2003/2004

Squirrel-cage motors - Industrial Drives and Controls Ltd.

Squirrel-cage motors - Industrial Drives and Controls Ltd.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

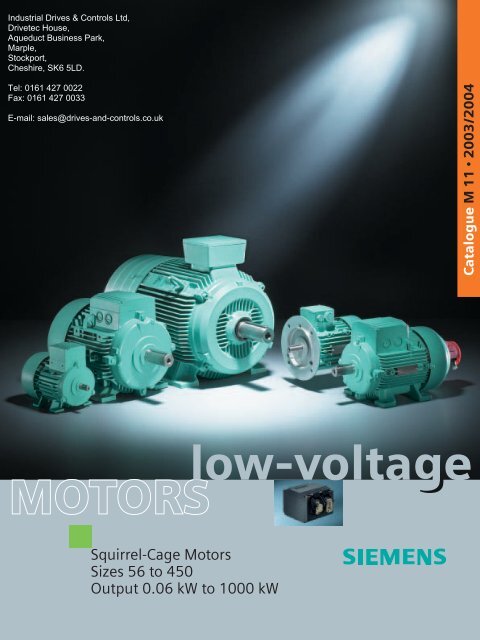

Catalogue M 11 • <strong>2003</strong>/<strong>2004</strong>MOTORS low-voltageSquirrel-Cage MotorsSizes 56 to 450Output 0.06 kW to 1000 kW

Other catalogues for “Standard Drives“MICROMASTER DA 51.2MICROMASTER 410/420/430/440InvertersOrder No.:German: E86060-K5151-A121-A4English: E86060-K5151-A121-A4-7600Catalogue CA 01 – SD configurator selection aidIn future the SD configurator selection aid will be available in combinationwith the CA 01 electronic catalogue and no longer on aseparate CD.MICROMASTER/COMBIMASTER DA 51.3MICROMASTER 411 InvertersDistributed Drive SolutionsCOMBIMASTER 411Order No.:German: E86060-K5251-A131-A2English: E86060-K5251-A131-A2-7600SIVOLT A/VAlternating current and three-phasecurrent controller(available only in German)DA 68Order No.:German: E20002-K4068-A101-A1Components for automation CA 01Order No.:German: E86060-D4001-A100-C1English: E86060-D4001-A110-C1-7600A&D MallInternethttp://www.siemens.com/automation/mallOn CD 2 of the selection and configuration aids you will find the SDconfigurator for low-voltage motors, MICROMASTER 4 inverters andSINAMICS G110 including:• Dimension drawing generator for motors• Data sheet generator for motors• Starting calculation• 3D models in .stp format• Extensive documentationHardware and software requirements• PC with Pentium II or comparable processor• Operating systems– Windows 98/ME– Windows 2000– Windows XP– Windows NT(Service Pack 5 upwards)• Minimum of 128 RAM• 1024 x 768 graphics with more than 256 colors / small fonts•CD-ROM drive• Windows-compatible sound card• Windows-compatible mouseInstallationYou can install this catalogue directly from the CD-ROM as a completeor partial version on your hard disk or in the network.Hotline:For technical advice and hotline support concerning our CA 01 catalogue:Tel.: +49 (0) 180 50 50 22 2E-mail: adsupport@siemens.comTrademarks® COMBIMASTER, DURIGNIT, ECOFAST, LOGO!,MICROMASTER, SIMATIC, SIMOTION and SIMOVERTare registered trademarks of Siemens.Other names in this catalogue may be trademarkswhich, if used by third parties for their own purposes,may violate the rights of the trademark owner.

Low-VoltageMotorsCatalogue M 11<strong>2003</strong>/<strong>2004</strong>Introduction1Technical information2Supersedes:Catalogue M 11 · 2002/<strong>2003</strong>The products in this catalogueare also included in theCD-ROM catalogue CA 01Order No.:E86060-D4001-A110-C1-7600Contact your local Siemens representativefor further information© Siemens AG <strong>2003</strong>Selection and ordering data1LA and 1LG squirrel-cage motors31MA squirrel-cage motorsIncreased safetyEEx e II type of protection 41MJ squirrel-cage motorsExplosion-proof enclosureEEx de IIC type of protection 5Squirrel-cage motorsSector solutions6The products and systemsdescribed in thiscatalogue are manufacturedunder applicationof a certified qualitymanagement systemin accordance withDIN EN ISO 9001(Certificate RegistrationNo. DE-000357 QM).The certificate is recognizedin all IQNet countries.DimensionsAccessories and repair partsAppendix78As

Welcome toAutomation and DrivesWe would like to welcome you to Automation andDrives and our comprehensive range of products,systems, solutions and services for production andprocess automation and building technologyworldwide.With integrated automation blocks, powerfulengineering tools and innovative concepts such asTotally Integrated Automation and Totally IntegratedPower, we deliver solution platforms based onstandards that offer you a considerable savingspotential.Discover the world of our technology now. If you needmore detailed information, please contact one of yourregional Siemens partners.They will be glad to assist you.1/2 Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

1/3Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 1/3

1Squirrel-cage motorsIntroductionTechnology that demonstrates expertiseSquirrel-cage motorsWhatever your drive applicationis, motors fromSiemens are sure to suit yourdrive system concept!And should you ever experiencea drive problem,whether large or small, wewill work out the optimal solutionwith you.The advantages of our motors:■ Optimum drive solutionsfor almost every sector■ Internationally recognizedmarket leading technology■ The simple, rugged constructionof the componentsguarantees an extremelylong service life■ Certified quality"DIN EN ISO 9001"■ Worldwide operationthanks to compliance withnational (DIN/VDE) andinternational standards(IEC/EN)■ Development and productionwith materials inaccordance with theSiemens standardSN 36 350 for environmentallycompatibleproducts■ Environmentally friendlyproduction technology■ Highly qualified engineeringadvice – locally –thanks to our global salesnetwork■ Worldwide service■ High-speed logistics system■ 50,000 standard motorsalways in stock1/4Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsIntroductionLow-voltage motors,surface air cooled, IP55 degree of protection1■ The "modular installationconcept" with rotary pulseencoder, separately drivenfan and brake makesspecial designs superfluous.This mounting technologymakes the 1LAstandard motors, quick,easy and economical touse in any application.The "modular installationconcept" reduces costsfor installation, commissioningand stock keeping(for further details, see"Modular technology" inSection 2 "Technical information").Basic versionEnergy-saving motorseff1, eff2, EPACTpole-changingFor converter-fed operation1LA and 1LG,see Section 3Increased safetyEEx e ll type ofprotection1MA see Section 4Explosion-proofenclosureEEx de llC type ofprotection1MJ see Section 5Sector solutionsSmoke extraction motors,marine motorsSee Section 6Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>1/5

Terminal boxesPage 2/18ConnectionPage 2/18Insulation and windingPage 2/17Cooling and ventilationPage 2/23NoisePage 2/28BearingsPage 2/29Selection of bearingsPage 2/30Diagrams of bearingsPage 2/34Shaft extensionPage 2/27TorquePage 2/16Paint finishPage 2/5Types of constructionPage 2/25Frame designPage 2/23Rating platePage 2/15

Squirrel-cage motorsTechnical informationGeneral information2Squirrel-cage motors■ Order number1st to 3rd position (number, letter, letter)Surface cooled squirrel-cagemotor, degree of protectionIP55Single-speed, pole-changing,Aluminum and cast iron designImproved efficiency eff2High efficiency eff1Increased power rating, converter-fedoperation1 2 3 4 5 6 7 8 9 10 11 12– – Z▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲11LLAGIncreased safety,EEx e II type of protection 1 M AExplosion-proof enclosure,EEx de IIC type of protection 1 M J4th position (number)Type series5th to 7th position (numbers) Motor frame size, coded from 56 to 4508th position (number)9th and 10th position (letters)11th position (number)12th position (number)Special designsNumber of polesDesignVoltage, connections and frequencyType of constructionPlease state in plain text or Order codeOrdering exampleThree-phase motor IP554-pole, 50 Hz, 45 kW,230 VB/400 V*,IM V 5 type of constructionwith canopySpecial designs:■ 3 PTC thermistors■ Separately mounted fanOrder No. 1LA5223 –4AA. .Voltage identifier – 1Type of construction identifier – 9Special designs –Z■ IM V 5 type of constructionM1Fwith canopy■ 3 PTC thermistorsA11■ Separately mounted fanIn order, specify:1LA5223 –4AA19–ZM1F + A11 + G17G172/2Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationGeneral information■ Order number (continued)Overview of "Special designs"The order codes for the individual motors can be found in the "Selection and ordering data".2Order code Special designs For detailedinformationseePageWindings and motor protectionA10 Motor protection with PTC thermistors for converter-fed2/17, 2/44operation with three embedded tempera-ture sensors for alarm in zonesA11 Motor protection with PTC thermistors with threeembedded temperature sensors for tripping2/17, 2/18,2/47A12 Motor protection with PTC thermistors with six 2/17embedded temperature sensors for alarm andtrippingA15 Motor protection with PTC thermistors for converter-fed2/17operation with three embedded tempera-ture sensors for trippingA16 Motor protection with PTC thermistors for converter-fed2/17operation with six embedded temperaturesensors for alarm and trippingA23 Motor temperature detection with embedded 2/44temperature sensor KTY 84-130A25 Motor temperature detection with embedded 2/44temperature sensors 2 x KTY 84-130A60 Installation of 3 PT 100 G resistance thermometers –A61 Installation of 6 PT 100 G resistance thermometers –A72 Installation of 2 PT 100 screw-in resistancethermometers (basic circuit) for rolling-contactbearingsC11 Used acc. to temp. class F (up to CT 40 °C) withservice factorC12 Used acc. to temp. class F (up to CT 40 °C) withincreased power ratingC13 Used acc. to temp. class F with increased coolanttemperatureY52 Used acc. to temp. class F –other requirements–2/17, 2/442/17, 2/442/17, 2/442/17Paint finishK23 Unpainted (only cast iron parts primed) 2/5K24 Unpainted, only primed 2/5K26 Special paintwork in RAL 7030 stone grey 2/5K27 Special paintwork in RAL 6011 mignonette green 2/5K28 Special paintwork in RAL 7031 bluish grey 2/5L42 Special paintwork in RAL 7032 pebble grey 2/5L43 Special paintwork in RAL 9005 jet black 2/5M16 Special paintwork in RAL 1002 sand yellow 2/5M17 Special paintwork in RAL 1013 pearl white 2/5M18 Special paintwork in RAL 3000 flame red 2/5M19 Special paintwork in RAL 6021 pale green 2/5M20 Special paintwork in RAL 7001 silver grey 2/5M21 Special paintwork in RAL 7035 light grey 2/5M22 Special paintwork in RAL 9001 cream 2/5M23 Special paintwork in RAL 9002 grey white 2/5Order code Special designs For detailedinformationseePageDesign for zones in accordance with ATEXM34 Version for Zone 21 for mains-fed operation 2/9M35 Version for Zone 22 for mains-fed operation 2/9M38 Version for Zone 21 for converter-fed operation 2/9M39 Version for Zone 22 for converter-fed operation 2/9M72M73Version for Zone 2 for mains-fed operation 2/9EEx nA II T3 acc. to EN 50 021, Ex nA II T3 acc. toIEC 60 079-15Version for Zone 2 for converter-fed operation 2/9EEx nA II T3 acc. to EN 50 021, Ex nA II T3 acc. toIEC 60 079-15Distributed drive systemsG55 ECOFAST motor plug Han-Drive 10e for 230 Vd/ 2/46400 VYG56 ECOFAST motor plug, EMC resistant,2/46Han Drive 10e, 230 Vd/400 V*H90 MICROSTARTER – direct on-line starter with 2/4724 V DC control with metric M25 cable entriesH91 MICROSTARTER – direct on-line starter with 2/4724 V DC control, with HAN Q8 plug connectorsH92 MICROSTARTER – direct on-line starter with AS- 2/47Interface connection, with metric M25 cable entriesH93 MICROSTARTER – direct on-line starter with AS- 2/47Interface connection, with HAN Q8 plug connectors(ECOFAST)H94 MICROSTARTER – reversing starter with AS-Interface2/47connection, with metric M25 cable entriesH95 MICROSTARTER – reversing starter with AS-Interface2/47connection, with HAN Q8 plug connector(ECOFAST)Marine version – "Operation under deck"E00 Not certified,6/2to ABS 50 °C/CCS 45 °C/RINA 45 °Ctemperature class F used acc. to FE11 Certified according to GL (Germanischer Lloyd) 6/2Germany, CT 45 °C, temperature class F usedacc. to FE21 Certified according to LRS (Lloyds Register of 6/2Shipping), Great Britain, CT 45 °C, temperatureclass F used acc. to FE31 Certified according to BV (Bureau Veritas), France 6/2CT 45 °C, temperature class F used acc. to FE51 Certified according to DNV (Det Norske Veritas), 6/2Norway, CT 45 °C, temperature class F used acc. to FE61 Certified according to ABS6/2(American Bureau of Shipping), USA, CT 50 °C,temperature class F used acc. to FE71 Certified according to CCS6/2(Chinese Classification Society), China, CT 45 °C,temperature class F used acc. to FE80 Motor for use in shipping,higher ambient temperature and/orused as F in accordance with B6/3Y54 Special paintwork in other colors: RAL .... 2/5Y53 Normal paint finish in other colors: RAL .... 2/5Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/3

Squirrel-cage motorsTechnical informationGeneral information2■ Order number (continued)Overview of "Special designs" (continued)The Order Codes for the individual motors can be found in the "Selection and ordering data".Order code Special designs For detailedinformationseePageModular technologyC00 Brake supply voltage 24 V DC 2/50, 2/54C01 Brake supply voltage 400 V AC, 50 Hz 2/50, 2/54G17 Mounting of separately driven fan from 2/44,from 2/56G26 Mounting of brake from 2/50H57H58H61H62Mounting of 1XP8 001-1 (HTL) rotary pulseencoderMounting of 1XP8 001-2 (TTL) rotary pulseencoderMounting of separately driven fan and1XP8 001-1 rotary pulse encoderMounting of brake and 1XP8 001-1 rotary pulseencoderfrom 2/47,from 2/562/47, 2/48,from 2/56from 2/47,from 2/562/48, 2/51,from 2/56H63 Mounting of brake and separately driven fan 2/49, 2/51,from 2/56H64H97H98H99Mounting of brake, separately driven fan, and1XP8 001-1 rotary pulse encoderMounting of separately driven fan and1XP8 001–2 rotary pulse encoderMounting of brake and1XP8 001–2 rotary pulse encoderMounting of brake, separately driven fan and1XP8 001–2 rotary pulse encoder2/48,from 2/56from 2/482/56from 2/482/56from 2/482/56K82 Manual brake release with lever 2/50, 2/51,2/54Further mountingsH70 Mounting of LL861 900 220 rotary pulse encoder from 2/56H71 Mounting of LL861 900 220 rotary pulse encoder from 2/57to be providedH72 Mounting of HOG 9 D 1024 I rotary pulse encoder from 2/56H73H74H75H78H79H80Y70Mounting of HOG 10 D 1024 I rotary pulseencoderMounting of HOG 9 rotary pulse encoder to beprovidedMounting of HOG 10 rotary pulse encoder to beprovidedPrepared for mounting of LL861 900 220 rotarypulse encoderPrepared for mounting of HOG 9 D 1024 I rotarypulse encoderPrepared for mounting of HOG 10 D 1024 I rotarypulse encoderMounting of rotary pulse encoder in specialdesignfrom 2/562/57, 2/592/57, 2/592/582/592/59Converter installationH15 Prepared for mounting of the MMI 2/44, 2/46Mechanical designD01 CCC China Compulsory Certification 2/7D02 Coolant temperature –50 °C to 40 °C 2/14, 2/15D03 Coolant temperature –40 °C to 40 °C 2/14, 2/15D04 Coolant temperature –30 °C to 40 °C 2/14, 2/15D30 Electrical acc. to NEMA MG1-12 2/8, 2/47D31 Design according to UL with "recognition mark" 2/8, 2/47–Order code Special designs For detailedinformationseePageMechanical design (continued)K10 Terminal box on LHS (view onto drive end) 2/19, 2/24K11 Terminal box on top, feet screwed on 2/24K16 Second standard shaft-end from 2/25,2/47K17 Drive-end seal for flange-mounting motors 2/23, 2/47K20 Bearings for increased cantilever forces 2/29, 2/31,from 2/37,2/47K30 VIK design 2/9, 2/47K31 Extra rating plate, loose 2/15, 2/47K32 With two additional lifting rings for IM V 1/IM V 3 2/25K36 Special bearing for drive end and non-drive end, 2/29 – 2/37bearing size 63K37 Low-noise design for 2-pole motors with clockwise 2/9, 2/28direction of rotationK38 Low-noise design for 2-pole motors with anticlockwise2/9, 2/28direction of rotationK40 Regreasing device from 2/29,2/47K45 Anti-condensation heating for 230 V 2/17K46 Anti-condensation heating for 115 V 2/17K50 IP65 degree of protection –K83 Rotation of terminal box by 90°,2/18 – 2/22inserted from drive endK84 Rotation of terminal box by 90°,2/18 – 2/22inserted from non-drive endK85 Rotation of terminal box by 180° 2/18 – 2/22K94 Located bearing drive end 2/29 – 2/35,2/47L03 Vibration-proof version –L04 Located bearing non-drive end 2/29 – 2/35,2/47L13 External earthing 2/18, 2/47L27 Insulated bearing cartridge 2/44L36 Sheet metal fan cover –L51 Protruding cable ends - right side –L52 Protruding cable ends - left side –L68 Full-key balancing –L99 Wire-lattice pallet 2/5, 2/47M44 Earth brushes for converter-fed operation –M46 Bolt-type screw terminal for cable connection, –accessories pack (3 units)M47 Saddle terminals for connection without cable lug –Y82 Extra rating plate 2/15, 2/47Notes on safety and commissioning/certificationB00 Without S&C note.–Customer's declaration of renouncement requiredB01 Complete with one set of safety and commissioning–notes per wire-lattice palletB02 Factory test certificate 2.3 acc. to EN 10 204 6/3D40 Canadian regulations (CSA) 2/8, 2/47K01 Vibration severity grade R 2/27, 2/47K06 Two-part plate on terminal box 2/20K09 Terminal box on RHS (view onto drive end) 2/242/4Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationGeneral information■ Paint finish and packagingPaint finishDesignStandard finishSpecial finish■For 1LA5, 1LA6, 1LA7, 1LA9,and 1MA7 as well as for1MA6/1MJ6 motors up toSuitability of paint finish for climate group inaccordance with DIN IEC 60 721, Part 2 – 1Moderate (extended)for indoors and outdoorsWorldwide (global)for outdoorsSuitable for use in the tropics for max. 60%relative humidity at 40 °CShort per.:Contin.:Short per.:Contin.:Also:frame size 200 L, the specialpaint is standard.up to 120 °Cup to 100 °Cup to 140 °Cup to 120 °Cfor aggressive atmospheresup to 1 % acid and alkali concentrationor permanent dampness in shelteredroomsFor very corrosive environments,the 1LA8, 1LG4 and1LG6 motors can be paintedwith off-shore paint CERAM-KOTE 54 ® (only on request).All motors can be painted overwith commercially availablepaints.When no color is specified, allmotors are painted in the colorRAL 7030.Special paint with increasedlayer thickness available onrequest.2Packing weights and dimensionsPacking weightsFor motorsFor land transportSize Type Size IM B 3 Type of construction IM B 5, IM V 11LA5 . . ./1LA7 . . .,1LA6 . . ., 1LA9 . . .,1LG4 . . ., 1LG6 . . .,1MA6 . . ., 1MA7 . . .,1MJ6 . . ., 1MJ7 . . .in cartonstareon battenstarein cratestarein cartonstareon battenstarekg kg kg kg kg kg56 M . . . . 050/053 0.65 – – 0.65 – –63 M . . . . 060/063 0.65 – – 0.65 – –71 M . . . . 0700.65 – – 0.65 – –. . . . 07380 M . . . . 080. . . . 0830.65 – – 0.65 – –90 S90 L. . . . 090. . . . 096/0970.65 – – 0.65 – –100 L . . . . 106/107 1.3 – – 1.3 – –112 M . . . . 113 1.5 – – 1.5 – –132 S132 M160 M160 L180 M180 L. . . . 130/131. . . . 133/134. . . . 163/164. . . . 166. . . . 183. . . . 1864.7 – – 5.2 – –4.8 – – 5.7 – –13.0 – – 13.4 – –200 L . . . . 206/207 13.5 – – 13.5 – –225 S . . . . 22013.7 7 20 13.7 10 20225 M . . . . 223250 M . . . . 253 – 20 36 – 20 40280 S280 M315 S315 M315 L. . . . 280. . . . 283. . . . 310. . . . 313. . . . 316/317/318Values for type 1MJ1/1MJ8 motors on request.– 20 36 – 20 40– 20223840– 2022in cratestare45■The figures apply to individualpacking. For frame sizes 56 to180 L, wire-lattice pallets canbe used, order code L99.Packing weights and dimensions for 1LA8 motorsFor motorsPacking weightsSize Type Land transport on battens Sea transport in wooden cases3153554004501LA8 . . . Size IM B 3tare. . . . 315/317. . . . 353/355/357. . . . 403/405/407. . . . 453/455/457Maximum motor dimensionsLengthWidthHeightType IM V 1tareSize IM B 3tarekg kg kg kg3040455055657585270320390450Type IM V 1tare310365445510Allowances for maximum motor dimensions(packing dimensions = motor dimensions + allowance)Land transport on battensSea transport in wooden casesSize IM B 3approx.Type IM V 1approx.Size IM B 3approx.mm mm mm mm+250+200+200+250+300+250+250+200+500Type IM V 1approx.+250+200+500Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/5

Squirrel-cage motorsTechnical informationGeneral information2■ Project planning aidsSD configurator (on CD2"Configuration" of catalogue"CA 01 – the Siemens A&DOffline Mall")More than 100,000 productswith approx. 5 million possibleproduct variants for drive engineeringapplications are listedin the interactive catalog CA 01– the Offline Mall of SiemensAutomation and Drives (A&D).To make the selection of thesuitable motor and/or inverterfrom the diverse A&D SD rangeeasier, the SD configurator hasbeen developed which is integratedinto the catalogue as a"selection aid".The SD configurator makes iteasier to find the right drive solution.In addition to the correctorder number, it also suppliesthe corresponding documentation.It can be used to display operatinginstructions, factory test certificates,and terminal box documentationsetc. as well as togenerate data sheets, dimensiondrawings, and start-up calculationsfor the correspondingproducts.It is also easy to assign a suitableinverter to the selectedmotor.The extensive help functiondoes not only explain the programfunctions, but also containsextensive technical backgroundmaterial.SD configurator productrange:Low-voltage motors(energy-saving motors, explosion-proofmotors) with correspondingdocumentation anddimension drawings, low-voltageinverters of theMICROMASTER 4 product series,SINAMICS G110 inverterchassis units, and much more.The interactive CA 01 Cataloguecan be ordered from yourlocal Siemens sales representativeor on the Internet underhttp://www.siemens.com/automation/CA01Under this address you can alsofind links to tips, tricks, anddownloads for functional updatesand documentation.Order number for the CA 0110/<strong>2003</strong> English:E86060-D4001-A110-C1-7600Energy-saving programThis energy-saving programhas been developed so that theenergy-saving potential can beutilized simply, quickly, andpractically. The tool offers versatileuser interfaces for calculatingthe individual energy-savingsfor Siemens energy-savingmotors of the highest eff1 efficiencyclass. With this extraordinarytool it is even possible toplan entire plants with eff1 energy-savingmotors for purposesof comparison.The individual fields of applicationare as follows:Case 1Calculation of the energy-savingsas well as the amortizationtime for the additional cost ofthe Siemens eff1 energy-savingmotor as compared with theSiemens eff2 energy-savingmotor.In this case, the motor data forthe Siemens energy-saving motorsas well as their order numbershave already been stored.In addition, you are told howlong it will take until the additionalcost for an energy-saving motorwill pay for itself.Useful Internet linksConverters:http://www.siemens.com/micromasterDistributed drive systems:http://www.siemens.com/combimasterGeared motors:http://www.siemens.com/gearedmotorsCase 2Calculation of the energy-savingsas well as the amortizationtime for the additional cost ofthe Siemens eff1 energy-savingmotor as compared with otherknown motors.The calculation, however, requiresexact knowledge aboutthe technical data of the motorwhich is to be used for the comparison.Case 3Calculation of the energy-savingsas well as the amortizationtime for the additional cost ofthe Siemens eff1 energy-savingmotor as compared with anynumber of other known motors –plant analysis.This offers an optimal basis formaking a decision when itcomes to finding the most costeffectivesolution. The total powerfactor and the total reactivepower are also indicated in thiscase.ECOFAST:http://www.siemens.com/ecofastMotors:http://www.siemens.com/motorsNewsletter:http://my.ad.siemens.com/myAnD/Internet: http://www.siemens.com/energysavingprogramOrder number of the CD-ROM04/2002 German/English:E80001-D40-P220-X-74002/6Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationStandards, specifications, and tolerances■ Applicable standards and specificationsThe motors comply with variousstandards and regulations, especiallywith those in the tableopposite.Title IEC DIN/ENGeneral regulations for rotating electrical machines IEC 60 034-1,IEC 60 085AC induction motors for general use with standardized dimensions andpowerIEC 60 072fixing onlyDIN EN 60 034-1DIN EN 50 347Restart characteristics, rotating electrical machines IEC 60 034-12 DIN EN 60 034-12Terminal markings and direction of rotation, rotating electrical machines IEC 60 034-8 DIN EN 60 034-8Designation for type of construction, installation and terminal box positionIEC 60 034-7 DIN EN 60 034-7Entry to terminal box – prDIN 42 925 (08/99)Built-in thermal protection IEC 60 034-11 –Noise limits for rotating electrical machines IEC 60 034-9 DIN EN 60 034-9IEC standard voltages IEC 60 038 DIN IEC 60 038Cooling methods for rotating electrical machines IEC 60 034-6 DIN EN 60 034-6Mechanical vibrations, rotating electrical machines IEC 60 034-14 DIN EN 60 034-14Vibration limits – DIN ISO 10 816Degrees of protection for rotating electrical machines IEC 60 034-5 DIN EN 60 034-52In addition, the following applies to EEx motors:General regulations IEC 60 079-0 DIN EN 50 014Explosion-proof enclosure "d" IEC 60 079-1 DIN EN 50 018Increased safety "e" IEC 60 079-7 DIN EN 50 019Type of protection "n" (non-sparking) IEC 60 079-15 DIN EN 50 021■ National standardsThe motors comply with the applicableIEC or European standardslisted above. The Europeanstandards replace the nationalstandards in the followingEuropean member states:Germany (VDE), France (NF C),Belgium (NBNC), Great Britain(BS), Italy (CEI), Netherlands(NEN), Sweden (SS), Switzerland(SEV) etc.The motors also comply withvarious national standards.The following standards havebeen harmonized with IEC publication60 034-1 or replaced byEN 60 034-1 so that the motorscan be operated with the standardrated output.Explosion-proof motors:■Since these correspond withEuropean standardsEN 50 014, EN 50 018,EN 50 019, and directive94/9/EU (ATEX), test certificatesissued by authorized testingagencies (PTB, DMT, etc.) areaccepted by all member statesof the EU. The remainingAS 1359CSA C22.2, No. 100IS 325IS 4722NEK – IEC 60 034-1members of the CENELEC alsoaccept the certificates, includingSwitzerland and the CzechRepublic.Australia(higher rated output assignment than statedin DIN EN 50347 for frame size 250 M orlarger)CanadaIndiaNorway■ Electrical tolerancesThe following tolerances arepermitted according toDIN EN 60 034:Motors which comply withDIN EN 60034-1 must have avoltage tolerance of ± 5%/frequencytolerance ± 2%(Design A).The tolerance of ± 5% accordingto DIN EN 60034-1 also appliesto the rated voltage range.If utilized, the permitted limittemperature of the temperatureclass may be exceeded by10 K.Efficiency forP N ˆ 50 kW: – 0.15 · (1 – h)P N > 50 kW: – 0.1 · (1 – h)with h being a decimal number.1cosKPower factor 6• Minimum absolute value: 0.02• Maximum absolute value: 0.07Slip ±20% 1 )Locked-rotorcurrent +20%Locked-rotortorque–15% to+25%Breakdown torque –10%Moment of inertia ±10%1MA motors:Add 10 % to the certified valuesfor the locked-rotor current.■ Export of low-voltage motors to ChinaCCC - China Compulsory Certification- Order Code D01"Small power motors" which areexported to China must be certifiedup to a rated output of:2-pole: ˆ 2.2 kW4-pole: ˆ 1.1 kW6-pole: ˆ 0.75 kW8-pole: ˆ 0.55 kW1) For motors

Squirrel-cage motorsTechnical informationStandards, specifications, and tolerances2 ■ Energy-saving motors with European efficiency classification in accordance with EU/CEMEP 1 )Two and four pole low-voltagemotors in the power range of 1.1to 90 kW are marked with the efficiencyclass (ImprovedEfficiency) or (High Efficiency)in accordance with theEU/CEMEP agreement.So that the requirements of theefficiency classes andare fulfilled, the active parts ofthe motor have been optimized.The procedure for calculatingthe efficiency is based on theloss-summation method accordingto IEC 60034-2.■ Motors for the North American marketFor motors which comply withNorth American regulations(NEMA, CSA, UL, etc.) it mustalways be checked whether themotors will be used in the U.S.or Canada and whether they aresubject to state laws.Minimum efficiencies requiredby lawIn 1997, an act was passed inthe U.S. to define minimum efficienciesfor low-voltage threephasemotors (EPACT) 2 ). InCanada there is an act which islargely identical, although it isbased on different verificationmethods. The efficiency ofthese motors is verified for theU.S. using IEEE 112, test methodB, and for Canada usingCSA-C390. Apart from a few exceptions,all low-voltage threephasemotors exported to theU.S. or Canada must complywith legal requirements on efficiency.The act requires minimum efficienciesfor 2, 4, and 6-pole motorswith a voltage of 230 and460 V / 60 Hz in the powerrange of 1 to 200 HP (0.75 to160 kW). Explosion-proof motorsmust also be included.1LA9 and 1LG6 are also availablein the design for zones2, 21, and 22. According toEPACT, the following are excludedfrom the efficiency requirements,for example:• Motors whose frame size outputclassification does not correspondwith the standard seriesaccording toNEMA MG1-12.• Flange-mounting motors• Asynchronous brake motors• Converter-fed motors• Motors with design letter Cand higherFurther information on EPACT:http://www.eren.doe.gov/Particulars of the U.S. EnergyPolicy ActThe act lays down that the nominalefficiency at full load and aCC number (Compliance Certification)must be included onthe rating plate. The CC numberis issued by the U.S. Departmentof Energy (DOE). The followinginformation is stampedon the rating plate of EPACTmotors which must be markedby law: Nominal efficiency, designletter, code letter, CONT,CC no. CC 032A (Siemens) andNEMA MG1-12.Special requirements for Canada:CSA – Energy EfficiencyVerificationThese motors fulfill the efficiencyrequirements laid down bythe CSA standard C390. Thesemotors are available as 1LA9 or1LG6 and can be ordered withorder code D40 and also includethe CSA-E energy verificationmark.NEMA – Order Code D30The motors with increased efficiencyaccording to EPACT aredesigned to meet the NEMAMG1-12 electrical standard,and are marked accordingly.The mechanical design of allmotors is compliant only to IEC,not to NEMA dimensions.All motors of designD30 correspond to NEMA DesignA (i.e. standard torquecharacteristic in accordancewith NEMA and no starting currentlimitation). For Design B, C,and D, the special design is required(on request). Accordingto NEC-ANSI-C1, Division 2,Class I and II, Group A, B, andD, all 1LA/1LG motors thatmatch Zone 2 can be used.All other 1LA/1LG motors mustbe ordered with order codeD30.Data on the rating plate: Ratedvoltage (voltage tolerance of±10 %), nominal efficiency, designletter, code letter, CONTand NEMA MG1-12.UL Approval – Order CodeD31 3 )The motors based on the basicseries 1LA/1LG are listed for upto 600 V by UnderwritersLaboratories Inc.("Recognition Mark" = R/C).The motors must be orderedwith the code D31, voltage code"9" and the code for voltageand frequency 4 ). The "UL RecognitionMark" is included onthe rating plate of the motor.4In addition, the motor is designedto meet theNEMA MG1-12 electrical standard.The following data is includedon the rating plate: Ratedvoltage (voltage tolerance of±10%), nominal efficiency, designletter, code letter, CONT,and NEMA MG1-12.Externally or internally mountedcomponents such as– Motor protection– Heating element– Forced ventilation– Brake– Encoder– Power terminal– Plug connector– MICROSTARTERare UL-R/C, CSA-C, and US-listedor used by manufacturers inaccordance with regulations. Itmay have to be decided whetherthe motor is suitable for theapplication.The motors can be operatedwith a frequency converter –separate converter or built-on(1UA./order code H15) – at50/60 Hz.Deviating frequency settingsmust be tested at final acceptance.CSA Approval –Order Code D40 3 )The motors based on the basicseries 1LA/1LG are approvedfor up to 690 V in accordancewith the Canadian regulations ofthe Canadian Standard Association(CSA). Built-on or built-incomponents which are used arelisted by CSA or are used by themanufacturers in accordancewith regulations. It may have todecided whether the motor issuitable for the application.The motors must be orderedwith the code D40, voltage code"9" and the code for voltageand frequency. The CSA signand the rated current (voltagetolerance of ±10%) are includedon the rating plate.4When energy-saving motors(1LA9, 1LG6) are ordered, theyalso include the CSA-E energyverification mark on the ratingplate.1) CEMEP = European Committee ofManufacturers of ElectricalMachines and Power Electronics.2) Energy Policy Act3) No approval for Zones 2, 21, 22and EEx e- or EEx de-motors.4) According to UL, motor voltagesup to 600 V are certified. For thisreason, voltage code "6", for example,is omitted (400 Vd/690 V*/50 Hz or 460 Vd/60 Hz).Voltages 400 Vd and 460 Vdmust be ordered as follows:VoltageVoltage code400 Vd/50 Hz or9 with L1U460 Vd/60 Hz (50 Hz rating)460 Vd/60 Hz (50 Hz rating) 9 with L2T460 Vd/60 Hz (60 Hz rating) 9 with L2F2/8Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationStandards, specifications, and tolerances■ Design and certification of explosion-proof motors in accordance with directive 94/9/EC (ATEX)Use of 1LA/1LG motors inhazardous areas (type of protection"n") 1 )Zone 2 according to EN 50021/IEC 60079-15M72 Mains-fed operationM73 Converter-fed operationThe 1LA/1LG motors are suitablefor use in hazardous areasof Zone 2 for temperature classesT1 to T3. The maximum surfacetemperature during servicemust be less than the temperaturelimit for the particular temperatureclass.The ventilation system mustcomply with DIN EN 50 014.Use in accordance with class Fon request.The motors are fitted with an externalearthing terminal.The design of the terminal box issimilar to EExe.Vertical mounted motors withthe shaft extension pointingdownwards must be providedwith a canopy.Motors designed for type of protection"n" (Zone 2; Category 3according to ATEX) bear a declarationof EC conformity whichthe manufacturer issues at hisown discretion.Ambient temperature -20 °C to+40 °C. Deviating temperatureson request.The rating plate or the supplementaryrating plate is stampedwith:II 3GEEx nA II T3 acc. toEN 50021Ex nA II T3 acc. toIEC 60079-15.The rating plates of the motorsare not marked with a rated voltagerange.Converter-fed operation:The standard requires that themotor and converter are testedas a unit. An inquiry is thereforenecessary (extra cost).When ordering 1LA8 motors it isnecessary to specify in theE line whether a constant torqueor pump and fan drive is required.The 1LA and 1LG motors are fittedwith PTC thermistor detectors.1LG4 and 1LG6 motors arefitted with an additional PTCthermistor in the terminal box.For some motors, the speed limitmust be reduced and metalfans used.Zone 21 according toIEC 61 241/EN 50 281M34 Mains-fed operationM38 Converter-fed operationZone 22 according toIEC 61 241/EN 50 281M35 Mains-fed operationM39 Converter-fed operationThe 1LA/1LG motors are suitablefor use in areas with dangerof dust explosions if variousprecautions are taken. Surfacetemperatures may not exceed125 °C during normal operation.The version for conducting dust,degree of protection IP65, is designedfor Zone 21;for non-conductive dust, degreeof protection IP55, forZone 22.The motors are fitted with an externalearthing terminal and withan external metal fan.The design of the terminal boxfor Zone 21 is similar to EExe.Certificates:• EC type test certificate(ATEX), issued by the DMT(Deutsche Montan-Technologie)test centre for Zone 21.• Declaration of EC conformityfor Zone 22.Marking on the rating plate:Zone 21: II 2D T125 °CZone 22: II 3D T125 °CFor motors in Zones 2, 21, and22, designs in accordancewith UL (Order Code D31) andCSA (Order Code D40) cannotbe supplied.Pole-changing versions cannotbe used for motors inZone 21. Pole-changing versionsfor Zones 2 and 22 onrequest.Type of protection EEx de IICExplosion-proof enclosure"d" 1 )■All 1MJ motors are certifiedfor the EEx de IIC type of protection.1MJ6, size 71M to 200L,1MJ7, size 225 to 315M, 1MJ1and 1MJ8 with EC type testcertificate according to directive94/9/EC (ATEX)The frames are designed towithstand internal explosion.An igniting flame to the outsideis impossible. The frametemperature is less than theignition temperature of thegases for temperature classT4.Temperature class T6 on request.■The PTB certificate of conformity,which is valid up to temperatureclass T4, covers thefollowing deviations: differentcoolant temperature (–20 °C to+60 °C), site altitude, frequencyand rated duty type, polechangingmotors, fitting oftemperature sensors and converter-fedoperation with fittingof temperature sensors, designwith explosion-proof terminalbox, insulated bearingon non-drive end. Please inquire.Markings on the rating plate:II 2G EEx de IIC orII 2G EEx d II CType of protection EEx e IIIncreased safety "e" 1 )■The 1MA motors are certifiedfor the EEx e II type of protectionfor temperature classesT1 to T3 and have an EC typetest certificate in accordancewith directive 94/9/EC (ATEX).Higher temperature classesare available on request.With the exception of 2-polemotors with frame size 225 Mor larger, all motors are standarddesigns i.e. the motorsare suitable for T1/T2 or T3and can be operated with thecorresponding rated output. Anew or supplementary certificatemay be needed for nonstandarddesigns (differentfrequency, output, coolanttemperature, site altitude etc.)(please inquire). It is essentialfor the temperature class to bespecified because if not, thestandard design for T1/T2 andT3 will be certified (doublecertification fee).Markings on the rating plate:II 2G EEx e II T.2■ VIK design – Order code K30Motors up to frame size 355 canbe supplied in accordance withthe "Technical Requirements" ofVIK (Verband der IndustriellenEnergie- und Kraftwirtschaft).Not possible for 1LA5 motors,1LG4 motors are delivered.A low-noise design is additionallyrequired for all 2-pole 1LG4,1MJ6, 1MJ7, and 1MA6 motors,frame sizes 315 S to 315 L, aswell as for all 2-pole 1MJ8/1MJ1motors (Order Code K37 orK38). 1LG4, 1LG6, 1MJ6, and1MJ7 motors are supplied witha special terminal box with a removablecable entry plate.Take account of the rated-outputclassification and the dimensionsof 1LA8 motors. Theterminal box cannot be rotatedby 4 x 90° for motors 1LA8,frame sizes 355 to 357.Vertically mounted motors withshaft extension pointing downwardsmust be provided with acanopy (type of constructioncode e.g. 9 (M1F), 4).Use acc. to class B is specified.Frame sizes 400 and 450 arenot available with the VIK design.Converter-fed operation on request.VIK design motors with externalmountings (brake, rotary pulseencoder, separately driven fan,and anti-condensation heating)do not comply with Zone 2 accordingto VDE 0165. No versionfor Zones 21/22.VIK design motors with metricscrewed glands as cable entriesare included in the scopeof supply.1) Ex-design motors (except forZone 22) include certified metricglands in the scope of supply. Noapproval for UL/CSA.Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/9

Squirrel-cage motorsTechnical information2Electrical features■ Voltages, currents, and frequenciesStandard voltagesEN 60034-1 differentiates betweenCategory A (combinationof voltage deviation ± 5% andfrequency deviation ± 2%) andCategory B (combination of voltagedeviation ± 10% and frequencydeviation +3/–5%) forvoltage and frequency fluctuations.The motors can supply their ratedtorque in both Category Aand Category B. In Category A,the temperature rise is approx.10 K higher than during normaloperation. According to thestandard, longer operation isnot recommended forCategory B.See page 2/15 for details of therating plate inscriptions and examples.The selection and orderingdata state the rated currentat 400 V. DIN IEC 60 038specifies a tolerance of ±10%for system voltages of 230 V,400 V, and 690 V.The rating plates of motors withvoltage code 1 or 6 also includea rated current range in additionto the rated voltage (see table).The rated currents at 380 V and420 V are listed in the table onpage 2/12 and on the ratingplate.The tolerance laid down byDIN EN 60 034-1 applies to allconverter-fed 1LA8 motors aswell as to 1LA5, 1LA7, and1LG6 motors with special 690 Vinsulation i.e. no rated voltagerange is specified on the ratingplate.For 1LA and 1LG motors, typeof protection "n" (Zone 2), norated voltage range is specifiedeither.1MA motors:For non-standard frequenciesthe t E output values may differfrom those stated in the selectiontables; in this case, a new orsupplementary certificate isneeded. For d-connection,overload protection with phasefailureprotection must be provided.Standard voltages:Voltages Rated voltage range Voltagecode1LA, 1LG, and 1MJ motors230 Vd/400 V*, 50 Hz400 Vd/690 V*, 50 Hz220 – 240 Vd/380 – 420 V*, 50 Hz380 – 420 Vd/660 – 725 V*, 50 Hz1LA and 1LG motorsSecond rating plate with 50 and 60 Hz data, frame sizes 56 to 315 Mfor 1LA9 and 1LG6 with output at 60 Hz additionally in HP460 V, 60 Hz 440 – 480 V, 60 Hz 1.61MA motors230 Vd/400 V*, 50 Hz400 Vd/690 V*, 50 Hz218 – 242 Vd/380 – 420 V*, 50 Hz380 – 420 Vd/655 – 725 V*, 50 Hz16162/10Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical information■ Voltages, currents, and frequencies (continued)Non-standard voltages and/orfrequenciesThe tolerance laid down byDIN EN 60 034-1 applies to allnon-standard voltages.Order Codes have been allocatedfor a number of non-standardvoltages at 50 and 60 Hz(11th position of Order No. =9).Order Codes for other rated voltages:L1X■L1Y■Standard windingNon-standard windingbetween 200 V and 690 V(other voltages to request)When ordering state in plaintext:Voltage, frequency, connection,and required rated output in kW.■This Order Code only determinesthe price.Electrical features2Voltage at50 HzRequired outputat 50 HzOrderCode for50 Hz(singlespeed)1 )Frame sizes for motors1LA5,1LA71LA6,1LA91LG4,1LG61LA81MA6,1MA7 2 )1MJ6 1MJ7 1MJ8,1MJ1220 Vd/380 V*(210 – 230 Vd/360 – 400 V*)380 Vd/660 V*(360 – 400 Vd/625 – 695 V*)415 V*(395 – 435 V*)415 Vd(395 – 435 Vd)400 Vd (460 Vdbei 60 Hz)(380 – 420 Vd)50 Hz output L1R 56 – 225 56 – 200 180 – 315M – 63 – 315L 71 – 200 225 – 315 –50 Hz output L1L 56 – 225 56 – 200 180 – 315L – 63 – 315L 71 – 200 225 – 315 –50 Hz output50 Hz outputL1C 56 – 225 56 – 200 180 – 315M –63 – 315L 71 – 200 225 – 315L1D 56 – 225 56 – 200 180 – 315L –63 – 315L 71 – 200 225 – 31550 Hz output L1U 56 – 225 56 – 200 180 – 315L – – – – –––Voltage at60 HzRequired outputat 60 HzOrderCode for60 Hz(singlespeed)Frame sizes for motors1LA5,1LA71LA6,1LA91LG4,1LG61LA81MA6,1MA7 2 )1MJ6 1MJ7 1MJ8,1MJ1220 Vd/380 V*220 Vd/380 V*50 Hz output60 Hz outputL2AL2B56 – 22556 – 22556 – 20056 – 200180 – 315M180 – 315M––63 – 315L–71 – 20071 – 200225 – 315225 – 280 S–315 – 450380 Vd/660 V*380 Vd/660 V*50 Hz output60 Hz outputL2CL2D56 – 22556 – 22556 – 20056 – 200180 – 315L180 – 315L315 – 450315 – 45063 – 315L–71 – 20071 – 200225 – 315225 – 315–315 – 450440 V*440 V*440 Vd440 Vd50 Hz output60 Hz output50 Hz output60 Hz outputL2QL2WL2RL2X56 – 22556 – 22556 – 22556 – 22556 – 20056 – 20056 – 20056 – 200180 – 315M180 – 315M180 – 315L180 – 315L––315 – 450315 – 45063 – 315L–63 – 315L–71 – 20071 – 20071 – 20071 – 200225 – 315225 – 315225 – 315225 – 315–315 – 450–315 – 450460 V*460 V*460 Vd460 Vd50 Hz output60 Hz output50 Hz output60 Hz outputL2SL2EL2TL2F56 – 22556 – 22556 – 22556 – 22556 – 20056 – 20056 – 20056 – 200180 – 315M180 – 315M180 – 315L180 – 315L––315 – 450315 – 45063 – 315L–63 – 315L–71 – 20071 – 20071 – 20071 – 200225 – 315225 – 315225 – 315225 – 315–315 – 450–315 – 450575 V*575 V*575 Vd575 Vd50 Hz output60 Hz output50 Hz output60 Hz outputL2UL2LL2VL2M56 – 22556 – 22556 – 22556 – 22556 – 20056 – 20056 – 20056 – 200180 – 315M180 – 315M180 – 315L180 – 315L––315 – 450315 – 45063 – 315L–63 – 315L–71 – 20071 – 20071 – 20071 – 200225 – 315225 – 315225 – 315225 – 315–315 – 450–315 – 450Voltage at60 HzRequired outputat 60 HzOrderCode for 1LA5,60 Hz 1LA7(polechanging)Frame sizes for motors1LA6,1LA91LG4 1LA8 1MA6,1MA7 2 )1MJ6 1MJ7 1MJ8,1MJ1220 V220 V50 Hz output60 Hz outputL4AL4B63 – 20063 – 200––180 – 280180 – 280––––––––––380 V380 V50 Hz output60 Hz outputL4CL4D63 – 20063 – 200––180 – 280180 – 280––––––––––440 V440 V50 Hz output60 Hz outputL4GL4E63 – 20063 – 200––180 – 280180 – 280––––––––––460 V460 V50 Hz output60 Hz outputL4JL4H63 – 20063 – 200––180 – 280180 – 280––––––––––575 V575 V50 Hz output60 Hz outputL4NL4M63 – 20063 – 200––180 – 280180 – 280––––––––––1) For Order Codes L1C, L1D, L1L,L1R and L1U, the rating platealso contains a rated voltagerange.2) Requires special certificate.Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/11

Squirrel-cage motorsTechnical informationElectrical features2■ Voltages, currents, and frequencies (continued)Rated currents for the rated voltage range from 380 V to 420 V at 50 HzCurrents for voltage and number of poles380 V2-pole420 V 380 V4-pole420 V 380 V6-pole420 V 380 V8-poleA A A A A A A A1LA7, 1LA5 motors1LA7 0501LA7 0530.270.330.260.320.210.300.210.31––––––––1LA7 060 0.520.530.420.44 ––––1LA7 063 0.680.700.560.570.480.5––1LA7 0701LA7 0731.051.381.021.410.801.070.771.060.660.800.640.800.360.510.360.521LA7 0801LA7 0831.752.451.792.501.501.901.501.921.181.621.251.660.731.010.801.101LA7 0901LA7 0963.404.703.354.652.603.502.603.502.103.02.152.951.151.631.181.601LA7 106 6.256.154.84.84.04.12.252.21LA7 107 ––6.56.8––3.03.01LA7 113 8.2 7.7 8.4 8.3 5.4 5.3 4.1 4.21LA7 130 10.610.411.411.97.37.55.96.01LA7 131 14.113.8––––––1LA7 133 ––15.415.59.59.77.97.91LA7 134 ––––13.013.1––1LA7 1631LA7 16421.028.020.526.022.3–21.5–1LA7 166 34.0 32.0 29.5 28.5 24.8 24.7 17.6 18.41LA5 1831LA5 1861LA5 2061LA5 2071LA5 2201LA5 22340–5567–8138–5264–763642–5769843541–5464781LA6, 1LG4 motors1LA6 106 6.256.154.84.84.04.12.252.21LA6 107 ––6.56.8––3.03.01LA6 113 8.2 7.7 8.4 8.3 5.4 5.3 4.1 4.21LA6 130 10.610.411.411.97.37.55.96.01LA6 131 14.113.8––––––1LA6 133 ––15.415.59.59.77.97.91LA6 134 ––––13.013.1––1LA6 1631LA6 1641LA6 1661LG4 1831LG4 1861LG4 1881LG4 2061LG4 2071LG4 2081LG4 2201LG4 2231LG4 2281LG4 2531LG4 2581LG4 2801LG4 2831LG4 2881LG4 3101LG4 3131LG4 3161LG4 3171LG4 31821.028.034.041.5–56566782–83100100134136162196198230280345–20.526.032.040–54526377–759093128126150182188215255315–22.3–29.53642.559–57707285104104138144168204205245295360–21.5–28.53541.560–556965779498134132156190194230275330–17.5––32.74046.5–6417.5–24.8–30.538.5374561–607373878710614614217020524529517.3––3138.545.5–6317.3–24.7–28.5373742.560–5466688180971341361621902252759.913.1–26.5–3440479.913.117.6–25.534.5–33.540.540.546.56460737692112110146174210250420 V10.613.4–23.5–31374310.613.418.4–2534.5–323936.54258576970841021041361641982402/12Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationElectrical features■ Voltages, currents, and frequencies (continued)Rated currents for the rated voltage range from 380 V to 420 V at 50 Hz (continued)2Currents for voltage and number of poles380 V2-pole420 V 380 V4-pole420 V 380 V6-pole420 V 380 V8-poleA A A A A A A A1LG6, 1LA8 motors1LG6 183 40.537.53634.5 ––––1LG6 186 ––42.540.530.52924.5231LG6 206 5451––3735.5 ––1LG6 207 666256544440.532.530.51LG6 220 ––7064––3834.51LG6 223 81738476595345411LG6 253 97 90 99 94 72 67 59 551LG6 2801LG6 2831LG6 3101LG6 3131LG6 3161LG6 3171LG6 3181LA8 3151LA8 3171LA8 3531LA8 3551LA8 3571LA8 4031LA8 4051LA8 4071LA8 4531LA8 4551LA8 457134158192230275340–4355406206908609501080690 1 )780 1 )880 1 )970 1 )124146174210250305–400495570630790880990640 2 )730 2 )810 2 )890 2 )138166200235285355–4505606407208809901100710 1 )810 1 )910 1 )1000 1 )128154184215265330–4255305906808209301040670 2 )750 2 )860 2 )940 2 )85104142166205245290360450–57072081089010001160740 1 )830 1 )7996134156190225275340420–5306707608409401060690 2 )770 2 )7591106142170205250310385–48060068076085096010801200The rating plates of 1MJ6 motors specify the maximum current in the voltage range in addition to the rated current.This maximum is approx. 5% higher than the rated current.420 V6983100136158194230295365–45556064072081091010201140■ Rated outputs and rating platesTable of rated output at 60 Hz for single-speed motorsMotor typeMaximum output at 60 Hzfor voltages between 220 Vor 380 V and 725 V2-pole 4-pole 6-pole 8-polekW kW kW kW1LA6, 1LG4, 1LG6, 1LA7, 1MJ6, 1MJ7 motors1LA7 0501LA7 0531LA7 0601LA7 0631LA7 0701LA7 0731LA7 0801LA7 0831LA7 0901LA7 0961LA7 1061LA7 107––––––––––1LA6 1061LA6 107––––1MJ6 0701MJ6 0731MJ6 0801MJ6 0831MJ6 0961MJ6 0971MJ6 1061MJ6 1070.1050.140.210.290.430.630.861.31.752.553.45–0.070.1050.140.210.290.430.630.861.31.752.553.45–––0.10.210.290.430.630.861.31.75–––––0.10.140.210.290.430.630.861.31LA7 113 1LA6 113 1MJ6 113 4.6 4.6 2.55 1.751LA7 1301LA7 1311LA7 1331LA7 1341LA7 1631LA7 1641LA6 1301LA6 1311LA6 1331LA6 1341LA6 1631LA6 1641MJ6 1301MJ6 1311MJ6 1331MJ6 1341MJ6 1631MJ6 1646.38.6––12.617.36.3–8.6–12.6–3.45–4.66.38.6–2.55–3.45–4.66.3Motor typeMaximum output at 60 Hzfor voltages between 220 Vor 380 V and 725 V2-pole 4-pole 6-pole 8-polekW kW kW kW1LA6, 1LG4, 1LG6, 1LA7, 1MJ6, 1MJ7 motors (continued)1LA7 166 1LA6 166 1MJ6 166 21.3 17.3 12.6 8.61LA5 1831LA5 186–1LA5 2061LA5 207–1LA5 2201LA5 223–––––––––––1LG . 1831LG . 1861LG . 1881LG . 2061LG . 2071LG . 2081LG . 2201LG . 2231LG . 2281LG . 2531LG . 2581LG . 2801LG . 2831LG . 2881LG . 3101LG . 3131LG . 3161LG . 3171LG . 3181MJ6 1831MJ6 186–1MJ6 2061MJ6 207–1MJ7 2201MJ7 223–1MJ7 253–1MJ7 2801MJ7 283–1MJ7 3101MJ7 313–––24.5–33.533.541.551–5162628484101123123148180224–21.325.334.5–34.542.542.55263638686104127127152184230––18222226.536–3644.544.55454669090108132158192–13.218–18222226.5363644.544.554666690108132158Speed increases to approx. 120% in relation to 50 Hz motors.1) Current at 690 V. 2) Current at 725 V.Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/13

Squirrel-cage motorsTechnical informationElectrical features2■ Rated outputs and rating plates (continued)Table of rated output at 60 Hz for single-speed motors (continued)Motor type1LA8, 1MJ8, 1MJ1 motors1LA8 3151LA8 3171LA8 3531LA8 3551LA8 3571LA8 4031LA8 4051LA8 4071LA8 4531LA8 4551LA8 457–––––––––––Maximum output at 60 Hzfor voltages between 220 Vor 380 V and 725 V2-pole 4-pole 6-pole 8-polekW kW kW kW280353398448560616693781–––28836240846057564472581792010401150230288–362460518575644725817920184230–288362408460518575644725Motor typeMaximum output at 60 Hzfor voltages between 220 Vor 380 V and 725 V2-pole 4-pole 6-pole 8-polekW kW kW kW1MJ8, 1MJ1 motors (continued)–––––––1MJ1 3531MJ1 3551MJ1 3571MJ1 4031MJ1 4051MJ1 4071MJ1 4531MJ1 4551MJ1 4571MJ1 4581MJ8 3131MJ8 3141MJ8 3161MJ8 3531MJ8 3541MJ8 3561MJ8 357190–240280–350–400450500560630on request180–220250280315355400450500560630710800900 1 )1000 1 )–132145175225–280–On request100120145180–225–On requestTable of rated output at 60 Hzfor pole-changing motorsFor 60 Hz, the rated output valuescan be increased using thecorrection factors in the tableopposite.The output is increased for eachpole number separately i.e. for6-/4-pole motors with frame sizes180 to 315, 60 Hz, the 6-poleoutput can be increased by20%, the 4-pole power by 15%.Size Number of poles Correction factor for 60 Hz output forvoltages between 220 V or 380 V and725 V56 to 160180 to 3152 to 8246 and 81.151.121.151.2Possible combinations of 2-pole motorsSize Horizontal motor Vertical motor50 Hz with foot 60 Hz with foot 50 Hz with flange 60 Hz with flange 50 Hz 60 Hz56 to 315 M V V V V V V315 L V V – – V On request315 V V – – V V355 and 400 V V – – V –450 V – – – V –Coolant temperature and altitudeabove sea level■The rated output refers to continuousduty according toDIN EN 60 034-1 at a frequencyof 50 Hz, a coolant temperature(CT) of 40 °C and a sitealtitude of up to 1000 m abovesea level (ASL).The motors are designed forclass F and used in class B. Ifthe actual operating conditionsdeviate from this class, the maximumoutput should be adjustedaccording to the following tables.If explosion-proof motors are tobe utilized at coolant temperaturesthat deviate from 40 °Cand which have a site altitudegreater than 1000 m above sealevel the corresponding correctionfactors must be requested.The Order Codes D02, D03 andD04 only apply to motors 1LG4and 1LG6. 1LA7 motors on request.Altitude above Coolant temperature in °Csea level ASLin m

Squirrel-cage motorsTechnical informationElectrical features■ Rated outputs and rating plates (continued)Coolant temperature andaltitude above sea level(continued)■Effective values, which mustbe stated when ordering, havebeen calculated for the followingoutput ratings and coolanttemperatures (CT) of 45 °Cand 50 °C.■For changes in the output ratingwith class F utilization see"DURIGNIT IR 2000 insulation".If utilized according to temperatureclass B, motors intendedfor coolant temperatures otherthan 40 °C or altitudes greaterthan 1000 m above sea levelmust always be ordered with thesuffix "–Z" added to the OrderNo. and the requirement statedin plain text.Additional derating of the outputwill result in a deterioration inperformance due to the lowerutilization factor of the motors.Rated Maximum output at 50 Hzoutput at CT 45 °C at CT 50 °CkW kW kW111518.522303745557590110132145160180200250280315355400450500560630710800900100010.514.517.8212935.5435372861061271391531731922402693023403844324805386056827688649601013.8172027.53441.5516983101122133147166184230258290325368414460515580653736828920For Order Codes for class F utilization,see"DURIGNIT IR 2000 insulation".For all motors:The motors are intended to withstand1.5 times the rated currentfor up to 2 minutes at ratedvoltage and frequency(DIN EN 60 034).Ambient temperatureAll motors with the standard designcan be used at ambienttemperatures of -20 °C to+40 °C.Exceptions with Order CodeC13:MotortypeSizeAmbienttemperature°C1LA7 56M – 160L –30 to +551LA6 100L – 160L –30 to +551LG41LG6180M – 225M250M – 315L180M – 225M250M – 315L–30 to +55–20 to +55–30 to +55–20 to +55Use acc. to class F• at 40 °C with service factor 1.1or 1.15 for 1LG6/1LA9,• above 40 °C in compliancewith rated output.When used acc. to class B withhigher ambient temperatures/greater site altitude, the poweris reduced according to the tableat the bottom of Page 2/13.Motors which are supplied directlyhave the service factormarked on the rating plate.Special design measures arenecessary for other ambienttemperatures.Inquiry is necessary if brakesare needed for subzero temperatures.2Rating plateMotortypeSize Rating plate Double rating plate50/60 Hz data forExamples of rating platesinter-de en de/natio-nalenfr/esit pt ru 500 V*and575 V*500 Vdand575 Vd1LA5 all C V C C1LA7 all C V C C1LA9 all C V C C1LA6 all C V C1LA6 100 to 160 C V C C1LG4 all C s C1LG6 all C s C1LA8 all C V V V1MA7 all C V1MA6 180 to 200 C V1MA6 from 225 V C V V V s1MJ6 71 to 200 C V1MJ7 225 to 315 C V V V s1MJ8 all C s s s s1MJ1 all C s s s s 400 V/690 Va. 460 V400 V/690 Va. 460 VDIN EN 60034-1 lays down thatthe approximate total weight forall motors from frame size 90(from approx. 30 kg) is indicatedon the rating plate.A second rating plate can besupplied loose for all motors,Order Code K31.In addition, a supplementaryplate with the order specificationsis available, Order CodeY82.C Standard designV with no extra charges with extra charge! JAlso, for type 1MA motors:With the exception of the2-pole motors with frame size225 M or larger, all motors aresimultaneously suitable for T1/T2 and T3 (standard design). Ifthe rated output for T1/T2 differsfrom that for T3, the data forboth outputs is stated on separaterating plates. ) ' $ $ ) $ - % " % 1- + - $ ! " - ) - ' # 0 2, - 5 1/ ) + , - + + ! ), ' # $ - H= C A C 1 * ! $ 12 # # 6 D + ) * " + # 0 " $ ' 8$ 0 " $ 8 & # 9 ! # & ) & # 9 % % )? I ' ' " E2 ' ! # # 4 2 ! & " $ $ % # 8! " ! # ' $ % $ ) / 5 # + 6! J / $ & $ " ) ) $ , ' # $ - H= C A 7 + " # # & C 1 * ! & 12 # # 6 D + ) * " + # 0 " $ ' 8$ 0 " $ 8 9 " # " ) 9 ! $ # )? I & " " % E2 & ! % % # 4 2 ! & " $ $ % # 8" # " # " # ! # )1- + - $ ! " - ) - ' " ! 0 2Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/150, - 5 1/ ) + , - + + ! ) / 5 # + 6 # & > # =

2Squirrel-cage motorsTechnical informationElectrical features■ Efficiency, power factor, and rated torqueEfficiency andpower factorThe efficiency h and power factorcos j values for each ratedoutput are listed in the selectiontables in the individual sectionsof this catalogue.For eff1 and eff2 motors, the 3 / 4load efficiency is also indicated.The part-load values stated inthe table opposite are averages;precise values can be providedon request.Part-load efficiency % at1/4of full load1/2 3/4 4/4 5/49392908988878685848079787674727068666462605856555453525150494847464544434241969593.592.591.5919089888786858483828180797775.574737271706867666564626160595756555497969594939291908988878685848382818079.578.577.5767574737271706967.566.56564636260.559.558.5979695949392919089888786858483828180797877767574737271706968676665646362616096.595.594.593.592.591.590898887868583.582.581.580.579.578.577.576.575747372717069686766656463626160.559.558.5Part-load power factor at1/4of full load1/2 3/4 4/4 5/40.700.650.630.610.570.530.510.490.470.450.430.410.400.380.360.340.320.300.290.280.270.260.860.850.830.800.780.760.750.730.710.690.670.660.650.630.610.590.580.560.550.540.520.500.900.890.880.860.850.840.830.810.800.790.770.760.750.740.720.710.700.690.680.670.630.620.920.910.900.890.880.870.860.850.840.830.820.810.800.790.780.770.760.750.740.730.720.710.920.910.900.890.880.870.860.860.850.840.830.820.810.800.800.790.780.780.770.770.760.76Rated torqueThe rated torque in Nm deliveredat the motor shaft is9.55¸P¸1000M nP Rated output in kWn Speed in rpm■If the voltage deviates from itsnominal value within the allowedlimits, the locked-rotortorque, the pull-up torque, andthe breakdown torque varywith the approximate squareof the value, while the lockedrotorcurrent varies approximatelylinearly.The normal practice is to startsquirrel-cage motors directlyon-line. The torque class indicatesthat with direct-on-linestarting – even if there is –5%undervoltage – it is possible tostart up the motor against a loadtorque ofup to160% for CL 16130% for CL 13100% for CL 1070% for CL 750% for CL 5of the rated torque.The individual torque characteristicsare available in the SDconfigurator. In addition, it ispossible to perform calculationswith the supplied start-up program.For type 1MA motorsIn the case of the standard designfor T1/T2 and T3 and differentrated outputs, the torqueclass specified for the higheroutput applies.In the case of squirrel-cage motors,the locked-rotor torque andthe breakdown torque are listedin the selection tables as multiplesof the rated torque.2/16Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationElectrical features■ Insulation, winding, motor protection, and anti-condensation heating.DURIGNIT ® Insulation IR 2000■The DURIGNIT IR 2000 insulationsystem comprises highgradeenameled wires and insulatingsheet materials combinedwith solvent-free impregnatingresin.The system ensures a high levelof mechanical and electricalstrength as well as good serviceabilityand a long motor life.The insulation offers generalprotection for the windingsagainst corrosive gases, vapors,dust, oil and increased humidity,and resists the normalstresses of vibration.The insulation is suitable for anabsolute humidity of up to 30 gwater per m 3 . The windingsmust not become moist. Highervalues on request!■The windings of the 1LA8 motorsare impregnated usingthe UV or VPI techniques.Please inquire about extremeapplications.All motors are designed forclass F.Utilization of motors for ratedoutput and mains-fed operationfor class B.All 1LA and 1LG motors canbe stamped with the ratings inaccordance with the selectiontables and rated voltage rangeas well as with a service factor(SF) of 1.1 (for 1LA9 and 1LG6SF = 1.15) and 1.05 for framesizes 400 and 450. Order CodeC11.The service factor is alreadystamped on the rating plate ofstandard ex-stock motors and1LA8 motors.If the motor is used for class F,the rated output specified in theselection and ordering data canbe increased by 10% (by 15%for 1LA9 and 1LG6 and by 5%for frame sizes 400 and 450).Order Code C12.If the catalogue ratings areused, it is permissible to increasethe temperature of thecoolant to 55 °C (or to 50 °C forframe sizes 400 and 450). OrderCode C13.The service factor (SF) is notstamped on the rating plate forOrder Codes C12 and C13.Restarting against residualfield and opposite phaseAll motors can be reclosedagainst 100% residual field aftera system voltage failure.Motor protection with PTCthermistorThe motors are usually protectedby delayed terminal overloadprotection devices (either circuit-breakersfor motor protectionor overload relays).This type of protection is current-sensitiveand is particularlyeffective under locked-rotorconditions.The motors can also be protectedby means of semiconductortemperature sensors (thermistors)embedded in the windingand operating in conjunctionwith a tripping unit (thermistormotor protection) (Order CodeA11 or A12).This type of protection is temperature-sensitiveand preventsthe motor windings from overheating,e.g. due to sharply fluctuatingloads or frequent switching.■All 1LA8 motors with the standarddesign are fitted with 6PTC thermistors for alarm andtripping.■The response temperature ofthe PTC thermistors for the1LA, 1MJ and 1LG motors correspondsto class F.In order to achieve full thermalprotection it is necessary tocombine a thermally delayedovercurrent release and a PTCthermistor. Full motor protectionimplemented only with PTCthermistors on request.For type 1MJ motors:Always use PTC thermistors ifthe duty is anything other thanS1.■PTC thermistors are absolutelynecessary if these motors areused for converter-fed operation.In this case, an additionalthermistor is fitted in the terminalbox for 1MJ6. Order CodeA15 or A16.No additional anti-condensationheater can be integrated in designswith temperature sensorsand frame sizes up to 200 L.Thermistor protection takes theform of three PTC thermistorsconnected in series and embeddedin the stator winding ofthe motor. The 3RN1 trippingunit which completes the systemmust be ordered separately– it is PTB certified. Further detailsabout its mode of operation,circuitry, and price can befound in Catalogue LV 10,Order No.:E86060-K1002-A101-A4-7600.Pole-changing motors with twoseparate windings need twicethe number of temperature sensors.If an alarm signal is to be outputprior to the motor being shutdown, two groups of three temperaturesensors will be needed.The alarm signal is usuallyoutput at 10 K below shutdowntemperature.Motor temperature detectionwith temperature sensorKTY84See "Converter-fed operation"Page 2/44.1MJ8 3153551MJ1 355400450Anti-condensation heatingSupply voltage 230 VOrder Code K45Supply voltage 115 VOrder Code K46Anti-condensation heaters canbe fitted to motors whose windingsare exposed to a risk ofcondensation due to the ambientclimate, e.g. stationary motorsin a damp environment ormotors subjected to considerablefluctuations in temperature.An additional M16 x 1.5 orM20 x 1.5 cable entry fitting isprovided in the terminal box forthe power supply cable.The anti-condensation heatermust not be switched on whilethe motor is running.An alternative to anti-condensationheaters (involving no extracost) is to connect a voltage ofaround 4 to 10% of the motorrated voltage to stator terminalsU1 and V1; 20 to 30% of the motorrated current provide an adequateheating effect (does notapply to 1MA6 motors, framesizes 225 M to 315 L, 1LA8).For 1MJ6 motors:No built-in anti-condensationheater is available for 1MJ6 motorsup to frame size 160 L whenequipped with PTC thermistors.For 1MA. and 1LA. motors inZone 21:No built-in anti-condensationheater is available up to framesize 200L.For 1LA. motors in Zones 2 and22:Built-in anti-condensation heatingon request.For motors Size Heat output (W) for Order CodeK45 (230 V) K46 (115 V)1LA5, á 56 to 80 25251LA6, â 90 to 112 50501LA7,1LA9ßã132 to 20022510078100781LG4, 1LG6 á 180 and 200 55551MJ6, â 225 and 250 92921MJ7/1MA6 ã 280 and 315 109/105 109/1051LA8 all 200 1831LG4/1LG6in (E)Ex nA180 and 200225 and 250280 and 315100200250250280489210510020025025028048921052Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/17

Squirrel-cage motorsTechnical informationElectrical features2■ Connection, switching, and terminal boxesThe position of the terminal boxalways refers to as viewed fromthe drive end.There are marked terminals forconnecting the protective conductor.On the outside of the motorhousing is an earthing terminal(special design for 1LA5, 1LA6,and 1LA9 motors). Order CodeL13).The terminal boxes for motorswith (E)Exn (Zone 2) type of protectionand protection againstdust explosions (Zone 21) deviatefrom the standard design.For type 1MJ motors:The terminal box is in accordancewith EEx e type of protection.The ends of the windingsfor motors up to frame size 160are routed through a shared explosion-proofleadthrough intothe terminal box; for frame size180 and higher through singleleadthroughs.■Motor connectionMains conductorsThe mains conductors mustbe dimensioned in accordancewith DIN VDE 0298.The number of required – possiblyparallel – feeders is determinedby• the maximum connectableconductor cross-section,• the cable type,• the laying arrangement• the ambient temperatureand• the permissible current inaccordance withDIN VDE 0298.Parallel feedersSome motors must be fitted withparallel feeders due to the maximumpermissible current perterminal. These motors aremarked in the selection tables.Two parallel feeders are usedfor motors with 1XB7 terminalboxes, with terminal box1XB1 631 up to four feeders arepossible.Motors with a terminal box coverand auxiliary terminals (e.g. forOrder Code A11) also have acable entry M16 x 1.5 orM20 x 1.5 with plug.For details please consult datasheet functions in SD configurator.1LA7 and 1LA9, frame sizes100 L to 160 LThe terminal box is integratedinto the frame. On each sidethere are knock-out openingsfor boltings.The bolting nuts for the boltingsare included with the terminalbox.Type gk030 Type gk130, 230, 330 Type gk330 for 1LA5, 1LG4Type gk 135, 235, 335 Type gk430, gt431 Type 1XB7 222Type gt 520, 540, 620, 640 Type 1XB7 422, 522 Type 1XB7 6222/18Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationElectrical features■ Connection, switching, and terminal boxes (continued)2Type 1XB1 621Type 1XB1 631Type gk465Type 1XC1 270, 380 Type 1XC1 480, 580 Type 1XB7 322Terminal boxes for 1LA and 1LG motorsMotors Size Number of cable entries Terminal box material Feeder connection1LA7, 1LA9 56 to 71 2 holes with plugs Aluminum alloy Without cable lug or with cable80 to 90100 to 160 2 holes 180° apart,4 knock-out openings in cast-iron skin,sealed (4 left, 2 right),Terminal box is mouldedlug1LA5, 1LA9 180 to 225 2 holes with plugs1LA6 100 to 160 Cast iron1LG4, 1LG6 180 to 200 Aluminum alloy 3 ) Without cable lug225 With cable lug250 to 315 Cast iron1LA8 315 and 355 1 )400 and 450 4 holes, sealedPossible terminal box positions for 1LA and 1LG motorsMotors Size Terminal box position Rotation of terminal boxTopRight-hand sideor left-hand sideRetrofittingpossible90° 2 ) 180° 2 ) Retrofittingpossible1LA5, 1LA7, 1LA9 56 to 71 V – – V V ✔80 to 90 V V – V V ✔100 to 160 V V – – 5 ) V ✔180 to 225 V V – V V ✔1LA6 100 to 160 V V – V V ✔1LG4, 1LG6 180 to 315 V V – 4 ) V V ✔1LA8 315 V V 1 ) – V V –355 V V 1 ) – V V –400 and 450 V V 1 ) – V V –V Available designFurther information under 1LA8 motors, see "Dimensions", "1LA8".1) Rotated by 15°.2) The position of the cable entrymust be specified when ordering.3) Terminal box in cast iron designwith Order Code K15.4) Retrofitable with screwed on feet(Order Codes K09, K10 andK11).5) Design for 1LA7 motors availableon request.Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/19

Squirrel-cage motorsTechnical informationElectrical features2■ Connection, switching, and terminal boxes (continued)Terminal boxes for 1LA5, 1LA6, 1LA7, and 1LA9 motorsSize Type Type Number ofterminals1LA51LA71LA91LA6Terminal screwthreadMax. conductorsizemm 2Sealing range inaccordance withDIN 46319mmCable entry1 ) 3 )SizeSplit plate 2 )Max. outer cablediameter56 gk 030 6 M4 2.5 9 – 17 M25 x 1.5 –63 4.5 – 10 M16 x 1.5718090100 gk 130 gk 135 6 M4 4 11 – 21 M32 x 1.5 –112132 gk 230 gk 235 6 M4 6 11 – 21 M32 x 1.5 –160 gk 330 gk 335 6 M5 16 19 – 28 M40 x 1.5 –180200 gk 430 6 M6 25 27 – 35 M50 x 1.5 –225 gk 431 6 M8 35 27 – 35 M50 x 1.5 –Terminal boxes for 1LG4 and 1LG6 motors180 gk 330 6 M5 16 19 – 28 M40 x 1.5 –200 gk 430 6 M6 25 27 – 35 M50 x 1.5 –225 gt 431 6 M8 35 27 – 35 M50 x 1.5 –250 gt 520 6 M10 120 32 – 42 M63 x 1.5 40 – 50280315 gt 620 6 M12 240 40 – 48 M63 x 1.5 40 – 60Terminal boxes for 1LA8 motors315 gt 640 6 M12 240 40 – 48 M63 x 1.5 40 – 60355 1XB1 621 6 M16 400 41 – 56 2 x M72 x 2/2 x M25 x 1.540 – 70400 1XB1 631 12 M16 400 – 4 x «80/4502 x M25 x 1.5mm40 – 75■The terminal box list does notapply to pole-changing motorswith three speeds.Terminal boxes for Ex-motors 1MA6, 1MA7 and for motors 1LA6/7/8/9 and 1LG4/6 in (E)Ex n-design and in Zone 21Motors Size Number of cable entries Terminal box material Feeder connection1MA7, 1LA7, 1LA9 63 to 90 2 holes incl. 1 certified bolting with sealingring and 1 certified plugAluminum alloy100 to 160 4 holes incl. 1 certified bolting with sealingring and 3 certified plugs1MA6, 1LA6 100 to 160 2 holes incl. 1 certified bolting with sealing Cast ironring and 1 certified plug1MA6, 1LA9, 1LG4, 180 to 225 2 holes incl. 2 certified boltings with sealing Aluminum alloy1LG6250 to 315 ringsCast iron1LA8 315 and 355400 and 450 4 holes, sealedWithout cable lug 4 ) orwith cable lug1) Designed for cable glands withO-ring.2) Split plate available at extracharge.Order Code K06.For standard design of terminalbox 1XB1 631.With strain relief for frame size250 M or larger.3) Contains speed nuts for the cableglands for 1LA7 motors with framesizes 100 to 160.4) The parts required for the connectionwithout cable lugs are suppliedin an accessories pack withthe terminal box for all motors withframe size 225 or larger.2/20Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationElectrical features■ Connection, switching, and terminal boxes (continued)Possible terminal box positions for 1LA6/7- (in (E)Ex n-design), 1MA and 1MJ motorsMotors Size Terminal box position Rotation of terminal box1MA7 and1LA7 in (E)Ex n1MA6 and1LA6 in (E)Ex nTopRight-hand sideor left-hand sideRetrofittingpossible90° 1 ) 180° 1 ) Retrofittingpossible63 to 71 V – – V V ✔80 to 90 V V – V V ✔100 to 160 V V V – V 2 ) ✔100 to 160 V V V V V ✔180 to 225 V V – V V ✔250 to 315 V V – V V –1MJ6 71 to 200 V V – V V ✔1MJ7 225 to 315 V V – V V ✔1MJ8 315 to 355 V V – V V ✔1MJ1 355 to 450 V V – V V ✔V Available design2Terminal boxes for 1MA6, 1MA7 motors and 1LA6/7/9 motors in (E)Ex n-design and Zone 21SizeTypeNumber of Terminal screw Max. conductorterminals threadsize1MA71LA71LA91LA61MA6mm 2Sealing rangemmCable entry 3 )63 gk 130 6 M4 4 11 – 16 M25 x 1.5 –71 5 – 9 M16 x 1.58090100 gk 135 14 – 21 M32 x 1.5 –112132 gk 230 gk 235 6 M4 6160 gk 330 gk 335 6 M5 16 19 – 27 M40 x 1.5 –180 1XB7 222 1XB7 222 6 M6 10 19 – 27 M40 x 1.5 –200 1XB7 322 1XB7 322 6 M8 50 24 – 35 M50 x 1.5 –225 –250 – 1XB7 422 6 M10 120 32 – 42 M63 x 1.5 –280 –315 – 1XB7 522 6 M12 240 40 – 48 M63 x 1.5 –Terminal boxes for 1LG4/6 motors in (E)Ex n-design and Zone 21180 gt 351 6 M6 10 19 – 27 M40 x 1.5 –200 gt 451 6 M8 50 24 – 35 M50 x 1.5 –225250 gt 540 6 M10 120 32 – 42 M63 x 1.5 –280315 gt 640 6 M12 240 40 – 48 M63 x 1.5 –Terminal boxes for 1LA8 motors in (E)Ex nA315 gt 640 6 M12 240 40 – 48 M63 x 1.5 40 – 60355 1XB1 621 6 M16 240 41 – 56 2 x M72 x 2/2 x M25 x 1.540 – 70400 1XB1 631 12 M16 240 – 4 x Ø80/2 x M25 x 1.5450Unused holes for 1MA motorsmust be sealed in accordancewith EN 50 014.SizeSplit plateMaximum outsidecable diametermm40 – 751) The position of the cable entrymust be specified when ordering.2) For frame size 100 or larger. 3) Designed for cable glands withO-ring.Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/21

Squirrel-cage motorsTechnical informationElectrical features2■ Connection, switching, and terminal boxes (continued)Terminal boxes (EEx e) for 1MJ6, 1MJ7, 1MJ8, and 1MJ1 motorsMotors Size Number of cable entries Terminal box material Feeder connection1MJ6 71 and 8090 to 1602 holes incl. 1 certified bolting with sealingring, 1 certified plug180 to 200 2 holes incl. 2 certified boltings with sealingringsAluminum alloysize 160 L cast ironAluminum alloy1MJ7 225250 to 315 Cast iron1MJ8 315 to 355 2 threaded holes without boltings1MJ1 355 to 450 Welded steelWithout cable lug or with cablelug 1 )Terminal boxes (EEx e) for 1MJ6, 1MJ7 motorsSize Type Number of terminals Terminal screwthreadMax. conductor sizeSealing rangeCable entry 3 )mm 2mmSize71 gk 330 6 M4 4 11 – 16 M25 x 1.58090 gk 420 6 M4 6 11 – 16 M25 x 1.5100 14 – 21 M32 x 1.5112 gk 420 6 M4 6 14 – 21 M32 x 1.5132160 gk 465 V M5 V 16 V 19 – 27 M40 x 1.5180 1XC1 270 6 M6 25 19 – 27 M40 x 1.5200 1XC1 380 6 M8 50 24 – 35 M50 x 1.5225250 1XC1 480 6 M10 120 32 – 42 M63 x 1.5280315 1XC1 580 6 M12 240 40 – 48 M63 x 1.5Terminal box (EEx e) for 1MJ8 motors315 without designation 6 M12 120 to 300 37 – 44 2 ) M63 x 1.5 2 )355 6 M16 35 – 75 2 )Terminal box (EEx e) for 1MJ1 motors355400áâ Available soon450ãV For frame size 160L■Explosion-proof terminal boxescan be fitted (to order), exceptfor frame sizes 180 and200.■Unused holes for 1MJ motorsmust be sealed in accordancewith EN 50 014.1) The parts for the connection withoutcable lugs are supplied in anaccessories pack with the terminalbox for all 1MJ7 motors withframe size 225 M or larger.2) Standard design from size 315 Lwith cable entry gland splitlengthwise for 35 - 75 mm andstrain relief.3) Designed for cable glands withO-ring.2/22Siemens M 11 · <strong>2003</strong>/<strong>2004</strong>

Squirrel-cage motorsTechnical informationMechanical design■ Frame designSome foot-mounting motorshave two fixing holes at the nondriveend (see dimensionstable).There is a cast inscription nearthese fixing holes to differentiatebetween frame sizes.2■ Degrees of protectionAll motors are designed forIP55.They are suitable for use industy or damp surroundings.The motors can be used in thetropics. Approx. value 60% relativehumidity at CT 40 °C. Otherrequirements on request.■All motors which have a shaftextension pointing upwardsmust have a means (providedby the user) of preventing theingress of liquids along theshaft.In the case of flange-mountingmotors with IM V 3 type of construction,the liquid level in theflange recess can be preventedfrom rising by means of drainholes (on request).These are standard for 1MA6and 1MJ7 motors with framesize 225 or larger and for all1LG4 and 1LG6 motors.For all motors with the shaft endpointing downwards, the version"with canopy" is recommended;see Section "TechnicalInformation", "Types of Construction".1LG4, 1LG6, 1LA8 or 1MA6 withframe size 225 or larger comewith condensation water holessealed with plugs.If the motors are operated orstored outdoors, a shielding oran additional cover is recommended,so as to avoid longtermeffects when exposed todirect, intensive sunlight, rain,snow, ice or dust. If necessary,consult with Siemens abouttechnical adjustments.■ Cooling and ventilationStandard motors with frame sizes63 to 450 are fitted with a radial-flowfan which functions independentlyof the direction ofrotation (cooling method IC 411to DIN EN 60 034-6). The air isblown from the non-drive end tothe drive end.Motors with frame size 56 haveno fan (IC 410).■Standard two-pole 1LA8 motors(with frame size 355 orlarger) come with an axial-flowfan with clockwise rotation.The fan can be retrofitted foranti-clockwise rotation.If the motor is installed in anarea with a limited air supply, itis essential to ensure a minimumclearance between the fancowl and the wall which is calculatedby subtracting thelength of the canopy from thelength of the cowl (dimensionLM – L).MaterialsType series Size Fan material 1 ) Fan cowl material1 )1LA9 63 to 2001LA6 100 to 1601MA7 63 to 1601MA6 100 to 3151MJ6 71 to 2001MJ7 255 to 3151LA8 315 to 4501LA5, 1LA7 63 to 225 Plastic Corrosionprotectedsteelplate1LG4, 1LG6 2 ) 180 to 315 Plastic Glass-reinforcedplastic1MJ8 315 to 355 Welded steel plate Corrosionprotectedsteel1MJ1 355 to 450plate■ Coupling to gearboxesThe flange-mounting motorscan be fitted with a radial sealfor coupling to gearboxes.Order Code K17.There must be adequate lubricationwith grease, oil spray oroil mist (pressure oil is not allowed).It is advisable to check the permittedbearing loads.Please enquire about 1LA8motors.1) Designs for Zones 2, 21, and 22and VIK design sometimes makeuse of other materials.2) Designs for Zones 2, 21, 22, VIK(Order Code K30), CSA (OrderCode D40) and UL (Order CodeD31) make use of a fan shroudmade of corrosion resistant sheetsteel.Siemens M 11 · <strong>2003</strong>/<strong>2004</strong> 2/23