488910 EUCOMAS.indd - VDI-Wissensforum

488910 EUCOMAS.indd - VDI-Wissensforum

488910 EUCOMAS.indd - VDI-Wissensforum

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

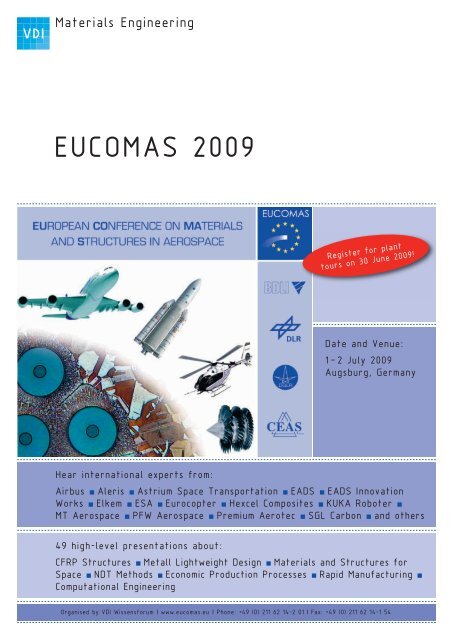

<strong>EUCOMAS</strong> 2009<br />

Register for plant<br />

tours on 30 June 2009!<br />

Date and Venue:<br />

1 – 2 July 2009<br />

Augsburg, Germany<br />

Hear international experts from:<br />

Airbus Aleris Astrium Space Transportation EADS EADS Innovation<br />

Works Elkem ESA Eurocopter Hexcel Composites KUKA Roboter<br />

MT Aerospace PFW Aerospace Premium Aerotec SGL Carbon and others<br />

49 high-level presentations about:<br />

CFRP Structures Metall Lightweight Design Materials and Structures for<br />

Space NDT Methods Economic Production Processes Rapid Manufacturing<br />

Computational Engineering<br />

Organised by <strong>VDI</strong> <strong>Wissensforum</strong> | www.eucomas.eu | Phone: +49 (0) 211 62 14-2 01 | Fax: +49 (0) 211 62 14-1 54

<strong>EUCOMAS</strong> 2009<br />

Welcome Address<br />

In the aerospace industry, new technologies will be the driver for the successful<br />

competitive positioning of the OEMs in an expected upturn of the “post-crisis”<br />

economy. One success factor is certainly the extended use of new materials and<br />

the specific design concepts for lightweight structures which promise huge<br />

economic and ecological benefits for the airlines and space vehicle operators.<br />

In that sense, the future seems black – not because of the crisis, but due to<br />

the wide use of black carbon fibre reinforced polymers (CFRP) especially for<br />

military and civil aircraft, as the programme Airbus A400M, Airbus A350 and<br />

Boeing 787 remarkably show. CFRP, due to its excellent material properties,<br />

offers huge potential for weight reduction and enhancement of life of primarily<br />

fuselage, wing and high-lift structures. But with all this euphoria, there is still a<br />

lot to do to obtain the greatest benefit from the properties of CFRP.<br />

The current “black metal” designs have to retreat and new CFRP-specific,<br />

anisotropy driven design concepts have to be developed. Aiming at an output of<br />

40 planes a month, the economical production of these CFRP structures forces<br />

a drastic increase in automation. In this context, new joining and assembly<br />

technologies play an important role, above all the adhesive bonding.<br />

Even the production-integrated quality control needs new, fast and precise<br />

non-destructive analysis tools, including the proper interpretation of structural<br />

defects. But the world of aerospace structures is not only CFRP. After years of<br />

hibernation, aluminium alloys are taking up the competition heading for lowcost<br />

– low-weight primary structures – with remarkable potential.<br />

<strong>EUCOMAS</strong> 2009 will consequently address all these important issues within<br />

the presentation programme, but will also give room for intensive discussion<br />

and networking in the specific workshops. In addition, the Aerospace Area<br />

Augsburg offers you excellent opportunities for excursions and contacts with<br />

renowned companies like Premium Aerotec, Eurocopter, EADS, MT Aerospace,<br />

Kuka and SGL. Consequently, <strong>EUCOMAS</strong> provides a platform for exchange and<br />

creativity and aims for pushing technology forward by cooperation.<br />

We warmly welcome you to <strong>EUCOMAS</strong> 2009 in Augsburg.<br />

Official Partners<br />

Heinz Voggenreiter Yann Barbaux<br />

German Aerospace EADS Innovation<br />

Center (DLR), Germany Works, France<br />

Council of European Aerospace Societies CEAS<br />

German Aerospace Industries Assocation BDLI<br />

German Association for Aerospace DGLR<br />

German Aerospace Center DLR<br />

The Association of German Engineers (<strong>VDI</strong>) – Society for Materials Engineering<br />

Technical Chair<br />

<strong>VDI</strong> Society for Materials Engineering<br />

Mediapartner<br />

Schedule of <strong>EUCOMAS</strong> 2009<br />

30 June 2009, 14:00–19:00 Plant tours<br />

1 July 2009, 8:00–18:25 Conference, Student Forum;<br />

followed by evening event;<br />

2 July 2009, 8:30–17:15 Conference; Student Forum<br />

Conference Language<br />

The official language of the conference will be English.<br />

Simultaneous translation will not be available.<br />

Organised by <strong>VDI</strong> <strong>Wissensforum</strong> | www.eucomas.eu | Phone: +49 (0) 211 62 14-2 01 | Fax: +49 (0) 211 62 14-1 54

Tuesday, 30 June 2009<br />

Plant tour to Eurocopter, Donauwörth, Germany<br />

14:00 Departure from IHK Schwaben, Augsburg<br />

15:30 Start of the plant tour in Donauwörth<br />

18:00 Return to Augsburg<br />

19:00 Arrival in Augsburg<br />

The number of participants is limited. Competing companies are excluded.<br />

Plant tour to MT Aerospace, Augsburg, Germany<br />

14:00 Departure from IHK Schwaben, Augsburg<br />

14:45 Start of the plant tour<br />

Visit the production of boosters, fuel tanks and structures<br />

18:00 Return to Augsburg<br />

18:30 Arrival in Augsburg<br />

The number of participants is limited. Competing companies are excluded.<br />

We would like to thank MT Aerospace for the kind support of the bus transfer.<br />

Wednesday, 1 July 2009<br />

08:00 Registration, reception with coffee and tea<br />

Plenary Session (Big Hall)<br />

09:00 Welcome and opening<br />

Heinz Voggenreiter, Director, German Aerospace Center (DLR), Cologne and Stuttgart, Germany<br />

Yann Barbaux, Corporate Technical Offi ce, EADS Innovation Works, Suresness, France<br />

09:15 Greetings of the Federal Minister of Economics and Technology in Germany<br />

Karl-Theodor Freiherr zu Guttenberg, Federal Minister of Economics and Technology, Germany (invited)<br />

09:30 Greetings of the Chamber of Industry and Commerce Swabia<br />

Gerd Finkbeiner, Vice President, Chamber of Industry and Commerce Swabia, Augsburg, Germany<br />

09:45 CFC Automation Technologies – Which one will secure the Introduction of CFC for Commercial Aircraft Structures?<br />

Gerd Berchtold, Vice President Commercial Aerostructures Assembly, Premium AEROTEC GmbH, Augsburg, Germany<br />

10:15 Aerospace Automated Manufacturing<br />

Otto Kellenberg, Key Technology Manager, Aerospace Application, KUKA Roboter GmbH, Gersthofen, Germany<br />

10:45 Coffee break<br />

CFRP Structures – Materials and Automated Manufacturing (Big Hall) Metall Light Weight Design – Materials and Structures (Hall “Welser”)<br />

11:15 Thermoplastic Manufacturing Processes Status and Perspectives<br />

Patrice Lefebure, R&D Engineer, Composite Technologies/Materials &<br />

Processes, EADS Innovation Works, Suresnes, France<br />

Co-authors: Eric Soccard, Mathieu Piana, EADS Innovation Works,<br />

Bouguenais, France<br />

11:40 Cost-Effi cient Processing of Thermoplastic Fiber Reinforced Composite<br />

Materials for Aerospace Applications<br />

Ralf Schledjewski, Group Leader Manufacturing Science, Institut für<br />

Verbundwerkstoffe GmbH, Kaiserslautern, Germany<br />

12:05 Vacuum Infusion Process in a Microwave Oven<br />

Fabrice Gaille, Material Sciences Engineer, EADS Deutschland GmbH,<br />

Munich, Germany<br />

Co-author: Heike Ringwald, Institut of Aircraft Design, University of<br />

Stuttgart, Stuttgart, Germany<br />

12:30 Hollow Composite Structure Design by Using Novel Soluble Core<br />

Technologies<br />

Steffen Kunze, Organic Materials and Processes, Eurocopter Deutschland<br />

GmbH, Ottobrunn, Germany<br />

Co-authors: Christian Wellhausen, Tom Kretschmer, Eurocopter<br />

Deutschland GmbH, Ottobrunn, Germany<br />

12:55 Lunch<br />

Source: Eurocopter<br />

Source: MT Aerospace<br />

Design and Technology Integration for a Combination of Metallic and<br />

Composite Materials in Aircraft Structures<br />

Jens Hinrichsen, Aerospace Consultant, Hawksland Associates,<br />

New Alexandria, USA<br />

Co-author: Gary Windas, Hawksland Associates, East Yorkshire, UK<br />

Magnesium Alloys and Magnesium Based MMC’s for Structural<br />

Aerospace Applications<br />

Hajo Dieringa, Deputy Head Department Magnesium Processing, GKSS<br />

Research Center Geesthacht GmbH, Geesthacht, Germany<br />

Co-authors: Norbert Hort, Karl Ulrich Kainer, GKSS Research Center<br />

Geesthacht GmbH, Geesthacht, Germany<br />

A New Aluminum Alloy for High Strength Heavy Aerospace Forgings<br />

Matthias Hilpert, Materials Development and Castings, Otto Fuchs KG,<br />

Meinerzhagen, Germany<br />

Co-authors: Gregor Terlinde, Thomas Witulski, Otto Fuchs KG,<br />

Meinerzhagen, Germany<br />

New Developments on Aluminium Products for Advanced Aircraft<br />

Applications<br />

Sabine Spangel, R&D Coordinator Aerospace, Aleris Aluminum Koblenz<br />

GmbH, Koblenz, Germany<br />

Co-authors: Achim Bürger, Matthias Miermeister, Ingo Kröpfl , Aleris<br />

Aluminum Koblenz GmbH, Koblenz, Germany<br />

Organised by <strong>VDI</strong> <strong>Wissensforum</strong> | www.eucomas.eu | Phone: +49 (0) 211 62 14-2 01 | Fax: +49 (0) 211 62 14-1 54

Wednesday, 1 July 2009<br />

CFRP Structures – Materials and Automated Manufacturing (Big Hall) Metall Lightweight Design – Materials and Structures (Hall “Welser”)<br />

14:30 Automated Manufacturing of High-Performance Composite Parts by<br />

the Gap Impregnation Process<br />

Kai Fischer, Process Development Liquid Composite Moulding, Institute of<br />

Plastics Processing, RWTH Aachen University, Aachen, Germany<br />

Co-author: Walter Michaeli, RWTH Aachen University, Aachen, Germany<br />

14:55 Automated Handling and Processing of Carbon Fibre Textiles<br />

Gerhard Straßer, Research Assistant, Manufacturing Technology, Institute<br />

for Machine Tools and Industrial Management (iwb), University of Technology<br />

Munich, Augsburg, Germany<br />

Co-authors: Gunther Reinhart, Claudia Ehinger, University of Technology<br />

Munich, Augsburg, Germany<br />

15:20 Automated Handling of Dry Carbon Fabric and Prepreg Material for<br />

Frame and Stringer Production<br />

Manuel Herkt, Research Engineer, Premium Aerotec GmbH, Varel, Germany<br />

Co-authors: Hilmar Apmann, Martin Lünemann, Premium Aerotec GmbH,<br />

Varel, Germany<br />

15:45 Product & Process Development for out-of-autoclave (O.O.A)<br />

Manufacture of Aerospace Secondary Structures<br />

Hans-Christian Kobow, Sales Engineer, Hexcel Composites GmbH, Stade,<br />

Germany<br />

Co-authors: Steve Mortimer, Matthew Smith, Hexcel Composites GmbH,<br />

Duxford, UK<br />

16:10 Coffee break<br />

Multidisciplinary Optimization of Titanium Milling<br />

Rudolf Gradinger, Head of Business Development Group, ARC Leichtmetallkompetenzzentrum<br />

Ranshofen GmbH, Ranshofen, Austria<br />

The Next Generation Green Aluminium Process<br />

Kai Johansen, Senior Vice President Research and Development, Elkem AS,<br />

Kristiansand, Norway<br />

Challenges of Electrolytic Titanium Extraction and Deposition<br />

Joachim Hausmann, Group Leader, Institute of Materials Research, German<br />

Aerospace Center (DLR), Cologne, Germany<br />

Co-author: Bernd Friedrich, Director, RWTH Aachen University, Aachen,<br />

Germany<br />

Development of New Materials Using High-Throughput Methods<br />

Alfred Ludwig, Professor for Materials for Microsystems, Ruhr-Universität<br />

Bochum, Bochum, Germany<br />

New NDT Methods (Big Hall) Rapid Manufacturing (Hall “Welser”)<br />

16:45 Recent Developments in Thermographic NDE in the UK<br />

Darryl Almond, Mechanical Engineering, University of Bath, Bath, UK<br />

Co-authors: Umberto Polimeno, Teng Li, University of Bath, UK<br />

17:10 CT Scanner – An Important Development Tool in Aluminum Casting<br />

Lutz Hagner, General Manager, Microvista GmbH, Wernigerode, Germany<br />

Co-author: Franz Mnich, Microvista GmbH, Wernigerode, Germany<br />

17:35 Application of Industrial Computed Tomography for Analysis and<br />

Inspection of Fibre Reinforced Polymers in Aerospace<br />

Stephan Mohr, 3D-Image Processing, Development Center for X-ray<br />

Technology, Fraunhofer Institute for Integrated Circuits, Fürth, Germany<br />

Co-authors: Ulf Haßler, Jonathan Hess, Fraunhofer Institute for Integrated<br />

Circuits, Fürth, Germany<br />

18:00 Fibre Reinforced Composits – Structural Integrity – Diffraction and<br />

Tomography<br />

Philip Withers, Professor of Materials Science and Director of the University<br />

of Manchester Aerospace Research Institute, University of Manchester,<br />

Manchester, UK<br />

18:25 End of Day One<br />

14:30 –<br />

16:10<br />

16:45 –<br />

18:25<br />

Structural Bonding – An Alternative Joining Technology?<br />

Workshops (Hall “Märker”)<br />

CFRP Production – The Way from Manufacture to Automated Production<br />

19:00 Evening Event<br />

Invitation of the City of Augsburg and <strong>VDI</strong> <strong>Wissensforum</strong> to an evening reception.<br />

Welcome address and opening of the buffet by a representative of the City of Augsburg.<br />

Enjoy the evening in the famous “Goldener Saal” (Golden Hall) of the town hall of Augsburg. Make new contacts<br />

with experts in a casual atmosphere and enlarge your network.<br />

Robot Based Manufacturing Concepts for Rapid, Near Net Shape and<br />

Direct Manufacturing<br />

Joachim Zettler, Advanced Manufacturing Concepts, Metal Forming<br />

Processes and Simulation, EADS Innovation Works, Munich, Germany<br />

Production and Quality Control of Aeronautical Parts Manufactured<br />

by LaserCUSING ®<br />

Florian Bechmann, R&D Manager, Concept Laser GmbH, Lichtenfels,<br />

Germany<br />

Co-author: Jens Henzler, Hofmann Innovation Group AG, Lichtenfels,<br />

Germany<br />

Cold Gas Spraying: Innovative Production and Repairing Processes for<br />

the Aerospace Industry<br />

Erik Bähr, Project Manager Cold Gas Spraying, CGT GmbH, Ampfi ng,<br />

Germany<br />

Co-authors: Helmut Höll, Peter Richter, CGT GmbH, Ampfi ng, Germany<br />

Techniques to Reduce the CTE Mismatch of Metallic Components<br />

Embedded in CFRP Structures<br />

Reinhard Schlitt, Technology Development, OHB System AG, Bremen,<br />

Germany<br />

Co-authors: Christoph Hoffmeister, Faserinstitut Bremen e.V., Bremen,<br />

Germany; Erik Markestein, EURO-COMPOSITES S.A., Echternach, Luxembourg<br />

Source: City of Augsburg<br />

Organised by <strong>VDI</strong> <strong>Wissensforum</strong> | www.eucomas.eu | Phone: +49 (0) 211 62 14-2 01 | Fax: +49 (0) 211 62 14-1 54

Thursday, 2 July 2009<br />

Plenary Session (Big Hall)<br />

08:30 Structure Technologies for Next Generation Airlines<br />

Klaus Kalmer, Head of Design Structures and Systems Installation, Airbus GmbH Hamburg, Hamburg, Germany<br />

09:00 Carbon Fibers as Strategic Future Materials – The European Position<br />

Hubert Jäger, Senior Vice President & Chairman Technology & Innovation, SGL Carbon GmbH, Meitingen, Germany<br />

Co-author: Jan Verdenhalven, SGL Technologies GmbH, Wiesbaden, Germany<br />

09:30 Advanced Materials Enabling Aircraft Eco-Effi ciency<br />

Rainer Rauh, Vice President Head of Materials and Processes, Airbus S.A.S., Bremen, Germany<br />

10:00 Coffee break<br />

CFRP Structures – Materials and Automated Manufacturing (Big Hall) Economic Production Processes (Hall „Welser“)<br />

10:30 Optimization of the RTM Process Chain<br />

Markus Zogg, Department Head Composites, ETH Inspire, Swiss Federal<br />

Institute of Technology Zurich, Zurich, Switzerland<br />

Co-authors: Paolo Ermanni, Gion Andrea Barandun, Centre of Structure<br />

Technologies, Swiss Federal Institute of Technology Zurich, Zurich,<br />

Switzerland<br />

10:55 Smart Repair Patches for Metallic and Composite Structures<br />

Alfredo Güemes, Department Aeronautics, Technical University of Madrid,<br />

Madrid, Spain<br />

11:20 Morphology Analysis of Epoxy Matrices to Determine Resin Interface<br />

Zones within Combined Prepreg and Infusion Processing<br />

Christian Wellhausen, Organic Materials & Processes, Eurocopter<br />

Deutschland GmbH, Ottobrunn, Germany<br />

Co-authors: Robert Schulze, Helmut Wehlan, Eurocopter Deutschland<br />

GmbH, Ottobrunn, Germany<br />

11:45 Toward “Everlasting” Functional Coatings<br />

Matthias Rehahn, Head of the German Institute for Polymers (DKI),<br />

University of Technology Darmstadt, Darmstadt, Germany<br />

12:10 Lunch<br />

Hen or Egg – A New Supply Chain for Taylored High Performance<br />

Titanium in Aerospace<br />

Rüdiger Fox, CEO, PFW Aerospace AG, Speyer, Germany<br />

Co-authors: Guido Löber, Volker Guether, GfE Metalle und Materialien<br />

GmbH, Nuremberg, Germany<br />

Friction Stir Welding of Aerospace Structures Using Low-Cost Serial<br />

Industrial Robots<br />

Bruno Monsarrat, NRC Research Offi cer & Project Lead, Aerospace<br />

Manufacturing Technology Centre (AMTC), National Research Council<br />

Canada (NRC), Montreal, Canada<br />

Co-authors: Laurent Dubourg, Yves Fortin, Antoine Bres, Maxime Guérin,<br />

Marius Banu, Claude Perron, Priti Wanjara, Aerospace Manufacturing<br />

Technology Centre (AMTC), National Research Council Canada (NRC),<br />

Montreal, Canada<br />

Investigation of Pre-treatment Processes and Surface Monitoring<br />

Techniques for Structural Assembly by Adhesive Bonding<br />

Susanne Markus, Group Leader Surface Monitoring, Fraunhofer Institute<br />

for Manufacturing Technology and Applied Materials Research, Bremen,<br />

Germany<br />

Co-authors: Stefan Dieckhoff, Ralph Wilken, Fraunhofer Fraunhofer Institute<br />

for Manufacturing Technology and Applied Materials Research, Bremen,<br />

Germany<br />

Advanced Production and Process Technologies for Chambers of<br />

Liquid Rocket Engines<br />

Torsten Sebald, Metallic Materials and Surface Technology, Astrium Space<br />

Transportation, Munich, Germany<br />

Co-author: Steffen Beyer, Astrium Space Transportation, Munich, Germany<br />

Computational Engineering (Big Hall) Materials and Structures for Space (Hall “Welser”)<br />

13:30 Current developments in modelling material failure of metallic<br />

structures<br />

Helmut Arnulf Gese, CEO, MATFEM Partnerschaft Dr. Gese & Oberhofer,<br />

Munich, Germany<br />

Co-author: Martin Groß, MATFEM Partnerschaft Dr. Gese & Oberhofer,<br />

Munich, Germany<br />

13:55 Numerical Optimization of a Composite High Lift Structure<br />

Wolfgang Machunze, Structural Analysis, EADS Innovation Works,<br />

Ottobrunn, Germany<br />

Advanced Ceramic Matrix Composites in Propulsion Systems and<br />

Industrial Applications<br />

Stephan Schmidt, Production Technology, Materials & Processes, Launcher<br />

Propulsion, EADS Astrium GmbH, Munich, Germany<br />

Co-authors: Steffen Beyer, EADS Astrium Space Transportation, Munich,<br />

Germany; Christian Wilhelmi, EADS Innovation Works, Munich, Germany<br />

The Role of Failure Analysis and Fracture Mechanics Testing in<br />

Spacecraft Systems Safety: an ESA Perspective<br />

Tommaso Ghidini, Engineer in the Product Assurance and Safety<br />

Department, Materials and Components Technology Division, European<br />

Space Agency (ESA), Noordwijk, The Netherlands<br />

Organised by <strong>VDI</strong> <strong>Wissensforum</strong> | www.eucomas.eu | Phone: +49 (0) 211 62 14-2 01 | Fax: +49 (0) 211 62 14-1 54

Thursday, 2 July 2009<br />

Computational Engineering (Big Hall) Materials and Structures for Space (Hall “Welser”)<br />

14:20 Computational Fatigue Optimization – Application for Purpose-Aimed<br />

Component and Forging Process Design<br />

Martin Riedler, Project Manager Fatigue Analysis, Research & Development,<br />

Böhler Schmiedetechnik GmbH & Co. KG, Kapfenberg, Austria<br />

Co-authors: Martin Stockinger, Böhler Schmiedetechnik GmbH & Co. KG,<br />

Kapfenberg, Austria; Michal Stoschka, Institute of Mechanical Engineering,<br />

University of Leoben, Leoben, Austria<br />

14:45 New Composite Load Introduction Rib For High-Lift Devices<br />

Tamas Havar, Specialist/Engineer, EADS Deutschland GmbH, Munich,<br />

Germany<br />

15:10 Computational and Experimental Characterization of Laminated and<br />

Extruded Metal-CFRP Composite Materials and Components<br />

Jan Both, Research Assistant, Institute of Lightweight Structures, University<br />

of Technology Munich, Munich, Germany<br />

Co-authors: Horst Baier, Max Wedekind, Institute of Lightweight Structures,<br />

University of Technology Munich, Munich, Germany<br />

15:35 New Frontiers in Composite Material Simulation<br />

Armando Mete, Technical Consultant, MSC.Software Corporation, Rome,<br />

Italy<br />

Co-author: Philippe Portal, MSC.Software Corporation, Toulouse, France<br />

16:00 Coffee break<br />

16:15 Presentation of the workshop results<br />

Plenary Session (Big Hall)<br />

16:40 Presentation of the results of the expert cooperations concerning “Simulation” and “EU27”<br />

Jörg Esslinger, Head of Materials, MTU Aero Engines GmbH, Munich, Germany<br />

Blanka Lenczowski, Senior Expert, Materials Technology, EADS Deutschland GmbH, Munich, Germany<br />

17:05 Closing remarks of the chairs<br />

17:15 End of the conference<br />

10:30–<br />

12:10<br />

NDT as an Integrated Tool for Engineering and Production<br />

Workshop (Hall “Märker”)<br />

Student Forum of the <strong>VDI</strong> and the DGLR<br />

1–2 July 2009, 9:00–18:00, IHK Schwaben, Augsburg, Germany<br />

Chair: Stephan Staudacher, Institute of Aircraft Propulsion Systems, University of Stuttgart, Stuttgart, Germany<br />

Materials in Lightweight Structures for Aircraft Propulsion Systems<br />

Tools and Methodologies for Damage Tolerance Verifi cation of<br />

Spacecraft and Launcher Structures at ESA<br />

Gerben Sinnema, Structural Engineer, European Space Agency (ESA),<br />

Noordwijk, The Netherlands<br />

Current Developments for Hot Structures and Thermal Protection<br />

Systems for Space Entry Vehicles<br />

Burkhard Behrens, Head of Thermal Engineering, Astrium Space<br />

Transportation, Bremen, Germany<br />

Co-author: Ralf Knoche, Astrium Space Transportation, Bremen, Germany<br />

Development of High Performance Full-CFRP-Struts for Aerospace<br />

Applications<br />

Aicke Patzelt, Development Engineer/System Engineer Aerospace Structures,<br />

Engineering – Composite Structures and Materials Group, MT Aerospace AG,<br />

Augsburg, Germany<br />

Co-author: Florian Eidmann, MT Aerospace AG, Augsburg, Germany<br />

New Assembly Techniques Using Advanced Thermoplastic Composites<br />

for Space Structures<br />

Conchur O’Bradaigh, Co-Managing Director, EireComposites Teoranta,<br />

Indreabhan, Ireland<br />

Co-authors: Christopher Semprimoschnig, ESA, Noordwijk, The Netherlands;<br />

Adrian Murtagh, Eirecomposites Teoranta, Indreabhan, Ireland<br />

Organised by <strong>VDI</strong> <strong>Wissensforum</strong> | www.eucomas.eu | Phone: +49 (0) 211 62 14-2 01 | Fax: +49 (0) 211 62 14-1 54

Cutting-edge Poster Presentations<br />

(during the whole conference)<br />

Friction Welding of Functionally Gradient Steels<br />

Ion Mitelea, Head of Research Group, Politehnica University of Timisoara,<br />

Timisoara, Romania<br />

The Dependency of the Mechanical Properties of Bonded and Integral<br />

CFRP Samples from Temperature Cycles and the Impact on Life Time<br />

Estimation of CFRP Tools<br />

Manuel Herkt, Research Engineer, Premium Aerotec GmbH, Varel, Germany<br />

Properties and Processes of Linear Polyphenylene Sulfi de (PPS) for<br />

Continuous Fiber Composites Aerospace Applications<br />

Michael Favaloro, Technical Marketing, High Performance Polymers, Ticona,<br />

Amesbury, UK<br />

Systematic Investigations on the Infl uences on Distortion caused by Laser<br />

Beam Welding<br />

Kai Schimanski, Research Engineer, Lightweight Materials, Stiftung Institut für<br />

Werkstofftechnik, Bremen, Germany<br />

Damage Evolution and Mechanical Properties after Impact of the TiAl-<br />

Alloy TNBV3B<br />

Susanne Gebhard, Research Associate, Hybrid Material Systems and<br />

Intermetallics, Institute of Materials Research, German Aerospace Center (DLR),<br />

Cologne, Germany<br />

Characterization of Ti-6Al-4V modifi ed with B<br />

Cecilia Poletti, University Assistent, Institute of Materials Science and<br />

Technology, Vienna University of Technology, Vienna, Austria<br />

Co-author: Hans Peter Degischer, Professor, Institute of Materials Science and<br />

Technology, Vienna University of Technology, Vienna, Austria<br />

Development and Testing of Ceramic Bearing for Hot Control Surfaces<br />

Karin Handrick, Head of Ceramic Department, MT Aerospace AG, Augsburg,<br />

Germany<br />

We would like to thank the committees for the kind support<br />

Organizing Board<br />

Heinz Voggenreiter, German Aerospace Center (DLR), Cologne and<br />

Stuttgart, Germany (Conference President)<br />

Yann Barbaux, EADS Innovation Works, Suresnes, France<br />

(Conference President)<br />

Peter Brandt, Deutsche Gesellschaft für Luft- und Raumfahrt, Lilienthal-<br />

Oberth e.V., Bonn, Germany<br />

Jörg Esslinger, MTU Aero Engines GmbH, Munich, Germany<br />

Karl-Heinz Gradl, Leistritz Turbomaschinen Technik GmbH, Nuremberg,<br />

Germany<br />

Blanka Lenczowski, EADS, Munich, Germany<br />

Rainer Rauh, Airbus S.A.S, Bremen, Germany<br />

Andreas Rohne, EADS Astrium, Munich, Germany<br />

Hans-Jürgen Schäfer, Verein Deutscher Ingenieure e.V., Düsseldorf, Germany<br />

Klaus Schmidt-Klyk, Lufthansa Technical Training GmbH, Frankfurt,<br />

Germany<br />

Axel Zwiener, German Aerospace Industries Association (BDLI), Berlin,<br />

Germany<br />

Exhibition & Sponsorship<br />

Are you interested in participating in this <strong>VDI</strong>-conference as exhibitor or<br />

sponsor? Please do not hesitate to contact us, we are looking forward to send you<br />

further information!<br />

Exhibition<br />

Christina Büttner<br />

Project Consultant, Exhibition<br />

Phone: +49 (0) 211 62 14-4 29<br />

Email: buettner@vdi.de<br />

Sponsorship<br />

Monika Berr<br />

Project Consultant, Sponsoring<br />

Phone: +49 (0) 211 62 14-4 07<br />

Email: berr@vdi.de<br />

We would like to thank our Bronze Sponsor for the kind<br />

support<br />

MSC.Software GmbH<br />

Am Moosfeld 13<br />

81829 Munich<br />

Germany<br />

Phone: +49 (0) 89 431 98 70<br />

Fax: +49 (0) 89 436 17 16<br />

Email: info.de@mscsoftware.com<br />

www.mscsoftware.com<br />

Scientific Committee<br />

Steffen Beyer, Astrium Space Transportation, Munich, Germany<br />

Piotr Czarnocki, Warsaw University of Technology, Warsaw, Poland<br />

Claudio Dalle Donne, EADS Deutschland GmbH, Munich, Germany<br />

Klaus Drechsler, Institute of Aircraft Design, University of Stuttgart, Germany<br />

Kim Grossmann, Rolls-Royce Deutschland Ltd. & Co. KG,<br />

Blankenfelde-Mahlow, Germany<br />

Tasadduq Khan, ONERA, Chatillon Cedex, France<br />

Palko Lukac, Charles University, Praha, Czech Republic<br />

Mario Marchetti, Università La Sapienza, Rome, Italy<br />

Thierry Merlot, Hexcel Composites, Montluel Cedex, France<br />

José Sanchez-Gomez, Airbus Spain, Spain<br />

Christian Sauer, Lufthansa Technik AG, Hamburg, Germany<br />

Wilfried Smarsly, MTU Aero Engines GmbH, Munich, Germany<br />

Constantinos Stavrinidis, ESA/ESTEC, Noordwijk, Netherlands<br />

Christian Weimer, Eurocopter Deutschland GmbH, Donauwörth, Germany<br />

Georgij Zamula, TsAGI, Moscow, Russia<br />

Organised by <strong>VDI</strong> <strong>Wissensforum</strong> | www.eucomas.eu | Phone: +49 (0) 211 62 14-2 01 | Fax: +49 (0) 211 62 14-1 54

<strong>EUCOMAS</strong> 2009<br />

<strong>VDI</strong> <strong>Wissensforum</strong> GmbH, P.O. Box 10 11 39, D-40002 Düsseldorf<br />

Surname<br />

Department (Abbreviation if applicable)<br />

Company<br />

P.O. Box or Street<br />

Phone<br />

E-Mail<br />

Different address for account<br />

Applications must be in writing. The registration confirmation and the<br />

invoice will be sent by post. Please do not pay until you have been invoiced.<br />

Venue<br />

IHK Schwaben, Stettenstraße 1+3, 86150 Augsburg – Germany,<br />

Phone: + 49 (0) 821 31 62-0, Fax: + 49 (0) 821 31 62-3 23,<br />

Email: info@schwaben.ihk.de, Internet: www.augsburg.ihk.de<br />

Hotel accommodation<br />

The Regio Augsburg Tourismus GmbH offers a special room reservation service<br />

for the participants of the conference. Please contact Ms. Rosemarie Jakob,<br />

Phone: +49 (0) 821 5 02 07-31, Fax: +49 (0) 821 5 02 07-45,<br />

Email: hotelservice@regio-augsburg.de<br />

Or use our free HRS booking service:<br />

www.vdi-wissensforum.de/hrs.<br />

General Information: The price includes the conference-CD, coffee-break<br />

beverages, lunch and the evening event. The conference-CD will be handed<br />

out at the beginning of the conference.<br />

First Name<br />

Date Signature<br />

X<br />

<strong>VDI</strong> <strong>Wissensforum</strong> GmbH<br />

Customer‘s Service-Centre<br />

P.O. Box 10 11 39<br />

D-40002 Düsseldorf<br />

Germany<br />

Fax: +49 (0) 211 62 14-1 54<br />

Phone: +49 (0) 211 62 14-2 01<br />

Email: wissensforum@vdi.de<br />

Internet: www.eucomas.eu<br />

Postal Code, City, Country<br />

Payment by credit card for participants resident outside<br />

Germany, Austria and Switzerland.<br />

Visa Mastercard American Express<br />

credit card holder card no.<br />

valid to<br />

Job Title<br />

Function<br />

Fax<br />

Over 53 international<br />

speakers<br />

3 workshops<br />

2 plant tours<br />

and one topic: Materials and<br />

Structures in Aerospace<br />

Please register me for (All prices plus VAT) PS Price Category 1 PS Price Category 2<br />

Conference (<strong>488910</strong>) 1 – 2 July 2009 1 EUR 740,- 2 EUR 666,-<br />

Conference & Eurocopter (N1) 30 June – 2 July 2009 6 EUR 790,- 7 EUR 711,-<br />

Conference & MT Aerospace (N2) 30 June – 2 July 2009 8 EUR 790,- 9 EUR 711,-<br />

Price Category 1 Price Category 2 (Personal <strong>VDI</strong>-Member) <strong>VDI</strong>-Member-No.<br />

Additional compulsory information for the participation of the plant tours<br />

Identification number<br />

Country of birth<br />

Nationality<br />

Dual citizenship, country<br />

Title<br />

Date of birth<br />

Terms and Conditions:<br />

Upon registering, the participant accepts the terms and conditions of <strong>VDI</strong><br />

<strong>Wissensforum</strong> GmbH. Cancellations must be made in writing. If registration is<br />

cancelled 14 days prior to commencement of the conference, an administration<br />

fee of EURO 50 plus VAT will be charged. After this date, the invoiced<br />

participation fee is payable in full. The postmark is decisive. In this case the<br />

conference documents will, upon request, be sent to the participant. It is<br />

possible for someone to attend the course instead of a registered person by<br />

arrangement with <strong>VDI</strong> <strong>Wissensforum</strong> GmbH. If a course has to be cancelled due<br />

to unforeseen circumstances, participants will be notified immediately. In this<br />

case, the participation fee will be fully refunded if already paid. In exceptional<br />

cases, we reserve the right to change lecturers and/or the conference<br />

content without prior notice. In any event, the liability of <strong>VDI</strong> <strong>Wissensforum</strong><br />

GmbH is limited solely to the participation fee.<br />

Data protection:<br />

Your personal data will be maintained for internal business and marketing<br />

purposes only in accordance to the by-laws, policies, and procedures of the<br />

<strong>VDI</strong>.