertaining to that area,and the resources available.Fire Pre-plans should be used to assess the resources required. They should be used for regulartraining and drills, and reviewed and updated after each event. Fire protection systems andemergency response resources (equipment and personnel) are generally designed to cope withthe greatest demand they are likely to face. At a given site – the controlling scenario is generallyreferred to as the fire case. Whilst a lot of attention is paid to this as it underpins the basicdesign requirements of the central fire protection systems, there are other cases that need alsoto be studied to ensure the site is prepared for a range of eventualities.1 • Fire Pre-plans

RISK ENGINEERING POSITION PAPER5. SPECIFIC REQUIREMENTS5.1 POLICY AND PROCEDUREThe Health, Safety and Environment Management System(HSE-MS) should include the procedure for thedevelopment and application of Fire Pre-plans. A copy ofthe Fire Pre-plans should be included in the EmergencyProcedures Manual for the site. Fire Pre-plans should bemanaged in the same way as all other controlleddocuments.Corporate standards for Fire Pre-plans should be availableto member sites.5.2 OWNERSHIP ANDDEVELOPMENTFire Pre-plans should be owned by the EmergencyResponse organisation at the site. There should be inputfrom all involved and affected groups and disciplines –particularly the operations teams. Where the external /local fire brigade plays a significant part in the emergencyresponse, they should be familiar with the Fire Pre-plans.Specific evacuation plans, muster points, headcount, etc.should be covered under a separate procedure in the SiteEmergency Response Plans.By definition, a Fire Pre-plan is a ‘desk-top’ derived plan,with additional input from exercise and incident feedback.The Pre-plan is best developed by a team effort. Teammembers should include:••Person responsible for site tactical emergency responseteam e.g. Fire Chief/Fire Engineer••Person responsible for first-line response e.g. ShiftSupervisor••Operations Representative - Area specific••Firefighting Team Representative••Risk Engineer••Safety OfficerThe Pre-plan should be seen as an evaluation of the type ofresponse required for typical scenarios. In the event of anactual incident, the Pre-plan should be seen as a guide andwould need to be adjusted to suit local factors, e.g.weather conditions, actual process conditions. The FirePre-plan acts as an aide-memoire in crisis situations whererational thinking time could be limited. The developmentof a Fire Pre-plan may also highlight where there may bedeficiencies in response capability or particular problemswith the subject scenario.Scenarios to be documented should be as comprehensiveas time and resource allows. Good starting points areevents typically highlighted in a Safety Case, or by highlevelunit assessment looking at other property damageevents.5.3 <strong>FIRE</strong> <strong>PRE</strong>-PLAN PORTFOLIOA comprehensive portfolio of Fire Pre-plans should include:••A Fire Pre-plan for each major storage tank and eachbund area (although these can often be combined foridentical tanks in a single local area).••A Fire Pre-plan for each pressurised storage vessel andcontainment area, including protection of the run-offand impounding area, and key steps to avoid a BLEVE.••A Fire Pre-plan for refrigerated storage tanks includingprotection of the run-off and impounding area.••A Fire Pre-plan for each berth at the marine terminal.••A Fire Pre-plan for each rail and truck loading gantry.••A Fire Pre-plan for each defined “fire area” of the unite.g. as limited by layout/drainage where this is practical/meaningful. At least the two or three most severe firecases for each process unit should be defined.••Any other specific cases that are equivalent to one of theabove.Marsh • 2

March 20115.4 FORMAT AND CONTENTThe plans are best represented on easy-reference A3 size documents, using a standardlayout. Data should be included on the diagrams where possible. Lengthy narrative shouldbe avoided and reference should be made to supporting documentationThe Pre-plans should include the following:SECTIONHeaderIncident DescriptionEquipment andContents DescriptionSpecial HazardsOperations ResponseTactical EmergencyResponseProtection ofAdjacent EquipmentRequired ManpowerDESCRIPTIONDate, Revision, Author and Approver.Unit/Section/Equipment Item/Scenario.Size: Volume, Diameter, Height or Length.Contents: Quantity, Chemical Description and Properties, e.g.Flash Point, Auto ignition temperature.Toxic Risk – including carcinogens such as Benzene and AsbestosExplosion Risk, e.g. VCE, BLEVE, Detonation.Environmental Impact & Odour Risk.Boil-over risk.Dispersion and Cloud Characteristics.Equipment and other units also at risk.Third Party Locations at Risk.Location of radioactive instrumentation elements.Location of electrical equipment with PCB.Location of equipment with water reactive chemicals.High pressure gas cylinders.Key operations response actions, e.g. shutdown, depressurisationand isolation, evacuations, remote activation of deluge/monitorsetc.Where possible the number of key actions should be limited toaround five to avoid excessive detail; they should also take intoaccount the nature of the emergency e.g. it may be necessary toshut down a pump with a leaking seal from the switch houserather than the local stop/start button.Key tactical emergency response actions, e.g. activation of fixedprotection if not automatic, deployment and position of mobileequipment, target areas for firewater and foam (cooling/extinguishment/precautionary).Where possible the number of key actions should be limited toaround five to avoid excessive detail.Identification of other key equipment and hazard arisingCooling requirements developed from radiation studiesUnit/Section/Equipment Item/Scenario.Level of initial response, e.g. shift first-line response, site brigade,local authority brigade, mutual aid partners.Minimum initial response numbers.Approach direction for various response teams, including entrypoint for non-site response, relative to specific and detailed wind/ weather conditions.3 • Fire Pre-plans

RISK ENGINEERING POSITION PAPERSECTIONRequired EquipmentFirewater RunoffDiagramsMaximum Foam andWater RequirementsDESCRIPTIONFixed equipment response, show equipment type & capacity, i.e. deluge(water, foam or chemical), foam to tank seals, monitors should alsoinclude deluge capacity, foam/chemical capacity and type.Mobile equipment response, show equipment type & capacity, i.e.deluge (water, foam or chemical), foam to tank seals and monitors andhydrants should also include deluge capacity, foam/chemical capacityand type.Response required from local authority brigade and mutual aid partnersas appropriate.Limitations, e.g. quantity of site available fire fighting consumables andsources of back-up.Limitations, e.g. volume of surrounding bunds and estimate of when fullif not being drained.Limitations, e.g. blocked routes due to equipment congestion.Route and destination of runoff.Location of runoff interceptors and control points (e.g. penstocks).Scenario plot plan showing position of fixed equipment includingactivation panels or valve stations and likely position of mobileequipment, hydrants, monitors, valve stations, water curtain provision,cooling provision, staging areas taking wind direction into account.Radiation contour diagram for human and equipment exposure.BLEVE profile, consequence and radiation contour diagram.Dispersion and toxicity diagram.For major fire cases only – i.e. those that are likely to test the capacity ofthe systems or define stocks to be accessible; and those that are likely torequire special equipment, specific system configurations or supplyarrangements to be set up early in the response plan.Assess the maximum quantities of foam and firewater required tocontrol and extinguish the fire. This should be based on likely durationand intensity and the attack strategy.5.5 DRILLS5.6 DISTRIBUTIONThere should be regular drills by the emergency responseteam in conjunction with the operations teams to maintaintheir familiarity with the Pre-plans and also to test that theinformation and response steps within them is valid.The Fire Pre-plans should be distributed as follows:••Master copies of all Fire Pre-plans to be retainedelectronically.••Controlled copies of all Fire Pre-plans to be kept in SiteEmergency Manual.••Controlled copies of area-specific Fire Pre-plans to bekept in area Emergency Procedure Manual.• • Controlled (laminated) copies of all Fire Pre-plans to bekept on Emergency Response Vehicles.Marsh • 4

March 20116. REFERENCE TO INDUSTRY LOSSESEVENT DATE 08/06/2001CountryLocationUnit TypeEventDescriptionPosition papercommentUnited StatesLouisianaStorageTank fireGasoline layer built up on top of 270 ft diameter floating roof tank due toheavy rain. Fire started by lightning, producing full surface tank fire.Emergency services set up fire fighting equipment, and once in place, thefire was extinguished in 65 minutes.This incident is the largest tank fire ever extinguished. It illustrates thebenefits of Fire Pre-plans.EVENT DATE 17/03/2008CountryLocationUnit TypeEventDescriptionPosition papercommentGermanyKolnStorageTank fireAn ethylene release from a major pipeline ignited to form a jet fire, whichimpinged on an adjacent Acrylonitrile storage tank. A major tank fireensued which took 9 hours to extinguish, during which a number of firetenders were in attendance with the deployment of 1180 fire fighters. Theflames had a devastating impact on the tank’s concrete wall, causing cracksand causing the stability of the whole tank to be in question. Note that theoriginal jet fire took 5 hours to extinguish. There was no active fireprotection available in the area, and no specific emergency plans for thisscenario. The total cost (Property Damage, plus Business Interruption) wasaround Euro 53 million.With clear scenario plans in place, the effects of this major fire could havebeen greatly reduced.7. REFERENCE TO INDUSTRY STANDARDSAPI RP 2001 Fire Protection in Refineries.5 • Fire Pre-plans

RISK ENGINEERING POSITION PAPER8. APPENDICESAPPENDIX AExample of a Fire Protection Pre-PlanABCDEGH1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16= .20 GPM/FT= .25 GPM/FT= .30 GPM/FTWATER APPLICATIONWATERWATERWATERAPPLICATION DENSITIES= .35 GPM/FT= .50 GPM/FT= .60 GPM/FTWATERWATERWATERDIRECTION OFEVACUATIONZONE 10ZONE 9WNE<strong>PRE</strong>VAILING WINDREV.ASPECIAL HAZARDSPECIAL HAZARD18ZONE 819SPZ6 ROADZONE 2F1291ZONE 1PX 4CONTROLROOMOILY WATER SEPARATORCONTAINS NO C4s THUSCLASSIFIED AS OPENDRAINF0764F1297ZONE 7F0770 A&BF0721 B&CU703 COOLING TOWERRECOVEREDXYLENE TANKZONE 3ZONE 4RECYCLELIQUOR SUBCOOLERE1208 C1282 CMOTHER LIQUORCOLUMNB1206C1282 A&BC1284L701F0749K705COOLINGTOWERS/STATIONLEGENDMOTHER LIQUORCOLUMN REBOILERF1295REFLUXDRUMSYMBOLDESCRIPTION<strong>FIRE</strong> MAIN FM<strong>FIRE</strong> MAIN LOW<strong>PRE</strong>SSURE LP<strong>FIRE</strong> HYDRANTSLUICE VALVECLOCKWISE OPENSLUICE VALVECLOCKWISE SHUTNON-RETURN VALVEZONE 5AWATERSTORAGETANKF0742ZONE 5ZONE 6SPECIAL HAZARD20H *RESTRICTOR PLATE RPMONITOR(350-750 GPM)MONITOR/FOAM(1000-2000 GPM)MONITOR/FOAM(350-750 GPM)GENERAL NOTESHYDRANTS <strong>PRE</strong>SENT ON ORIGINAL PLANT. WHILST 6" FW MAINPROBABLY STILL EXISTS THERE IS NO PHYSICAL EVIDENCEOF THE <strong>FIRE</strong> HYDRANTSREFERENCE DRAWINGSTITLEDRAWING NO.A APPROVED M.P. J.W. A.W. 11.02.2002P1 <strong>PRE</strong>LIMINARY M.P. J.W. 14.01.2002REV.H140 H288DESCRIPTION OF ISSUEDRAWNCHECKED APPROVAL APPROVAL APPROVAL APPROVAL APPROVALFINALAPPROVALDATEFINAL APPROVAL:THIS DRAWING AND THE INFORMATION HEREIN CONTAINED ARE THE PROPERTY OF HUNTSMANAND/OR SUBSIDIARIES THEREOF WHICH HAS BEEN FURNISHED IN CONFIDENCE UPON THEUNDERSTANDING AND CONDITION THAT ALL PERSONS, FIRMS OR CORPORATIONS RECEIVING SUCHDRAWING AND INFORMATION SHALL BY THE ACT OF RECEIVING THEM BE DEEMED TO HAVE AGREEDTO MAKE NO COPY, DUPLICATION, DISCLOSURE OR USE WHATSOEVER OF ALL OR ANY PART THEREOFEXCEPT AS EX<strong>PRE</strong>SSLY AUTHORIZED IN WRITING BY HUNTSMAN NOT TO GIVE, LEND OR OTHERWISEDISPOSE OF THIS DRAWING, AND TO RETURN THIS DRAWING PROMPTLY UPON REQUEST.PARAXYLENEAREA 2<strong>FIRE</strong> PROTECTION <strong>PRE</strong>-<strong>PLANS</strong>HEET 1 OF 2SCALE:N.T.S.NORTH TEES WORKSDWG. NO.REV.A(P:/BORDERS/HUNTSMAN/HUNTSA0.DWG)FIJ222222Marsh • 6

March 2011APPENDIX BABCDEFGH1.2.3.4.SYMBOL1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 162= .20 GPM/FT2= .25 GPM/FT2= .30 GPM/FTLEGENDWATERWATERWATERAPPLICATIONS ARE BASED ONDESCRIPTION<strong>FIRE</strong> MAIN FM<strong>FIRE</strong> MAIN LOW<strong>PRE</strong>SSURE LP<strong>FIRE</strong> HYDRANTSLUICE VALVECLOCKWISE OPENSLUICE VALVECLOCKWISE SHUTNON-RETURN VALVERESTRICTOR PLATE RPMONITOR(350-750 GPM)MONITOR/FOAM(1000-2000 GPM)MONITOR/FOAM(350-750 GPM)WATER APPLICATIONAPPLICATION DENSITIESGENERAL NOTESNOTES ALL DENSITIES REFLECT U.S. GALLONS2= .35 GPM/FT2= .50 GPM/FT= .60 GPM/FTTANK <strong>FIRE</strong> FIGHTING NOTES<strong>PRE</strong> BURN IS LESS THAN 45 MINUTES PRIOR TO INITIAL APPLICATIONTANK LEVEL IS 50% OR GREATERMODERATE TO LIGHT WINDSMINIMUM 4" WATER WAY FOR APPLICATION 1500 GPM OR LESSWATERWATERWATERAPPLICATION IS MADE USING LARGE VOLUME EQUIPMENT WHEN APPLICABLEMINIMUM 6" WATER PER MONITOR/NOZZLE FOR APPLICATIONS 1501 GPM OR GREATERVALUES RE<strong>PRE</strong>SENT MINIMUM APPLICATION RATE REQUIREMENTS, INCIDENT COMMANDERMAY ELECT TO INCREASE APPLICATIONS RATES IF <strong>PRE</strong> BURN TIME EXCEEDS 45 MINUTESOR IF FLAME COLLAPSE AND CONTROL IS NOT ACHIEVED WITHIN 30-45 MINUTES OF INITIAL APPLICATIONINITIAL APPLICATION SHOULD NOT BE ATTEMPTED UNTIL ALL APPLICATION EQUIPMENT, MANPOWER ANDCONSUMABLES ARE AVAILABLE ON SITEWATER CAPACITYAPPLICATION DEVICES1 HOUR FOAM CONCENTRATE MINIMUMCOOLING OF ADJACENT TANKS SHOULD BE AT THE DISCRETION OF THE INCIDENT COMMANDERBUT IN ANY CASE, CARE SHOULD BE TAKEN TO APPLY MINIMUM AMOUNTS OF COOLING WATERNECESSARY (AND STILL ACHIEVE REQUIRED RESULTS) TO MINIMIZE FLOODING IN BUND AREAS.ONLY EXPOSED AREA OF ADJACENT TANKS SHOULD RECEIVE COOLING CONSIDERATIONSZONE8TANK No.F-764PRODUCTREFERENCE DRAWINGSTITLEDRAWING NO.ZONE FLOW DATAZONE 1 = 703 GPM @ 0.35 GPM/FTZONE 2 = 426 GPM @ 0.50 GPM/FTZONE 3 = 985 GPM @ 0.50 GPM/FTZONE 4 = 217 GPM @ 0.25 GPM/FTZONE 5 = 1184 GPM @ 0.35 GPM/FT 2ZONE 5A = 257 GPM @ 0.50 GPM/FT 2ZONE 6 = 2671 GPM @ 0.60 GPM/FTZONE 7 = 349 GPM @ 0.25 GPM/FTZONE 8 = 84 GPM @ 0.25 GPM/FTZONE 9 = 805 GPM @ 0.35 GPM/FT 2ZONE 10 = 552 GPM @ 0.50 GPM/FT 2 2STORAGE TANKS34TANK BUND BUNDTOTALSURFACE5 ELEVATED FIN-FANSPRODUCT TANK DIA.APPLICATION SURFACE APPLICATION APPLICATIONAREA(GPM)6AREA (GPM) TANK & BUND78C9 - C1021 337.5084.371395 348.75433.129 L.P.G.10 H.P. FUEL GAS1112FLASH POINT FLAMMABLE VAPOR SPECIFIC13 DRUM STORAGE°C °F BPRANGE DENSITYSOLUBILITYGRAVITY14 HIGH <strong>PRE</strong>SSURE STM.15 <strong>FIRE</strong>D HEATERS16 BENZENE17 CATALYST STORAGE18 NO BUND CONTAINMENTAROMASOL H 50°C 122°F (BP 170-200°C) 1 - 8 Approx. 4 0.88 INSOLUBLEXYLENE 25-31°C 77-88°F (BP 137-143°C) 1 - 9 3.7 0.87 INSOLUBLEPENTANE -50°C -122°F (BP 28 - 36°C) 1.4 - 8 2.5 0.6 IMMISCIBLEBENZENE -11°C -52°F (BP 80.1°C) 1.4 - 8 2.7 0.88 MARGINALLYTOLUENE 4.4°C 40°F (BP 110.6°C) 1.2 - 7.1 3.2 0.87 INSOLUBLE22222221 ~ FOAM TRAILER (NTW)1 ~ FOAM TRAILER (B'HAM)4 ~ FOAM TRAILER (WILTON)3 ~ DEDICATED TRACTOR (WILTON)TOTAL FOAM FROM TRAILERS & TOTES = 180,000 L.POSITIVE <strong>PRE</strong>SSURE SELF-CONTAINED BREATHINGAPPARATUS REQUIRED FOR EMERGENCY RESPONSEPERSONNEL DURING MANUAL ATTACK IN ALL ZONESUNTIL AUTHORIZED PERSONNEL DETERMINE OTHERWISE.1920212223SECONDARY L.P. - 15", 18", 21", 24"AVAILABLE FIXED <strong>FIRE</strong>WATER PUMPSPORTABLE EMERGENCY RESPONSE EQUIP.6000 GPM FOAM/WATER <strong>FIRE</strong> ENGINE - (NTW)3000 GPM FOAM/WATER <strong>FIRE</strong> ENGINE - (WILTON)3000 GPM SKID MOUNTED DIESEL PUMP - (NTW)3000 GPM SKID MOUNTED DIESEL PUMP - (NTW)1000 GPM SKID MOUNTED DIESEL PUMP - (NTW)1000 GPM SKID MOUNTED DIESEL PUMP - (WILTON)1000 GPM SKID MOUNTED DIESEL PUMP - (WILTON)1000 GPM SKID MOUNTED DIESEL PUMP - (B'HAM)AMBULANCE - (NTW)DISTRIBUTION SYSTEMPRIMARY - 4", 6", 8", 10"SPECIAL HAZARDSSUBSTATION (ELECTRICAL)CHLORINE (RESPIRATORY/OPTICAL)HIGH <strong>PRE</strong>SSURE CYLINDERSHIGH <strong>PRE</strong>SSURE HYDRO-CARBONELEVATED PIPES/EXCHANGERSH.P. HYDROCARBON LIQUID LOADINGLOADING CONFIGURATION (FLANGES ONLOADING ARM ARE BOLTED TO FLANGES ON SHIP)MULTI HYDROCARBON FEED STOCK LINESHIGH <strong>PRE</strong>SSURE ETHYLENEC9/C10ELEVATED AREACOVERED AREAPROPYLENECONGESTIONWILTON SITE4 Tees Valley Water PumpsFOAM TRAILERSADDITIONAL MANPOWER/EQUIPMENT*CLEVELAND <strong>FIRE</strong> BRIGADE WILLRESPOND FROM MUTUAL AID.RESPIRATORY HAZARDSREV.THIS DRAWING AND THE INFORMATION HEREIN CONTAINED ARE THE PROPERTY OF HUNTSMANAND/OR SUBSIDIARIES THEREOF WHICH HAS BEEN FURNISHED IN CONFIDENCE UPON THEUNDERSTANDING AND CONDITION THAT ALL PERSONS, FIRMS OR CORPORATIONS RECEIVING SUCHDRAWING AND INFORMATION SHALL BY THE ACT OF RECEIVING THEM BE DEEMED TO HAVE AGREEDTO MAKE NO COPY, DUPLICATION, DISCLOSURE OR USE WHATSOEVER OF ALL OR ANY PART THEREOFEXCEPT AS EX<strong>PRE</strong>SSLY AUTHORIZED IN WRITING BY HUNTSMAN NOT TO GIVE, LEND OR OTHERWISEDISPOSE OF THIS DRAWING, AND TO RETURN THIS DRAWING PROMPTLY UPON REQUEST.AA APPROVED M.P. J.W. A.W. 11.02.2002P1 <strong>PRE</strong>LIMINARY M.P. J.W. 14.01.2002REV.DESCRIPTION OF ISSUEDRAWNCHECKED APPROVAL APPROVAL APPROVAL APPROVAL APPROVALFINALAPPROVALDATEFINAL APPROVAL:PARAXYLENEAREA 2<strong>FIRE</strong> PROTECTION <strong>PRE</strong>-<strong>PLANS</strong>HEET 2 OF 2SCALE:N.T.S.DWG. NO.REV.A(P:/BORDERS/HUNTSMAN/HUNTSA0.DWG)IJ217 • Fire Pre-plans

RISK ENGINEERING POSITION PAPERTHE ENGINEERING SERVICES TEAMMarsh’s Risk Engineering team hasbeen established for over 25 yearsand is uniquely qualified to providerisk managers and underwriters withthe essential information they need todetermine the right limit and scope ofcover and the right price.Each member of the team is aqualified engineer, with practicalexperience in design, construction,operation and maintenance across abroad range of oil, gas andpetrochemical risks.They have all been trained inadvanced insurance skills, in theability to assess and analyse risk andto communicate effectively andfrequently in more than onelanguage.The goal is to build bridges betweenrisk engineering, insurance and riskmanagement and between the clientand the underwriter. At the sametime, the comparative skills of theteam permit a benchmarking systemwhich gives a global opinion of therisk, assessed against peer plantsworld-wide.From the earliest planning stage tothe last operational phase, theengineering services team is able tocontribute practical andcost-effective advice and assistance.In addition to tailored programmes,the team has a series of corepackages, covering everything frommanaging a major emergency to riskreduction design features and safeworking practices.The Engineering Services team isunmatched among insurance brokersand risk advisers because of the scaleof investment, the breadth ofexpertise and the experience itincorporates.More importantly, the team uses itspractical knowledge and practicalskills to communicate a realunderstanding of physical risks, theirinsurance implications and thecommercial operating environment.Marsh • 8

For further information, pleasecontact your local Marsh office or visitour web site at: marsh.comBEIJINGTel: +86 10 6533 4070Fax: +86 10 8529 8761CALGARYTel: +1 403 290 7900Fax: +1 403 261 9882CAPE TOWNTel: +27 21 403 1940Fax: +27 21 419 3867DUBAITel: +971 4 223 7700Fax: +971 4 227 2020HOUSTONTel: +1 713 276 8000Fax: +1 713 276 8888LONDONTel: +44 (0)20 7357 1000Fax: +44 (0)20 7929 2705MADRIDTel: +34 914 569 400Fax: +34 913 025 500MOSCOWTel: +7 495 787 7070Fax: +7 495 787 7071MUMBAITel: +91 226 651 2900Fax: +91 225 651 2901NEW YORKTel: +1 212 345 6000Fax: +1 212 345 4853OSLOTel: +47 22 01 10 00Fax: +47 22 01 10 90PERTHTel: +61 8 9289 3888Fax: +61 8 9289 3880RIO DE JANEIROTel: +55 21 2141 1650Fax: +55 21 2141 1604SAN FRANCISCOTel: +1 415 743 8000Fax: +1 415 743 8080SINGAPORETel: +65 6327 3150Fax: +65 6327 8845Marsh is one of the Marsh & McLennan Companies, together with GuyCarpenter, Mercer, and Oliver Wyman.The information contained herein is based on sources we believereliable and should be understood to be general riskmanagement and insurance information only. Theinformation is not intended to be taken as advice withrespect to any individual situation and cannot berelied upon as such.In the United Kingdom, Marsh Ltd isauthorised and regulated by theFinancial Conduct Authority.Copyright © 2013 Marsh LtdAll rights reserved.